Crushed stone is a bulk material in the form of stones, which is a product of crushing raw materials and then sifting through sieves. This is one of the basic materials used in construction, road, and landscape work.

Crushed stone comes in different types depending on several factors.

The material can be classified:

- By origin

- By faction

- By post-processing method

The possibility of using crushed stone in certain works directly depends on this classification. Therefore, below we will describe each in detail.

Types of crushed stone by origin

Crushed stone is an artificial material. In order to obtain it, rock is first mined in quarries and then crushed. This can be done for different purposes and in different ways.

Firstly, mining rock for crushed stone can be:

- Focused

- Side

In the first case, raw materials are specially mined for crushed stone, in the second, waste remaining after the main production (for example, after sawing rock into slabs) is processed into crushed stone.

If we talk about methods, here mining can take place:

- Explosive method

- Using vertical saws

- Using stone cutting machines

- Using diamond threads

- Manual method

Most often, raw materials are extracted using the first method - using explosives. Then the rock fragments are immersed in crushing plants, and the output is crushed stone. Next, it is sifted, divided into fractions, and possibly subjected to post-processing. Other methods are used mainly for extracting raw materials for production. Read more about this on the page Mining crushed stone.

Regardless of the purpose and method of extraction, the type of rock plays an important role in classifying crushed stone by origin.

So, depending on the source raw material, crushed stone is:

- Granite

- Diorite

- Gabbro

- Basaltic

- Dolerite

- Diabase

- Limestone

- Marble

- Serpentinite

- Quartz

- Quartzite (quartzite)

- Gravel

- Dolomite

- Slate

- Amphibolite

- Pyroxenite

- Shungite

- Andesitic

- Expanded clay

- Agloporite

- Perlite

- Secondary

- Slag

- Plaster

Now more details about each.

Granite crushed stone

Granite is a durable igneous rock that resulted from the solidification and crystallization of magma. This process takes millions of years. Therefore, it is not surprising that crushed stone made from this rock has excellent characteristics. In addition, granite is no longer just a type of material, but a sign of quality, meaning reliability and durability.

Visually distinguishing granite rock from another is quite simple - thanks to its specific color. Granite has a heterogeneous gray color with numerous black (dark gray) and white small inclusions.

Granite crushed stone has high strength and can withstand increased mechanical loads and temperature changes. Therefore, it is used everywhere. This rock is, in principle, one of the most popular varieties. It is widespread in the earth's crust and forms the basis of most of all continents.

In the Sverdlovsk region, crushed granite is already a brand.

Diorite crushed stone

Diorite crushed stone is the result of crushing the igneous rock diorite. In terms of its characteristics, it is practically not inferior to granite, and is also very similar in appearance to it. He has the same spotted black and white color, with gray, possibly green splashes.

How then can you visually distinguish diorite from granite?

In fact, there is a difference. Thus, granite is characterized by a light gray color, and upon closer examination it is clear that there are much more white inclusions than dark ones. And with diorite it’s exactly the opposite. Therefore, in general, such crushed stone looks dark gray, sometimes it can have a brown tint.

Many suppliers take advantage of this similarity and sometimes sell diorite crushed stone, passing it off as granite. This is due to the fact that diorite is cheaper than its twin. Therefore, be careful.

Crushed gabbro

Gabbro is a deep-seated igneous rock formed under conditions of high pressure and high temperature. It contains practically no quartz in its composition, and this determines its dark color. Gabbro can range from dark gray to almost completely black.

Gabbro deposits are located all over the world: in Europe, North America, Australia and even Africa. In Russia, this breed is distributed mainly in Karelia and the Urals.

And here we need to make one important clarification. The fact is that gabbro has two completely different purposes. The main activity is the production of facing materials and slabs. For this purpose, a breed of noble dark, almost black shades is used. As a rule, such material has a very high cost, and the raw materials for it are mined in quarries from great depths. For example, Australian gabbro is one of the most valuable representatives of this breed.

But gabbro is also widely used in construction (read more about this in the article Crushed stone for construction). True, here we are talking about a completely different material in appearance. It is mined in open-pit mines (that is, practically from the surface). The raw material has a gray tint and, due to the lack of special decorative properties, is immediately crushed into crushed stone of different fractions.

