Work on the base of a pile-screw foundation. Part 2 insulation

19.09.2017

When building a house on screw piles, an unheated area is formed under the floor of the first floor.

Therefore, insulating the foundation on screw piles is an important and necessary process, which is carried out in several ways, based on the type of structure and material of the base.

With the help of an insulated base, an optimal microclimate in the room is ensured, and energy costs are also significantly reduced.

Thermal protection technology is a simple process that can be done independently.

To know how to insulate a foundation on screw piles, it is important to study the technological process and follow some recommendations

Features of insulation

When wondering whether it is necessary to insulate a structure of this type, it is worth considering a number of problems that may arise if the work is refused:

- Freezing of water supply and sewerage pipes located under the building;

- sweeping snow, which melts underground in the spring and forms dampness, which will lead to mold;

- strong cooling of the floor due to constant drafts.

To make your stay more cozy and comfortable, it is important to provide thermal protection, which will help eliminate the above problems. What to know, how to close the foundation, it is recommended to follow the instructions below

Insulation methods

The foundation of a wooden house is insulated with the following options:

- Insulation of the base from the outside along the entire length. First, the plinth frame is constructed from the ground to the base of the walls, then the screw foundation is insulated.

- Lining the base with insulation from the inside. Thermal insulation is performed on the outside of the floor.

- Continuous insulation of the wooden floor of the first floor.

Before insulation, a number of specific features of the structure are taken into account, including the location, height of the pile pillars and the material used.

Process technology

The work is performed in the following sequence:

- Arrangement of a brick plinth or installation on a frame with cladding.

- External or internal insulation of the base.

It is important to have ventilation ducts, the functional purpose of which is to constantly ventilate the ceiling

Material used

To insulate a pile-screw structure, polystyrene foam is often used due to its high thermal insulation and sound insulation. The thermal protection technology provided by panel ceilings using this material is produced as follows:

- Elimination of cracks from the surface, treatment with a primer mixture for reliable fixation of insulation sheets.

- Then you need to sew up the sheets from the inside, using adhesive or foam glue.

- Carefully “foaming” the joints of the sheets.

- In order to ensure better insulation, the panels are glued in several layers.

- Installation of a metal mesh that will protect the material from various rodents.

If you don’t know how to cover the area under the house to prevent the possibility of blowing, you can pour soil or expanded clay under the insulated base. In addition, foundation insulation with penoplex, foam glass, polystyrene foam and polyurethane foam is widely known.

Practical advice

Experienced experts advise following some recommendations on how to properly insulate the base:

- upon completion of the insulation work, it is advisable to wait at least 7 days and only then begin installation of waterproofing;

- equip ventilation with a hole distance of 1.5-2 m;

- in order to protect the structure from permitting, the pile supports of the insulated foundation should not be moved or unscrewed;

- to increase the level of strength and reliability of the base, you need to additionally seal a layer of reinforcing mesh;

- if the work is carried out properly, the space in the middle of the SVF can be used for your own needs;

- work on cladding a pile-screw foundation must be carried out in strict compliance with technology.

When wondering how to insulate a pile-screw foundation, an experienced builder will answer that strengthening the foundation through thermal insulation is a simple procedure that everyone can do. There is no need to use specialized equipment or learn special skills.

Problems of uninsulated pile foundations

For low-rise construction, solid reinforced concrete piles, steel screw piles and bored concrete piles are most suitable. Regardless of the design of the piles, the method of their installation and the grillage installation technology, this type of foundation has a number of disadvantages.

Disadvantages of a pile foundation:

A pile foundation that is not insulated during the cold season can lead to big problems

- Cold underground. Increased heat loss through the floor in winter.

- If the grillage is made of reinforced concrete, then a powerful cold accumulator is created. If there are interruptions in heating, it takes a very long time (up to several days) to restore the normal microclimate in such a room.

- Danger of freezing of utilities laid under the floor.

- Pushing out piles caught in the freezing zone. Piles are a conductor of cold. If anti-frost measures are not taken, metal and concrete supports can cause local heaving.

- Uneven shrinkage under the weight of the house when individual piles fall into areas of low soil density.

- From an aesthetic point of view, a conventional pile foundation is a purely utilitarian design solution that requires decoration.

- The emptiness under the house, blown by the winds, quickly becomes littered and periodically requires time to restore order under the house .

