First of all, they are disks that unite vertical structures into a single spatial geometrically unchangeable frame.

The second purpose of the elements is to create a supporting structure that can withstand constant and useful loads, allowing the room to be used in accordance with its functional purpose.

Floor slabs also serve as enclosing structures that divide the internal volume of the building into floors. The upper surface of the elements serves as the basis for the floors of the upper level, and the lower surface serves as the ceiling of the previous one. If there are no special requirements for the ceilings in the room, developers resort to reducing the cost of construction and installing reinforced concrete floors using corrugated sheets.

What it is?

Corrugated sheet for floors is an element of permanent formwork intended for the construction of a lightweight span structure. The height of the corrugation is taken based on the results of two calculations - for the period of installation and operation. Corrugated sheet floors are widely used in the construction of public buildings, office centers, free-standing parking lots, shops, industrial buildings and other real estate objects.

This design has the following advantages:

When used, up to 30% savings in concrete are achieved due to the inclusion of corrugated corrugated sheeting in the work - in this case, the protruding elements play the role of beams, which is why the floor is designed as a ribbed structure.- Cold-deformed steel sheet serves as external reinforcement of the slab. This reduces the consumption of steel for the construction of the internal reinforcing frame.

- The minimum thickness of a standard monolithic floor cannot be less than 120-140 mm for structural reasons.

In practice, slabs with a thickness of 160-240 mm are used, depending on the span and the perceived load. The profiled sheet makes it possible to create an average slab thickness of 70 mm, excluding corrugations. The weight of the finished structural element is reduced by 25-35%, which entails a reduction in vertical loads on walls, pylons and columns. - Galvanized corrugated sheets do not require additional corrosion protection and can be used in aggressive environments without destruction.

- When installing corrugated sheets as permanent formwork, there is no need to purchase or rent laminated plywood, which wears out during the construction of the building and most often must be disposed of.

- Installation of a structural element is much faster compared to the installation of a conventional monolithic floor.

- The surface of the ceiling is ribbed, without sagging, cracks, oil stains and uneven color. This allows you to beat the ceiling in the room with an industrial style.

When installing corrugated sheets for the installation period, you should first calculate the pitch of temporary supports, since raw concrete does not have the calculated load-bearing capacity for 2-3 days.

Scope of application

Profiled sheets for floors are widely used in the construction of buildings and structures with different functional purposes. Most often, such an element can be found in the following types of span structures :

As permanent formwork for all types of interfloor floor slabs. In this option, a successful combined use of galvanized sheet and reinforced concrete is achieved.- Like a covering arranged on metal mutually perpendicular beams. In such cases, the sheet acts as a base for the roofing cake.

- In some cases, corrugated sheeting with high corrugation is used as a load-bearing element of flooring on beams for the organization of mezzanines and floors, which are not subject to high load-bearing capacity requirements. In this design, an underlying layer of light and elastic material is placed on top of the profiled sheet, after which sheets of plywood or ACL are laid, forming a smooth surface.

When using a cold-deformed sheet as an independent load-bearing element, it should be remembered that it works exclusively along the corrugations. This obliges the designer to carry out calculations of a beam scheme consisting of a complex of linear horizontal elements laid perpendicular to the corrugated sheeting.

Material marking ↑

Sheets of corrugated sheets are marked with markings that indicate their main purpose. The material discussed in the article is marked in the nomenclature with the initial letter of the word “bearing” - “N”.

High load-bearing capacity makes it possible to use them to cover low-slope roofs (up to 7°). It should be noted that the thicker the sheets, the greater the weight of the snow layer they can withstand. This material is practically indispensable for large roofs, where especially a lot of snow accumulates in winter.

Load-bearing corrugated sheets are also actively used in the formation of interfloor ceilings as formwork. Reinforcement is inserted into it and filled with concrete. Thus, there is no need to use additional materials, installation is extremely simplified and is much cheaper.