How does gabbro differ from other types of crushed stone?

At first glance, the difference is not very noticeable, so gabbro can be confused with some other crushed stone. However, if you look closely, the differences are visible even to the naked eye. The gabbro rock has a uniform gray color without inclusions. On large fractions, a pattern in the form of thin veins of a lighter color may be visible.

If there may be difficulties with visual identification, then there is a sure-fire tactile way to recognize gabbro. You will need dust particles that cover the crushed stone. It is necessary to collect this dust on the pads of the fingers and make a rubbing motion with the pad of the thumb along the index and middle fingers. And only if it is gabbro, you will feel smoothness, softness, the movements will be sliding, “soapy”.

Basalt crushed stone

Basalt is an igneous rock that was formed as a result of a volcanic eruption. According to one version, its name comes from an Ethiopian word meaning “containing iron.”

Basalt can be black, often gray, sometimes with a greenish tint, glassy or porphyritic structure. The latter was formed during the process of minerals entering the lava. When the minerals solidified, they remained in the rock and formed inclusions of different colors. Thus, olivine gives the particles a marsh-yellow color, plagioclase - white, pyroxene - black.

Basalt crushed stone has high strength and flexibility, and is heat resistant. Thanks to its characteristics, it surpasses even the “standard” granite variety.

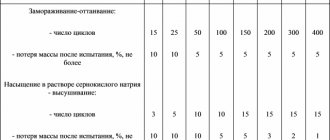

Crushed stone of this breed is, in principle, one of the most durable. Its strength indicators range from M1200 to M1600. In addition, basalt stone has one of the highest frost resistance parameters - F400. This means that it can easily withstand 400 consecutive freezing and thawing cycles without loss of quality characteristics. After this period, the material will also not collapse and will last for a very long time. In other words, structures made from such crushed stone will retain their strength for hundreds of years.

Most often the material is used in construction and road work.

For example, it is used as:

- Coarse aggregate in high-strength concrete

- Pillows under the foundations of multi-story buildings

- Foundations under federal highways

- Filling of ballast layer when laying railways

- Cladding material

Most basalt deposits are located in the USA, India and Hawaii. In Russia, deposits of this rock can be found in Transbaikalia, Kamchatka and Altai. There are no basalt quarries in the vicinity of Yekaterinburg. The closest deposit to us is located in the Kurgan region, so these products are not found on the local market.

However, sometimes this crushed stone can be found in the Kamensk-Uralsky area. Some suppliers are also ready to bring basalt stone to Yekaterinburg. But it is worth considering that the price for such crushed stone will be very, very high. It makes no sense to overpay for it.

Why is that?

Firstly, the basalt quarry is located 142 kilometers from Yekaterinburg, and therefore the most expensive will not be the material itself, but its transportation to your site. Secondly, the strength of basalt crushed stone from a quarry nearby is only M1200. For basalt this is far from the limit.

For comparison, the strength of crushed stone from other rocks in our region:

- Granite – from M1000 to M1400

- Amphibolite – M1200

- Serpentinite – from M1200 to M1400

- Diorite – M1400

This means that in the vicinity of Yekaterinburg you can easily find more durable crushed stone at a lower price.

Thirdly, the basalt material that is sold on the border of the Sverdlovsk and Kurgan regions has an unremarkable light gray, sometimes beige color. Therefore, it is not particularly in demand in landscape design. An alternative to it in these works is decorative marble stone (we will talk about it a little later in our article).

Thus, we can conclude that although basalt crushed stone is a durable building material, it is not the best in our region in terms of price and quality ratio.

Dolerite crushed stone

Dolerite crushed stone is crushed material from holocrystalline, fine-grained igneous volcanic rock. The igneous analogue of dolerite is basalt. Often they are so similar to each other in appearance that they can only be distinguished after laboratory testing.

Dolerite has excellent strength characteristics. It has a dense and massive texture, a crystalline structure. It is widespread in the oceanic crust, folded areas, traps and various plateaus. Most often, dolerite is dark gray in color, but it can be even darker or lighter, depending on the admixtures of various minerals.

