What is a grillage and a foundation with a grillage?

A grillage is a part of a columnar foundation, which is located on its top and distributes the load between all the pillars, and also serves as a support for all elements of the building. The grillage has the form of beams, the design of which combines the heads of the pillars. Usually the grillage is made of wood, less often of metal, but modern construction uses reinforced concrete or concrete.

A foundation with a grillage is already a structure that has a reinforced upper part that combines the heads of the pillars. It comes in two types:

- tape;

- solid.

The type of foundation used depends on the following indicators:

- soil;

- material;

- device method.

How to make a columnar foundation: general principles

Regardless of what material is used for the columns and to what depth they are lowered into the ground, there are general rules for constructing such a foundation.

- The construction site is cleared of debris, large uneven areas (located above or approximately at the level of the intended bottom of the building) are removed, and the fertile layer of soil is removed (optional).

- Mark the site. To do this, use a cord (rope) and a level.

- Prepare the base for the supports - dig holes or drill wells, level areas for surface installation.

- Arrange a sand and gravel cushion (if necessary), compact it. To increase strength, you can spill the pillow with “concrete milk”. This measure is especially useful for shallow foundations. The height of the pillow is at least 150...200 mm.

- Mount the supports. For buried columns, waterproofing is required over the entire height; for non-buried columns, a waterproofing layer is installed only on the contact surface with the grillage.

- Set up a grillage. If it is located close to the ground and is monolithic reinforced concrete (like the columns), formwork is used similar to that used for strip foundations. Reinforcement is required for a concrete grillage. Timber or metal are installed according to the general fastening concept.

The installation nuances for different materials and types of supports are discussed below using the example of a columnar foundation for a frame house.

Advantages and disadvantages

The main advantages of a columnar foundation with a grillage are:

- The scope is unlimited. Can be built on clayey, rocky, hard and unstable soils. The terrain of the site also does not matter, which saves the architect from standard solutions and high construction costs;

- Proper installation will ensure the building's durability (more than 70 years);

- Relatively low price ;

- It is possible to select the type and type of foundation and its grillage, which makes it possible to save on the price and timing of the work;

- The simplicity of the technology makes it possible to build the foundation yourself.

But, in addition to the above advantages, there are also several disadvantages :

- inability to build a basement or cellar;

- low resistance to soil deformation during the heaving process.

Application area

The scope of application of columnar grillage foundations is quite wide:

- with threats of frost heaving;

- when constructing walls of the above-ground part of a building made of brick;

- in cases where too deep subsidence of supports is unacceptable.

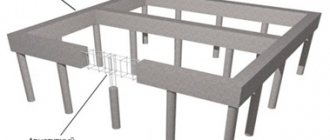

Diagram of a columnar-pile foundation with a grillage:

Calculations of a columnar foundation with a grillage

Undoubtedly, it would be better to entrust the first calculation stage of constructing the foundation to specialists, but if the budget is limited, you can try to figure it out yourself using technical literature and the Internet.

The calculation stage includes the following steps:

- geological surveys . They are required to determine the load per unit area of soil, which, therefore, will determine the support area of the future columnar foundation, which must support the entire weight of the constructed building. Existing load per 1 sq. cm of soil can be found in technical literature;

- calculation of the weight of the building. This indicator depends on the material used during construction, as well as the existing load from wind and snow;

- calculation of the base area of a columnar foundation. This indicator can be obtained by dividing the approximate weight of the building by the weight that 1 square meter can withstand. cm of soil. To equalize the calculations, we increase the resulting figure by 25−30%;

- number of pillars . This indicator is obtained by dividing the area of the base of the foundation by the area of the base of one pillar.

After the calculations have been carried out, the stage of marking the foundation with a grillage begins, where an important point is marking the place where the holes for the piles will be located. There are recommendations for installing supports:

- presence of support at every corner of the building;

- the presence of support at the intersection of walls;

- if there are no corners or intersected walls along the foundation line, the distance between the supports is 2.5-3.5 meters. If supports are installed more often, this will increase the cost of building material; if less often than every 3.5 meters, then the building may deform, which will lead to cracks.

