Industrial electric motors are complex technical devices that convert electrical energy into mechanical energy. Widespread use in household and industrial equipment was ensured by the design and technological thought of many people. An electric motor assembled by self-taught craftsmen from scrap materials is unlikely to find the same distribution as industrial designs. However, it is quite suitable as a teaching aid that clearly demonstrates the principle of operation of an electric motor.

Examples of electric motors made by self-taught craftsmen

Self-made electric motors are distinguished by various available materials used as blanks for the rotor and stator. We present some options for such homemade products.

Electric motor made from a Pepsi-Cola can

For such a homemade product you will need the following components and tools:

- an empty aluminum soda can that will serve as the base for the rotor;

- spool from a sewing machine;

- insulated copper wire with a diameter of about 0.35 mm, approximately 10 meters long;

- a wooden board 10–15 mm thick, in dimensions in accordance with the size of a Pepsi-Cola can;

- 4 (four) round permanent magnets in the form of thin plates that will create a magnetic field instead of a stator;

- metal knitting needle;

- two small wooden blocks measuring 15x15x60 mm;

- a short block in the form of a cube with a side size of 15 mm;

- copper wire 1.0 mm thick for making contacts;

- to fix the coil you will need a 3.5×30 mm self-tapping screw, and to secure the contacts you will need 2×15 mm self-tapping screws (3 pcs.) and 3 wide washers for them;

- 12V power supply;

- tube of superglue;

- calipers and scriber for marking;

- marker for marking points;

- hand-held electric drill;

- multimeter to check the presence of contact;

- a set of screwdrivers, a stripping knife, pliers, side cutters and possibly other tools for installing electrical wiring.

Work order

We recommend performing the work in the following sequence.

- Carefully wind the copper wire onto the spool by hand. Be sure to fix the ends.

- In the center of the wooden plank we fix the wound coil, which has already turned into an electromagnet, using a long self-tapping screw.

- Using a marker, mark the location of the permanent magnets, as in the image:

- We glue magnets to the designated places, while observing their polarity.

- Using a drill, drill holes in the center of the can for the axle (knitting needle).

- We install the spoke into these holes.

- In wooden blocks 15x15x60 mm, drill a hole for a knitting needle from one of the edges.

- Using glue, we fix the rotor structure with wooden blocks (stands) on a wooden plank.

- We additionally install a block in the form of a cube on the spoke (rotor axis), and its edge should coincide with the axis of installation of the magnets.

- We make control contacts from copper wire 1.0 mm thick, one end of which is fixed to a wooden base. The distance between the contacts is selected in such a way that when rotating, the cube should close them when touching the edge.

- The electromagnet contacts are stripped and connected to a section of thick copper wire contacts secured to a wooden base.

After connecting the 12V power supply, the motor can run.

Electric motor made from wine cork and spokes

This option is similar to the previous one, only for the manufacture of the rotor, improvised material in the form of a wine cork is used and instead of four small magnets, two larger ones with additional wooden supports for them.

The process of making a rotor from a wine cork is as follows.

- The ends of the wine cork are trimmed to even surfaces.

- Drill a hole for the knitting needle in the middle of the ends of the cork. Electrical tape is wound around one edge of the knitting needle.

- Two copper wires 1.0 mm thick are inserted into the end of the plug and fixed with glue.

- The plug is wound with thin copper wire in one direction, as shown in the image:

- The junctions of thick and thin copper wires are cleaned and fastened (it is better to solder).

Next, the assembly process is practically no different from the previous version and you get a do-it-yourself electric motor with a rotor made of wine cork.

Only the most famous of many similar homemade products are shown.

Electric motor for an electric car how to make it

DIY electric car. Domestic experience of alterations

The writing of this article was prompted by material found on the Internet, where a group of enthusiasts decided to convert a regular car into an electric car in a week. And, I must say, they succeeded. The technical characteristics of such a modification are the subject of a separate discussion, but the very fact of the possibility of making an electric car with your own hands forced you to take a closer look at this topic. As it turns out, there are plenty of enthusiasts who come up with similar ideas not only “over the hill,” but also in the post-Soviet space.

Briefly about the technical aspects of the rework

In a nutshell, the internal combustion engine is removed from the car along with the other systems that are connected to it (fuel, exhaust). Instead, an electric motor is installed, connected to the gearbox, and the mounting of the engine to the body is thought out. This frees up space for the battery, and the batteries are also located in the rear of the car. The installation and mounting system of the battery is thought through, after which the batteries are connected to each other. Power cables and wiring are laid, an ammeter and a voltmeter are connected. A DC converter, controller, and vacuum pump controlled by a vacuum sensor are installed to operate the brake system. The car charging system is being thought out; as a rule, the standard tank neck is used for a new battery charging connector, etc. As you can see, a lot of different work is being done, including welding work, so it is still necessary to have some knowledge and skills when assembling an electric car yourself. For those who are going to remodel a car alone, this process can take a long time. However, this does not frighten interested people; the examples of alterations presented below are clear confirmation of this.

