Types of plasticizers for masonry mortars

When constructing conventional masonry, cement or cement-lime based mortar is used to connect bricks or silicate blocks to each other. In addition to the requirements for compliance with the regulations for the preparation of the mortar mixture, it must be plastic, mobile and elastic in order to lie evenly on the surface of the brick or block. To impart these properties, plasticizers are used - special substances that are introduced into the solution to improve its technical and operational characteristics.

Making masonry mortar correctly

Masonry mortar is a mixture of components. These include a binder, filler, solvent and various additives.

The binder is responsible for the hardening of the solution, which occurs during the hydration reaction. Cement or lime is used as a binder in masonry mortar.

Filler.

Increases the volume of the solution and improves its mechanical characteristics. The most common filler is sand with a grain fraction of up to 2 mm. Sometimes fiber is also used. It relieves internal stress in the solution during shrinkage and reduces the risk of cracking.

Fillers with a coarse fraction, such as crushed stone or gravel, are not suitable for masonry mortar and are used mainly in monolithic structures.

Solvent

. To dissolve the dry ingredients, water is added to the mixture. Moreover, such water must meet the requirements of a separate standard - GOST 23732-2011. Using it, you can use drinking, ground, technical and sea water to prepare the solution. But it is prohibited to use peat, waste or swamp water.

Supplements

To improve the technical properties of the solution, plasticizers, antifreeze additives, hardening accelerators and even coloring pigments are added to it.

The importance of quality composition

The mixture for laying fireclay bricks is a viscous substance that contains several components that ensure fastening of structural fragments. The right mixture has the following properties:

- resistance to external factors;

- reliable bonding with brick;

- easy application - for laying a uniform thin layer;

- insulation characteristics.

The brand indicates the compressive strength, for example, M50-50 kg/cubic meter. cm.

Types of plasticizers

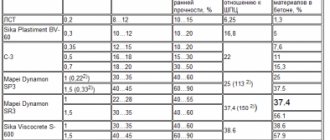

Plasticizers for masonry mortars are produced in the form of a dry powder, a liquid concentrate, or completely ready for use without the need for prior dilution with water.

The main active ingredient is a surfactant (surfactant). As part of imported plasticizers, mixtures of sodium salts of fatty carboxylic acids or carboxylates (the basis of ordinary soap), as well as melamine resins are used as surfactants. Domestic plasticizers are produced on the basis of by-products during the production of cellulose - lignosulfonates. The latter are in no way inferior to carboxylates, and in some respects they are even superior to their foreign “brothers”.

Attention! Very often, in the process of preparing masonry mortar, washing powders, liquid soap or dishwashing detergents are used as a plasticizer. This is absolutely forbidden to do! The absolute majority of household chemicals contain, in addition to surfactants, salt-forming sulfates. Over time, this can lead to sulfate corrosion of concrete and destruction of the masonry.

Types of solutions

There are several types of most commonly used bricklaying mortars:

➤ Lime mixtures

. Most believe that cement mortar is the ideal option for laying bricks, but there are times when a more plastic composition is needed to build a structure. In this case, it is better to use a lime mixture, which consists of quicklime ground lime and sand. All elements are mixed until homogeneous, then water is poured in. The solution mixes very well, there should be no lumps or any foreign impurities left in it.

➤ Cement mortars

. The main components are sand and cement. The steps for preparing this solution are as follows: first, dry cement and sand are mixed, then water is slowly added, then the whole mixture is thoroughly mixed until a thick mass is obtained. However, such a mixture is not the most ideal option, because the cement mortar is inactive, rigid, and excessively strong.

➤ Cement-lime mortar

. The main components of this mixture are cement, lime and sand. The preparation steps are as follows: slaked lime must be diluted to the consistency of thick milk, then filtered. Cement and sand are mixed dry, then lime mortar is added to this mixture. All components are carefully mixed. This mortar is recommended for laying all types of bricks.

You can buy mortars for bricklaying in Astana inexpensively, thanks to the offers of our company.

You can also find various construction chemicals in our assortment.

Many repairmen and professional builders recommend the use of chemical-based compounds. Thanks to this, the time required for construction work is reduced. Our catalog contains such types of construction chemicals as:

Plasticizers. These are additives to concrete that give it special characteristics (increase fluidity, waterproofing, impart durability, etc.). Plasticizers are mixtures that increase the ductility and flexibility of various materials, and also improve their performance.