Why are individual piles pushed out, leading to a situation where the plane of the grillage is disrupted? One of the common reasons is uneven soil moisture: it is stronger around the perimeter and corners than in the center. This, in turn, leads to uneven freezing depth. In addition, specific expansion during heaving also depends on the percentage of humidity.

4 of the 7 problems listed in the list are directly related to exposure to cold and can be solved with the help of a competent thermal insulation device.

Pile foundation insulation technology

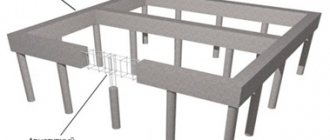

The entire process of insulating a screw pile foundation for a wooden house can be divided into the following work:

- performing waterproofing;

- construction of a frame mesh for the base;

- installation of insulation on the frame;

- external finishing with insulation;

- internal insulation of the foundation.

Performing waterproofing

Regardless of what material the piles are made of, they require proper protection. If the installation of waterproofing under the insulation layer depends on the selected material, then the main structures of the foundation must be protected from the aggressive action of moisture.

Metal piles are coated with a primer, wooden piles are impregnated with special antiseptics

It is important to carefully treat all exposed surfaces to prevent early destruction.

Construction of a frame mesh for the plinth

The frame mesh is made of wood or metal. These structures also need to be protected from moisture.

The operating principle is simple. A sheathing is created for the selected insulation so that the cells are smaller than the insulation boards. This will make it possible to attach the insulation to the frame.

An improvised basement is being built throughout the outside of the house, which will retain heat inside. For strength, the metal frame is welded and sunk slightly into the ground.

It is necessary to ensure the strength of the structure so that it can withstand significant wind loads and not collapse in bad weather. To further strengthen the frame, concrete is sometimes poured onto the base of the frame around the perimeter of the building.

The second version of the base is built of brick. The process is more labor-intensive, but the result is a truly durable structure that you don’t have to worry about during operation.

We insulate the pile foundation with brickwork

You definitely need to build your own for such a base. Then half a brick is laid, followed by insulation.

Installation of insulation on the frame

If the frame is built correctly, installing the insulation will not cause problems. The insulation boards are laid and pressed tightly against the frame. Additional fastening can be done using retaining bolts.

All resulting joints should be carefully sealed. Polyurethane foam is well suited for this.

If you use a material that is afraid of moisture, it is necessary to apply a layer of waterproofing. This will protect the insulation from rodent attacks.

In this regard, it is not recommended to use polystyrene foam, which is a favorite material for mice and rats. Over time, they find how to get into this warm place and create entire labyrinths there, weakening the effect and effectiveness of the insulation.

External finishing with insulation

Any available façade system is suitable for exterior finishing. Most often, siding or decorative PVC panels are used that imitate brick or natural stone.

Basement siding "burnt brick"

You can also choose external protective panels that look like wood. This will make a wooden house stylish.

Installation of any external system is carried out taking into account the requirements specified by manufacturers. Work should start from the very bottom, installing the guide profile. Then the rest of the planks are laid on it, which are closed with a snap.

When choosing exterior finishing, you need to look for not only a beautiful material, but also one that is sufficiently durable and moisture-resistant.

Internal insulation of a pile-screw foundation

The interior of the foundation is insulated using expanded clay bedding. It is necessary to dig a small trench near the piles along the entire perimeter of the house, fill it with expanded clay and, if possible, pour a small layer of concrete on top to prevent contamination of this strip of insulation with soil and plant impurities, which over time destroy the effect of using expanded clay.

It is important to make ventilation holes in the formed base that will ventilate the subfloor. This will prevent the appearance of fungus, rot and early destruction of structures. The openings must be covered with a grill to prevent rodents and other pests from getting inside.

In winter, the ventilation is usually completely closed. In some cases, additional care must be taken to install hoods to prevent the appearance of moisture in the underground

The holes must be covered with a grill to prevent rodents and other pests from getting inside. In winter, the ventilation is usually completely closed. In some cases, additional care must be taken to install hoods to prevent the appearance of moisture in the underground.

Features of foundation insulation

One of the negative characteristics of a pile-grillage foundation is the presence of free space under the floor. As a result, cold actively enters from below, and a cold floor is unlikely to contribute to a comfortable atmosphere inside the house. High-quality insulation of a pile-screw foundation will help solve this problem in the most effective way. If desired and have the appropriate experience, thermal insulation work can be done with your own hands.

