Definition of concepts

Cement is a granular, fine-grained material. It is not a homogeneous mass. This substance is a mound of microscopic elements, between which there is air. Therefore, its density does not have a single meaning. To define this characteristic, two terms are used:

- true density;

- bulk density.

The specific gravity of cement is defined as the ratio of mass in kg to volume in cubic meters. m. Dividing these values gives the desired result. To obtain the first parameter, the mass is taken into account, which consists exclusively of grains of building material without air particles. True density is an indicator found in educational and methodological literature. When determining this parameter, it is assumed that the substance is monolithic.

Bulk density is more important to builders. It indicates the specific gravity, taking into account the air that is between the particles. Powdered substances always take up more space in space. Therefore, its true density will be significantly less.

Structure of cement under a microscope Source docplayer.ru

Volumetric weight of cement

Today, almost all construction work uses cement mortar. For its proper preparation, it is necessary to know some physical characteristics of cement, in particular, its specific gravity and bulk density.

Specific (volume) gravity is the ratio of the weight of a substance to the volume it occupies. In physics, this quantity is called density. But cement is a special substance whose density can change over time. Therefore, in practice, another concept is used - bulk density.

Bulk density is the density of cement, which is in a loosened state. The bulk density for fresh cement varies between 1000 – 1100 kg/m3, for compacted cement 1500 – 1600 kg/m3. For all calculations, an average density value of 1300 kg/m3 is taken. The actual physical density of cement is several times higher than the bulk density, and sometimes its value reaches 3200 kg/m3.

What determines the specific gravity of cement?

It is known that freshly made cement has the lowest density. The fact is that each particle of cement during grinding receives an electrostatic charge, and therefore is repelled from neighboring, equally charged particles. But during transportation, pouring, storage, the electrostatic charge is lost, the cement becomes compacted, which means its density increases. Its specific gravity also becomes larger.

The volumetric weight of cement is significantly influenced by its production technology, that is, grinding. It determines the size of cement grains, and, consequently, the total volume of air voids formed between them.

Storage conditions can also affect the specific gravity of cement. If cement is stored in damp, damp rooms, then moisture gradually displaces the air located between the particles of the substance, and its weight increases significantly.

The type and brand of product affects the density of cement. Today you can buy plasticized cement, hydrophobic, alumina and others.

What is the specific gravity for different brands of cement?

When, to calculate the weight of cement, we take the accepted average value of 1300 kg/m3, then approximately 0.038 m3 or 30 - 38 liters of cement are poured into a bag weighing 50 kg. Then the mass of 1 m3 of cement will be approximately equal to 1300 kg. For different brands, the weight of cement will be slightly different.

If for each specific brand of cement we take not the average value of its bulk density, but a more accurate one, then smaller errors will be made when preparing the solution.

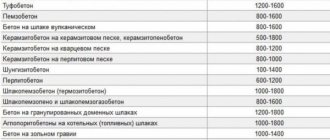

| Cement brand | M100 | M200 | M300 | M400 | M500 |

| Bulk density(kg/m3) | 700 | 900 | 1100 | 1200 | 1300 |

How do the properties of a material change in the external environment?

The density of Portland cement is not a static value. It changes depending on the conditions in which the material is located.

The position of particles is greatly influenced by static electricity. Upon contact, microscopic elements accumulate a charge of the same name. According to the laws of physics, such particles repel each other. As a result, the volume of material will increase slightly.

Therefore, freshly prepared cement powder has the lowest density. The same indicators apply to material that was recently shipped. During transportation, the bulk substance is compacted. Under the influence of vibration, microscopic particles occupy a position that implies maximum filling of voids. Bulk density also increases during long-term storage. Over time, static electricity “dissipates”, which leads to compaction of the mass.

Transportation of cement powder in bulk Source perevozka24.ru

See also: Catalog of companies that specialize in facade and finishing materials.

