Laying the floor yourself

This may seem like a difficult point only at first glance, but in reality, we have only three base options for a foam block structure:

Moreover, with all their cardinal differences, in our case they simply slightly change the order of work and how to make floors in a house from foam blocks at the time of installation of the sheathing. However, let's talk about everything in order.

Selection of base and materials

Let's decide on the choice of foundation, which we will take as an example, and since it is for the foam block version of the structure that the tape and monolithic base is most often used, we will talk about the lathing in turn, taking into account the design features of each foundation.

Important! Let us immediately note that we will use wood in the construction of the floor, and the conversation will be strictly about the draft version.

The first step we will have is to select the material for the draft, and since we have agreed on wood, we will need:

Depending on the type of base, a screed may be required, but we'll talk about that later. Now let's start with the strip foundation for a foam block house.

Tape base

A foam block structure does not always require a strong foundation, so a strip foundation is ideal for construction technology.

Let's take a step-by-step look at how to make a floor in a house from foam blocks, taking into account the strip base:

Let's make a small digression here.

To attach beams to concrete walls, we need:

Now that we have attached the perimeter beams, we can begin the sheathing.

Advice! Depending on the future floor covering, we determine the level of the first floor covering, that is, if we still have insulation and laminitis, we must reach the zero level at which the door will open normally.

Next, we begin to install the beam on the shelves, and we try to ensure that it lies perpendicular to the short side of the room, if we have a rectangular room. That is, we place them by width, not length. (see also the article Is it necessary to insulate a house made of foam blocks: expert advice)

We keep the step at 60 centimeters, and fasten the beams with wood screws. Naturally we put them on the edge.

Advice! All wood, even though it is dry and we have waterproofing, must be treated several times with an antiseptic to prevent the occurrence of mold and mildew and rot in the future.

You can cover the beams with either a floorboard or plywood. The main thing is that we get a fairly flat surface on which we place a vapor barrier film and then a coating of our choice. That is, the further instructions refer to another work.

Advice! If the area of the rooms is large, it will be necessary to arrange additional supports for the timber. This can be done using bricks or foam block remains. You will just need to make one more marking, at the very beginning of the work, dig holes for supports, and pour concrete into them. After a few days, use bricks or blocks to bring the support to the required height, waterproof it and lay the timber on the surface. In this way, sagging can be avoided.

Monolith

With a monolithic foundation, installing a floor in a house made of foam blocks is a much simpler process. Here we need to bring the draft to the desired level and make it even.

By the way, if the monolith itself is already flat, then for many specialists this is the floor. And indeed, all we have to do is cover it with waterproofing, and we can already install the covering, for example, laying tiles, and even laminate.

We will consider the option in which the monolith is flat, and we will proceed immediately to the sheathing:

When installing beams we can use two simple methods:

Not to say that this changes the price greatly, however, from the point of view of speed of work, the second option is, of course, more preferable.

READ How to set up an account on a Huawei phone

Next, we lay insulation, mineral wool, and cover everything with plywood or floorboard. (see also the article Insulating a foam block house - how to keep warm and not spend all the money)

Interesting option

There is another interesting option for constructing a screed in the case of a strip foundation, when instead of a cushion of sand and expanded clay we use a floor made of foam blocks. The material has excellent thermal insulation properties, so the rough version is warm and durable.

Monolithic foundation

If the foundation is a monolith, then the process is greatly simplified. The main thing is to bring it to the required level and make it even. In this case, you will need to make a screed. After leveling the monolith, you need to cover it with waterproofing, and then move on to the decorative coating.

Please note that when waterproofing, concrete is coated several times with mastic or covered with dense polyethylene. Roofing felt can also be used for this purpose. The beams are treated with an antiseptic, and only after that the beams are installed, which in this case can be arranged in two different ways:

- According to the “lighthouse” principle, building materials made of wood are laid on concrete, after which the beam is fixed, and the concrete connects it to a monolithic slab.

- When laying and fastening beams, metal corners are used.

You can see in the photo how the fastening is done in a house made of foam blocks.

Then you will need to lay insulation, mineral wool, and lay plywood or board on top. Parquet boards, laminate, linoleum, etc. can serve as decorative coverings.

A promising alternative

In addition, of particular interest is the device of a screed with a strip foundation, in which a cushion of sand and expanded clay is replaced by a floor of foam blocks. This draft version is considered warm and durable.