Dolerite is usually used as a building and facing material. It is also used for stone casting, paving streets, making large tables for precision measuring instruments, in architecture and even jewelry.

For example, Red Square in Moscow is paved with dolerite mined in Crimea. The Vorontsov Palace in Alupka (Crimea) was built from the same material (precisely Crimean). The famous Stonehenge (England) was also built from dolerite.

Diabase crushed stone

On many sites you can find the statement that diabase is an allegedly outdated name for dolerite. Many foreign scientists also think so. However, diabase is usually classified as a separate subspecies.

The main igneous analogues of diabase are basalt and dolerite. It is close to them in mineral and chemical composition. Diabase is also characterized by high hardness and strength. Crushed stone from diabase often has a dark color: dark gray (almost black), dark green, greenish-black.

Diabase rock deposits are widespread throughout the world. So, they are in the Caucasus, Karelia, Crimea, Siberia, as well as in Ukraine, Great Britain, the United States of America, Scandinavia, France, and Germany. In Karelia, for example, there is such a variety of this rock as gabbro-diabase. She is highly valued in our country.

The main application of high-strength crushed stone from diabase is the construction of roads and railways, concrete work. It is also used as a raw material for wear-resistant and acid-resistant stone casting.

Limestone crushed stone

Limestone is a sedimentary rock that consists mostly of calcium carbonate (CaCO3; this in turn is, for example, the basis of chalk). May be of organic or chemogenic origin. In the first case, limestone was obtained through the cementation of shells and coral skeletons (then called shell rock), in the second, it was formed through complex chemical reactions.

Of course, limestone will never be able to compete in terms of characteristics with rocks formed during the process of magma reaching the surface and solidifying. Therefore, along with low properties, crushed limestone has a fairly low price.

Limestone comes in different colors:

- White

- Light gray

- Brown (closer to red, due to the content of clay impurities)

Despite the difference in color, they all have a homogeneous structure with a very weakly expressed texture. The rock contains virtually no inclusions of other colors or shiny crystals. And, unlike other types, limestones are characterized by dullness.

Marble crushed stone

Marble is a metamorphic (altered) rock. Crushed stone from it is very popular among landscape designers. It is especially valued for its beauty.

And if in terms of technical characteristics marble crushed stone is inferior to most other varieties, then in terms of external data it has no competitors.

Take its color, for example. The most common shades of material are:

- White

- Grey

- Yellow

- Pink

- Black

The entire palette is very wide, and there are combinations (for example, gray with bluish).

Serpentinite crushed stone

The word “serpentinite” itself comes from the Latin “serpens”, which means “snake”. Hence the second name for serpentinite – serpentine. It belongs to the metamorphic rocks. Unlike other representatives of these rocks, serpentinite has high characteristics and is close in performance to igneous rocks.

It happens that some people confuse this material and granite. Visually recognizing serpentinite is quite simple. Unlike granite, it has a darker gray color. On large fractions, a green tint is easily distinguishable. The structure of the coil is more homogeneous, with a less pronounced texture compared to granite. Upon closer inspection, a pattern interspersed with granite becomes visible. But, unlike the latter, here the specks are not white, but green.

Quartz crushed stone

Quartz crushed stone is obtained by crushing the quartz mineral. This is perhaps the most unusual type of crushed stone - because for its production they use not rock, but a mineral.

The material is in demand among landscape designers and is often used as a decorative element (read more about this in the article Crushed stone for landscape design).

Visually distinguishing the quartz variety from other types of crushed stone is not difficult. It can have a color from white to white-yellow. In addition, quartz stands out among other materials due to its structure. Thus, crushed stone from rocks will have a rough, granular surface, and crushed stone from a mineral will have a smooth surface.

Besides its color, quartz is easily identified by its appearance: it appears as slightly clear and shiny crystals.

Quartzite (quartzite) crushed stone

Quartzite, or quartzite crushed stone, is the result of crushing the metamorphic rock of the same name. It is considered very durable and difficult to process.

The basis of quartzite is quartz and admixtures of various minerals. Therefore, the color of the material is often light: white, gray, various shades are possible. It is used in the construction industry, when laying roads, and constructing industrial and production facilities.