Practical meaning of the specific gravity of cement for the developer

This characteristic has informational and applied significance, which is used to calculate components for the preparation of concrete and cement mortars, and also characterizes the quality of a particular binder and the strength of the structure being built on its basis.

Due to the fact that cement as delivered consists of dust particles and air bubbles, and hardened cement (after mixing with water) is a stone, two types of density (specific gravity) of cement are considered: bulk and true.

The true density of cement is a constant value, ranging from 2,700-3,500 kg/cm2, depending on the brand and type of binder. Bulk density, which is a variable value, is in the range of 1,100-1,600 kg/m3, and depends on the following objective factors:

- Type and brand of cement;

- Production technologies (wet, dry or combined);

- "Freshness" of the substance. Freshly ground cement has a minimum density. When transported over long distances or long-term storage, cement cakes, and accordingly the density (specific gravity) increases;

- Storage conditions. Cement stored in a special tank - a silo - fully complies with the guaranteed parameters, which cannot be said about cement stored in paper bags or big bags.

The bulk density of the binder is of wide practical importance. Concrete plants have laboratories to accurately determine the specific gravity of each specific batch of cement, and for the convenience of calculations for private developers, its average value is accepted - 1,300 kg/m3.

How much does cement weigh?

The specific gravity of cement depends on many factors. On average, this figure is 1100-1600 kg/cubic meter. m. The density value is influenced by the following factors:

- Brand . The higher it is, the greater the specific gravity.

- Production technology. The method of making cement affects the size and shape of its constituent parts. Therefore, it is natural that it will have different physical properties.

- Composition of the building mixture . It may contain hydrophobic additives and various additives, which affect the physical characteristics.

- Compliance with storage conditions . Hermetic containers and optimal microclimate parameters in the room where the material is located ensure that it has the characteristics declared by the manufacturer for a long time.

- Date of manufacture . “Fresh” cement has a higher density than material that has been significantly compacted over a long period of time.

Proper storage Source 1nerudnyi.ru

Weight of cement mortar in 1 m3

To find out the weight of a solution M100, for example, or M400, just look at the corresponding data in a special table. Although there is no direct relationship between weight and strength, the rule generally works is that heavier mixtures have greater density, and this tends to increase proportionally with the level of strength.

Types of concrete by specific gravity:

- Particularly light (grades from M50 to M75) with a specific weight of up to 500 kg/m3 - the material contains cement and fillers that form a structure that is 85% voids. Typically, such concrete is used for thermal insulation; it is fragile; in order to increase this indicator, plasticizers can be used. Porous structures are poorly resistant to water and frost, so they require mandatory waterproofing. Lightweight (grades from M100 to M200) with a specific gravity of 50-1800 kg/m3 - the mixture is used to create special building blocks with a porous structure. Pores are formed through the use of cellular fillers or the introduction of special foaming substances into the composition. Heavy (grades from M200 to M400) with a specific gravity from 1800 to 2500 kg/m3 - ordinary concrete, which is most popular in construction. Load-bearing structures are erected from it. The weight of the material directly depends on the proportion of sand and coarse filler, as well as the density of the latter. Thus, the weight will be different when using gravel and granite filler in the same volume. Particularly heavy (grade M450 and higher) with a specific gravity from 2500 to 3000 or more kg/m3 - such concrete is prepared with metal fillers. The solution is used to create special-purpose structures to prevent the spread of radioactive radiation through walls.

Currently reading: Monolithic frame made of reinforced concrete

The relationship between the type of concrete and the type of filler: Lightweight concrete is made using foaming agents (foam concrete), aluminum powder (aerated concrete), tuff, expanded clay, pumice. Lightweight concrete - use slag concrete and similar fillers. Heavy concrete - used mineral fillers (gravel, quartz sand, crushed stone, etc.). Particularly heavy concrete - fillers based on mineral groups (limonites, magnetites, barites and others). When performing calculations of concrete/reinforced concrete structures, SNiP 2.03.01-81 and GOST 25192-82, which regulate the physical and technical properties of concrete (density among them), are taken as a basis. When calculating the weight of concrete in practice, remember the following nuances: The weight of the solution and the hardened monolith are different, since water evaporates during the hardening of concrete. The density of the material is largely determined by its internal structure and fillers. The final mass of the concrete mixture also depends on the method of its preparation - manual kneading usually involves lower density compared to the mechanical method. Using a deep vibrator to compact the mixture, for example, M100, the specific weight of the material increases, since the density is higher.

