What mechanisms are there?

Nowadays, there are several types of street gates:

Swing gates are the classic type. The gate consists of two leaves, attached on rotary hinges to a vertical base, deeply and firmly installed steel frame. To open the doors manually or automatically, you definitely need space in front of them.

Sliding doors on rollers, usually a single leaf, have a technically simple design, since the weight of the gate is distributed over the rollers, and additional reinforced guides are installed to withstand wind and lateral loads. Such mechanisms have some operating features, but at the same time, it’s quite easy to make the mechanical part for them with your own hands.

Roller type garage doors are a set of slats made of metal and plastic, interlocked with a movable lock, placed in guide grooves and connected into one single structure. Moving along metal guides, the segments bend, positioning themselves under the ceiling and freeing the entrance to the garage.

Up-and-over garage doors perform a complex maneuver, moving up and clearing the passage. The automatic lifting mechanism for them is difficult to install and operate, so we will not consider it in this article.

Features of the lifting and turning mechanism

This type of sashes is a continuous sheet. When the doors are opened, the door leaf moves toward the ceiling, changing the vertical direction to the horizontal. The product is economical and does not take up much space. But there should be no foreign objects near the sash at a distance of 1/3 of the height of the opening. Otherwise the door will not be able to open.

The lift-and-turn type is an ideal solution for rooms with low ceilings. If the ceiling is high, give preference to guillotine doors with a lift.

What is the difference between cantilever sliding gates?

Sliding fences and fences are equipped with rails, thanks to which the doors move. But the cantilever version is made in such a way that the rail moves according to a roller mechanism. The doors are secured in the lower and upper catchers.

The maximum permissible width of such doors in industrial facilities reaches 24 m. Traditional parameters are 12 m. They can be increased by purchasing additional gates that can open in the other direction. This will help you create a beautiful landscape design and plant different plants.

To bring the structure into working condition, you need to install a drive. If there is no electricity, the gate opens with your own hands.

Operating principle

The swing gate opening mechanism is a set of two motors and an automation system that monitors the position of the gates and the sequence of their opening/closing, and also captures and recognizes commands from the remote control. The shutter with an overlay profile-groove should start moving first when the gate is automatically opened and finish moving last when closing, in order to avoid jamming and damage to the shutters. Also, movement should stop at the extreme points of the valve position. The power of the motors directly depends on the weight of the sashes and the smoothness of their movement - the heavier, the more powerful the motor and gearbox are needed to control them. It is also worth considering the area of the canvas and the effect of wind on them. On a windy day, it is much harder for the motors to move the gates. It is better to provide and make an emergency opening of street gates, in case of breakdown or lack of electricity, in manual mode.

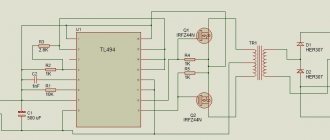

In both factory and home-made drives, an actuator or linear drive is mainly used, which is shown in the photo below:

It is a threaded rod that is connected to a motor and rotates on bearings. Due to the rotation of the pin, the mating part, the coupling, is screwed onto the thread, thereby moving along the pin. This drive design is also sometimes called a worm drive.

The reduction coefficient depends on the thread pitch; the smaller the pitch, the greater the force the actuator can transmit, but the speed in this case decreases. As an electric motor, you can use a gear motor for car wipers or window lifts.

The mechanism of automatic sliding gates is quite simple to implement. One motor, one gearbox. The transmission of linear motion can be to a rack with teeth, or through a motorcycle chain. Automation monitors the extreme positions of the sash, closed or open. The main highlight is the rigid structure of the sash and the system of rollers that hold this structure during closing and opening. It also provides resistance to lateral loads during windy conditions. The main task is to make sure that the balanced sash moves easily and effortlessly along the rollers and guides. During the development of the gate, it is necessary to provide for emergency opening in the event of a breakdown or power outage. As an email For drive, it is also possible to use a motor from a window lifter or wipers.

Automatic garage doors, in turn, are also divided into roller doors (they can also be called sectional) and up-and-over doors. This type is difficult to make on your own due to the complexity of the production technology. Their advantage is that production takes place according to individual orders in the workshop, and installation is carried out as a whole unit, so it does not take much time.