The entire process of insulating the foundation of a house can be divided into the following stages:

Waterproofing of piles and grillage

Regardless of what specific material the foundation grillage of the house is made of, it is necessary to waterproof all joints. If this is not done, moisture may penetrate from the outside, which will inevitably lead to wood rotting, mold formation, or metal corrosion. When performing waterproofing with your own hands, you must be especially careful to ensure that all open areas of the structure are subjected to high-quality treatment.

Manufacturing of a special frame

Insulation of a pile-screw foundation is impossible without creating a special frame that will replace the missing base of the house foundation. First you need to dig a small trench into which to pour a reinforced foundation. After final drying, all that remains is to make a red brick wall.

Another method is to attach special horizontal bars to the piles. This is done either by bolts or by welding using metal guides.

Installation on the insulation base

Insulation of foundations on screw piles is carried out by installing roll or sheet insulation on a previously erected improvised base. Most often, insulation is made with polystyrene foam, mineral wool or polystyrene foam.

When working with mineral wool or any other rolled material, a distance of approximately 1 cm less than the width of the insulation is most often left between the guides. This is necessary to ensure that the material fits as tightly as possible to the guides. Additionally, it is necessary to cover the mineral wool with a vapor barrier. This will provide adequate protection from moisture.

If the insulation of the pile foundation of a house is carried out with polystyrene foam or polystyrene foam, the seams must be treated with polyurethane foam. Penoplex does not require additional processing, since it is not afraid of physical impact and does not absorb moisture in any way. With polystyrene foam, in this regard, it is much more difficult. It should not only be thoroughly waterproofed, but also care should be taken to ensure that rodents do not build nests inside the insulation.

Fastening to the plinth of decorative panels

Finishing the insulation on the outside can be done with your own hands from various materials. One popular option is siding (metal or vinyl). To install it yourself, a starting profile is attached to the lower part around the perimeter of the building. Then work on fastening individual siding sheets is carried out in an upward direction. In recent years, the use of decorative PVC panels made in the form of brickwork has become an increasingly popular finishing option.

In the same case, if you are still afraid that the floor in your house will freeze, you can always make additional insulation of the base of their screw piles in the winter with your own hands, simply by throwing snow on the base.

Backfilling the inside with expanded clay or soil

From the inside of the insulated base on screw piles of a house built on heaving soils, it is recommended to add expanded clay. Among other things, this will significantly reduce airflow and help ensure that the floor does not freeze even in the most severe cold.

How to make an insulated base out of brick?

The construction of a brick plinth is a very labor-intensive process and requires a certain amount of time. However, this option is more reliable and durable. First of all, to create a brick wall, you need to dig a trench on all sides of the building. The depth of such a trench should be approximately 20-25 centimeters. The width is selected depending on the width of the brick; it is advisable to make the trench several centimeters wider than the material. The resulting recess is filled with concrete along the entire perimeter with additional reinforcement in the form of reinforcement. Reinforced parts should be selected with a diameter of 10-12 millimeters. This concrete base will serve as the foundation for the constructed brick wall of the basement.

After the concrete has completely hardened, you can begin laying the brick wall. The structure must be erected in small sections, approximately 2 meters in length, so that a polystyrene or foam plastic panel can be placed quite comfortably on the inner surface of the basement wall. If foam panels are used for thermal insulation, they are attached to the brickwork using a special construction adhesive that does not contain organic solvents.

Insulation and preservation of a pile-grillage foundation for the winter

Recently, the question of maximum heat preservation in the house has interested almost everyone. There are many different ways to do this, and one of them is to insulate the load-bearing building structure, which takes on the main load of the entire building - the foundation. Let's talk about how to insulate a pile-grillage foundation.

Is it possible to make a pile foundation in winter?

First, let's figure out whether it is possible to make a pile foundation in winter? If we are talking about an ordinary concrete foundation, then of course it is impossible. But you can install a pile-screw foundation even at the lowest temperatures, without at all compromising its quality and reliability. In this case, dry pouring compounds are used for concreting piles.

Pile-grillage foundation

Is it necessary to insulate a pile-grillage foundation?