The final density is very important to know when designing and creating construction projects.

What does specific gravity depend on?

Specific gravity is an indicator of mass, which is calculated as the ratio of the weight of the material and the volume it occupies (in this case, 1 cubic meter of concrete is taken as a guide, which can weigh differently depending on all of the above factors).

The specific gravity of concrete increases in proportion to the increase in the density of the material (in fact, density is determined in kilograms per cubic meter). Density determines the scope of use of the concrete solution. Thus, the densest mixtures are used to make strong reinforced concrete structures, loaded and critical elements of buildings. Where the loads are not very large, less dense mixtures are used.

The specific gravity is influenced by the grain composition of the filler and the water content. To increase density, plasticizers can be used - special additives that regulate the properties of the mixture by reducing the need for concrete in water while maintaining its mobility (which is very important for comfort in work).

Despite the fact that there is no direct relationship between specific gravity and the properties of the material, many important parameters are determined by this criterion. Thus, lightweight porous concrete with a minimum specific gravity is usually fragile and loose, acting as materials for heat/sound insulation, but not as elements of load-bearing structures. Dense and heavy concrete is extremely durable and moisture/frost resistant.

The specific gravity of concrete can range from 300 to 2500 kilograms per cubic meter. Ordinary cement-crushed stone mortar belongs to the group of heavy concretes and exhibits a specific gravity of around 2400 kg/m3. When choosing concrete for repair and construction work, the following factors are taken into account: the low weight of concrete implies greater porosity and better insulating properties, but low strength; large mass gives poor insulation, but high strength and a minimum of air in the structure.

What affects the weight of a cubic meter of concrete solution: Type and characteristics of the filler. Size of filler granules. Method and quality of mixing. Volume of water. Percentage of air in the structure, number of voids. Specific gravity is not usually used as a defining characteristic in construction. Most often, volumetric weight and specific indicators of density, resistance to loads and various impacts are taken into account.

Density value for different types of cement powder

The regulatory construction documentation indicates the following density indicators for different types of cement (true/bulk, kg/cub.m):

- pozzolanic – 2800/900;

- slag – 2900/1200;

- aluminous – 3100/1100;

- Portland cement – 3200/1200.

The bulk density of M500 cement is 1300 kg/cubic. m. This is a standard value for a reference material that does not contain additives and is stored under ideal conditions. The bulk density of cement M400 is 1200 kg/cubic. m. For material of the same brand, which is characterized by a long setting time, this figure is 1500 kg/cubic. m.

How to calculate the weight of cement for preparing building mixtures

When calculating the necessary ingredients for preparing concrete or mortar, novice builders have difficulties. The amount of mixture for work is determined in cubic meters, and cement is measured in kilograms. It is sold in bags in standard packaging of 25 and 50 kg.

Cheat sheet for preparing different grades of concrete Source cemmix.ru

To calculate how much a bag of cement weighs (more precisely, its volume), use the average density - 1300 kg / cubic meter. m. Therefore, 1 cubic. m of material weighs 1300 kg. A 25 kg bag has approximately a volume of 19 liters, a 50 kg bag has a volume of approximately 38 liters.

A bucket of cement (standard 12 liters) will weigh 15.6 kg. The mass of the material can also be determined experimentally. It is enough to weigh the mixture directly in the bucket, after subtracting the weight of the container. If the measured value differs greatly from the calculated value (15.6 kg), the quality of the material can be suspected. To determine its approximate density, the resulting weight must be divided by the container volume.