Now on the market there is a wide range of mechanisms and elements so that you can make your own automatic gates with remote opening and closing from the remote control.

In our article, we tried to acquaint readers with existing types of mechanisms and suggest an idea for self-assembly or choosing a suitable option for automatic gates for a country house, indicating points that need to be paid closer attention to, namely:

- Windage. Wind resistance.

- Weight. Load on the opening mechanism.

- Emergency opening in manual mode. Ease of implementation.

- Suitability for repair and ease of maintenance.

We hope you now know how to make automatic gates with your own hands and what their mechanism should consist of. If you liked the material, why not share it with your friends on social networks?

Homemade drive

If you really want to, you can make automatic gates yourself. Anyone who wants to save money can try it. If you have an interest in this matter, the process of assembling it yourself can be fun. The main element of such an electric drive is the satellite dish mechanism. It is equipped with a worm gear, which replaces the electric drive.

Gate drive

The satellite television system is based on a rotating mechanism. It is an engine that can be used to install automation. The principle of a worm gear is similar to the operation of an electric drive. This option is more profitable than magazine drives, since it operates on a voltage of 36 V, while magazine drives operate on a 220 V network.

Mechanism assembly

For assembly you will need 2 working satellite dish drives. Select actuators with the longest stems. You will also need a remote control and a transformer, the power of which should be from 36 to 40 V.

The remote control is used to close and open the structure. It needs to work at a distance of about 50 m. There should also be 2 key fobs, which can be bought from a company that specializes in security.

The drive can be assembled in about 6 hours. In order for the automation to work efficiently, supplement it with a current relay. If there is no relay, the motor may overheat or even break down.

This way you can easily make a gate drive at minimal cost. At the same time, if you prefer a ready-made assembly, you can save money by installing the automation yourself.

Automation with retractable internal rod

Types of automatic gates

The high cost of purchased auto gate models discourages owners of suburban areas from such a purchase.

If your budget is limited, homemade automatic gates are an ideal option.

Automatic designs come in the following types::

- garage;

- recoil;

- swing

Automatic designs are divided into 3 types

Swing structures

The most popular and long-known are swing structures. They consist of 2 doors, which are attached to the side posts using 2-3 hinges. They are highly reliable. The downside is the need for additional space for opening outside or inside the site.

Swing gates are mainly installed in narrow passages where other structures are not suitable. In this case, the reliability will be the best. Another disadvantage of such gates is the need to strengthen the support pillars. If they do not have sufficient rigidity, they will eventually tilt inward, which will lead to jamming of the sashes.

Also, when installing automation on this type of gate, you need to buy two mechanisms that will work synchronously, unlike other types, where you need to purchase one electric motor.

Recoil variety

Sliding gates are easy to use. In the open position, they are located close to the fence and take up virtually no space on the site. In addition, this type of gate has three types of supports.

Depending on the supporting surface, sliding gates can be:

- Console. The support is provided by roller mechanisms, which are attached to the concrete using brackets or bolts. Such a mechanism is located outside the roadway area. In practice, designs with lower roller support mechanisms and upper guides are considered the most reliable and convenient option. Basically, such gate designs are installed.

- Rail. A guide rail is installed at the bottom of the roadway along the entire perimeter, along which rollers welded to the doors ride. Today, it has lost its popularity, since it cannot be installed on all surfaces, and the guide also requires constant repair and cleaning.

- Hanging. They are characterized by a top guide. The doors themselves move on rollers. They are installed in places where the required gate height is more than 2 meters. If necessary, this type of gate can consist of 2 parts. Install double suspended structures in places where there is not enough space on the sides to install a single-leaf structure.

Sliding gates are used in many areas: private, industrial, etc. This type of gate is the most convenient, as it does not require additional space at the entrance.

The disadvantages of the design are:

- the need to install a foundation;

- more complex design compared to swing ones;

- If there is a narrow passage, sliding structures cannot be installed, since a minimum of 4-5 meters away from the passage will be required to place them in the open position.