The choice of wood as a building material is due to its good performance characteristics. In the video you can get acquainted with a detailed description of all the stages of laying the floor of houses made of foam blocks with different types of foundation.

How to make a floor in a house from foam blocks

One-story house made of foam blocks.

Buildings made of cellular concrete belong to light low-rise buildings; for a house with a basement, slabs - hollow cores or timber - are used as a floor.

In any case, the floor in a house made of foam blocks must have the characteristics necessary for comfortable and safe living, these include:

Insulation of houses made of foam blocks

You can insulate the walls of a house made of slabs with your own hands.

Houses made of foam blocks perfectly insulate heat. This is due to the porosity of the material: air filling small hollow formations from the inside perfectly maintains a certain temperature. However, to avoid unpleasant surprises in winter, it is better to carry out insulation in advance.

If the building is insulated from the inside, the material can subsequently be easily replaced after its service life has expired. But in this case, the total area of residential premises is reduced, so more often the owners decide to insulate the facade from the outside.

In addition, the outer cladding protects the walls from the effects of precipitation and temperature changes outside.

External thermal insulation

Foam block houses are insulated from the outside, usually using tile materials.

External insulation of the facade of a house made of foam blocks is carried out in several stages:

- surface preparation;

- installation of thermal insulation material;

- seam processing;

- plastering of the structure and final decoration.

Before you start insulating the facade of the house, it is worth preparing the surface.

When preparing walls for insulation from the outside, all old paint and other parts are removed from them. The plaster is cleaned, and irregularities are treated with mortar or knocked down. If it is impossible to get rid of any protrusion on the surface, you need to scrape out a hole on the insulation board in the appropriate place.

The insulation is attached to the walls of a foam block house using special glue. In this case, the slabs must be arranged in a checkerboard pattern, aligned with the level of the plank previously installed near the foundation.

Important! During installation, special attention should be paid to the edges of the slabs: the more thoroughly they are coated with glue, the more securely the joints will fit together from the inside. The insulation of the walls of a private house must be of the highest quality, so all seams are carefully blown in with polyurethane foam to avoid the spread of drafts and heat losses

The insulation of the walls of a private house must be of the highest quality, so all seams are carefully blown in with foam to avoid the spread of drafts and heat losses.

Before applying the plaster, a reinforcing mesh is attached to the outside wall of the house. This design creates better protection for the facade.

About walls and slopes

Before insulating the house, you need to check how correctly the ebbs and slopes of windows and doors are installed. Their extension should be wide enough so that there is enough space to install a heat insulation slab. If problems arise with this, it is better not to waste time, but to install them again.

In principle, there are no difficulties when insulating these structural elements. The main thing is to clearly define the dimensions.

Ceilings and floors

Insulating a foam block house is not just covering the facade. Cold can also penetrate through the floor - from frozen ground. Therefore, thermal insulation of it and the foundation walls is very important.

Most often, the floors of foam block houses are made of concrete. In this case, a wooden sheathing is built on its base, inside which expanded clay is poured - a lightweight clay material with very low thermal conductivity. After this, the structure is poured with concrete and covered with parquet or linoleum.

When insulating the roof and ceiling, you need to decide how the attic will be used. If a living room is planned in it, careful insulation of the roof and walls from the inside is necessary. Otherwise, you can limit yourself to insulating the attic floors. To do this, several layers of cardboard and sawdust are placed between the beams.

Important! It is better if the beams are completely covered with insulation and do not protrude above it

Warm floor

Floor insulation technology.

Recently, many owners have decided to install heated floors in their homes. There is an easy and inexpensive version of this system - electric. You can cope with it without the help of specialists.

Before installing the system, waterproofing in the form of polyethylene and thermal insulation, which most often is simple foil, are laid on the floors. Then the heating cable is installed, which is subsequently filled with concrete. The thermostat, with which the temperature of the floors can be adjusted, is located on the wall.

Thus, insulating the walls, facade and other elements of a private house made of foam blocks both inside and outside is a fairly simple process. The materials used for this are affordable, and the technology is no different from conventional decorative cladding.

Timber ceiling

Wooden beams are a reliable option for flooring. This material is durable, environmentally friendly, convenient and easy to install; in addition, an important selection criterion is the price, which will save significant money.

Floor beams for flooring in a foam block house.

The basis of the floor are beams made of coniferous or hardwood, their dimensions are determined independently, based on the expected load, the dimensions of the beam can be as follows:

It is not recommended to use a larger cross-section of timber; this will not improve performance characteristics, but will significantly increase the cost of the structure.

