Not only its load-bearing capacity, but also its elasticity and resistance to the influence of temperature deformations depends on how well the soil is compacted. The land itself for future buildings is heterogeneous. It can form voids, zones of increased and decreased density. If compaction is not carried out and construction begins immediately, then under the influence of mechanical loads deformations will begin, which will lead to subsidence. As a result, potholes will appear on the roads, and buildings will also begin to collapse faster. If you compact the soil even by 1%, its strength characteristics and resistance to mechanical loads will increase to 10-15%. Therefore, it is important to perform this procedure using any of the available methods.

Soil compaction methods

Depending on the type of soil, several compaction methods are used.

Tamping

This is a mechanical method of influence, during which voids and air cavities are removed from the soil. The main advantage of this method is the ability to work with large formation thicknesses. But tamping is not recommended if the soil is too wet. Otherwise, it may have the opposite effect and only loosen the soil.

Healthy! Compaction is most effective when compacting coarse soil and embankments.

You can do the tamping yourself using a steel pipe or a heavy log. It is necessary to secure a square base on it. The principle of such compaction is simple - it strikes the soil at right angles. However, the efficiency of such compaction is low, and in order to process a large area it will require a lot of effort and time.

Slabs weighing up to 15 tons are also used. The depth of soil compaction in this case will depend not only on the weight, but also on the area of the slab (the larger it is, the deeper the effect) in contact with the soil. But using such equipment will require heavy equipment, so this method is not used so often in construction.

Rolling

Heavy weight rollers are used for compacting soil. It is enough to drive them repeatedly around the site and it will quickly compact due to the weight of the equipment. But there is one drawback - the load can only be adjusted by choosing rollers of different weights, or by increasing the contact area.

Rolling is performed in several stages. First you need to do a tackle. To do this, during experimental work it is necessary to determine the required level of soil compaction. Only after receiving the results can you determine which type of technology is best to use.

Healthy! Since machines of this type are usually rented, it is important to correctly determine the type of skating rink required.

Types of compaction rollers

Rollers differ depending on the type of working element - rolling roller:

- Trailed vibration. The weight of the skating rink can be 3-15 tons. Such models are applicable to most soils.

- Static three-roller. Weighs 8-15 tons. One roller is driven, and the other two are driven. There are newer models in which all three rollers are driving. Additionally, the skating rinks are equipped with corrective water loading.

- Self-propelled vibration (3-17 tons). Such models have only one roller, and the wheels are pneumatic driven. Some rollers are equipped with cams that increase efficiency when compacting clay soils or when deep compaction is necessary.

- Manual two-roller. Quite light and relatively inexpensive mechanism. Used for small areas. The weight of the skating rink is 4-10 tons.

- With pneumatic tires (10-35 tons). Tires can be from 7 to 11 pieces. They roll over each other. Additionally, a water or sand load can be installed.

- Static tamping action (15-30 tons). The roller has 4 cam rollers. With a large mass, such vehicles move quite quickly.

If the roller has a smooth surface, then it can be used for any type of soil. Cam models are more effective when working with clay soils. With a machine weight of 10 to 25 tons, the depth of soil compaction reaches 30 cm. If you need to compact up to 50 cm, then it is better to give preference to heavier equipment, up to 50 tons. When compacting up to 50 cm, the most expensive and heaviest type of machine will be required, weighing up to 100 tons.

Vibration

For compaction, special vibrating mechanisms are used (usually a rotating eccentric weight). During the work, the soil is exposed to not just a mechanical impact, but a combination of static and dynamic loads. Due to rapid impacts on the soil surface, vibration is transmitted through it, which causes the particles of the underlying soil to shift.

By vibrating, higher densities and greater compaction depths can be achieved. This requires fewer approaches, which means significant time savings can be achieved. Vibration is suitable for any type of soil. More than 70% of work is performed with such equipment. Accordingly, this is a universal method, although initially vibration was used exclusively when working with sandy or large-block soils. But the technique gained popularity, so more modern devices were created to work also with loams, clays and other “difficult” soils.