Let's now see whether it is necessary to insulate a pile-grillage foundation during construction. It is advisable to do this, and precisely because without good thermal and waterproofing, it is the grillage that can fail and crack during the shrinkage of the building, which will immediately affect the solidity of your building.

This is the only gap in such material, so we emphasize once again that insulating the pile foundation grillage during the construction of your building is extremely necessary.

Insulation materials: characteristics and cost

First, prepare materials for insulation. Which types of them to choose based on the characteristic data, determine after you make a calculation showing the conditions and intensity of penetration of frost and moisture to the foundation.

Natural insulation materials

- Paroc Linio 80, thermal insulation boards for plastering systems. These lamellas or strips of mineral wool do not allow the cold to pass through, but in order to prevent moisture from penetrating into them, additional waterproofing must be added.

- ROCKWOOL LAMELLA MAT, stone wool.

Does not allow cold and moisture to pass through. Very practical and easy to use. Almost half the price of the first insulation. - Steico Isorel, ecological, natural wood fiber insulator. Just as in the first case, it retains heat well, but to prevent moisture from entering, it is better to simultaneously waterproof the original material. Quite budget friendly.

- They also use simple sawdust, tow or plywood.

Stone wool for foundation insulation

Polyurethane foam

These are either cans that spray this material, or synthetic foam-like slabs. Quite good quality material, protects well from the cold.

Innovative products consisting of mixed film and roll raw materials. Very easy to use thanks to the presence of an adhesive side. Waterproof and heat resistant.

Mineral wool

This is a textile that looks like cotton wool, in the structure of which glass, blast furnace slag and rock alloys are mixed. Not flammable. Easily tolerates changes in temperature. Excellent sound and heat insulation.

Extruded polystyrene foam

It is essentially polystyrene foam, but without many of its disadvantages. It has strong heat resistance and also resists chemical irritants well. The material is strong and durable. The truth is quite expensive.

Foam plastic (pressless polystyrene foam)

Perhaps the cheapest, but most successful insulation option. Shows a high level of protection against water and frost. Easy to install. True, it can also easily be damaged during installation, this must be taken into account. But it lasts for a long time.

Polystyrene foam protects the foundation from water and frost

There are many ways to insulate a grillage; we will focus on the best of them.

Pile-grillage foundations

This option is designed to insulate the outer layer of the foundation from water and cold.

To insulate the grillage on piles in this way, the following steps are performed:

- First bitumen. It is poured in a layer into the ground floor, it fills all the sides of the grillage from the outside and thereby already creates a thorough safe protection for it.

- Next is polystyrene foam. The raw materials are glued onto the flat surface of the grillage itself or the bitumen with which you previously covered it. Reliable and for many years.

- Be sure to “blow out” all the seams with foam to block access to frost through them.

- Then it is advisable to cover the structure with reinforcing steel mesh to protect all preliminary coatings from rodents and prepare the base for plaster.

- And the final stage is the plastering of the base itself. Perform this only when the glue has dried and the mesh has tightened.

Pile foundation with intermediate grillage

Insulate the foundation with an intermediate grillage with thermal panels. Attach them either to the grillage itself or to the sheathing; there is no need to bury them too deeply in the soil.

There are many ways to insulate a grillage

Since the pile-screw foundation is in greatest demand, we will tell you how to deal with its insulation. To do this, a false base is created from a wooden frame or brickwork.

Waterproofing insulation

Since water is present in the soil in any region, it is imperative to protect your insulation from moisture penetration, especially when it comes to preserving a pile-grillage foundation for the winter. It is quite easy to carry out waterproofing, using sheets, in the form of a spread, in rolls, as well as using spray cans and insulation.

You can combine them, this will give a better effect and lead to higher performance.

Errors and tips

At the very beginning of any construction, you should take into account all the advantages and disadvantages of your business, and, if possible, avoid them, since this will inevitably lead to disastrous consequences.

We will advise you:

- Check the bonding connections between the grillage and the piles around the perimeter of the foundation. If they are not strong, then severe shrinkage during frosts is inevitable, and this will lead to mobility of the pillars. This is a deplorable nuisance that should be corrected in time.

- If the grillage lies directly on the ground, then be sure to additionally insulate it with polystyrene foam. Place insulation between the soil and the grillage. Otherwise, during the period of freezing of the ground, the piles may break due to their expansion under such conditions.