Important! The wood must not contain rot or cracks; before laying, the beams are dried and treated with antiseptic agents to protect against rotting and fire-fighting impregnations.

To secure the beams to the foundation during pouring, the following embedded parts are installed:

Wooden floor technology

Ready-made mixture for screeding on wooden or concrete bases.

If you make the flooring in a house using foam blocks yourself, then you need to know some basic points about preparing the base for installation:

Important! The farther apart the logs are installed, the greater the danger of the covering deflecting, so the maximum distance between them should be no more than 50–60 cm.

Wooden floors in a foam block house, features and installation technology

A ceiling is a horizontal element of a building that serves as a division between floors or between the inside of a building and the attic. It undergoes serious mechanical loads in the form of partitions, interior items, and people located on it. Wooden floors in a house made of foam blocks have a number of advantages, thanks to which they are superior to almost all of their analogues.

Wooden flooring in a house made of foam blocks

Characteristic

The main advantages of wooden floors include:

- The ability to “breathe” - we should not forget that wood is a living and warm material that can provide the most comfortable microclimate inside the house; no other building material can boast of this;

- Lightness of the material - thanks to this advantage, the installation of wooden floors can be easily handled even without the use of heavy equipment. Do not also forget that for buildings made of foam blocks, the weight of the floors is of great importance;

- Price – in aggregate, the total cost of wooden floors is much lower;

- Assembly speed - in terms of installation speed, only ready-made reinforced concrete slabs can compete with wooden floors, the loading of which requires heavy equipment and, again, due to its weight, is not a suitable option for buildings made of foam blocks;

The disadvantages of this material include:

- Susceptibility to bugs and mold;

- Relatively short service life;

- Requirement for maintenance during operation.

Installation of wooden floors in a house made of foam blocks

Houses made of foam blocks have recently become increasingly popular, this is largely due to the low cost of the material, its light weight, as well as the simplicity and high speed of constructing buildings from it for various purposes. The construction of wooden floors in a house made of foam blocks is generally not much different from their construction in buildings made of any other material and comes in the following types:

- With continuous flooring - represents a continuous laying of timber as a floor; it is rarely used due to the high cost and not the best insulating characteristics;

- With 1 flooring - the simplest option for installing wooden floors, has practically no sound and heat insulation properties;

- With a simple roll;

- With trimmed knurling - this is a variant of simple knurling, but with a hem;

- With filing without knurling;

Types of flooring

Floors in a house made of foam blocks can be made from various materials; let’s look at the most popular types.

Wooden floors

Construction of the floor on wooden floor beams.

They are laid on the subfloor, using a floor strip 27–32 mm thick and 120–150 mm wide. Before laying, floorboards are coated with an antiseptic composition on three reverse sides to protect against rot, insects, and microorganisms.

After installing the floor, the boards must be planed to level the surface, then dusted off and a special impregnation applied, after which they can be painted or covered with waterproof varnish in several layers. If you plan to lay parquet, then a continuous flooring made of chipboard, thick plywood or OSB is made under it along the beams.

Linoleum

This is the most common and relatively inexpensive material, it is easy to install, easy to cut, and does not require special preparation or special devices. The variety of colors, sizes and types allows you to choose a coating for any room, style, or interior.

It can be laid on either a wooden or concrete base, but for the second it is advisable to take insulated linoleum, produced on a special substrate. Before laying out, the base must be leveled, potholes in the concrete must be repaired, protrusions must be knocked down, debris must be removed and the surface must be dedusted.

Important! For a more even installation without waves and bubbles, the linoleum must be spread on the floor and allowed to rest for 24 hours.

To avoid shifts, the coating can be glued to the surface completely or only the seams can be coated, aligning the stripes with the pattern before applying the glue.

Laminate

Laying laminate, tightening strips using clamps.

Laminated boards are deservedly in demand as a reliable and high-quality floor covering:

If you do not know how to make a laminate flooring, then the detailed instructions included will help you easily implement your plan.

Ceramic tiles or porcelain tiles

This is the most popular material for rooms with high humidity or high traffic, such as a kitchen, bathroom, hallway, corridor, veranda or terrace. Although now the trend is in bedrooms and living rooms with ceramic tiles laid on the floor in a design that matches the interior.