- Vibrating plates. They are also called vibration platforms. The equipment is equipped with a massive sole, which is capable of transmitting vibration due to impacts. Plates come in different weights. The higher it is, the deeper the compaction will be carried out. When working on private properties, slabs weighing 75-90 kg are usually sufficient. In this case, it is possible to achieve compaction of a layer up to 25 cm deep. The area of the sole can be 1600-6000 cm2. There are also more massive ones up to 15 centners (1.5 tons).

- Vibrolegs. This is simpler equipment, less durable and works on a slightly different principle. The vibroleg does not hit the soil, but bounces, due to which compaction is carried out. The impact area of the equipment is no more than 1000 cm2. The weight of the vibroleg is 60-70 kg. With all this, a more compact device is capable of influencing a depth of up to 40 cm. But during the work, more force must be applied, the area is processed much more slowly.

When choosing the right equipment or special vehicle, you must also take into account the specifics of the work.

Soil Compaction Basics

Compaction is the process of increasing the density of a material by applying external forces, which can be plistatic or dynamic. The most common areas are highways, streets and highways, airfields, earthen dams, railroad embankments, and building foundations. Other applications include car parks, storage areas, sports fields, industrial and residential areas, ports, reservoirs and canals.In the field of construction, the bearing capacity and stability of stone materials, soils, asphalt concrete and cement concrete, their impermeability and ability to withstand loads is always related to the degree of compaction of the materials; for example, an increase in the degree of compaction by 1% usually corresponds to an increase in strength by at least 10-15%.

Although the cost of compaction may only account for 3-5% of the total construction cost, the role of compaction in the quality and longevity of the finished project is much greater. If it is not done sufficiently or incorrectly, precipitation or other damage will occur, resulting in high maintenance costs.

In the above applications, the durability of the structure also depends on the quality of the surface, especially on roads, airfields, parking lots and warehouse areas. Surface evenness, uniform layer thickness, correct longitudinal and transverse slopes are also necessary for long-term operation without high maintenance costs. The performance of the laying equipment is critical in this regard.

The main factors that determine compaction results are:

- soil type (classification);

- moisture contents;

- compaction method and applied energy.

Soil types:

Quicksands

| contain small clay or sand particles diluted with water. The degree of buoyancy is determined by the amount of water in the soil | |

| Loose soils | consist of loosely interconnected particles of different sizes (sand, gravel, crushed stone, pebbles) |

| Soft soils | contain loosely interconnected particles of earthen rocks (clayey or sandy-clayey) |

| Weak soils | consist of loosely interconnected particles of porous rocks (gypsum, shales, etc.) |

| Medium soils | consist of interconnected particles of rocks of medium hardness (dense limestones, dense shales, sandstones, calcareous spar) |

| Hard soils | contain interconnected particles of rocks of great hardness (dense limestones, quartz rocks, feldspars, etc.) |

Soil classification:

| sand, sandy loam, light loam (wet), soil of the plant layer, peat |

| loam, fine and medium gravel, light clay (wet) |

| medium or heavy clay, loosened, dense loam |

| heavy clay, permafrost or seasonally freezing soils: plant layer, peat, sand, sandy loam, loam and clay |

| strong clayey shale, weak sandstone and limestone, soft conglomerate, permafrost or seasonally freezing soils: sandy loams, loams and clays with an admixture of gravel, pebbles, crushed stone and boulders up to 10% by volume, moraine soils and river sediments containing large pebbles and boulders up to 30% by volume. |

| clayey sandstone and weak marly limestone, soft dolomite and medium serpentine, permafrost or seasonally freezing soils: sandy loam, loam and clay with an admixture of gravel, pebbles, crushed stone and boulders up to 10% by volume, as well as moraine soils and river sediments containing large pebbles and boulders up to 50% by volume. |

| silicified and mica shales, dense sandstone and hard marly limestone, dense dolomite and strong serpentine, marble, permafrost seasonally freezing soils: moraine soils and river sediments containing large pebbles and boulders up to 70% by volume. |

Influence of humidity.