Despite the significant disadvantages, sliding gates are very popular, since it is much easier to install an automated system on them than on swing or other types of structures.

Garage types

All three types of structures are suitable for a garage.

But, as a rule, the following varieties are distinguished :

It is difficult to make similar designs of automatic garage doors with your own hands. They are not very suitable for DIY production and installation.

Swing automatic gates

The most common option is automatic swing gates, which can be made by a trained home craftsman with his own hands. The design of such gates is quite simple and understandable. Does not cause difficulties during independent installation and commissioning.

We can say with confidence that this is the most budget option, since complex and expensive fittings are not required.

Advantages of swing gates

- You can do the installation yourself.

- The cost of finished gates is relatively low.

Disadvantages of swing gates

- The main disadvantage is the availability of free space for opening/closing.

- During the snowy season, mandatory cleaning of the opening path of the sashes is required.

Automation for swing gates

To make automatic gates with your own hands, you can get by with a minimum of equipment:

- Two drives - a separate drive for each leaf;

- Control unit;

- Pocket remote control for opening/closing. Such a mechanism can most often consist of two flaps, but is simplified by installing one flap.

- The most common type of opening is lever.

Such a system consists of three elements:- Electric motor;

- Gearbox;

- A set of levers.

- Linear type

The gearbox, through a worm gear, controls the movement of the rod, which is mounted directly on the gate leaf. The entire system is driven by an electric motor.

The easiest system to install and operate is a linear drive system. But on large sliding gates mounted on large and powerful supports, it is more logical to install a lever system. And, based on the weight of the sash, the power of the drive itself is selected.

Drive systems

In order for the mechanism to start operating and the rotational movement of the motor to be transmitted to the gate, it is necessary to install the appropriate mount.

The drive system consists of several elements

It comes in several types:

- crank mechanism;

- helical gear;

- worm gear;

- use of slats;

- mechanism using a gear wheel;

- chain transmission.

All types of gears are suitable for any door, even for a garage.

Mechanisms for swing structures

In order for homemade automatic swing gates to start closing and opening on their own, you need to install a lever or linear type drive on them. The latter, at first glance, look like a car shock absorber and operate on the principle of extending the drive rod. Lever-type mechanisms resemble the movement of a hand. Their size does not change during operation, but they are attached with a movable hinge.

If you need the structure to open in any direction, it is better to use linear mechanisms. But if the sashes are hung on brick pillars, then it is better to use lever ones, since they are not so demanding on the placement of the fulcrum.

To independently produce a linear mechanism, craftsmen use parts from satellite dishes and also make screw mechanisms.

For lever transmission types, available factory tools are also used. They are often drives from automatic window lifters or windshield wipers.

Also, for self-production, a gearbox from an electric motor is often used.

Automation of sliding gates

If you don’t want to come up with a mechanism for the design yourself, you can purchase it in specialized stores.

Included in the package:

Drives for automation

The actuator that sets the entire system in motion can be of different types:

- crank;

- with a screw (worm) gear;

- with rack, gear;

- chain transmission.

For swing doors

To create a swing structure, drives belonging to linear or lever groups are often used. The first type is most often used; it is easily mounted on swinging double-leaf gates and can move in any direction. Here, independent inventions based on screw gears are often used.

When the gate leaf is hung on pillars made of brick or stone, a lever mechanism is used; it does not require the creation of a certain fulcrum. Here, drives taken from automatic window lifters are used.

Automation for sliding curtain

Gate automation can use factory-made devices to move the door leaf. It will include the following elements:

- drive unit;

- gear type rack;

- control unit equipped with sensors.

Self-installation

You can assemble an equally high-quality system yourself. In addition, this will save your budget on components.

To make your own drive you will need:

- old but working electric motor;

- 2 stars;

- chain for transmitting torque from the motor to the gate.

There are many factory models of swing gates. Drive mechanisms are also sold separately. They are made with high quality and are able to work in different weather conditions. Purchased mechanisms differ in the required force for opening, the amount of electricity and current required.

The only big disadvantage of installing such options is their price. For a simple mechanism with a control unit you need to pay around 20,000 rubles. This factor is decisive to think about installing the gate yourself.