Quartzite has also found application in decorative and facing works. It is even classified as a semi-precious ornamental stone. For comparison, jade, rose quartz, lapis lazuli, malachite and rock crystal belong to the same group.

crushed gravel

The raw material for crushed gravel is sedimentary rock with low characteristics. Gravel is formed as a result of the natural breakdown of rocks and minerals of varying sizes. It can be mountainous, lake, sea, river and glacial.

As for the strength of crushed gravel, it is stronger than limestone, but much inferior to granite. However, this material boasts low radioactivity and low price. It does not crush or wear out during operation.

Crushed gravel is very popular in regions where there are no deposits of igneous and metamorphic rocks. The extraction of gravel is carried out in the beds of the Kama, Yenisei, and Irtysh rivers. In the Sverdlovsk region, gravel materials are not popular, as they are by-products of sand production.

Dolomite crushed stone

The starting material for this type of crushed stone is sedimentary carbonate rock, 95% consisting of dolomite, a natural mineral. Its properties resemble limestone, but it is durable and wear-resistant. At the same time, it is quite fragile and scratches easily. Dolomite crushed stone is valued for its frost resistance, resistance to fire and water.

Dolomite most often has a diamond-shaped shape with its characteristic curvature on the edges. It is usually transparent, white or yellowish in color with a glassy sheen or matte. Depending on the impurities, it may have a gray, greenish or pink tint. Therefore, landscape designers often take the material.

Dolomite is mined in the USA, Canada, Switzerland and Ukraine. In Russia, deposits are located along the western and eastern slopes of the Urals, in the Caucasus, Karelia and the Volga region.

Slate crushed stone

Slate is a rock of volcanic origin. It can be located both on the surface and under water. The characteristics of the material largely depend on this. Slate especially varies in strength. One material perfectly retains its shape under high loads, while the other collapses even with minimal physical impact.

Crushed stone obtained from these raw materials can be yellow, brown, gray, black or green with an oily or matte sheen. Crushed slate is easy to distinguish from other varieties. It is characterized by a flattened shape; it resembles thin plates.

Slate is mined in the USA, Austria, China, and the British Isles. In Russia, large deposits are located in the Urals, the North Caucasus, as well as in Mordovia and Chuvashia.

Most often, crushed slate stone is used for roofing work; it can be used in the production of reinforced concrete products and in construction. It has also found a place in landscape design: it is used to create paths and decorative elements.

Amphibolite crushed stone

Amphibolite is a metamorphic rock somewhat similar to granite. It can be distinguished by its layered texture and different colors depending on the chemical composition of the sample. The structure of the amphibolite is granular, with a grain size from 1 to 3 mm. The more pronounced the layering of the mineral components, the more decorative the material is considered.

Amphibolites consist of almost a third of the known minerals. The rock-forming minerals are hornblende and plagioclase (up to 50% of the total composition). The rest is made up of various combinations of minerals. This is mainly reflected in the coloring.

Based on the presence of impurities, it is customary to distinguish 7 types:

- Garnet – the presence of pomegranate is responsible for the reddish tint

- Quartz - due to quartz it may be lighter than its counterparts

- Epidote - impurities give green, bluish and brown shades

- Zoisite – contains pink inclusions

- Scapolite - may have blue, yellow or orange tones

- Biotite – colored dark green, dark brown and almost black

- Kyanite - mostly blue and rarely purple inclusions

The most prized is amphibolite interspersed with garnet, which is used as a facing material.

In the Urals, this breed cannot boast of a variety of colors. The amphibolite has either a light or dark uneven gray-green color with white parallel streaks. The structure and texture are also unclear, which is why this material is used for the production of crushed stone.

Amphibolite deposits are found in Karelia; there are also accumulations of rock on the shores of Hudson Bay, on the Kola Peninsula, the Azov region, in the Alps and in the Ural Range region.

Pyroxenite crushed stone

Pyroxenite is a deep-seated igneous rock. It is of volcanic origin, that is, it was formed as a result of lava solidifying on the surface of the earth. Its rock-forming mineral is pyroxene.