“N” profiled sheets do not require additional painting, since they already have a protective layer – zinc or zinc-polymer. Moreover, you can always choose the appropriate color of the material; fortunately, the choice is really large.

The letter marking is supplemented with a number that indicates the height of the corrugation.

A universal brand of material that can be used in the construction of formwork, interfloor slabs, enclosing elements, and roofing work is load-bearing profiled sheet H57.

It is designed to withstand significant loads. The distance between the supports can be chosen large enough, and this will not affect the strength of the structure in any way. Corrugated sheeting of this brand is in great demand in fairly snowy areas.

The profile height of 57 cm allows it to withstand severe wind loads. In addition, bearing profiled sheets H57 can cover spans up to 3 m. Many builders prefer it due to the optimal price/quality combination, the width of the sheets and their load-bearing characteristics. It is no coincidence that during the construction of this or that object, this material is the basis for most calculations to determine the maximum loads.

Load capacity and dimensions

For the construction of load-bearing span structures, only certain types of corrugated sheeting are used, which have increased strength characteristics and load-bearing capacity. The most popular brands of profiled sheets used for installation of floors with basic technical characteristics are given in the following table:

| № pos. | Brand of corrugated sheet | Full width , mm | Working width , mm | Profile height , mm | Metal thickness , mm | Weight 1 m , kg | Load-bearing capacity per 1 m2, kN/m2, with a support spacing of 2 m | Types of coverage |

| 1 | NS 35 | 1060 | 1000 | 35 | 0,45-0,9 | 6,3-8,4 | 2,09-2,22 | Roofing, permanent formwork |

| 2 | NS 44 | 1070 | 1000 | 44 | 0,5-0,9 | 8,3-9,4 | 2,48-2,73 | Roofing, permanent formwork |

| 3 | N 57 | 960 | 900 | 57 | 0,5-0,9 | 5,4-7,3 | 2,9-4,10 | Roofing, permanent formwork |

| 4 | N 60 | 902 | 845 | 60 | 0,5-1,0 | 7,3-9,2 | 3,24-4,60 | Roof, permanent formwork, load-bearing |

| 5 | N 75 | 800 | 750 | 75 | 0,7-1,2 | 8,3-10,2 | 5,82-7,21 | Roof, permanent formwork, load-bearing |

| 6 | N 80 | 800 | 750 | 80 | 0,7-1,2 | 9,3-10,7 | 6,02-6,80 | Roof, permanent formwork, load-bearing |

| 7 | N 114 | 807 | 750 | 114 | 0,7-1,2 | 8.3-11.7 | 6,60-9,72 | Roof, permanent formwork, load-bearing |

From the given indicators it is clear that the use of corrugated sheeting with a corrugation height of less than 60 mm as load-bearing structures is not recommended , since the load-bearing capacity of such elements does not meet the requirements for the safe operation of buildings and structures.

The length of corrugated sheets supplied from the factory depends on the technological capabilities of the production line. This indicator, as a rule, is limited by transport dimensions, and sheets with a length of 3.0-6.0 meters are delivered to the construction site.

Material requirements for the installation of monolithic reinforced concrete structures

Not every cold-deformed galvanized sheet is suitable for use as permanent formwork for the installation of monolithic floor slabs. The following requirements apply to these elements :

The height of the corrugation and the thickness of the metal must satisfy the calculation of the load-bearing capacity for the installation period - no local deformations should occur when laying raw ready-mixed concrete.- Sheets must have high corrosion resistance or have an appropriate protective coating to eliminate the risk of loss of load-bearing capacity during operation.

- The sheet must be selected to such a thickness that it has a fire resistance limit no lower than that of the concrete structure.

- The product must be of high quality without any manufacturing defects.

If any of the requirements listed above are not met, the finished structure cannot be assigned the required class of responsibility for a capital structure, in accordance with its functional purpose.