Preparing the site

The correct choice of location is a decisive factor for successful construction.

In order for the design to be practical, it is necessary to take into account several nuances :

- installation location;

- the ability to open in one or two directions, only outward or inward, etc.;

- sash sizes;

- features of installation of support posts;

- type of fastening of the drive mechanism, as well as its installation location;

- method of installing cables to supply electricity to the gate;

- presence of an additional battery;

- features of the fixing element.

Also, do not forget about the characteristics of the materials from which the gates will be made. If all the design details have been resolved, then you can begin selecting a drive and drawing up a diagram.

Design dimensions

First you need to decide on the width of the future opening. When drawing up a project, it is necessary to take into account what cars will pass through the gate. If the farm does not have special equipment, then an opening of 2.5 m is sufficient. But when there is a tractor or trucks, the minimum width should be 3.5 m.

It is also necessary to take into account the possibility of a car passing at a right angle. If the road near the site is too narrow to make a U-turn and enter the driveway at an angle of 90°, the width of the gate is increased by 1-2 meters. Don’t forget about whether the gate will open onto the roadway or not. If yes, then you need to add a few more tens of centimeters to the width of the passage.

If it is possible to make the structure wider, even when this is not necessary, then it is better to do so. As practice shows, a width of 4-4.5 meters will be sufficient for the passage of any special equipment.

Necessary materials

Steel profile pipes are ideal for the structure frame. They are as reliable as possible and make the structure rigid.

Don't forget about the necessary material

For upholstery of the frame, you can use the following materials :

- sheets of metal;

- polycarbonate sheets or corrugated sheets;

- boards;

- forged elements.

Designs with a combination of several elements look extravagant. For example, you can make gates with forged and wooden elements.

To make supports you need to prepare:

- steel pipes or ordinary channels;

- wooden beam;

- concrete;

- stone or brick for laying columns.

The strength of the racks must correspond to the weight of the canvases. Otherwise, they will converge inward, and normal operation of the automatic system is out of the question.

To build a gate frame you will need a classic template or diagram. It is also better to design automation for swing gates yourself using a template. Which schemes to choose is everyone’s business. The quality of materials, production and level of craftsmanship are decisive. You can choose classic templates, original ones or self-drawn ones if you have experience.

Do-it-yourself sectional doors - step-by-step installation process

Segmental doors are today used to insulate and seal various rooms (including the garage). Such structures consist of vibration-absorbing springs on the wing, other fasteners and guides. The panel itself is equipped with special mechanisms for remote opening/closing using a remote control, which is part of the kit.

Sectional doors

Segmental doors are mainly used where there is a limited amount of free space. Once the wing is opened, it floats upward, saving a lot of space.

Structure of a split garage door

Attention! Door panels, made in any color, are covered with a special polymer coating during the production process, which is protected by the structure from corrosion and ensures long-term strength.

If necessary, the wing can be built into a solid acrylic window that illuminates the garage, and thanks to the sandwich panel insulation, the design can operate over a fairly wide temperature range (from -50ᵒC to +70ᵒC).

Gate construction

It is also worth emphasizing the safety of such a structure, since the closure provides a special locking system that allows the panel to be automatically locked immediately after it is lifted. In proper operation and strict adherence to the manufacturer's recommendations, the design will withstand about ten years without repair or replacement of individual elements. And now let's find out how to assemble segment gates with your own hands.

Gate symgram

Varieties of design

Modern segmental doors are suitable for all types of premises.

Attention! Previously built garages often do not meet existing construction standards, so the doors are produced in various modifications.

Vertical lift structures

Suitable for garages with high garage door height. They are sold only in construction hypermarkets and stand out because they take up minimal space during assembly.

High lift structures

Such doors are more expensive and are used where the low height does not allow vertical lift of the wing. The high price results from the use of suspension holders, special manuals and a large number of consumables.

Standard lift designs

They are used in premises that are completely ready for assembly, in which the minimum height of the linear tape is at least 18 cm. All elements are made of stainless steel. The simplest and most convenient option, which is why it is the most popular.

