Why you can’t adjust the fan speed with a dimmer 02/25/2016 06:29

To regulate the rotation speed of single-phase electric motors with a supply voltage of 220 V, triac rotation speed controllers are used. The dimmer (triac dimmer), in turn, is designed to control a resistive load and should be used only as a regulator of lamp brightness. Datasheets and operating manuals usually contain instructions that it is inadmissible to use a dimmer to control the motor. For example, the description of a 300W dimmer from Eljo (Sweden) states: inductive and capacitive loads (conventional transformers, fluorescent lamps and electric motors) cannot work with these dimmers.

Methods for adjusting the rotation speed of household fans

There are quite a few different ways to adjust the fan speed, but only two of them are practically used at home. In any case, you can only reduce the engine speed below the maximum possible according to the device data sheet.

It is possible to accelerate an electric motor only using a frequency regulator, but it is not used in everyday life because it has both a high intrinsic cost and the price of the service for its installation and commissioning. All this makes the use of a frequency regulator not rational at home.

It is allowed to connect several fans to one regulator, unless their total power exceeds the rated current of the regulator. When choosing a regulator, keep in mind that the starting current of the electric motor is several times higher than the operating current.

Ways to adjust fans at home:

- Using a triac fan speed controller is the most common method, allowing you to gradually increase or decrease the rotation speed in the range from 0 to 100%.

- If a 220-volt fan motor is equipped with thermal protection (overheating protection), then a thyristor regulator is used to control the speed.

- The most effective method of adjusting the rotation speed of an electric motor is to use motors with multiple winding leads. But I have not yet seen multi-speed electric motors in household fans. But you can find connection diagrams for them on the Internet.

Very often the electric motor hums at low speeds when using the first two adjustment methods; try not to operate the fan for a long time in this mode. If you remove the cover, then using the special regulator located under it, you can, by rotating it, set the lower limit of the motor speed.

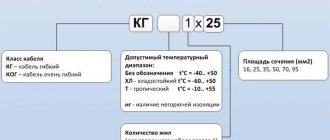

The triac regulator circuit differs from the dimmer circuit in the following ways:

- The lower threshold for the voltage supplied to the fan motor is set

- The power of the triac is selected so that its maximum operating current exceeds the operating current of the fan by at least 4 times.

- With a resistive load of 2 A, it is enough to take a triac also rated at 2 A.

- The fuse is selected based on the power of the electric motor.

- Typically, the maximum fuse current should be 20% greater than the motor operating current.

- For more correct formation of a sinusoid, an additional phase-shifting damping capacitor is installed.

- To reduce network interference, an additional noise suppression capacitor is used

Bathroom ventilation

In this room, ventilation is necessary to remove large amounts of moisture that constantly accumulates here. Thanks to the presence of a hood, it is easy to breathe in the room, plumbing fixtures and household items do not deteriorate, and mold and mildew do not appear.

Recommendations from engineers when choosing bathroom ventilation

Engineers recommend not purchasing expensive, large equipment. The main thing is to correctly calculate the required power. Experts advise paying attention to the power of the wiring in the room. Since the hood has considerable power and pressure, the cable may be damaged due to an overload of the electrical network. When purchasing, quality, productivity, and dimensions are taken into account.

How to install a fan in the bathroom

When installing, you must follow the rules:

- remove the cover;

- Lubricate the places that will be adjacent to the wall surface with liquid nails or reliable glue;

- place the product in the hole in the wall (the working part is hidden);

- press the body well;

- install a mosquito net;

- Place the cover, securing it with dowels or self-tapping screws.

At the end of the work, the wires are laid, and the structure is connected to the electrical network.

The principle of connecting to the electrical network

The ventilation duct is separately wired for automatic activation by programming the device or a motion sensor. If the model has a cord, then you can turn on the system mechanically.

Important! Wiring should be installed using terminal blocks, and not using conventional twists.

Control by turning the lighting on/off

Often electrical equipment is turned on at the moment when the lights in the room come on. But since an exhaust hood is usually necessary during bathing, this option is not very convenient - electricity is wasted, for example, during washing. Therefore, it is better to automate the system in order to save energy and provide additional convenience.

Why do you need a timer for a bathroom fan?

