- December 4, 2018

- Construction

- Daisy Angel

A brick staircase can become a real decoration for your home. However, its construction should be approached with special attention, because the structure will have an impressive weight and requires a foundation.

Since the porch will be located outside the house, its operation will be accompanied by exposure to negative factors on the materials, which increase the requirements for the foundation. Some argue that a regular reinforced concrete platform can be made under the porch. This belief is a fallacy.

What should be the foundation for the stairs?

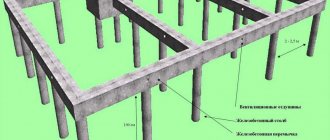

A brick staircase must have its own foundation, which is a structure identical to a strip foundation for a house. The depth should be the same as that of the main tape. You should not make the foundation shallow, laying it only 40 cm deep. An ordinary concrete slab tied with reinforcement to the main foundation will not work either. Some people believe that this provides reliability, but this recommendation is not correct.

Before building a brick staircase, it will be necessary to create a foundation that should not be tied to the base of the house with reinforcement. This is due to the fact that the task of the foundation is to take on the load and distribute it evenly around the perimeter. If the base of the porch is tied to the main foundation, the load will be distributed skewed. The porch has less mass than the house, while the foundation will be common.

There will be less pressure on the strip foundation from the porch. On the opposite side the load will be greater, which will certainly cause unequal shrinkage. As a result, you may experience cracking of the main tape. The negative consequences do not end there. If the dressing is done correctly and connects the two elements, then the technique has a right to exist.

When to pour the foundation

The foundation under the porch can be poured at the same time as the tape under the house. However, sometimes architects recommend pouring the foundation under the porch separately. Work must be carried out taking into account the physical characteristics of the soil, the weight of the structure and the amount of precipitation.

When the ground freezes in winter, the porch will be subject to large heaving forces, which are more impressive than in the case of the foundation of the house. The freezing of the latter is less due to the warm underground. The humidity in this case is greater than at the porch, because there is no drainage. As a result, the heaving lifts the porch while the house remains motionless.

Filling time depending on soil type

If the building is light and the soil is sandy, then the foundations for the porch and the house must be made at the same time; they can be tied with a reinforcing belt. In the case where the house is heavy and the soil is clayey, the foundation should be made separately, but the depth should be the same. Another problem when building a brick staircase may be that ceramic tiles begin to fall off during use. This can happen due to improper waterproofing between the brick and the concrete or deck slab. Concrete is affected by moisture from the ground.

The water then hits the brick and accumulates under the ceramic tiles. In winter, the liquid freezes and the ice expands, causing the tiles to come off. In order to eliminate such phenomena, it is necessary to pay special attention to waterproofing. All junctions of materials, depending on the architectural characteristics of the structure, must be insulated. The possibility of moisture getting from the ground under the tiles should be excluded.

DIY concrete staircase to the house

- After the master makes all the calculations, you need to build the formwork - it will hold the concrete when pouring. For it, use laminated waterproof plywood.

- Place the flange (a kind of limiter when pouring concrete) of the stairs - the steps will be attached to it.

- Reinforce the formwork with a board, the stronger the better.

- As support boards, take those 50x100 mm in size and reinforce everything you can with them - plywood will not cope with a large mass of concrete.

- Visually inspect the resulting formwork - it will determine the size of the steps.

- The next stage is knitting the frame.

- Reinforcement takes on the protective functions of concrete and increases the strength of the stairs. The fittings are used with a diameter of 12 mm.

- A frame made of reinforcement is attached to the wall, thus forming a cell that has a size of 200mm by 150mm. Reinforcement consists in the fact that all parts of the reinforcement are fastened together with wire - it is tied with a special hook.

After the reinforcement is completed, the stairs are poured. A special solution is used. For a bucket of cement, 3 buckets of sand, 6 buckets of crushed stone, a bucket of water. By the way, with the help of such a solution you can repair concrete steps - remove small chips.

- First of all, a pair of lower stages are completely formed.

- After 3-4 days, remove the formwork from the hardened concrete. Remove the formwork itself after 1-2 weeks.

- Sand the steps.

- The finished concrete staircase only needs decorative finishing work.

Now you know how to make steps with your own hands, but do not forget to use high-quality materials and maintain drying times.

Step parameters

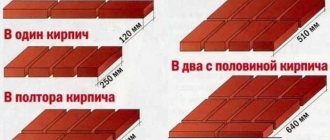

If you are faced with the question of how to make brick steps with your own hands, you must understand the features of the masonry. The steps can be straight. In the front part, the porch will have steps, and the side surface should be solid vertical in this case. The number of steps should be calculated in advance.

Work of this type is carried out before laying the foundation. The distance from the house strip to the main foundation and the dimensions of the horizontal platform, if any, will depend on these values.

The parameters of brick steps are prescribed by building codes. The porch should be easy to climb. This is true if the double height plus the width of the step is equal to the length of the step. This parameter varies from 60 to 64 cm. The rise and width are determined by the ratio 2a + b, where a is the height of the riser, and b is the width of the step itself.

What to consider before building a brick porch

To prevent the constructed structure from collapsing after a few years, you first need to create a competent design and make a drawing.

How to properly fill the base of a porch

The duration of operation of the porch depends on the strength and quality of the foundation, because to it:

- Considerable weight.

- The structure is constantly exposed to the negative influence of the environment: precipitation, temperature changes, etc.

The main requirements that the porch foundation must meet:

| Photo | Description |

| Requirement 1 The foundation should be similar to the base of the building. This means it must have the same configuration and depth. | |

| Requirement 2 Rigidly connecting the foundations of the porch and the house is unacceptable. They take different loads and shrink differently. At the same time, the building undergoes more significant changes.

| |

| Requirement 3 Sometimes it is highly desirable to pour the base slab under the porch at the same time as the main foundation of a private house. This choice is influenced by the type of soil on the site, the average annual precipitation and the total mass of the structure. |

Let me give you an example: when construction is taking place on sand, and the weight of a country house is small, the optimal solution is to make the overall foundation monolithic, and tie its parts together with a frame made of reinforcement.