Low rise structures

Low lift gates are suitable where the opening height (lintel) is limited. The controls and torsion springs are attached to the ceiling, or if the ceiling is low, the entire unit is attached to the rear of the rails. In particular, such a device consists of:

- torsion roller; winding pulleys; balancing springs.

After choosing a suitable project, you can begin preparatory work.

Stages of work

To get a good result, you must strictly follow the step-by-step instructions.

First, the support posts are installed. To avoid bending of the racks, the depth to which they must be lowered into the ground must be at least 1 meter.

The racks must be installed in the following sequence :

- Mark the installation location.

- Dig 2 holes at least 1.3 m deep and 0.6 m wide.

- Pour fine crushed stone 15-25 cm thick into the bottom of the holes.

- Install and level the support.

- Fill with concrete.

If the weight of the canvases is large, then additional strengthening of the racks will be required. This can be done using a bottom bandage, having first dug a trench from post to post. Then strengthen everything with reinforcement and fill it with concrete.

It is important not to continue further work until the concrete has dried well. In warm weather, a week is enough.

Welding of the sashes is carried out in several stages:

- The profile is cut according to the dimensions in the drawing.

- Cut the ends of the profile at an angle of 45° in the elements that create the main rectangle.

- The structure is welded.

- The remaining elements of the middle are welded.

- The hinges are welded.

- All welded elements are cleaned with a grinder.

- Profile sheets are attached using bolts, and the structure is sewn up.

After welding the opposite hinges on the posts and installing the gate, you can proceed to installing the automatic mechanism.

After installation of the entire structure, the quality of gate opening, operation of the automated mechanism, etc. is checked. The engine and all electrical parts can be protected from rain with a casing made from scrap materials.

For the owner of a summer cottage who knows how to work with tools such as welding and a grinder, making a gate is not difficult. But a more complex procedure is process automation. Not all homeowners risk making automatic gates themselves, fearing complex electrical mechanisms. However, making automated gates is not difficult. The main thing is desire and compliance with the weight of the gate, the reliability of the mechanism and support pillars.

DIY remote controlled gates

Automatic gates with remote opening are the most suitable option for a private home, which has many advantages:

- To open and close you do not need to get out of the car, which is very convenient in bad weather.

- The gate opens in less than 15 seconds.

- It is possible to install lighting in the local area.

- The device is reliable and durable.

- Additional security is provided, because Without the control panel, the system will not work.

- If the equipment fails, you can open the gate with a special key.

You can install automatic gates yourself. There are a large number of designs on sale from different manufacturers and at various prices.

How to make automatic gates with your own hands

You drive up to your garage or garden, press a button on the remote control (or the built-in transmitter in the car), and the entrance opens automatically. This is convenient: there is no need to get out of the car (especially in the rain).

Of course, there are also disadvantages that can negate all possible advantages:

- Automatic gates with remote opening reduce the level of security of your home. The signal from the remote control can be intercepted. Attackers, using simple devices, read the radio code and can gain access to the territory after your departure.

- The electric drive in a sense limits freedom: in the event of a malfunction, or a banal lack of electricity, opening the doors manually can be problematic.

- The installed actuator takes up a certain place and spoils the aesthetics of the fence of your home.

- Mechanical doors with incorrectly configured automation are an object of increased danger: animals or even people can fall under their influence.

- A guaranteed free area along the trajectory of the valves is required.

- The main disadvantage is that automation for swing or garage doors costs a lot of money.

While installing automatic gates with your own hands is still possible, making actuators and a gate control system is quite difficult. You will need a factory engine, mechanical rods, possibly gears, etc. Of course, the sliding gate mechanism can be purchased at a specialized store.

However, the cost of such a set most often exceeds the cost of manufacturing the doors themselves. In addition, installing automation on ready-made swing gates with your own hands can be complicated by incompatibility in geometry.

However, automatic garage doors are created with your own hands and can be easily installed both in the fence (fence) and in the garage door. The savings in this case are significant, plus moral satisfaction after successfully completed work.