The color of pyroxenite is usually gray, brown, black, maybe with a greenish tint - it all depends on the admixtures of other minerals. A characteristic feature of the appearance of the material can be called a peculiar shine, not typical of crushed stone.

An interesting fact about pyroxenite: next to this rock there are often deposits of precious ores (mainly platinum), as well as chromium and nickel ores, and asbestos deposits.

Shungite crushed stone

Shungite is a rock that, in composition and properties, occupies an intermediate position between anthracite and graphite. The structure of shungite is very similar to the latter. It was formed several million (possibly billions) years ago from organic sediments of freshwater bodies.

Shungite crushed stone has a gray, black, or less often brown color. The material has found its application in metallurgy. Shungite is also used to produce lightweight porous concrete aggregate – shungizite.

The largest shungite deposit in Russia is located in Karelia.

Andesite crushed stone

It is obtained from igneous volcanic rock. The name “andesite” comes from the Andes, a mountain system in South America. The breed is gray, dark gray or black in color.

Andesite crushed stone is used mainly in construction. In addition, it is used for the manufacture of acid-resistant materials and stone slabs.

In appearance, andesite can be very similar to diorite. And this is not surprising: both breeds have similar origins. Their only difference is that andesite was formed as a result of lava solidifying on the surface, and diorite was formed at depth. Another minor difference is the grain. Diorite is considered a coarse-grained rock, while andesite is considered a fine-grained rock with a large number of mineral inclusions.

Expanded clay crushed stone

Expanded clay is an artificial material that is obtained by firing clay. It is easily recognized by its appearance - round brown granules of different sizes. Particularly large particles are crushed into crushed stone.

The main works in which expanded clay crushed stone is in demand are the preparation of concrete, sound and heat insulation equipment, insulation of soils and plants.

Agloporite crushed stone

Agloporite is very similar to expanded clay. Its difference is that to create it, it is not clay that is fired, but clay rocks and soils (loam, sandy loam, loess). In addition, various industrial wastes, including those containing fuel, serve as raw materials for agloporite.

Agloporite is mainly used as a porous filler for concrete; it is used to make thermal insulation backfills. The material can be sold in the form of gravel or crushed stone (crushed coarse gravel).

Perlite crushed stone

Perlite is a rock of volcanic origin. It was formed as follows: the edge of the lava, coming out and coming into contact with the earth's surface, quickly cooled and solidified. This frozen edge is the so-called volcanic glass. Subsequently, under the influence of groundwater, the material is hydrated, or water molecules are added to its ions and molecules. The result of hydration is perlite.

Crushed stone and sand are obtained from perlite. To do this, the raw materials are crushed and subjected to heat treatment. The result is a beautiful snow-white material. Fine perlite is sand, and larger particles are crushed stone.

Along with expanded clay and agloporite, perlite crushed stone is used in the preparation of concrete and thermal insulation solutions.

Recycled crushed stone

The material is not of natural origin. It is obtained by processing waste construction materials (primarily bricks, concrete). In this case, large pieces are crushed into smaller ones.

The difference between this material and others is also that the strength of recycled crushed stone is low. But it is sold at a fairly low price. It can be used in non-critical work.

In the Sverdlovsk region, secondary crushed stone is not produced in large volumes.

Slag crushed stone

Slag material also does not belong to the types of crushed rocks. It is obtained by crushing waste metallurgical slag. It has a low price, but is limited in use due to the 3rd hazard class of the product (moderately hazardous substance). Therefore it is rarely used.

Gypsum crushed stone

Gypsum is a sedimentary rock consisting mainly of minerals and has very low strength. Gypsum stone (or gypsum crushed stone) is a product of rock crushing. The material is not crushed stone in the truest sense of the word; it cannot be used everywhere, like, for example, granite stone. His characteristics are too weak for this. And gypsum stone is called crushed stone primarily due to the shape of its particles. Subsequently, these stones are processed into smaller fractions or crushed into powder.

Gypsum is used very widely: in construction, manufacturing, agriculture, chemical, cement, ceramic, textile, paper, and agricultural industries. Gypsum-based binders are popular.

We talked about the types of crushed stone depending on the raw materials. The next classification is the division of material by size.