- Be very careful in all calculations and calculations; an unprofessional approach in this matter can lead to many undesirable consequences, including a short service life of your structure.

- Take into account a very important rule - do not install piles above the depth of the soil to which it freezes. Lower them lower to prevent the foundation from subsiding.

- Be sure to insulate the foundation at the construction stage, otherwise doing so later will be either too expensive and difficult, or completely impossible.

- Take your time when doing insulation work.

Any mistake or miscalculation, or technical damage can lead to a longer completion of the task that you are currently performing. Pile-grillage foundation is suitable for one-story houses

The pile-grillage foundation has long attracted the attention of ordinary self-developers. It is ideal for one-story residential buildings, bathhouses, garden buildings, and country houses. Take our information into account and let your home always be warm and cozy!

Source: https://pobetony.expert/stroitelstvo/uteplenie-i-konservaciya-svajno-rostverkovogo-fundamenta-na-zimu

External and organic insulation of foundations

When insulating rooms, it is necessary to achieve such a temperature that at floor level its values differ by no more than 2°C. Such indicators can be achieved by insulating not only the floor and walls, but in addition to them, the very foundation of the house. The foundation is insulated both from the outside and from the inside. Thus, from the outside, to achieve the set goals, the following materials are most often used:

- expanded polystyrene;

- penoizol;

- polyurethane foam;

- polyethylene foam and other insulation materials.

The inside of the grillage can be insulated with the same insulating materials. You can use the usual scheme for insulating log buildings, most often their subfloors; backfilling the grillage with soil is also used for this purpose. However, the main thing is not to forget to eliminate all the cracks in the foundation using polyurethane foam or cement mortar.

Insulation materials with moisture-proof properties

If you turn your attention in time to insulation materials that can repel water, you can save a lot on foundation insulation. Waterproof materials include:

- Airgel;

- Foam glass;

- Extruded foam (polystyrene).

By covering the base of the house with such insulation in a timely manner, you can not only save money, but also avoid unpleasant surprises in the form of corrosion on the foundation structure or gradual destruction of the building.

Insulation of a pile-grillage foundation is not only the comfort and coziness of your home, but, above all, the health of you and your family. As follows from the laws of physics, all the heat of the house always accumulates under the ceiling, therefore, the floor is already always cold, not to mention the foundation made of screw piles. By approaching the construction and insulation of your home more seriously, you will not only preserve your health, but also extend the life of all its inhabitants.

The grillage is the most important detail. Its functions include distributing the weight of the building onto the base and onto the land as a whole. In this way, maximum stability of the pile foundation is achieved. The base element must be made in accordance with technological standards, and in addition, it is necessary to select the correct insulation for a foundation made using this technology.

A properly executed foundation of a house is a tax on reliability and comfort. The first ensures the stability of the structure. But comfort is achieved due to the fact that the base is an additional insulator of the structure from low temperatures. The roof and walls protect the house from wind and rain, and the foundation becomes an obstacle to the cold coming from the ground.

In fact, it is simply impossible to build a house without a foundation. The simplest insulation option is to insulate the foundation with expanded clay and sand. This is a universal remedy. They can be used to insulate a strip foundation or to insulate a grillage type foundation. The latter is often insulated with polyurethane foam, but expanded clay should not be discounted.

Types of heat insulators

Foam photo

It has good thermal insulation ability, but is afraid of direct rays of the sun and precipitation. When cutting, it begins to crumble, so it is recommended to use it whole;

Expanded polystyrene. It is a derivative material from polystyrene foam, and is produced by the polymerization of styrene and pentane. Depending on the production process, it can be of three types: autoclaved, extradited and pressed. It is usually produced with a standard thickness of five centimeters, but there are other options.

For construction work in the private sector, a pressed one with a high density is well suited; this is exactly what you need to buy if you decide to insulate any load-bearing structures in your home.

Expanded polystyrene

When purchasing a polystyrene foam board, you get additional convenience when working with it, since such boards fit tightly together and form an additional layer of overlap. Interpanel connections overlap when installed, but compared to conventional polystyrene foam, it has a lower thermal conductivity.