Corrugated sheeting for permanent formwork - main characteristics

The load-bearing corrugated sheet must withstand the weight of the poured liquid concrete until it hardens and “takes” the load upon itself. These declared characteristics have a profiled sheet in Kyiv with an edge height of 57 mm and a metal thickness of at least 0.7 mm.

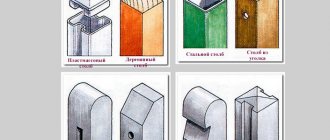

In cases where the corrugated sheet is a finished part of the ceiling, a metal profile with a colored polymer coating is used.

The load-bearing metal profile, unlike roofing and wall profiles, has additional stiffening ribs in the form of grooves, which give the sheet additional strength and load-bearing capacity.

Advantages of profiled sheets

As an independent building material, galvanized profiled sheet has many advantages :

- Relatively low price compared to formwork elements for standard monolithic slabs.

- The galvanized surface is resistant to corrosion, which is why the service life of the sheets is up to 30 years or more.

- From the table above it can be seen that the material has a small mass per 1 m2.

- Corrugated sheeting does not burn and does not emit toxic substances when heated.

- The material is presented on the market both in a technical version and with various powder coating options, which gives designers freedom when decorating the interior.

- Despite the reduced metal consumption, low weight and low cost, corrugated sheeting has an impressive load-bearing capacity (load-bearing capacity indicators are given in the table above).

- The structural element has a low coefficient of linear thermal expansion.

In addition to its structural, functional and aesthetic advantages, corrugated sheets take up little space when stored, are easily transported and do not require special storage conditions.

Flaws

In addition to the advantages, the profiled sheet used for flooring has some disadvantages:

When arranging a classic interior, a suspended ceiling is required, since upon completion of installation the steel corrugations remain visible.- In the event of unexpected deformation, it is no longer possible to return the element to its original appearance.

- If the galvanized coating is damaged, the thin steel quickly decomposes in a humid environment.

- Steel overhead may cause interference when using wireless communications.

Thus, the owner of the property must make an informed decision before purchasing a profiled sheet for the ceiling installation.

Manufacturers and prices using the example of the h75 brand

There are many manufacturing enterprises on the Russian market offering profiled sheets for flooring. These companies actively compete with each other.

The determining criterion is quality, adherence to GOST requirements, as well as the average cost of finished products and flexible pricing, depending on the volume of the order, the frequency of one client contacting the sales department and other parameters. Among the main market players, the following companies can be identified (using the example of the cost of H75 grade corrugated sheets):

- "Neva-Stal", St. Petersburg. 600 – 900 rub/m.

- "Metal Profile", Lobnya, Moscow region. 700 – 1000 rub/m.

- "Orenburg Profmetall", Sol-Iletsk. 550 – 600 rub/m.

- PC "Metallregionstroy", Lipetsk region. 410 – 620 rub/m.

- "Profstalprokat", Tula. Price 600 – 800 rub/m.

- "Pokroff-Vostok", Pavlovsky Posad, Moscow region. 800 – 900 rub/m.

The final cost of the product depends on the type of powder coating of the surface, metal thickness, weight of 1 m2, total order volume and other factors. To clarify the price, you must contact any of the suppliers presented above and indicate the individual characteristics of the order.

Advantages and features of profiled sheets

The profiled sheet is economical and easy to use. The products are used in various fields of construction. In accordance with GOST and depending on the purpose, profiled flooring is produced in three types: load-bearing, wall and composite, which combines the first two functions.

The advantages of bearing brands include the following factors:

- reliability with low dead weight;

- affordable pricing policy;

- resistance to temperature changes;

- non-flammability;

- resistance to aggressive environmental conditions;

- galvanized and polymer layers increase service life;

- does not have a negative impact on the environment.

The fundamental difference between load-bearing corrugated sheeting and wall models is the greater rigidity of the first type due to its height. A special feature is also the possibility of using the material in the construction of buildings and use as roofing.