Expanded clay - technical characteristics, GOST

It is almost impossible to manage construction without expanded clay. This material, unique and inexpensive in terms of its properties, will be used at various stages of house construction. You can use this material without hesitation, it is used correctly and in the required place, and it will not let you down. Let's look at the technical characteristics of expanded clay.

Expanded clay is special granules, usually oval or round in shape, and they also look like gravel - this is why it is called “expanded clay gravel”. Expanded clay will be sold in bulk and in bags.

The technology for processing granules will directly affect such a characteristic as density, which can vary from 250 to 700 kg per cubic meter.

Expanded clay – granules you can’t do without

The lower this indicator is, the more porous the expanded clay is, and, therefore, it will have higher thermal insulation properties; it is much lighter, but due to this, its degree of fragility will sharply increase, as a result of which denser expanded clay from 410 kg per cubic meter is used for construction.

Moreover, the material will differ in size, fraction 0, for example, from 0.8 to 2 cm or t 0.4 to 1 cm. Based on this size, products should be divided into sand, crushed stone and even expanded clay gravel. Expanded clay gravel will be familiar to us, and at the same time, expanded clay crushed stone has gained enormous popularity in Europe - it is angular in shape and has dimensions from 0.5 to 4 cm.

This product is obtained by crushing the expanded mass of expanded clay. Expanded clay sand will be a filler, the particles of which have a size of 0.01 to 0.4 cm. Sand is obtained by burning clay fines in shaft or even rotary kilns, by crushing large pieces or the main expanded clay mass. This is practically industrial waste, which is still used in business.

Properties of expanded clay

So, the properties are as follows:

- Not subject to rotting.

- It will not lose its properties and will not be destroyed when frozen.

- Long lasting.

- Does not absorb water.

- Does not contain harmful impurities.

- Fire resistant.

- High degree of strength.

Also, the products are absolutely safe for humans and the environment. Expanded clay is a quickly fired product for low-melting clays. From Greek, a word such as “expanded clay” is translated as “burnt clay,” and this will fully correspond to reality. Despite the heat treatment, it will not lose the properties that are inherent directly in the clay, but will also acquire additional ones and become porous. Based on them, it is possible to make expanded clay concrete blocks, the mechanical and thermal insulation properties of which make it possible to use them for the thermal insulation construction of walls, floors, ceilings, foundations and basements. Thanks to expanded clay filler, such blocks also acquire its properties. They are durable, lightweight, fireproof, acid resistant and more.

Technical properties

| Indicators | 0.8/2 cm | 0.4/1 cm | 0/0.4 cm |

| Bulk type density, kg per cubic meter | From 280 to 370 | From 300 to 400 | From 500 to 700 |

| Crushing strength, N/mm2 (Mpa) | From 1 to 1.8 | From 1.2 to 2 | From 3 to 4 |

| Frost resistance 20 cycles, loss of gravel mass, % | From 0.4 to 2 | From 0.2 to 1.2 | Not regulated |

| Percentage of crushed particles, % | From 3 to 10 | From 3 to 10 | No |

| Thermal conductivity, W/mK | 0.0912 | 0.0912 | 0.01099 |

| Water absorption, mm | 250 | 250 | 250 |

Scope of expanded clay use

So, you know about all the properties of expanded clay, and one of the main uses of the material is as a filler for lightweight concrete. Monolithic walls are erected from this material, and rough screeds are also poured. This will be especially true when you need to lay a screed of an impressive size, however, you cannot overload the ceiling. Expanded clay makes it possible to reduce structural weight and its cost. The construction of expanded clay concrete walls will provide high sanitary and hygienic characteristics, and they are also durable and at the same time have an affordable cost.

Moreover, expanded clay is also used as insulation, but it must be a highly porous material, and before using it as a backfill insulation, you will need to perform not very complex calculations, but only accessible to specialists. Regarding its capabilities in terms of thermal savings, we will only say that as a backfill option it will be inferior to other insulation materials. The estimated thickness of a backfill made of expanded clay with a density of 600 kg per cubic meter is approximately 0.4 meters. This is not effective at all.