It is convenient to saw, and unlike polystyrene foam, it does not crumble, but forms an even cut; moreover, it is not afraid of a humid environment, so it can be used for external insulation of walls;

Penoplex. It is derived from expanded polystyrene and has greater porosity, and, consequently, a greater breathable structure. Due to this characteristic, it is widely used for both internal thermal insulation work and external

Therefore, if you have not yet decided how best to insulate the base of the foundation, then you should pay special attention to this material

Appearance of penotex

Insulation process

In the process of insulating plinths, work can be carried out using two technologies: adhesive or frameless and frame (in this way the plinth of a pile-screw foundation is insulated).

In the latter case, due to the fact that the pile foundation consists of point supports, there is a need to create a frame around the entire perimeter of the house. It is also commonly called a false base. This structure can be thermally insulated with polystyrene foam or polystyrene foam.

In the first case, the insulator will need to be placed in the frame itself, because it is afraid of precipitation, and in the second case, the insulation is glued using a special adhesive directly to the frame. Due to the fact that the price of expanded polystyrene is affordable for everyone, all construction companies and developers have begun to use it.

The process of gluing the heat insulator

Instructions for carrying out insulation work:

- If the foundation is piled, then you must first create a frame, but if it is ordinary, for example, strip, then you must perform hydraulic insulation. Bitumen mastic is well suited for waterproofing;

- A small groove is made near the blind area; it serves for the thermal insulation sheets to fit into it. If there are any leaks, they can be blown out with foam;

- Each sheet of material is glued to a special glue, and the work itself needs to start from the bottom of the corners;

- At the next stage, the heat insulator slabs are puttyed, and after the putty has dried, grouting is done;

- At the final stage, the entire structure is painted.

Bituminous composition applied to the wall surface

If you use the services of specialists, you will get a substantial amount, since for one square meter of area they charge 400-550 rubles, and if you have a large house, then you can already roughly estimate the considerable cost for everything.

It must be said that such work seems complicated only at first glance, but if you study it in detail, even a novice master can handle it, so if you want to save money, then carefully read the information presented again.

Insulation of the pile foundation of a house

In buildings with a columnar foundation, the floors often freeze during the cold season. This is due to the open space under the building. In this regard, the question arises: how to insulate a pile foundation? It is very difficult to choose the appropriate type of insulation for this type of foundation. Here it is necessary to take into account the peculiarities of the constructed building, namely the height of the foundation pillars and their material. However, there are only two options.

- One option involves installing a frame around the entire perimeter of the building, which must be covered with facing material. This way you can organize the insulation of the pile foundation from the outside. The resulting object can be adapted for economic needs. The disadvantage of such insulation is that it will require a large amount of time, financial costs and material, especially if the floor is located quite high in relation to the ground. But this is the most optimal option for insulating the foundation if the distance between the floor and the ground is not particularly large.

- The second option involves insulating the floor with a pile foundation, and not the foundation of the building. This option is suitable for buildings where there is a very large space between the floor and the ground. You can use polystyrene foam (expanded polystyrene) as insulation. The most important thing is to secure the material correctly. It should dock closely with adjacent layers. If necessary, you can lay the foam in two or three rows. Between each layer it is necessary to lay waterproofing.

It is best to insulate the base of a building from the outside of the building, but if this is not possible, in this case it can be insulated from the inside. The optimal solution is to insulate the base of the house on both sides, but not every construction project can afford this.

Necessary materials

To carry out the work, you need insulation and a profile pipe with a cross-section of 50x30 mm and a thickness of 2 mm.

From the tools:

- welding machine,

- screwdriver,

- building level.

Calculations

An important point is to correctly calculate the required amount of insulation and profile pipe. If there are surpluses left, it doesn’t matter. Well, if it’s not enough, you’ll have to go to the hardware store again.

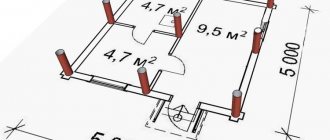

Eg:

- house 10x10 m - perimeter 10x4=40 m;

- plinth height – 0.5 m.

The area of the covered surface is: 0.5x40 = 20 m. This means that this amount of insulation must be purchased. It is better to be 5-10% larger, because it is often necessary to trim to the required dimensions. You can save a lot if you choose a material with a width equal to the height of the base.

The profile pipe is laid on the piles in two rows. Accordingly, its quantity is determined by the double perimeter of the house. That is, in our case we will need 80 m of this material.