By faction

Fraction is the marking of crushed stone grains by their size. It is measured in millimeters - ranging from the smallest to the largest. The separation of crushed stone into fractions occurs immediately after crushing the rocks. To do this, the crushed rock is sifted on special sieves (screens).

The following main fractions of crushed stone are distinguished:

1. Small:

- 3-5

- 3-8 (euro crushed stone)

- 3-10

- 5-10

- 5-15

- 5-20

- 5-25

- 10-15

- 10-20

- 15-20

2. Medium:

- 20-40

- 20-70

- 20-80

- 25-60

3. Large:

- 40-70

- 40-80

- 70-120

- 80-120

- 70-200

This parameter affects the cost of the material and the ability to use it in certain works. For example, there are much more areas of application for small fractions than for large ones. That's why they cost more.

The most popular and in demand materials are the factions:

- 5-20 - its main purpose is concrete work. In addition, it is used for decluttering road pavement, laying cushions, creating paths and all kinds of fills (flower beds, parking lots).

- 20-40 is suitable for a wide variety of work: from the construction of building foundations to roads and highways with high loads, railway and tram tracks. In addition, crushed stone of this category is used for filling the supporting structures of bridges and highways.

- 40-70 is ideal for drainage systems, filling holes and ditches. It is used to create a base under the foundation or road surface, for landscape work, design of parks, courtyards, and landscaping.

The remaining factions are considered less popular. Although the scope of application of each of them is the same as those listed above. Thus, small stones are used for concrete, decluttering, road work, and larger stones, for example, for filling gabions.

The exception, perhaps, will be the faction 25-60. It is considered the most specific of those that we offer for sale. It is used exclusively in railway construction. The material is used to create a ballast layer on railway tracks. This requirement is specified in SNiP.

Description

Limestone crushed stone of the 40-70 mm fraction is a material of natural origin, which is mined in open-pit mines. It has high performance properties: heat resistance, strength, environmental friendliness, and can be treated with chemicals. Lime crushed stone fr. 40–70 is characterized by a low level of radioactivity, environmental friendliness, and improved flakiness.

offers to buy crushed limestone 40-70 in bags of 25 and 50 kg with delivery in Moscow and other localities in the central region of Russia. We have long-term direct contracts with manufacturers, so we are ready to provide delivery of crushed limestone 40-70 mm in any quantity. All material undergoes thorough quality checks, which is confirmed by relevant certificates.

Crushed limestone is obtained from rocks containing calcium carbonate. Limestone, calcareous dolomite, or a mixture of these rocks can be used as raw materials. The production process involves crushing rocks and then sifting them to separate them into fractions. The fraction 40-70 mm is one of the largest.

Limestone crushed stone has lower density and strength characteristics compared to crushed stone made from granite and gravel. In addition, deposits of raw materials for its production are much more common. It determines a more favorable price for limestone crushed stone of the 40-70 mm fraction. Despite the lack of strength, the material has the following important advantages:

- high frost resistance and resistance to temperature changes;

- low level of water absorption;

- low radioactivity;

- low bulk density coefficient, which leads to lower material consumption.

Application area

Taking into account the totality of the properties of the material, the optimal solution would be to buy crushed limestone of a fraction of 40-70 mm for road construction.

The main areas of application are:

- use as a cushion for road surfaces;

- use in the production of asphalt concrete mixture as a filler;

- use as a component of a protective layer when performing road repairs.

Due to its low cost, the use of this material can significantly reduce the cost of road construction. However, given the lower level of strength, crushed limestone is recommended for use on roads with a low level of traffic load.

The material is also used in the chemical industry, glass production and some other industries.

By post-processing method

Already finished crushed stone (crushed and dispersed into fractions) can be subjected to additional processing.

Depending on this, there are the following types:

- Washed crushed stone

- Black rubble

- Colored crushed stone

- Galvanized crushed stone

Below you can read more about each.

Washed crushed stone

This technology is used only for raw materials with a high clay content. After extraction, the grains are, as usual, dispersed into fractions. And then the resulting material is cleaned of foreign inclusions, such as dust and clay particles. This is done by washing with water using special equipment. Hence the name.