Most soils reach their greatest density at a certain optimum moisture content for a given compaction effort. In other words, dry soil is quite strong and resists compaction, while wet soil is soft and easier to compact. However, the higher the moisture content, the lower the density of the material. Soil compaction should be done at optimal humidity. Permissible deviations for cohesive soils – ± 10%; for non-cohesive soils – ± 20%. If there is insufficient moisture in cohesive soils, they should be moistened, as a rule, in areas of development (in reserves, quarries). If there is insufficient moisture in non-cohesive and low-cohesion soils, it is allowed to moisten them in the backfill layer. If there is excessive soil moisture, it should be dried.

The amount of water – g [t] required to soak 1 m3 of soil by volume in an excavation in order to increase its humidity should be determined by the formula:

g=Yc*(Wo+Wп-Wк)

Yc – volumetric weight of soil in the quarry [t/m3];

Wo – optimal humidity;

Wк – soil moisture in the quarry;

Wп – moisture loss during development, transportation and laying of soil.

Clean sand and gravel, as well as other draining granular materials, are less sensitive to variations in moisture content and can reach maximum density when completely dry or saturated. The low density at moisture content between the dry and saturated states is the result of apparent cohesion resulting from capillary forces that are generated by water in partially filled voids that retain particles through elastic bonds. The smaller the particle size, the higher the apparent connectivity.

Compaction methods.

Compaction equipment for soil and asphalt concrete materials is based on two important principles:

Static compaction equipment uses the machine's own weight to apply force to a specific surface and compact the underlying layer material. The only way to control the static load transferred to the surface is to change the mass or contact area of the equipment. Static machines under normal conditions provide the necessary compaction mainly in the upper layers of the material, since due to the “thrust” effect in the soil particles, the deep impact is insignificant. Common types of static compaction machines that have been used for many years include static three-drum rollers, static tandem rollers, pneumatic tire rollers, and trailed pad rollers.

Vibratory compaction equipment uses a vibrating mechanism, which usually consists of a rotating eccentric weight. Vibratory compactors use a combination of dynamic and static loading. They transmit rapidly successive impacts to the contact surface, from where vibration or compression waves are transmitted to the underlying material to set its particles in motion. This effectively reduces internal friction and facilitates the repacking of particles into as few voids and as high a density as possible. Increasing the number of points of contact between particles leads to high stability and strength. Clay and other cohesive materials require higher loads and therefore relatively heavy compaction equipment must be used. However, these materials can only be compacted in fairly thin layers. Initially, vibration compaction was considered suitable for coarse soil, sand and gravel, but with the development of vibration technology, this method became suitable for clay soils, and subsequently for compacting asphalt concrete.

Vibratory compaction achieves higher densities and greater depth effects than static compaction, and complete compaction is achieved in fewer passes. All this explains why vibration equipment is more efficient and economical in almost all cases. Vibration can be used to compact all types of materials, and vibration equipment now accounts for about 70% of the market.

IMPORTANT: the compacting effect is influenced by the strength state of the underlying soil layer. Compaction is not achievable if the surface of the underlying layer is pliable. It is often impossible to achieve high density in an embankment resting on an underlying layer of low bearing capacity, such as fine-grained soil with a high moisture content.

Soil compaction equipment.

There are several types of rollers used for linear compaction of rock fill and general soils. The most common types of machines and their common uses are presented below. Static rollers, i.e. Three-wheel, tandem (two-wheel), pneumatic tire and cam rollers dominated the market until the early fifties, when significant advances were made in the development of compaction technology using vibratory trailed rollers. By the early seventies, tractors and rollers were combined into one self-propelled device. The better maneuverability of this type of roller ensured its rapid recognition and it replaced the trailed roller. The self-propelled vibrating roller with a padfoot drum is used to compact cohesive materials. The largest vibratory two-axle rollers with one vibrating drum were also improved in the early fifties. The size of these machines has gradually increased and today they reach loads of up to 15 tons with vibration and drive on both drums.