READ How to set up fireworks in summer

Porcelain tiles are resistant to abrasion, accidental impacts, and frequent washing. It is non-toxic and looks great throughout its entire lifespan. From the huge number of collections offered by manufacturers, you can always choose the one that will decorate the interior of your home.

Floor tiles are laid using the following technology:

Leveling the horizontal plane of the laid tiles using a level.

Self-leveling floors

This is a seamless polymer coating that is made by filling the base with a special composition based on polyurethane, epoxy or cement-acrylic components.

This coating is used on hard, durable, perfectly leveled bases; wooden floors will require thorough preparation, and even then there is no guarantee that the quality of the fill will be at a sufficient level.

To install self-leveling floors, the following activities are carried out:

Pie of self-leveling floor device.

Important! To obtain a perfectly smooth, homogeneous surface, air bubbles are removed from the mixture by running a special roller with spikes over the filled floor.

If all the requirements and recommendations are met, the self-leveling floor will delight the owners with its beauty, smoothness and durability for many years, and if the existing paint becomes boring over time, then you can always pour a new one over the old coating, painting it a different color or creating a 3D floor.

In conclusion, we can say that the choice of type of flooring depends only on the desires and capabilities of the owner, but we hope that the information provided, as well as photos and videos in this article, will help you make the right decision.

Source

Advantages and disadvantages of aerated concrete floors in the house

In a house made of aerated concrete, you can make a base for finishing coating using different technologies. But let's start the conversation with the one that involves constructing a floor from aerated concrete blocks. For this purpose, thermal insulation panels AEROC Energy (format 600*200*100 mm) or BONOLIT D200 (format 600*250*100 mm) can be used. Their length is standard and very convenient for installation on joists with a pitch of 600 mm.

The height of the block - also known as the width when it lies flat - differs slightly (200 or 250 mm). The thickness can be selected according to calculation: the minimum size is 100 mm, but if necessary, thicker blocks can be used - 150 or 200 mm. The weight of the 100-thick panel is only 3.09 kg. Physical and mechanical characteristics make the material one of the best for floor insulation.

Let's compare the properties of aerated concrete panels with extruded polystyrene foam slabs, which are most often used for floor insulation:

Note: Floors can be installed either on joists or on a cement screed poured over a heat-insulating layer. If you use ceramic tiles (or porcelain tiles) with proper waterproofing under the adhesive layer as a finishing coating, even water spilled on the floor will not be able to penetrate the floor cake. And its heat transfer in this case will be most effective.

The design of the floor depends on the foundation

The structuring of the floor pie of the first floor depends on the type of foundation of the house, and on the floors - on the design of the floor. The chosen finishing material also matters, but the main thing is a strong and well-waterproofed base.

Plate

The best conditions for constructing a floor are created when the house is built on a slab foundation, since in this case there is a ready-made base for laying insulating blocks. That is, in this case there is no need to make a subfloor in a house made of aerated concrete. A special underfloor heating layer is laid on top of the thermal insulation, heating elements are installed, and a screed is poured.

Ribbon

Before insulating the floor in a house made of aerated concrete with a strip foundation, it is necessary to pour a rough foundation of heavy concrete class B12.5 over the ground. The thickness of the screed is 10-15 cm, reinforced with a steel or composite mesh made of rods with a diameter of 6-8 mm. Before pouring, the soil base is leveled with sand and well compacted. After pouring, you need to wait until the concrete has completely hardened, and only then lay a layer of thermal insulation on it.

Grillage

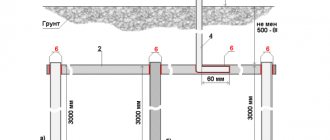

There is a third option for the foundation, which affects the structure of the floor. These are piles tied with a grillage. When aerated concrete is used not only for floor insulation, but is also the main building material, the grillage should only be reinforced concrete.

In essence, this is the same strip foundation, only its base is not buried, but is located above the ground level.

Sometimes unfavorable hydrogeological conditions of the area force one to take such a measure. In this case, it is not always possible to lay the floor on the ground and you have to structure it using a frame type. Then a beam of the lower trim is mounted along the grillage, logs are installed on it, the sidewalls of which are tacked with a cranial block. Boards or plywood are supported on the bars, which will hold the insulation.

READ How to install a weather informer on a website

Note: If such a design can withstand a thick layer of expanded clay, which is often used for insulation, then it will also withstand aerated blocks with their low weight. Although in this case, it would be more convenient to use sawdust or polystyrene chips.