For washing crushed stone, the following installations are used:

- Trough washing (using a tank)

- Drum Rumble

- Irrigation rumble

Washing crushed stone is unpopular due to:

- Labor intensity

- Poor performance

- High process cost

In our region, washed crushed stone is not produced. This is simply due to the lack of need for this processing. The deposits of the Sverdlovsk region produce high-quality raw materials, which practically do not contain dust particles and clay (less than 1%) and do not require post-processing.

Black rubble

Black crushed stone is a material that, after extraction, is covered with binders (bitumen or tar additives). It is also called “bitumen crushed stone”.

Such a product is produced using technology similar to the production of asphalt (usually even on the same equipment). Crushed stone from dense rocks (with high performance characteristics) is used as raw material.

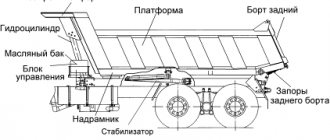

The bitumen impregnation process takes place in special installations. The emulsion is supplied under pressure and at high temperature. After mixing, the finished material from the plants is loaded into dump trucks, avoiding the stage of warehousing and storage, since it has a limited use time.

Black crushed stone is used for the construction of asphalt roads. But due to its relatively high cost, it is not in great demand.

Road builders in our region are actively using a more economical option - the impregnation method.

This method assumes:

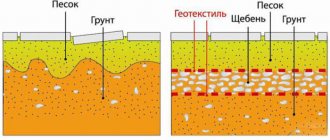

- Construction of a road cushion made of ordinary crushed stone

- Compacting the pillow using a roller

- Uniform pouring of hot binder emulsion onto compacted crushed stone

Impregnation is not a complete replacement for black crushed stone, since it does not ensure uniform flow of the emulsion over the surface. In addition, in places that have not been impregnated, the asphalt surface is damaged over time, causing potholes to form on the road.

We also recommend that you read our article Crushed stone for asphalt.

Colored crushed stone

In fact, this is the same crushed stone, only artificially colored.

The production technology is quite simple: it consists of impregnation with polymer paint and drying. As a result, you can get non-standard colors for use in landscape design.

However, colored crushed stone has a number of disadvantages:

- After dyeing, the material turns out unnatural, looks cheap and not aesthetically pleasing

- The paint fades over time or even chips and comes off completely.

- Paint may contain toxic elements

Do not forget that different rocks themselves come in different colors: from white and transparent to green, pink and blue.

For example, pay attention to marble, which can be white, honey, light gray, even pink, blue and yellow. There is also quartz, which is characterized by pastel shades. The greenish color is that of serpentinite. Amphibolite has a wide range of colors: red, pink, blue. Even classic granite comes in red!

Thanks to the variety of shapes, sizes and colors of crushed stone, you can get very beautiful texture combinations. Unlike colored stone, combinations of natural crushed stone shades will create a natural design that will fit into any space.

You can read more about decorative crushed stone on the page Crushed stone for landscape design.

How to buy crushed stone 40 70 with delivery

From us you can quickly and conveniently buy crushed stone 40 70 of the appropriate strength grade. The price of crushed stone of fraction 40 70 depends on the volume of purchased products. For your convenience, we have presented the price per ton of crushed stone of fraction 40 70 and the price per cubic meter. The offered products comply with GOST 8267-93.

You can buy crushed stone of fraction 40 70 with delivery to any region of the Russian Federation and neighboring countries. Moscow and the Moscow region are a priority destination, but we also order delivery of crushed stone 40 70 to Ivanovo, Kostroma, Yaroslavl, Nizhny Novgorod, Yoshkar-Ola, Saransk, Kazan, Cheboksary and other cities and remote regions of the Russian Federation.

Depending on the volume of supplies and the distance, various types of transport can be selected: delivery of crushed stone 40 70 by rail (from the company’s own loading station Kovrov-Gruzovaya (240902) of the Gorky railway) or by the company’s motor transport. Pickup of finished products is also possible.

Products are certified, limestone crushed stone GOST 8267-93

We ship products by rail to any region of the Russian Federation and neighboring countries

We also deliver using the company’s own vehicles.