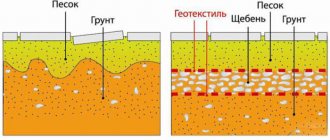

At the same time, when used in the manufacture of expanded clay concrete blocks, it will significantly increase their heat-saving characteristics. Expanded clay will also be actively used when constructing dry screeds. Nowadays this method is extremely popular because it allows you to obtain a solid base for linoleum, laminate, and cork in a short time, literally in 1 day. Due to its unique characteristics, including immunity to frost and moisture, it is actively used for pouring foundations during the construction of various structures and buildings. This will make it possible to reduce the depth of the foundation by almost a couple of times - from 1.5 meters to 0.8 meters, and this will lead not only to savings in building materials, but also to the prevention of freezing of the ground near the foundation of the building. By the way, the latter will be fraught with distortion of doors, as well as window frames in the building.

Expanded clay

This group of ceramic products includes light brick, tripoli (diatomaceous earth), cellular piece products, and expanded clay.

Thermal insulating tripoli (diatom) products are made using the plastic method from tripoli or diatomite, sometimes with burnable additives. Based on average density, products are divided into grades 500, 600, 700. The thermal conductivity of such products at a temperature of 350° is 0.18...0.27 W/(m-°C). They are used for thermal insulation up to 900 °C.

Foam diatom products are made from tripoli or diatomaceous earth by preparing a dough from the powder of these materials and adding a stable foam to the dough. The resulting foam mass is poured into molds. After drying, the products are fired. The density of diatom foam products is 350..450 kg/m3, thermal conductivity at 25 °C is 0.08…0.12 W/(m-°C).

Expanded clay is a cellular material in the form of gravel. The raw materials for its production are clays containing iron oxides and organic impurities. During firing, gases (oxygen formed during the deoxidation of higher iron oxides, carbon monoxide formed during the combustion of organic impurities and dissociation of carbonates, water vapor formed during the dehydration of clay minerals) swell the clay at the moment of its transition to a pyroplastic state. Bulk density of expanded clay gravel (grade) 250... ...600 kg/m3, water absorption 8...25%, frost resistance of at least 15 cycles. The compressive strength (when compressed in a cylinder), depending on the grade of gravel, is not less than 0.6...2.5 MPa. Expanded clay is used as a filler for lightweight concrete and reinforced concrete (see Chapter 6), and also as thermal insulation backfill.

The name "expanded clay" is of Greek origin. If translated into Russian, this word means “burnt clay.”

Expanded clay is porous round granules that are obtained from clay by melting and firing it. This is an absolutely safe, environmentally friendly material with high heat and sound insulation characteristics, fire resistance and frost resistance.

Expanded clay is a natural material, its strength and durability are an order of magnitude higher than that of synthetic insulation.

Since expanded clay is made from clay, it is resistant to rotting, mold and mildew. The structure of expanded clay is not affected by hot or ice water or temperature changes.

Varieties of expanded clay.

Expanded clay sand is a lightweight aggregate for expanded clay concrete and mortars with particle sizes ranging from 0.14 to 5 mm. Also used for thermal insulation fills with a small thickness of the insulation layer (up to 50 mm).

Expanded clay gravel has grains with a fraction of 5-40 mm, is resistant to frost and fire, absorbs little water and does not include those impurities that are incompatible with cements. It is used as a filler in the production of lightweight concrete and is used as insulation in backfills on roofs, floors and walls.

Expanded clay crushed stone is a lightweight filler for expanded clay concrete of any type (the most common shape is angular) with a grain fraction of 5 to 40 mm, which is obtained by crushing large pieces of expanded expanded clay mass.

Expanded clay is also usually considered based on such indicators as: 1. Moisture absorption , expressed as a percentage of the weight of the dry filler. The resulting burnt outer layer helps to retain moisture penetrating inside, which is not available for fillers that lack such “protection.” We can talk about the defectiveness of the material if there is low porosity of the granules, which significantly increases the ability to absorb and retain moisture. High-quality expanded clay has a correlation coefficient of at least 0.46.

2. The ability to deform , predetermined by the porous structure of which expanded clay consists. Since the deformation coefficient of fillers such as expanded clay is not large, after the first test cycle most samples show the most accurate shrinkage result, which should not exceed 0.14 mm/m.

3. Thermal conductivity of the material is characterized by how well the expanded clay has passed through the glassy phase, which negatively affects this indicator. That is, the more glass, the lower the thermal conductivity of the material. High-quality expanded clay has a thermal conductivity of 0.07 - 0.16 W/m, which helps retain up to 80% of lost heat.