Domestic conversion experience

The converted Opel Monza is the creation of Valery Vasilyevich Beznoskov. Photos of electric cars are quite common on the Internet.

The range was more than 80 km on a single charge.

Another creation of Beznoskov V.V. – electric trike. This direction is also gaining popularity. Made on the basis of the Ural motorcycle. Capable of traveling 80 km on a single charge.

The Gas-M21 car, successfully converted by Kyiv entrepreneur Alexey Helemendik, deserves special attention. Weighing 1715 kg, the car reaches speeds of up to 80 km/h. Engine power – 88 kW. The battery charge is enough to travel 100 km. A total of 30 Li-ion batteries are installed. Battery charging time – 3.5 hours.

Another Ukrainian experience in remaking an electric car, this time the experimental material was Deo Matiz. The stated speed is 65 km/h. The range on one charge was 60 km. The battery charging time (only 6 pcs 12V 180 Ah) is from 6 to 8 hours.

It can be noted that Belarusian citizens who are interested in alterations are also present at thematic forums. We haven’t actually come across any completely converted cars, but let’s hope that soon homemade ones will appear here too. By the way, the design of such a homemade car deserves special attention. Those who have experienced this find the process quite difficult.

Sources: stisle.com, electro-mobiles.ru

This is interesting:

How to make an electric car with your own hands » general and electrical diagram of an electric car.

Topic: general diagram of an electric car - making an electric car with your own hands.

Let's take a look and analyze the general electrical circuit of an electric car. After which you will have generalized ideas of what’s what and where exactly to move in this regard. So, the electrics of an electric car consist of several fundamentally important parts. This is an electrical supply element (battery), an electric DC motor, an engine control unit (controller), a potentiometer (a rheostat that responds to pressing the gas and brake pedals). Each of these parts is of fundamental importance. Each part must be correctly selected and properly configured. The operation of the electric vehicle as a whole depends on this. This will make it possible to answer the question - how to make an electric car correctly.

Since the total power of the electrical system (primarily the electric motor) for an electric vehicle is in the range of 5-10 kW, or even more, we will proceed from these data. We select an electric motor for this power. The specific controller circuit and the number of batteries (the type of connection between them) depend on the motor supply voltage. Please note that you should not follow the principle - the more power I supply to the electric motor, the better and stronger the car will be. Additional problems with batteries will appear. Choose the best option based on the available weight of the vehicle, required technical characteristics, speed, driving range per charge cycle, etc.

How to make an electric car with your own hands in terms of mechanics is a matter of creativity and electromechanical skills of the master. And we will analyze the most complex elements in this system from an electrical point of view. And this part is the controller. Why? Yes, because the subtleties of the operation of the entire electric vehicle depend on it. The controller is an electrical (electronic) circuit, the main task of which is to control the rotation speed of the electric motor. If we directly connect the battery to the electric motor, we will get its maximum speed without the ability to control the speed of movement. This is not right and not good. If the control is carried out by an ordinary powerful variable resistor, then in this case the “cut off” electrical energy will simply be lost to heat. There is no sense of saving here.

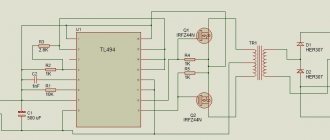

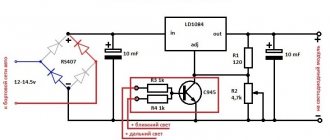

How to make an electric car with your own hands anyway? The most acceptable option for controlling the speed of an electric vehicle is a special controller circuit. The circuit consists of a low-power variable resistance, a direct circuit for setting the rotation speed (pulse circuit) and a power section, which supplies the required amount of electricity to the electric motor. The power part can consist of powerful thyristors, triacs, bipolar or field-effect transistors. The important thing is that the entire controller circuit must respond correctly to measurements of variable resistance and smoothly produce the required portion of energy that will be supplied to the electric traction motor of the electric vehicle.

In this article, as you can see, two electrical circuit diagrams of controllers are given. Their general principle of operation is similar. The only difference is that one is assembled according to a more simplified circuit and uses one supply voltage, while the second is more complex and contains other electronic elements. If you don’t want to tinker with and invent circuits yourself, then you can purchase a ready-made converter without fooling yourself with homemade products.