Features of installation of automation

When choosing and installing automation, you need to be guided by the weight and size of the sashes. This applies to the purchase of any mechanism. For solid gates made of corrugated sheets, which are often used in our country, it is recommended to choose an automation with a weight reserve of 1.5-2 times so that it does not quickly fail when there is a strong wind acting on the doors.

Any automation is installed on a narrow profile pole. If the shutters must open outward, then the correct solution would be to install a linear drive at the top of the structure. The lever system allows the doors to open inward and outward up to 110 degrees. Through the gearbox, the energy of movement is transferred to the central shaft, to which the lever and the sash are attached.

Before installing automatic swing gates with your own hands, you should check that the structure is working correctly. The doors must open without interference and close without distortions or defects. If the distance from the loop to the inside of the post is less than 15 cm, a linear actuator will do. In other cases, lever type.

Main types of automatic gates

To understand the amount of work, consider the main types of automatic gates

Hinged doors

This is a true classic: casement structures have been around since people learned how to make fences and fortress walls. Do-it-yourself automatic swing gates are usually made on the basis of an existing fence with an entrance. You have been using the doors for a long time, and at some point you wanted to install a remote control.

The wiring diagram looks like this:

On the inside, between the leaves and support pillars, actuators are installed: one for each half of the gate. Depending on the remote control, an antenna or an infrared signal receiver is installed. In the second case, direct visibility to the signal is ensured. There must be a warning light in a visible place that lights up when the mechanism starts operating. When making swing gates with your own hands, many people forget about this essential safety element.

Another element that is often ignored is photo sensors. If the trajectory of the gates is crossed by any object (car, animal, person), the gate should not operate in closing mode. Together with sensors, do-it-yourself gate automation should ensure that the voltage supply to the motor is stopped when the doors reach their extreme positions: open/closed.

If the drive can be activated by manual force (without supplying power), for safety, you should install a lock or other locking device that can be used if the yard is left unattended for a long period of time.

Recoil systems

In fact, it is a part of the wall (fence) that moves to the side using a support roller mechanism. This design was originally intended for a mechanized drive; manual gates are too heavy. Automation for sliding gates with your own hands is easier to manufacture, but the implementation of the project will require a large amount of materials.

Sliding gates must be installed on a strong foundation. Regardless of the material (metal, wood, plastic), the canvas has a lot of weight. The soft soil under the support rollers will sooner or later sag, and the opening mechanism may jam due to distortion.

For sliding gates made by yourself, you can select an actuator from various industrial and household components. There is an opportunity to save on the purchase of expensive drives. There is no need to create high-risk areas: the free space for moving the blade is not delicate. However, the control mechanism for do-it-yourself sliding gates requires the installation of photo sensors. When an object appears in the plane of the gate, movement should be blocked: just as precisely as in swing gates.

Sectional lifting mechanisms

Such systems are most often implemented in a garage. In essence, these are ordinary roller blinds, only the sections are made of more durable material. Lifting gates move along guides and, as they open, are placed along the ceiling.

Making a drive for sectional doors with your own hands is easier than making the door leaf itself. This element must fit perfectly to the guides. In addition, the slightest misalignment of the hinge joints can block the entire structure. Considering the fact that many (not all!) home craftsmen order canvas (regardless of the design) from professionals, making overhead garage doors with your own hands is not difficult. In this case, you will only have to make the actuator.

Particular attention should be paid to various sensors. If, when entering (entering) the garage, the roller blinds unexpectedly go down, the damage to the car will be significant. Not to mention the possible injury to a pedestrian, on whom a heavy structure will literally fall.

The main problem with do-it-yourself lifting gates is the drive power. To move swing or sliding gates horizontally, relatively little effort is required. And to lift a heavy sectional structure, the engine power must be many times greater.

How to make automatic swing gates with your own hands simply and inexpensively

Do-it-yourself automation for sliding gates is not unattainable when a person has minimal technical skills.

To create such a system you will need the following set of tools:

- screwdriver;

- roulette;

- drill (perforator);

- hammer;

- pliers;

- fasteners.

After selecting the necessary tools, it is important to inspect the support columns, assessing their condition. To mount a linear drive, you need to have a maximum distance from the extreme part of the pole of 150 mm. If other parameters exist, you should prefer a lever type of device for moving the valves.