Production of expanded clay

The raw materials for the production of expanded clay are clayey rocks, mainly related to sedimentary rocks. Some rock-like clay rocks, shales, and mudstones are classified as metamorphic.

Clay rocks are distinguished by the complexity of their mineralogical composition and, in addition to clay minerals (kaolinite, montmorillonite, hydromica, etc.), contain quartz, feldspars, carbonates, ferruginous, and organic impurities.

Clay minerals make up clay matter - the most dispersed part of clay rocks (particles finer than 0.005 mm). Actually, clays are called clayey rocks containing more than 30% clay matter.

For the production of expanded clay, the most suitable are montmorillonite and hydromica clays containing no more than 30% quartz. The total content of SiO2 should be no more than 70%, Al2O3 - no less than 12% (preferably about 120%), Fe2O3 + FeO - up to 10%, organic impurities - 1-2%.

The suitability of a particular clay raw material for the production of expanded clay is determined by a special study of its properties. The most important requirement for raw materials is swelling during firing. Intumescence is characterized by the swelling coefficient.

The second requirement for raw materials (largely related to the first) is fusibility. The firing temperature should not be higher than 1250°C, and at the same time, the transition of a significant part of the smallest clay particles into the melt should ensure sufficient softening and viscosity of the mass. Otherwise, the gases formed during clay firing, which are not retained by the mass, will freely escape without swelling the material.

The third most important requirement is the required swelling interval. This is the name for the difference between the maximum possible firing temperature and the temperature at which the raw material begins to swell.

The temperature at which expansion begins is taken to be the temperature at which expanded clay with a granule density of 0.95 g/cm3 is already obtained. The maximum possible firing temperature is the temperature at which the surface of the granules begins to melt.

To expand the temperature range of swelling, a technique such as dusting raw clay granules with refractory clay powder is used, which makes it possible to increase the firing temperature and at the same time avoid melting of the granules.

How to choose high-quality expanded clay

Expanded clay is sold either packaged in bags or in bulk. In the first case, it is most likely a factory-sewn 30-liter bag, and in the second, you need to go to the base or “expanded clay plant” yourself and pack it as you want and in whatever you want. For minor apartment renovations, it is preferable to choose the first option.

First of all, you should pay attention to the appearance of the bags: if it is clean on the outside and light in weight, then you can count on the fact that inside there is even, not split, good expanded clay, grain by grain. If the bag is dirty, brown or red in color, then it is very likely that there is a lot of dust in the bag.

Application of gravel (expanded clay)

By the way, expanded clay will also be useful for those who lay heating networks near their home. Firstly, you will be sure that your pipes will warm you, and not the cool ground. Secondly, in the event of an accident, you will not need to tediously and for a long time dig the ground in search of the leak. Thirdly, after a successful repair, nothing will prevent you from using the material again, and it will not lose its excellent qualities. Expanded clay can be used not just in construction. With its help, it will be possible to improve paths in the country and even increase the yield of fruit trees by creating an unusual drainage system for their roots. This will apply to indoor flowers, as well as plants. For such purposes, expanded clay is used, which is smaller in size. When using expanded clay as a filler when pouring a foundation, it is not recommended. In this case, it is better to use any crushed stones, even granite or crushed stone. Expanded clay is bad in this matter because it will have rounded and even edges, and this will not prevent the appearance of shear work (shear-fracture) of the concrete mass. But the foundation must exclude cracks (that is, shifts) of the tape in its cross section.

Expanded clay, perlite or agloporite - what are the differences?

You can insulate the house with expanded clay or do other work. By the way, sometimes builders use terms such as perlite/expanded clay/agloporite as synonyms. But is this legal? Such materials probably have only one similar feature - their production will take place through expansion of the raw materials. This is where all the similarities end. There are somewhat more similarities in properties, but it turns out that in areas of application - they are non-flammable, inert and lightweight. The raw materials for the formation of expanded clay are algoporite, clay - clay-containing rocks, perlite - volcanic glass, vermiculite - mica containing water. Expanded clay gravel is made by firing granules made from intumescent clays. This is a durable and lightweight filler. Its large bulk bulk mass will range from 240 to 700 kg per cubic meter. When fractured, the expanded clay granule has the structure of a frozen foam. The shell, which is sintered and covers the granule, gives it a high degree of strength.