Choosing the finishing finish for an insulated base

From a technological point of view, it is permissible to use all types of cladding and finishing coatings. This can be plaster, decorative clinker, and various types of linings. Some EPS collections are produced with a finished coating already applied, which reduces costs and speeds up work.

Insulation of pile foundations with decorative EPS boards

If we talk about the aesthetic side, then when using imitation of any materials, you should think about naturalness. For example, is it worth using clinker bricks as cladding for the basement of a house made of wooden beams?

Types of insulation

So, what is the best way to insulate the foundation? We offer a list of materials. With the help of which you can perform reliable insulation of the foundation of a house on screw piles.

Polyurethane foam

Laying is carried out in a dense layer, evenly distributed along the foundation perimeter. In terms of thermal insulation properties, the material is superior to other modern insulation materials; it retains thermal energy due to the forming cells filled with air.

It has excellent adhesion, which allows the material to be applied to various surfaces, regardless of their configuration and design features. The material is lightweight and does not create additional load for the foundation piles.

The disadvantage of this method of insulation is the need to purchase or rent special equipment.

Penoplex

With the help of this material you will quickly and reliably protect the basement and underground space from the cold wind. In addition to its insulating function, penoplex protects against moisture and groundwater penetration. The lightweight material does not create additional load for the foundation and can withstand temperature fluctuations in the range from minus fifty degrees to sixty degrees, for which reason it is used in all regions. In addition, developers note the acceptable cost of such insulating material.

Foam glass

This option for insulating a house on a pile foundation is distinguished by its advantages and disadvantages, determined by the technical features of the insulating material. The main advantage is a long operating period. If installation work is carried out in accordance with technology, then the insulating layer will last up to a hundred years, while reliably protecting it from exposure to a humid environment. This quality reliably protects metal structures from corrosion.

The material is not flammable, its melting point is one thousand degrees, which additionally provides fire protection.

As negative aspects, the high cost of the material and the difficulties associated with installation work are noted, since the fastening of fragile blocks will have to be done with dowels.

Mineralized cotton wool

No special skills are required to work with such material. Cotton wool is light in weight and retains heat well. But for a comfortable stay, cotton wool is not able to protect against moisture, so the insulation layer will need to be finished with waterproofing material, which entails additional financial costs. In addition, the service life of mineral wool is short, and the material can be subject to deformation.

Penofol

This roll material successfully combines thermal insulation technical characteristics and cost. It is made of aluminum foil, covers large areas, and is placed on various surfaces. It has the ability to dampen extraneous noise and protects against moisture penetration.

The insulation is resistant to temperature changes, easy to install, and lightweight. True, paint or putty solution will be applied to the foil surface.

Insulation of a foundation made according to a pile scheme with a reinforced concrete grillage

This or that decision on thermal insulation is made depending on the height of the base. Small heights make it advisable to install floors on the ground. In this case, the principle of insulation is the same as in the uv scheme.

Pile foundation insulation scheme

The grillage, like the MZLF, takes the load only from the walls. The floor slab is cast over a layer of polystyrene boards. The slabs are laid out on a compacted sand bed. Under the pillow there is a main layer of backfill consisting of anti-capillary crushed stone.

External perimeter insulation consists of vertical cladding of the base and insulated scaffolding. There are no original engineering solutions unique to houses on pile foundations here. Everything is done according to the principle of eliminating cold bridges. There should be no gaps or breaks between the insulating layers of the wall, plinth and scaffold. In this case, overlap connections are preferable to butt contacts.

Insulation of a pile foundation

To cover the base with insulation and finishing, it is necessary to form a sheathing. For this purpose, piles are tied. The strapping can consist of rolled metal and wooden moldings. The idea that this measure is an additional factor in increasing the rigidity of the pile foundation has no real basis. Sometimes, instead of cladding with EPS, half-brick masonry is used on the sheathing. But they try to rest it from below not on the blind area, but on the channel, which is welded to the bottom of the piles.

The version with a high base differs in that the floor slab rests not on the ground, but on a grillage. In this case, it is acceptable to perform both external and internal insulation of the slab. In any case, it makes sense to exclude the cold bridge from the ceiling to the piles through the grillage. For this purpose, a thermal break in the horizontal plane is used. It can be done by installing EPS between the grillage and the belt of additional foundation blocks on which the ceiling directly rests.