Requirements for loading machines

Based on the requirements of the regulations of the PUE and PTEEP, it is necessary to monitor the serviceability of the machines. This rule applies to all cases of electrical measurements, that is, the following circumstances are necessary:

- if the product has just been developed and has been certified;

- if the installation has just been put into operation;

- during preventive and scheduled inspections;

- after carrying out repair work: planned, major or emergency.

Specialized testing equipment

Please note! The tests are carried out by trained employees whose electrical safety certification must be at least group 3. Specialized equipment is used for the work.

During the test, loading is carried out with current pulses, and the indicators obtained from the test results are recorded. Fractions of milliseconds lie between determining the suitability of the machine for further use, therefore it is not allowed to independently make a decision about the operation of the device.

How the tests are carried out

The checks carried out confirm the actual serviceability of the device, but not the correctness of the adjustments made.

Important! The conclusion that the switch is working can only be given by accredited laboratories.

Operating principle of the device for loading circuit breakers

Setting up and loading the circuit breaker requires strict adherence to all rules and requirements. In addition, there is a certain methodology according to which load tests are carried out to determine the performance of the equipment.

Indications of the functioning of switching devices must necessarily correspond to the declared nominal data.

The main purpose of protection devices is to prevent a short circuit from occurring in the electrical circuit. In this regard, it is necessary to carry out electrical installation strictly according to the design.

A more detailed study of the inspection schedule reveals:

- Response spectrum of the device under test;

- Electromagnetic protection activation area;

- Thermal protection zone.

It is worth noting that the switch is considered faulty if, during the test, the protection does not turn it off within the strictly allotted time frame. If this happens, it is prohibited to use it for subsequent operation. To ensure a more comfortable connection, you need to install extended studs on the device. It is advisable that all required work be performed by a qualified technician, as it is important to strictly adhere to safety precautions.

Devices for loading machines

The parameters characterizing the machine are:

- response period at different overload currents or short circuit currents;

- tripping at short circuit currents.

These characteristics can be removed if available means.

For testing there is a stand consisting of:

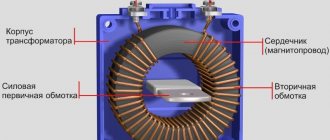

- source for converting alternating currents;

- equipment for measuring and monitoring parameters;

- connecting elements: blocks and cables;

- dielectric tabletop or workplace equipment;

- to protect the worker dielectric mat.

Workplace equipment

Note! Devices for loading circuit breakers are made portable for ease of testing.

Loading machines

Source: https://www.stroi-tk.ru/service/jelektrolaboratorija/ispytanie_avtomaticheskih_vykljuchatelej/

Why is it necessary to load circuit breakers?

As you can see, a circuit breaker is a complex electrical device that consists of many elements that interact with each other. A new element of any machine is a release, which controls a given parameter of the protected circuit and affects the release mechanism.

Failure or incorrect operation of the release can lead to serious consequences. To prevent this from happening when putting the electrical installation into operation, as well as during operation, the circuit breakers are loaded.

In this case, the results obtained are compared with GOST and data from the manufacturer.

Using a faulty machine can lead to serious consequences. For example, electric shock or fire!

What device is used to test circuit breakers?

There are many different devices designed to test the characteristics of circuit breakers. Their operating principles are similar. They usually consist of several blocks - load, adjustment and measuring. The load block generates a test current, the strength of which can be changed using an adjustment block. Accordingly, the measuring unit measures the operating parameters of the releases.

The measuring and control unit, as a rule, are made in a common housing. The most common devices for checking machines are: “Saturn”, “UPTR”, “Retom”, “UPA”, “RT”, “AP”, “Sinus”. All devices of the brands presented above are available in various modifications. Modifications differ from each other in the magnitude of the test current and the presence of additional functions. Our company’s engineers use “UPTR-1MC” and “UPTR-2MC” devices.

The first is used to test characteristics with rated current up to 350 amperes, the second - up to 800 amperes.

Who can carry out testing of automatic machines?

Work on checking circuit breaker releases must be carried out by employees of specialized organizations. These organizations must have a certificate of registration of an electrical measuring laboratory with permission to test the operation of circuit breaker releases.

Short periodicity in loading circuit breakers

Tests are carried out in accordance with the recommendations from the manufacturer, but there are deadlines strictly specified by regulations. When operating in normal mode and at the rated current, the frequency is once every three years.

You might be interested in Features of a wind generator for home

Important! If there were any emergencies during operation, an additional unscheduled inspection is carried out. These recommendations apply to all devices, regardless of where they are installed: at work or at home.

Based on current regulations, the load on sectional or input devices, lighting networks or security alarms is 2%. For other installations this figure is 1%.

Inspection regulations

If the machines do not meet the manufacturer's specifications, then the entire batch must be checked. After the work is completed, each device is stamped with a stamp indicating the laboratory that carried out the tests. This is an indicator indicating the suitability of the device for use.