Fugue. Filling the seams is necessary both to give the walls a beautiful appearance and to add durability. Fugue is a special composition that is used to fill seams. Fugue increases the elasticity of seams, adhesion, eliminates shrinkage, and gives the seams water-repellent properties.

Types of plasticizers for concrete

Based on the principle of action, antifreeze additives in concrete are divided into three groups:

- Antifreeze.

They lower the freezing point of water in the solution, facilitating the normal setting process. In addition, they maintain the plasticity of the finished composition during transportation, which is especially important when working with large masses of concrete. - Additives based on sulfates

(iron, aluminum and other metals). Their special property is the ability to generate heat. After adding sulfate additives to the solution, they begin to actively warm up the building mixture, preventing the crystallization of moisture. In addition, their use helps to transform the components of the solution into a homogeneous substance and accelerate the hydration of concrete. - Accelerators

(electrolyte supplements). They help accelerate the hydration of cement by increasing the rate of dissolution of silicate components, thereby reducing the setting and hardening time of the solution.

| Froststop -25 Complex additive | Hardass -25 Liquid complex additive | Hardass -25 Dry complex additive |

| Find out the price | Find out the price | Find out the price |

Features of “winter” concreting using antifreeze additives

The main factors complicating the process of laying concrete in winter are:

- Slowing down the process of cement hydration at sub-zero temperatures, which accelerates its hardening.

- Expansion of frozen water, which reduces the strength of concrete (when water crystallizes in the hardening mixture, pressure develops, destroying the structure of the composition that has not yet set and reducing its performance characteristics).

That is why adding antifreeze additives to the solution allows you to avoid these problems and continue construction work in cold weather. However, in order for winter concreting to be successful, it is necessary to take into account the characteristics of a particular additive and other nuances. To do this, before adding a plasticizer to a cement mortar, you need to carefully read the manufacturer’s instructions, especially with regard to the composition of the product and proportions (additives presented in the form of aqueous solutions have different water concentrations, which directly affects the thickening time of the solution). For example, concreting metal structures covered with steel requires a special approach. Only a nitrite-nitrate additive can be added to such a solution.

It is also worth paying attention to the fact that antifreeze additives can be added either to a cold solution or to a solution preheated to room temperature. This depends on the task at hand and the possibility of delivering the mixture in liquid form to the site of application. However, as practice shows, it is better to concrete with heated material, since when applying the mixture to cold walls there is a risk that when it warms up, the entire layer will fall off. In addition, you need to take into account that an unheated solution will take much longer to harden.

Cement-lime

It differs from cement sand by adding lime to the composition. Hardening time – up to 5 hours, at temperatures above +25 – 1 hour.

For preparation, cement M-400 or M-500, fine sand, and hydrated lime are used. To prepare 1 cubic meter you will need 191 kg of cement, 1760 kg of sand, 106 kg of lime and 470 liters of water. It is also prepared in a concrete mixer.

First, pour 2/3 of the water, then add cement and lime, after everything is mixed, add the remaining water and sand. Stir for at least 3 minutes; clay can be added for plasticity.

Masonry mortars and their types

Masonry mortars serve as the main connecting material when constructing the walls of a house. The seams are the most vulnerable point of the masonry, since destruction and the appearance of cracks usually occur along the seams. To extend the service life of a building, it is necessary to select high-quality masonry mortar that meets all GOST requirements.

Masonry mortar is an artificial stone material obtained after hardening of a mortar mixture, which includes a binder, sand, water and various additives. Masonry mortars are used for rubble, stone and brick masonry.

Sand for masonry mortar should be no larger than 2.5 mm.

Organic substances (technical lignosulfonates - LST, sulfite-yeast mash - SDB and soap naft) and inorganic (volcanic ash, ash, ground slag, etc.) can be used as additives. Winter solutions contain antifreeze and air-entraining additives.

Technology for producing cement-based masonry mortar

Steps for making the mixture by hand:

- Prepare tools and equipment - a large mixing container, a shovel, a trowel, as well as all the components of the mixture.

- Dry components are mixed in a container - cement, sand, pigments, if they are in dry form, and only then water is gradually added. On average, it is assumed that the amount of water per 1 kg of cement binder should be 0.8 liters.

To prepare large volumes of solution, use a concrete mixer.