PS Before you start creating your electric car, be sure to think through all your wishes, namely, what parameters your future device should have. This will allow you to significantly save time, effort and finances.

Traction motor for an electric car: how electric cars work on it

Traction motor for Tesla Model S electric car

The inevitable future of the automotive industry, whether we like it or not, is electric cars. Car manufacturers around the world are investing huge amounts of money in their development, wanting to reduce the concentration of harmful substances emitted by traditional cars, making trips safe and comfortable, as well as economical. Work on their creation is carried out in two directions - the creation of new models and the reconstruction of serial ones, which is more preferable because it is less expensive. Electric cars, compared to traditional ones, are more reliable because they are simpler in design, i.e. characterized by a minimum of moving parts.

The largest markets for electric cars today are: the USA and Norway, Japan and Germany, China and France, the UK, etc. Our country is still on the sidelines from the production and use of new vehicles, excluding the enthusiasts who developed the Lada Ellada. But this is an isolated case so far, so it does not count, especially since the car was assembled using imported components.

The term “electric car” means a vehicle driven by several (or one) electric motors. Theoretically, the motor can be powered by a battery, fuel cells or solar panels. However, the first option has become more widespread. The battery powering the engine requires charging, which can be done using external sources, recuperation or a generator installed on board the vehicle. The electric motor, which is the main element of an electric vehicle, is usually powered by a lithium-ion battery. In recuperation mode, it also plays the role of a generator that charges the battery.

Purpose of the traction motor

A traction electric motor (TED) is designed to propel a vehicle, i.e. it converts electrical energy into mechanical energy. They are classified according to the method of power supply, type of current, design, type of wheel pair drive. In most environmentally friendly cars: hybrid cars, serial electric cars, fuel cell cars, which are gaining enviable popularity these days, they are the main driving force.

They use DC traction motors as engines, which operate in two modes – motor and generator.

Video: How the Tesla Model S electric car engine works

Principle of operation

Operating principle of the Golf blue-e-motion electric vehicle with traction motor

Their work is based on the principle of electromagnetic induction, i.e. the occurrence of an electromotive force in a closed loop when the magnetic flux changes. The electromechanical TED differs from a traditional machine in its greater power, more compact size, and in addition, it has a higher efficiency.

According to the method of power supply, motors are divided into DC and AC motors. According to the number of phases - single-phase (with one winding connected to a single-phase alternating current network), two-phase (two windings located at an angle of ninety degrees), three-phase (three windings with magnetic fields every 120 degrees).

According to their design, motors can be: commutator, predominantly operating on direct current (universal modern ones can also operate on alternating current), brushless, synchronous, asynchronous. Finally, according to the method of excitation, they are divided into: motors with series, parallel, series-parallel excitation and permanent magnets.

Main characteristics of the traction motor of an electric car

In modern cars, the electric motor can be AC or DC. Its main task is to transmit torque to the vehicle's engine. The main characteristics of the traction motor, in addition to the maximum torque and power, are: rotation speed, current and voltage.

In cars, commutator engines are more often used (one of them, due to its ability to rotate in the opposite direction, can work as a generator). But, in some models, electric motors of other types are installed - magnetoelectric motors, divided into AC and DC motors. Electric traction motors installed in electric vehicles do not differ from other electric motors in design.

Motor-wheel

If at first they used one traction motor for an electric vehicle, the gearbox of which was connected to a transmission, today they are increasingly turning to a motor-wheel. The essence of the concept is that a computer program controls each of the wheels using separate motors. The main advantage is the absence of a transmission, due to which the power plant loses a significant part of its energy. In addition, it is possible to eliminate the hydraulic brake system, the function of which is taken over by electric motors, as well as individual ESP and ABS mechanisms.

Video

Making your own electric car

Our usual gasoline-powered cars are gradually fading into the background. This is due to the fact that electric cars are gaining more and more popularity in society. Indeed, machines powered by electricity are easier to make, use and operate. In addition, a car of this type does not pollute the atmosphere with fuel combustion products, which means it protects the environment. Considering all the advantages of an electric car, the problem of its independent production becomes urgent.

Making an electric car means creating an excellent replacement for a gasoline-powered car. With the help of modern technology, it is very easy to solve the problem of fuel costs. After all, once you invest a tidy sum of money on the elements of your electric car, you will save significantly more on fuel in the future.

Today, many automobile giants produce electric or hybrid cars. But their cost is beyond the reach of the general public, so creating a car powered by an electric engine is an ideal solution for everyone who wants to buy one.