Protocol for loading circuit breakers

After each test performed, a protocol is prepared. The instruments used to check automatic devices must initially be verified, which confirms the presence of a certificate.

To fill out the protocol, use:

- employees who have been trained under a special program and certified to at least group 3;

- chief specialist responsible for the work, having at least 5 categories;

- inspectors, of whom there must be at least 2.

Important! The inspection determines the operability of electrical installations and electrical networks, so untrained workers are not allowed to perform this task.

Specialists who have not undergone training are not allowed to take part in the tests.

When filling out the protocol, the following nuances are taken into account:

- at the top right is information about the customer, the object of study and the specific time of inspection;

- Information about the laboratory is indicated at the top left (name, certificate, license validity);

- the act states its number, what conditions were observed during the implementation, the purpose of the task, and filling out the table.

Table data:

- switch with number;

- marking and place on the diagram;

- releases, their type of action;

- rated current;

- response (delay);

- setpoint;

- Carrying out short circuit and overload current testing.

Formalized results

Important! The document must be stamped and signed by specialists.

Samples and examples for filling out are indicated in the manuals.

Loading circuit breakers

Automatic switches are devices designed to turn on, carry current, turn off, and also protect users and conductors from overcurrents, that is, from short circuit currents and overload currents.

In the event of an emergency, the circuit breaker must turn off quickly and safely, preventing flames and sparks that could damage a nearby device, creating a fire hazard. The use of high quality protection devices is justified.

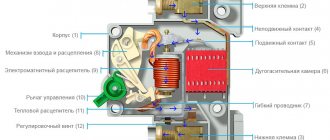

Schematic diagram of the operation of a modular circuit breaker

Electric current flows from one terminal to the magnetic release coil, then to the contact system and through the bimetallic strip to the second terminal.

- Electromagnetic release – instantaneous actuation electromagnet for protection against short circuit currents. The response time is a few milliseconds.

- Thermal release is a bimetallic plate that is triggered when overload currents occur. The response time can last up to 2 hours.

- Control lever - an element with which you can turn on and off a circuit breaker

- Free release mechanism – connects the control handle with a moving contact. It also provides automatic shutdown in case of overload and short circuit.

- Arc chamber – el. magnetic energy is released in the form of an arcing arc

Main releases used in modular circuit breakers

1. Electromagnetic release

The electromagnetic release consists of a solenoid with a movable core and a spring.

In the event of a short circuit current flowing, the core is instantly retracted, creating a force greater than the tension force of the return spring, which actuates the trip lever.

When the contacts open, an electric arc is formed passing through the reflective plate and the protrusion into the arc-extinguishing chamber. Here it is divided into separate small arcs, this leads to a rapid decrease in current to zero. This process lasts from 2 to 4 milliseconds.

2. Thermal release

The thermal release is a bimetallic plate consisting of two metals connected to each other, having different expansion coefficients.

The passage of current through the circuit breaker is accompanied by heating of the bimetallic plate, and when the current in the circuit increases above the rated value or, in other words, overload, the plate is deformed and affects the free tripping mechanism, thus turning off the circuit breaker.

Due to the increasing number of cases of counterfeit circuit breakers, you can contact our laboratory to test new purchased circuit breakers. The test period is up to 1 hour.

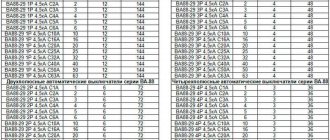

Circuit breaker tester

Testing of circuit breakers is carried out with the Saturn-M1 device, by creating an artificial circuit with smooth regulation of the current value in the circuit of the circuit breaker being tested, measuring its value and the time the device is turned off.

Stages of checking circuit breakers

- Checking the markings of the circuit breaker

- We clarify the operation current, overcurrent response characteristics, and time-current characteristics

- Testing an electromagnetic release (using the example of a C16A circuit breaker): - we connect the device for testing Saturn-M1 circuit breakers to the loaded circuit breaker - we set on the device the maximum operating current of the circuit breaker in accordance with its time-current characteristic - we supply an increasing current, the C16 A circuit breaker should operate in accordance with time-current characteristic in the range from 80A to 160 A.

- the machine operated at a current value of 155 A, which means the electromagnetic release is working. - Testing the thermal release (using the example of the C16A machine): - we connect the device for testing Saturn-M1 machines to the machine being loaded - we set the time interval for exposure of the thermal release to three times the rated current. - we supply three times the rated current to the machine, which should operate in accordance with the time - current characteristic in no more than 60 seconds

- the machine worked after 11.16 seconds, which means the thermal release is working - We record the measured values of the response current of the electromagnetic release and the response time of the thermal release and make a conclusion about the suitability of the circuit breaker. Based on the test results, a test report for circuit breakers is drawn up

Cost of checking circuit breakers

The basic cost of testing a switch with an electromagnetic, thermal or combined release in our electrical laboratory is not expensive and ranges from 120 rubles. for 1 piece More detailed information on cost in the Prices section.

Source: https://elaba24.ru/avtomat-viklucatel/