Floors with a frame structure can be installed on all types of foundations, so we will tell you about them in more detail.

Types of wooden floors

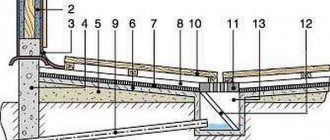

Often the finishing floor of the first floor in a house made of aerated concrete is made of wood or its derivatives: parquet or engineered boards, tongue-and-groove chipboards such as Quick Dec. Solid wood boards are mounted directly on the joists. Coverings with interlocking joints require a flat, continuous base, for the construction of which particle board materials or plywood are installed. This is how the floor pie is structured in certain cases.

Standard beam floors

Beam floors are installed either on a solid concrete base or on a strip one. In the second case, to support the beams in the inner perimeter of the future floor, it is necessary to install columns made of bricks or blocks.

For installation of parquet boards or laminate, the base should not be ribbed, but solid. Therefore, the rough flooring is mounted not at the bottom of the beams, but on top of them. Accordingly, insulation of the floor in a house made of aerated concrete will be carried out not from below (between the joists), but above them.

The layers can be structured like this:

Lightweight floors made of aerated concrete slabs

The lion's share of heat loss in a house made of aerated concrete occurs through the floor of the 1st floor. This happens because it is impossible to introduce insulation into the slab structure, and surface installation can significantly raise the level of the finished floor, which is not always acceptable.

From below, for the purpose of additional insulation, all this is covered with modular foam inserts.

Beam-ribbed floors

It is not at all necessary to use logs to install a floor in a house made of aerated concrete. In houses with a large floor area, the technology of monolithic pouring of beam-ribbed floors is used. The concrete used for this is heavy, but given the presence of caissons, the structure is lightweight.

The protrusion of the ribs that form the voids is obtained due to special convex shapes laid on the formwork, supported from below by load-bearing posts. After the overlap has gained strength, they are simply removed and can be reused. A gap is provided between the void former corresponding to the thickness of the ribs, which are reinforced by three A3 reinforcement bars.

A double row of reinforcement forming the frame is mounted above the plastic forms, on top of which concrete is poured. The pouring is carried out simultaneously with the beams and crossbars, which fastens the entire structure into a single durable monolith.

How to make a floor in a house from aerated concrete with your own hands

As an example, consider the option when the floor in an aerated concrete house is made on the ground, and the ceiling is made on beams. Let's start from the first floor.

Subfloor installation

When installing a floor resting on the ground, the structure is multi-layered and can have up to 8-9 layers. It depends on the insulation material. Expanded clay or expanded polystyrene are often used for it, but when making floors on the ground in a house made of aerated concrete, it is better to use heat-insulating aerated blocks. Due to low thermal conductivity, high strength and reasonable price, they can be considered the best choice.

The second option is shown in the diagram:

Heated floor installation

For heating to be most effective, it is advisable to lay the elements of the heating system in the screed. Before pouring it, a special foam substrate is laid out on the surface of the aerated concrete insulation. On top it is also covered with foil roll material made of foamed polyethylene (Penofol, Tepofol, Isolon).

Note: The selection of materials and tools for laying the floor is carried out based on what kind of decorative covering will be installed. When heating elements are placed in a screed, it is most often tiles. Therefore, in addition to general construction materials: a level, a hammer drill, a set of drills, a hammer, an electric mixer, you will need a set of spatulas, a notched trowel and a tile cutter.

Floor covering

The coating made from aerated concrete slabs using prefabricated monolithic technology has already been discussed above. However, a house made of aerated concrete can have two or even three levels, and you need to think about how to structure the floor covering.

Installation will be carried out according to the following scheme:

The boards are mounted with a gap so that it is possible to lay metal heat-reflecting plates. Heating elements are placed in their grooves and covered with a plank covering.

Types of floors in aerated concrete houses

One may come across the opinion that aerated concrete construction technology requires the installation of wooden floors. Traditional wooden beams, with the construction of a rough wooden floor using traditional technologies. However, the use of D600 aerated concrete blocks for external walls in the construction involves the use of aerated concrete slabs, as well as hollow-core concrete floor slabs.

You need to understand that the desire to use floor slabs instead of wooden beams changes and increases the cost of construction technology. In this option, it is necessary to install a reinforced concrete ring belt along the outer walls.

Aerated concrete floor slabs are considered universal and preferable in aerated concrete houses. They are warm, do not require additional insulation, and create a smooth base floor surface.