How to make an electric car? Where to begin?

So, are you determined to build your own electric car? Then it is necessary to acquire some components of the future mechanism. Firstly . automobile. A specific model that serves as the basis for a future electric vehicle. That is, creating a machine that runs on electricity with your own hands is a conversion, not manufacturing from scratch.

Secondly . Electrical engine. It is natural that an electric car cannot exist without a heart.

Third . batteries, their charging and housing. An electric car needs to be powered. Batteries can handle this task with ease.

Fourthly. voltage regulator and synchronizers. Your invention can only function on an electric current of a certain voltage. Constant fluctuations can lead to short circuits and completely damage the electric vehicle.

Fifthly. electric gas pedal. Since the car and its operation are built on a different principle, you need a special pedal that will set your final invention in motion.

It would be advisable to consider each component of the future electric vehicle.

Car model

The base of your future car can be almost any car. Small cars are best suited for this, because one of the characteristics of an electric car is lightness. This property is directly affected by the size and material of the base car.

Our VAZ, Zaporozhets, OKA and Slavuta, as well as foreign Fiat 126 and small cars produced before 2000, are best suited to serve as the basis for creating an electric car.

You can create a specific body with your own hands, but keep in mind that this is a labor-intensive and expensive undertaking.

The heart of an electric car

The electric motor must be purchased taking into account the dimensions of the car and the method of connecting it to the car.

If such an engine is connected to a gearbox, then even a motor with low power will do. 5-7 kilowatts is enough to move the car. If the electric motor is connected through the main bridge, then a more powerful motor is needed. There is a pattern: engine power directly depends on the dimensions and weight of the car. A weak electric motor on a small car will provide a travel speed of no more than 75-80 km/h when connected to a gearbox.

It is worth noting that energy costs are independent of motor power and distance traveled. There is a dependence only on driving speed. The faster the car goes, the faster the battery discharges. So feel free to choose a more powerful motor.

Battery

When creating a new generation car with your own hands, opt for a lithium battery. It is this type of power source that can operate without recharging at a speed of 80 km/h for 5 hours. Such batteries are quite durable - on average they can last 5 years. But lithium-filled energy carriers are not cheap.

Lead batteries are a more economical option. They will last less than two years, and only function during heavy traffic for about an hour.

To extend the life of the battery, you need to select them in the right volume. Small power supplies die earlier due to severe wear and tear, as they are quickly and completely discharged when the car is moving. Therefore, it is more profitable to buy a large energy carrier with an extensive resource.

Heating

If, when creating an electric car with your own hands, you plan to use it in cold seasons, you should think about the heating system.

Heating a car with electricity is an expensive proposition. In such conditions, a charged battery is not enough even for one trip. Based on this, it is worth installing a gasoline-powered heater or a seat heating system. For electrical equipment, it is better to buy a separate battery.

Power regulator

The power regulator is one of the main components of an electric vehicle, which regulates the engine's thrust. The most reliable devices from American manufacturers. You can also get a cheaper analogue from China.

The regulator must be selected taking into account the current power. For daily travel, you can purchase a standard 150-volt device.

In addition, instead of a generator, a converter with identical functions must be connected to an electric car created by yourself.

How to make an electric car: instructions

To work productively and quickly, involve others in your venture. The help of acquaintances and friends never hurts, and if they also have useful knowledge and skills, the result will exceed all expectations! If you yourself have enough knowledge in the field of engineering, mechanics and can cope with everything, with friends the process will go much faster

Create an algorithm and work plan that you should strictly adhere to. And also create drawings and diagrams of the future electric car and prepare the necessary materials and tools

- Remove from the car the gasoline engine and everything that does not belong in a car powered by electricity.

- Install the electric motor and connect the gearbox to it. Prepare a place for the batteries, install the power supplies in the rear of the car and connect them. Create wiring and connect instruments and voltmeter

Connect emergency brakes, vacuum pump, converter, control, etc. Power cables need to be laid under the bottom of the car, so make a few brackets first

Create a platform for power supplies at the front of the machine. Install the batteries and fill the transmission with oil.

Check the devices: 12-volt at ignition, vacuum pump, converter at 96-volt power supply. Check engine operation at 12 volts. If everything works, the car is a success!

Children's electric cars

You can create an electric machine with your own hands for your own child, but is it really necessary? There are many battery-powered children's cars on the market today. They are beautiful, bright, convenient and practical to use.

It's up to you to decide, of course. But purchasing a children's electric car is much more profitable than making it.