| Name | Application | Appearance |

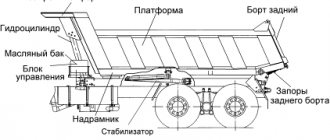

| Trailed vibratory roller | Suitable for a wide range of soils. Heavy models with a thick drum shell are used on rock and large block fills. Weight range: 3-15 tons. | |

| Static three-drum roller | Two driven steel rollers and one driven one. Rigid frame. The compacting force can be changed by adding water. Weight 8-15 tons. | |

| Single drum self-propelled vibratory roller | With one vibrating drum and driven pneumatic wheels. Used on rock embankments and soil. Special models with padfoot cams are most effective on clay soils. Weight 3-17 tons. | |

| Double drum manual roller | Two rollers on a rigid frame. A common, common version of lightweight equipment. Weight 400-1000 kg. | |

| Roller with pneumatic tires. | Usually - 7-11 pneumatic tires. The front and rear tires overlap each other's tracks. The compacting pressure can be changed due to loading with water or sand. Weight 10-35 tons. | |

| Vibratory tandem roller | Usually vibration and drive are on both rollers. It is used on the ground, mostly on underlying layers, as well as on asphalt concrete surfaces. Weight 2-15 tons. | |

| Static roller with tamping action | Four cam rollers. Mobile control panel. Moves at higher speeds than vibratory rollers. Effective on cohesive soils. Weight 15-30 tons. | |

| Lightweight tandem vibratory roller | Usually - with a vibrating rear drum. Rigid or articulated frame. Weight 1-2 tons. |

Mechanisms of static and vibration action for compacting asphalt concrete.

There are many types of rollers for compacting asphalt concrete. The choice of machine depends on the type and volume of work and is associated with specific conditions. A range of lightweight asphalt compaction equipment is also available, including vibratory plates, twin-drum hand rollers and lightweight tandem vibratory rollers. The compacting effect of a static steel drum roller depends primarily on its static weight as well as the diameter of the drum. The compacting effect of pneumatic rollers is determined by their static weight and tire pressure. They are often used in combination with static rollers or vibratory rollers at the end of rolling to remove roller marks and to smooth the surface. The use of smooth and vibrating rollers in this case is associated precisely with the completion of rolling, and not with compaction.

Vibratory rollers combine static loads from rollers with dynamic loads. Vibration significantly eliminates internal friction in the mixture and improves compaction action, even when rollers with relatively low static linear loads are used. A vibratory roller always has a higher capacity (expressed in tons of asphalt placed per hour) than a static roller of the same weight. With hard mixtures these differences are even more pronounced.

| Name | Rollers (models) | Appearance |

| Static three-drum rollers | Modern types of three-drum rollers have three large drive drums and integral steering, as opposed to conventional models that have two steel drive drums and a smaller steering roller. The compaction effect of these rollers may vary depending on water ballasting. The weight of the rollers is 8-15 tons. | |

| Vibratory tandem rollers | Usually they have two driving and controlled rollers. Combined steering. The weight of the rollers is 2-15 tons. | |

| Double drum manual rollers | Two vibrating rollers on a rigid frame. Vibration-isolated handle for operator comfort. The weight of the rollers is 400-1000 kg. | |

| Static tandem rollers | Static tandem rollers have one drive roller. The compaction effect may vary depending on water ballasting. Rigid frame. The weight of the rollers is 6-12 tons. | |

| Combined rollers | One vibrating drum and rear axle with three or four pneumatic tires. Rigid frame or combined control. The weight of the rollers is 4-15 tons. | |

| Pneumatic rollers | Usually 7-11 pneumatic tires. The compaction effect can vary depending on ballasting, usually water or sand, and changes in tire pressure. The weight of the rollers is 10-35 tons. | |

| Lightweight vibrating tandem rollers | Usually only the rear drum is vibrating. Rigid or articulated frame. The weight of the rollers is 1-2 tons. |

Areas of application of rollers.