Arrangement of a grillage for a columnar foundation

For its manufacture, prefabricated or monolithic reinforced concrete is usually used. Builders debate whether the grillage should be laid on the ground or raised above its surface. The main argument in favor of a hanging one is that it is not affected by heaving forces.

Sample grillage arrangement for a columnar foundation

Install continuous formwork around the perimeter of the foundation. Place a layer of sand on its bottom and cover it with cellophane. From rods d 12–14 mm, tie a frame and install it. Calculation of the amount of required reinforcement is carried out similarly to a strip foundation. The frame can be tied or welded to reinforcement bars protruding from the ground. It is necessary that the rods are at least 5 centimeters away from the formwork walls.

The grillage also needs to be poured at the same time so that seams do not form. Remove the air with a vibrator or piece of fittings. After the concrete has set, remove the formwork and sand from under the grillage.

Instead of sand, board formwork in the shape of an inverted letter P is suitable. It is installed between the supports on several brick columns, a reinforcement frame is laid in it and filled with concrete. After three to four days they are removed along with the bricks.

How is a columnar grillage foundation constructed?

The construction of a columnar grillage foundation is not that complicated. The main elements of the foundation are load-bearing supports (pillars), which can be made of various materials: concrete, rubble stone, brick, metal pipes.

As mentioned above, the pillars are installed in the corners and at the intersections of walls, and the step of their installation depends on the design and expected load of the building.

Calculations of the diameter of each support are made for each building individually. The burial depth should be below the soil freezing level, and the lower support point should be placed in a stable layer of soil. A prerequisite is the presence of grillages for connecting pillars to distribute the load on all existing structural elements of the building.

Recommendations for building a foundation from asbestos pipes

Another equally popular and relatively cheap option for constructing a foundation for a bathhouse, terrace or light house structure is to pour pillars using asbestos pipes as formwork. Their diameter is selected depending on the required load-bearing capacity. So, if about 15 cm is enough for the construction of light buildings, then to build a house from timber or logs it is necessary to make more massive supports - up to 30 cm.

Brief instructions for constructing a columnar foundation from asbestos pipes with your own hands are as follows:

As in the case described above, first of all, the site is cleared of debris, all turf and all kinds of plantings are removed, and the foundations of old buildings, if any, are removed. The contour of the base is marked

In this case, it is important to control the perpendicularity of adjacent sides - as a rule, all buildings have a rectangular shape. For this purpose, it is enough to use a rope to check the equality of the diagonals

All cords are secured to pegs at the level to which the supports will rise. The entire contour must form one horizontal plane, which can be easily checked with a building level or using a level. Using a hand drill, holes are made in the places where the pillars are installed. In cases where it is necessary to install supports below the freezing depth of the soil, special equipment is used. The bottom of the well is often widened using a special TISE drill. The diameter of the pits should be slightly larger than the size of the asbestos pipes. The depth is calculated taking into account the construction of the sand and gravel cushion - its height should be about 20. After the holes for the foundation pillars are ready, the sand cushion is backfilled and compacted, which is abundantly moistened with water during the compaction process. Next, a layer of rolled waterproofing is placed on the bottom, preventing water from leaking into the sand from the poured solution. The pipes are installed strictly vertically to a height slightly higher than the filling level. In this position they should be securely fixed, for example, using bars. To ensure reliable waterproofing at high groundwater levels, it is important to treat the part of the pipes located in the ground with a polymer or bitumen composition. The pre-prepared solution is poured to a third of the height of the pipes, after which they are raised 10 cm so that the cement spreads along the bottom of the holes. At this point, work is suspended until the mixture has completely hardened. Such foundations are created so that the future columnar foundation can withstand buoyancy forces from the soil during seasonal heaving. After the concrete base has completely hardened, which will take about 3 weeks, the pipes are covered with sand in a circle. It must be compacted thoroughly, moistened with plenty of water. All pipes are cut to the required level. Then frames are inserted inside the formwork, fastened with knitting wire and consisting of 4 vertical reinforcement bars with a diameter of 10 to 14 mm. It is advisable to bend the lower ends into an L shape in order to form a heel. When erecting a pile-grillage foundation structure, it is necessary that the frames protrude above the level of the pillars by about 10 cm. In the event that timber piping is laid on the columnar base, the reinforcement is lowered slightly below the upper edge of the pipe formwork. At the final stage, asbestos pipes pre-cut to the required height are filled to the brim with solution. In this case, the mixture should be periodically pressed every 15–20 cm in height to remove air bubbles.