Installation of automation should be carried out strictly according to the instructions included with the equipment. You cannot deviate one step from it, so as not to disrupt the operation of the device. For example, it is very important to choose the right place to install the system. Even concrete and brick foundations may require additional reinforcement.

After installation of the automatic system is completed, it is connected to the electricity supply. After turning on the mechanism, the final adjustment of the movement of the valves occurs, equipping the entire structure with signal and photocells. As a rule, all systems require a backup button to be able to open the valves without exposure to electric current.

Practical implementation

There is no point in telling how to make automatic gates with your own hands, based on ready-made projects in a complex. Each design is purely individual, and it is not always possible to repeat it exactly in your own backyard.

As we have already said, the easiest way is to make swing gates with your own hands. Most likely, you already have gate leaves. Let's consider possible designs of drive elements.

- A suitable actuator is a worm gear steering gear from a large car, preferably a truck. Do-it-yourself garage doors made from this element are a fairly popular option. You can find similar automation in any cooperative. Any suitable motor (for example, from a washing machine) is connected to the steering column rod. To reduce speed, you can install a simple gearbox consisting of two pulleys of different diameters. The rod for the shutters is mounted on the bipod of the steering mechanism.

- Another shareware drive is the window lift mechanism. It is better to use a design from a large domestic car. If the hinges are well lubricated and the doors are balanced, the effort is quite enough. As can be seen in the illustration, only minor modifications are required in the form of a rod made from a corrugated pipe.

- The next option can be made from an industrial worm gear. Most often, a caliper drive from a decommissioned processing machine is used. You can turn a pair of worms in a mechanic shop, depending on the cost of the project.

- The operating principle is simple: a screw stud is directly connected to the motor shaft (along the axis). When the screw rotates, the carriage moves in the desired direction, creating a powerful traction force. All that remains is to connect the mechanism with a rod to the doors and adjust the opening angle.

The question of how to make automatic swing gates has been resolved.

Drive types

Linear actuator

This drive is the simplest in design and use. Inside the drive, the screw is rotated by an electric motor inside the gearbox, after which mechanical energy is generated that pushes the gate. The smoother the opening movement, the longer the service life of the mechanism. It is an electromechanical drive for swing gates.

Hydraulic drive

A very reliable, but expensive operator for swing gates. The mechanisms are driven by hydraulics, into which the pump pumps in and out the solution. Special sensors are responsible for safe operation.

Lever drive

Energy is transferred from the engine using mechanical pistons. The drive operates thanks to the operation of the motor. Energy from the engine passes through the gearbox to the piston. The drive takes the longest to open the gate, but is very practical.

Positive aspects of the electric drive

A self-made electric drive will last for many years. The gate opening time will be 14-16 seconds, which is 10 seconds less than the factory gate. Usually, when installing automatic gates yourself, they forget about installing sensors that make sure that there are no obstacles in the gate opening path. If the electric drive encounters any obstacle in its path, this can lead to jamming of the drive and failure of the main module.

When installing it yourself, you usually use a special satellite dish, which consumes many times less electricity than the factory one. That is, a homemade drive is more economical and consumes 34 V, while a magazine drive operates on 220 V.

Before you start making the drive, you should calculate the mass of the gate and the drive force that will act on the gate. You also need to purchase a remote control with a range of 30-40 meters. In addition, you need to think about safety. The main small but very important part is the current relay, without which the automation can overheat and fail.

Various types of gates with automatic remote control

Depending on the device, the following types of automatic gates with remote control are distinguished:

- lifting;

- recoil;

- swing

Lifting structures have their own varieties - roll, sectional and rotary.

Rolling gates

This type of design is simple and convenient. Its construction does not require much space. The gate consists of many aluminum slats connected into one sheet. When the gate is opened, this fabric is wound onto a drum, which is located under the ceiling.

Opening is possible manually or mechanically using a remote control. The system consists of: canvas, guides, a box with a motor and shaft, a remote control receiver, photocells.

Advantages:

- A reliable way to protect your room from the cold.

- Compact, can be installed in low ceilings and at low heights.

- They have a low cost.