How much does a bucket of cement weigh?

How much does a bucket of cement weigh?

- The bulk density of cement is about 1250-1300 kilograms per 1 cubic meter. The volume of the bucket is 10-12 liters, let's assume that we have a 10-liter bucket, the weight of cement in a full bucket will be about 13 kilograms, the bucket weighs about a kilogram, it turns out that a 10-liter bucket of cement will weigh 13-14 kilograms.

- To find out the weight of a bucket of cement, you must first decide on the brand of cement, because no matter how outwardly cement of different brands may look similar to each other, they still differ in density and in extreme cases this difference is very noticeable. Portland cement is considered the lightest, but it is also the most common and cheapest among its analogues. The weight of a bucket of Portland cement, depending on the brand, will be from 10 to 15 kilograms. Portland slag cement weighs approximately the same - 11-12.5 kilograms. Another common brand of cement that hardens in water, alumina cement weighs 10-13 kilograms in a loosened state, and the same cement GC 400-600 in a compacted state weighs 16-19 kilograms in a 10-liter bucket.

- To find out the weight of cement in a bucket, you need to multiply the volume of the bucket in liters by the bulk density of the cement. Each bucket has its own volume, and the bulk density of cement is 1200 - 1300 grams per liter. So make calculations from these data.

- An average bucket of cement will weigh about 12-13 kilograms. This is if we take into account the standard 10 liter bucket, which can often be found at construction sites. Now the construction season is underway and the question will be relevant.

- What kind of cement are we talking about, do you need dry cement or a ready-made mortar? The finished weight depends on its components and density. And in dry it depends on the size of the bucket. In general, a 10-12 liter bucket weighs 15 kilograms.

- In general, the average weight of a bucket of cement is about twelve kilograms. I wouldn’t say that it’s not enough, but in principle it’s not that much. Although it depends on what kind of construction work you need cement. You will need a lot of it to fill the foundation!

- In order to find out the amount of cement in kg in one bucket, you must first find out what the density of the cement is. And the density of cement is 1200 g per cubic centimeter.

Now you need to decide on the volume of the bucket. The bucket can have a volume of 7, 10, 12, 15 and 20 liters (that is, cubic centimeters).Now you need to multiply 1200 by the volume of the bucket and divide the resulting figure by 1000.

Usually a 10 liter bucket is used.

1200 * 10 / 1000 = 12 kg of cement in one 10 liter bucket.

- If we consider that the average bulk density of cement is 1200 kg/cm, and the volume of a bucket in liters is 10 kg, then we can easily calculate the weight of a bucket of cement.

To do this, we need to multiply the density of cement by the volume of the bucket in liters.As a result, we get the weight of a full bucket of cement.

- Experience shows that one fifty kilogram bag of cement can be poured into 4 buckets with a volume of 8 liters. From here it is easy to calculate that an eight-liter bucket of cement weighs approximately 12.5 kilograms.

- It is not clear why there is such a need to know the weight of a bucket of cement. Why do you need this? After all, mortars are prepared not by weight, but by proportions. To find out its weight, you just need to weigh it. But I’ll tell you as a builder, its weight is about twelve - twelve and a half kg.

info-4all.ru

Rules for performing calculations

Calculating the bulk density of a material is quite simple. To do this, you do not need to use complex equipment and a specialized laboratory. To determine the necessary parameters, you will need the following devices:

- funnel , the hole in which is sufficient for the free passage of mixture particles;

- graduated cylinder - for measuring the volume of material;

- scales - to determine the mass of a bulk substance.

Briefly about the main thing

Experts distinguish true and bulk densities of cement, which differ significantly from each other. Also, this indicator is influenced by many factors - mixture composition, duration and quality of storage, production technology, strength brand.

Determining the specific gravity of cement powder is quite simple at home. For this you will need a scale and a measuring cylinder. Also, the approximate density of the material can be determined directly at the construction site by weighing a bucket filled with cement.

Ratings 0