| Stone materials | When compacted, rock materials place a lot of pressure on the compaction equipment, and rollers designed for soils do not have the strength required to compact rock materials. Therefore, a particularly thick roller shell made of high-quality steel is required. Extra-heavy smooth rollers can compact all types of stone materials. International contracts now often call for compacting the rock material in 1.0 m layers using a vibratory roller whose roller module weighs 10 tonnes. Heavier rollers can be used to compact layers as thick as 2.0 m. |

| Sand and gravel | Sand and gravel are ideal for vibratory compaction. Medium smooth drum rollers effectively compact clean sand and gravel in layers up to 0.5 m thick or more. Sand and gravel with a certain content of fines are also easily compacted by these rollers. |

| Sandy loam | Medium and heavy smooth drum vibratory rollers are suitable for compacting sandy loam and sandy loam soils. On moraine soils containing large stones, heavy types of rollers always make it possible to compact thick layers. |

| Clay | The high compressive strength of clay soils requires a large compaction force. Vibratory padfoot rollers (with cams in the form of a truncated prism) are gradually replacing models of the "sheepfoot" type (with cams in the form of a truncated cone). One reason for this is that they compact the surface layer to a higher, more uniform density than sheepfoot rollers. Self-propelled padfoot vibratory rollers are the most economical in most cases. Their high maneuverability is a great advantage when compacting in cramped conditions, for example near bridge supports. Clays can also be compacted with static rollers in layers of about 20 cm. Using their mass (15-30 tons) and operating speed, a certain impulse force is created, transmitted through a padfoot-type drum. Thanks to their high speed, they have very high productivity. That is why they are economical for large volumes of work on compacting clay soils. |

| Additional layers and bases of pavement | Additional layers consist mainly of non-cohesive soils. However, in many countries a relatively high percentage of fine particles is allowed, causing the additional layer material to become cohesive. Therefore, a large number of types of vibratory rollers are suitable for these layers. Since the base layers provide the greatest degree of strength to the pavement, a high degree of compaction is often required - 98-100% of the modified Proctor. Medium self-propelled rollers and tandem rollers are suitable for compacting the base layer. Vibratory rollers with a static linear load of 18-45 kg/cm are usually used. Dual amplitude is a big advantage. Vibratory rollers are equally effective on hardened gravel base layers. |

| Asphalt concrete | Static smooth rollers, pneumatic rollers and vibratory rollers are all used in asphalt concrete laying. Vibratory rollers for asphalt concrete combine high compaction effect and high productivity. One vibratory roller can usually replace two or three static rollers. The good compacting effect is especially noticeable on stiff mixtures and in cases where a high degree of compaction is required. Since different asphalt concrete jobs require different compaction effects, it becomes necessary to install two amplitudes. Lightweight vibratory rollers are the predominant type for small paving jobs. Pneumatic rollers complement vibratory rollers on difficult and unstable mixtures, and in many cases are required to complete the surface rolling. |

Common mistakes when compacting and choosing a compaction method

Before performing compaction, you need to take into account several nuances, or rather errors:

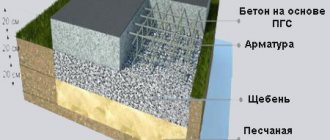

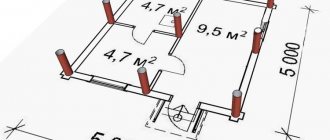

- If a single-layer compaction is performed, then you should not immediately fill in the foundation substrate, since in this case it will be the one that will be compacted, and the soil itself will remain porous. This is especially true for manual tamping, with which the compaction depth will be no more than 15-20 cm, even when using heavy equipment.

- Some people believe that it is unnecessary to compact crushed stone and chips. In bulk soils, voids form in the same way as in other types of soil. The only exception is expanded clay, which due to its round shape is very difficult to compact. However, it is extremely rarely used as a substrate for massive structures.

- Communication exit areas need to be sealed, although many do not do this. But you should not use vibrating plates for work, as the pipes can be damaged (when surface compaction is performed). In such areas it is better to use a hand tamper. But it is also necessary to compact the soil under communications.

- It is important to monitor the quality of tamping, since this procedure is called hidden. That is, it is impossible to check the quality of work in the future.

Healthy! To check whether the soil is compacted enough, you need to pierce the ground with a small rebar. If it passes freely into the ground, then compaction is not enough. You need to check hard-to-reach places (for example, corners) especially carefully.

Accordingly, soil compaction is a mandatory stage of construction. You can read more about it in SNiP 3.02.01-87, as well as GOST 22733-2002.