Expanded clay type sand (grains up to 0.5 cm) is obtained in the production of expanded clay gravel (albeit in small quantities), and also using the fluidized bed method by firing raw materials in a suspended state. Moreover, it can be obtained by crushing a substandard product - gravel grains larger than 4 cm in size and welds. Expanded type perlite is made by burning volcanic glassy rocks (obsdians and perlites) that will hold a small amount of water. At temperatures from +950 to +1200 degrees, water will begin to separate, and perlite will increase in volume from 10 to 20 times.

Expanded perlite is used as a filler to produce lightweight concrete and molded thermal insulation products. Moreover, it is good in the role of acoustic sound insulation, as a component in plaster (a layer of plaster containing 3 cm of perlite is equal in thermal insulation properties to 0.15 meter of brickwork). Expanded perlite is even used for the production of decorative and acoustic panels, and as a granulate for rooting plant cuttings, a substrate, and for soil conditioning. And this is not a complete list at all. Expanded vermiculite is a porous granular material obtained by firing water-containing micas. This filler is used to create heat-insulating lightweight concrete.

Agloporite will be obtained by firing clay-containing raw materials with an addition of up to 10% on the grate of a sintering machine. The coal will burn out, and the raw material particles will begin to sinter. The production of the composition is profitable when local types of raw materials are used for production - fusible clay and also loess rocks, and also industrial waste - ash, fuel slag and coal-containing mine rocks. Agloporite is produced in the form of crushed stone and porous sand. It is necessary to use some kind of building material taking into account the tasks facing the construction. For example, you need to insulate the floor of a room where there is a high level of humidity. In this case, the best option would be to use perlite - its hygroscopicity is higher. Expanded clay is much harder and stronger, and this quality can be useful in solving special problems. You should look at the bulk density of the materials - perlite is much finer and lighter, and this can significantly lighten the structure. If lighter and more porous expanded clay is used mostly for wall panels, then the main area of use for algoporite is lightweight structural concrete. Algopritobeton is used for the production of prestressed reinforced concrete structures of roofs and floors, long-span beams and trusses, span bridge structures, etc.

Application example

Since the technical characteristics of expanded clay are excellent, it is often used. For example, if you want to insulate the attic on the second floor, and fill the ceiling between floors with expanded clay (does it matter whether it is large or small?).

Will it serve as insulation and is it necessary to lay a vapor barrier and waterproofing film on it and under it? Expanded clay has thermal insulating properties, but in this case it does not matter, because there is no point in separating one warm room from the second with a thermal insulation layer. After the roof is insulated, the cold will not penetrate through it and the entire home space will become uniform from a temperature point of view. At the same time, when laying a layer of expanded clay, it is possible to reduce the noise that comes from above.

It is advisable to use a film, but only so that the expanded clay does not collect dust; they can be the simplest, polyethylene, which, as a rule, cover greenhouses.

Technical properties

Let's take a closer look at the characteristics of expanded clay.

- Strength. This characteristic directly depends on the composition of the feedstock and the size of the fractions. The less porosity of the material, the stronger it is.

- Compaction coefficient - taken into account when storing and selling building materials. This parameter for expanded clay should not exceed 1.15.

- The thermal conductivity of expanded clay is in the range of 0.1-0.18 W/meter (at 0°C). Expanded clay with a thickness of 25 cm retains as much heat as an 18-centimeter thick polystyrene foam crust. The more holes in the granules, the higher the thermal insulation qualities of this insulation.

- Moisture absorption. The proportion of water in its composition can reach 20% if stored improperly. Insulation with a burnt crust allows less moisture to pass through. The more water in expanded clay, the faster it loses its thermal insulation properties.

Dry expanded clay Source userapi.com

- Noise insulation. Expanded clay has excellent soundproofing properties, so it is often used in the construction of interfloor and interior floors.

- Fire safety. Expanded clay is a good insulator. It is non-flammable and chemically inert.

- Heat resistance Expanded clay granules tolerate temperature changes well and can be stored for a long time in frosty open air. The main condition is to keep the material away from water. At high humidity, expanded clay can be destroyed due to freezing of water in its holes.

Among other properties of expanded clay, buyers highlight the low cost of this material and the safety of its use - both for humans and for the environment.

Expanded clay is an environmentally friendly material Source ogorod.ua

See also: Catalog of companies that specialize in home insulation