Price

The picture of self-manufacturing an electric car will be incomplete without describing the costs of its production. If we take into account the cost of all the components of the future electric machine, we get 5000-8000 dollars. But this entire amount pays off when the electric vehicle is used for 2 years.

Therefore, if you have the appropriate skills, capabilities and desire, you can try to make an electric car with your own hands. After all, this is the future of all vehicles.

conclusions

If you are tired of unstable fuel prices and expensive car maintenance, you can create an electric car yourself.

An electric car is a car powered by an electric motor that operates on batteries, unlike common gasoline cars. The movement of the machine is based on electricity. A significant advantage of such a car is that it can be charged from a standard voltage using a regular outlet. This way, you can save money, since electrical energy today is much cheaper than fuel. Servicing an electric vehicle is simple, since you do not need to monitor the oil and antifreeze levels and replace them periodically.

This car is very convenient to move around the city. Constant changes in terrain increase fuel consumption, but intermittent movement has no effect on an electric car at all.

The electric car gradually begins to move and is silent due to the small number of elements that move. Such a machine does not pollute the atmosphere with fuel combustion products. This is the transport of the future!

Subscribe to news

Sources: www.energya.by, electrohobby.ru, motocarrello.ru, ekowheel.com

How to avoid burning out an electric motor?

⌚ — 2 minutes 41 seconds

Electric motor for running crawler crane DEK-321

⌚ — 20 seconds

Electric motor of the crane DEK-321 slewing gear

⌚ — 16 seconds

Electric motor AC-Motoren FCMP 280S-4/PHE Article: IE3AC28S4000

⌚ — 14 seconds

Electric motor AC-Motoren FCMP 315LA-4/PHE Article number: E3AC31LA402

⌚ — 21 seconds

Electric motor AVE 071 4C UHL 4

⌚ — 19 seconds

Electric Scooter Traction Motor

⌚ — 2 minutes 6 seconds

They brought an electric motor of 9 kW 1000 rpm. for Valera

⌚ — 5 minutes 13 seconds

REPAIR OF ELECTRIC MOTOR 6000v. Repair Electric Motor.

⌚ — 1 minute 41 seconds

Elevator SLZ (1976) after replacing the electric motor, lift capacity 320 kg, V=0.71 m/s (m/m Bombay, Zaporozhye)

⌚ — 3 minutes 23 seconds

Electric motor for all-wheel drive clutch pump Haldex 1, 2 and 3 generations 12V

⌚ — 23 seconds

How to choose a used electric motor

⌚ — 13 minutes 45 seconds

Electric motor 2.2 kW 1400 rpm type AD90L4U3 Feet and Flange 380 V, Motor-Gearbox-Prom-KR

⌚ — 58 seconds

Air taxi, ultra-short take-off “Annushka”, electric-powered Yak-40 and flying “AURUS”

⌚ — 15 minutes 14 seconds

Electric motor ELVEM 6T163A2 6SM 63A2

⌚ — 23 seconds

Electric motor ELVEM 6XM 90S2 B35

⌚ — 26 seconds

Electric motor ELVEM 6T3 90S2 (B5 flange)

⌚ — 22 seconds

electric motor from a tape recorder review

⌚ — 1 minute 34 seconds

Commented video:

A large fire in Chaadaevka, Penza region, was captured on photo and video

⇒ “Terrible footage!

I can’t even imagine what it was like to be next to this fire for the person who shot this video, but even sitting at home in front of the monitor, it was not a pleasant feeling. My balcony once caught fire in my apartment, someone from above threw a cigarette butt from above and it flew towards me, only I noticed the fire..." View in full... Added - 08/01/2021 Star-Lord Dance - Come and Get Your Love - Guardians of the Galaxy (2014) HD

⇒ “Good song” Watch in full... Added - 08/01/2021

Korea d 9, - Watch online

⇒ “Very dynamic and exciting!

It was as if I had ridden a bicycle myself. It's sunny, cats, you can hear Russian speech in the background! Dedicated bike paths and beautiful buildings. Thanks for the review. I’ve always dreamed of visiting Korea - a unique and culturally rich country, but in today’s ..." View in full... Added - 08/01/2021 NEW WORKING CHEAT FOR NEXT RP.

SPEEDHACK FOR NEXT RP. BOT NEXT RP ⇒ “You are the best, tell me the cheat code, I threw you 300 rubles” Watch in full... Added - 08/01/2021

MUSIC FROM VIDEOS OF FAMOUS YOUTUBERS [WITHOUT AP] #2

⇒ "top" Watch in full... Added - 08/01/2021

What's wrong with you happening?

(1975) Full version ⇒ “I starred in this film” Watch in full... Added - 08/01/2021