After pouring, the columnar foundation should stand for at least a couple of days, after which it will be possible to begin building the walls. It is not recommended to leave the foundation unloaded for a long period of time. After the soil swells, the pillars may squint or rise, as a result of which you will have to spend a lot of time correcting the situation.

Construction of a columnar grillage foundation

If you want to do without specialists (engineers, architects) and start building a house or structure on your own, then you should consider several main aspects:

- grillage type. It depends on the type of soil and the properties of its movement;

- design of the future building. Area, number of floors, building material affect the pressure level;

- location relative to the ground.

Stages of construction of a columnar foundation with a grillage:

- Settlement . The theoretical part was presented above.

- Preparatory . Includes clearing the site of all uneven areas, as well as planning the site according to your project. To check the correctness of the layout, you need to measure the diagonals and angles. Vertical holes for mounting posts can be dug manually or using a drilling rig. It is important not to miss the moment and arrange formwork at a depth of one meter to prevent the soil from collapsing. The width of the hole dug should include the dimensions of the post, formwork and spacers.

- Installation of formwork. Usually they use wooden boards, less often plywood with moisture-resistant properties, wood boards, and metal sheets.

- Reinforcement . It is carried out using a metal rod up to 1.5 cm thick, which are connected to each other with wire in a horizontal position. In order to connect the post to the grillage, it is necessary to provide for the installation of reinforcement in a vertical position above the support at a distance of 1.5 cm.

- Pouring concrete mixture . It is produced in several layers, each of which is 2 cm. Each layer is compacted with a hand-held vibrator.

- Waterproofing . This is carried out by laying any waterproofing material inside the formwork.

- Installation of the fence . A fence is a wall that covers the empty space under a columnar foundation. It is needed for communications, as well as to avoid the entry of cold air and various precipitation. The best option would be to think through the removal before starting the foundation, since it will be more difficult and inconvenient to do later. Brick can be used as a pick-up material. The intake device includes ventilation and communication openings. The only drawback of the pick-up is its possible settlement under the influence of ground movement.

The final stage is removing the formwork and grouting the ends .

The construction of a columnar foundation with a grillage is an advantageous option for a low-rise building on difficult, swampy and sandy soils, which are characterized by mobility. And the ease and speed of installation does not require the help of special equipment, unlike a slab foundation.

Reinforcement of columnar foundation supports

Reinforcement of a columnar foundation is made with reinforcement with a diameter of 10-14 mm (more is usually not required). The rods should be placed inside the formwork so that they are spaced at least 5 cm from its edge.

The longitudinal bars of the reinforcement are tied, which is preferable, or welded to horizontal jumpers with a diameter of 6 mm, which should be placed every 30-40 cm. The shape of the horizontal jumpers will be either round or rectangular, depending on the chosen shape for the foundation pillars. The length of the longitudinal rods is selected so that after pouring the concrete pillar they rise 30-40 cm above ground level. Subsequently, a reinforced grillage frame will be attached to them, and excess reinforcement can always be cut off if necessary.

The frame is assembled on the ground, after which, already assembled, it is lowered into the hole under the post.