Equipped with a timer, the hood will turn on when the light is turned on, and turn off a few minutes after the person who took the shower has left the bathroom. During this time, the device extracts moist air. If the stay in the room was short, the structure will not turn on, since there is no need for its operation.

Connecting a bathroom timer

The timer is a compact device. It should be connected using 6 pins. To connect correctly, you need to use the diagram.

Wiring diagram in the bathroom for a fan with a timer

Wiring diagram in the bathroom for a fan with a timer

Bathroom timer connection diagram

Wiring diagram in the bathroom for a fan with a timer

Connection via switch

Before you start connecting the power wires, you need to turn off the switches on the switchboard. Then the front panel of the device is removed and wires are inserted into it through the channels.

How to connect an exhaust fan to a switch

The wires are connected to the terminals of the device located under the cover. In the absence of grounding, 2 wires are enough: phase and zero. The wires are connected to the terminals, secured with bolts, and a protective cover is installed.

Why is this necessary:

- The torque of an asynchronous motor decreases in proportion to the square of the applied voltage. When the lower voltage threshold is reached, the engine may not start. For single-phase axial and duct fans, the lower value is 40-60 V. Since the motor is not rotating, it still consumes current, the fan windings begin to heat up. The engine begins to make a characteristic sound (hum). As a result, if the engine is not equipped with reliable internal thermal protection, it burns out within an hour. In triac regulators, the minimum voltage supplied to the fan is set at the factory. Typically this is 80-100 V. This guarantees normal operation of the fan at low voltages.

- When starting, the engine briefly consumes current, 6-7 times the maximum operating current (starting current). For reliable operation when starting the engine, a triac with a high operating current is used.

- To properly protect the motor from overcurrent (overvoltage, bearing overheating, etc.), the maximum fuse current must be selected according to the type of motor. For triac regulators, this value is 15-20% higher than the maximum motor current.

- When a reduced voltage is applied, the engine power drops and the rotor begins to slip relative to the stator field. At certain speeds, a phase shift occurs and the engine begins to briefly consume current higher than the maximum operating current. To prevent such a situation, an additional damping capacitor and a more powerful triac are installed in the triac regulator circuit.

- The shape of a sinusoid during phase control of an inductive load is more complex than when controlling an active load, so an additional capacitor is required to suppress the high-frequency spectrum of interference. The dimmer that controls the fan may cause interference visible on the computer or TV screen.

Types of fans for domestic use

The equipment is available in two varieties: built-in and separately located. The most common activation is by pressing a switch. Automatic electrical appliances are equipped with electronics that simplify and control operation.

Additional features are:

- on/off timer;

- lighting in different colors;

- humidity sensor.

The device turns on when the permissible humidity level is exceeded and turns off when this value returns to normal. By design, hoods can be radial (centrifugal) and axial, ceiling-mounted and wall-mounted, with or without blades.

Requirements for exhaust equipment in the bathroom

In accordance with regulatory documents, in order to create normal air exchange, you need to adhere to the following indicators:

- 8-10 sq.m/h. per 1 cu. for a combined bathroom;

- 6-8 sq.m/h. - For bathroom.

The volume of exhaust air from these rooms is more than 30 cubic meters per hour. The permissible norm is 30 dB - if higher, then for people this sound will be too loud and annoying.

Calculation of productivity using the formula

Before purchasing equipment that is optimal for productivity, calculations are necessary. First you need to calculate the volume of the room (height multiplied by area), which is multiplied by the aeration rate.

Attention! The maximum air exchange value in rooms with high humidity is approximately 10.

Example: a room has an area of 8 m3, a height of 2.5 m, resulting in a volume of 20 m3. The resulting number is multiplied by 6...8, resulting in 120...160 m3/h. Therefore, for a room of 8 m3, equipment with a capacity of 120...160 m3/h is required.

Modern additional devices

Modern additional functions increase the power of the hood. It increases by a maximum of 10%. The most popular electrical appliances are those that operate economically and silently - their power varies from 7 to 18 W. If the power indicator is too high, then a draft and noise of air flow is created.

Location of ventilation ducts

It is easy to install the unit if the shaft is located directly behind the wall of the bathroom, even if it is combined with a toilet or is located next to the kitchen. If these two rooms are separated, then a channel design is required. It is installed on a shaft segment, at the junction of 2 air ducts.