Things are different when the soil is clay and the building is massive. Then the base of the porch is affected by a much greater force of frost heaving of the soil than the foundation of the building itself.

This happens because:

- the porch foundation freezes more, since the structure does not have a warm basement;

- the brick porch is not equipped with drainage, so the soil around it is wetter;

- its weight is less than that of a house.

As a result, the brick porch is squeezed out by frost heaving, and the building remains in place. If they are connected by a reinforcement cage, then the foundation of the entrance staircase will crack.

Construction of expansion joint

To prevent this from happening, an expansion joint is created with your own hands at the border of the two bases. It levels out seasonal soil movements. The seam is made about 2 cm wide and filled with rubber or dense basalt wool.

Construction of a porch: 5 rules

Scheme of proper construction of the entrance staircase.

Here are the main rules for constructing a porch made of blocks or bricks:

| Photo | Description |

| Rule 1 The height of the porch platform should be at least 20 centimeters. Then water will not enter the structure during rainy weather. | |

| Rule 2 The site must be filled with high-quality concrete. Before laying it, the base should be poured and compacted. It is made from a 10-centimeter layer of crushed stone and sand. | |

| Rule 3 A brick porch should be 1.5–2 times wider than the front door of the house. | |

| Rule 4 To make the porch convenient to use, the brick steps must be made with a slope. Its optimal value is 30˚. In this case, moisture will quickly drain from the steps without creating puddles. | |

| Rule 5 The optimal height of the riser (the vertical part of the steps) is 15–18 cm. The recommended tread width (horizontal section of steps) is 25–30 cm. |

Creating a Staircase

With a step height of 170 mm, 2 bricks will be needed per step. You can adjust the exact height by the thickness of the seam. The bottom seam can be increased to 3 cm, while between bricks this parameter will be 1 cm. You can adjust the length of the step during the process of tying the rows. To fill the non-main masonry, you can use waste from hollow bricks and broken concrete blocks. The main condition is the need to level the surface for laying the steps.

When making a brick staircase with your own hands, you must waterproof the foundation from the base material. It is better to use roofing material for this, but thick polyethylene will also work. If there is a horizontal platform, it is necessary to waterproof using a special technology. If the porch on one side is located close to the facade, steps should be marked on it. This will make the laying process easier.

Features of the construction of a round structure

The semicircular structure is laid according to the following scheme:

When constructing the vertical part of the steps, the spoons should be on the outside.

- To construct risers, the blocks are placed with the spoon facing outwards. A semicircular brick is formed by trimming its butt at the desired angle.

- For treading, the blocks are turned with their ends outward with a small outlet and placed on a spoon. The horizontal sections of the porch always remain visible, and the ribs of smaller width will make it possible to make semicircular steps with a smooth radius.

- When constructing a round porch, you need to lay the brick from the middle of the steps. So the trimming along the edges of the structure will be the same.

When constructing a semicircular structure, its correct marking is very important.

- After installing the first step and backfilling the next one, it is necessary to carry out the markings again. In this case, its radius should be reduced by the width of the second element.

You can build a brick porch yourself. In this case, you need to follow several important rules. In this case, the structure will last a long time.

If you have questions, ask them in the comments. Therefore, I say goodbye and success to you in your endeavors.

Expert advice

A solution is laid on the waterproofing, after which you can make the opposite corner of the porch. Check the position of the bricks using a level. A tape measure will allow you to control the length and height of the structure. As soon as the opposite ends are ready, a thread is pulled between them, which will allow you to continue laying out the steps along the length. If they are not very wide, then you won’t need a rope; a flat strip will be enough.

The masonry is filled with various building materials. The side surface is laid out simultaneously with the steps, then the parapet is installed. The space under the platform is filled with sand, which should be poured onto the waterproofing. It is laid in such a way that it does not interact with the soil.

Porch construction

Before you build a brick porch, you need to prepare materials and tools for work. Before this, you should calculate the purchase volumes from the drawing.

Stage 1. Tools and materials

You will need the following building materials:

- ordinary solid bricks;

- Portland cement M-400;

- quartz sand;

- crushed stone;

- steel rods for concrete reinforcement;

- boards for formwork;

- waterproofing;

- adhesive for external tiling;

- primer;

- facing tiles

Necessary tools:

All this needs to be prepared for brickwork.

- shovels and bayonet shovels;

- container for mixing mortar and concrete;

- trowel for brickwork;

- bubble level;

- an angle grinder and a diamond disc for cutting bricks and tiles;

- pegs and cord for marking;

- rubber hammer for laying stone or ceramic tiles;

- notched spatula.

Stage 2. Construction of the foundation

The monolithic base for the porch is constructed in the form of a reinforced concrete slab:

| Photo | Instructions |

| Step 1. Marking the construction site The exact dimensions of the pit are indicated with wooden stakes and a cord. | |

| Step 2. Digging a pit The hole is dug with a bayonet shovel. Its width must correspond to the size of the structure. The depth should be the same as that of the base of the building (50–70 cm). | |

| Step 3. Assembling the formwork It is assembled from boards. | |

| Step 4. Laying the frame It should be a mesh of reinforcing bars. Before assembling it, a cushion of sand and crushed stone is poured into the pit. Its thickness should be 15 cm. |

The finished foundation must be completely dry. You can start making a brick porch 1.5–2 weeks after it is poured.

Stage 3. Construction of the porch

The initial step is laid in three rows.

The first step should be laid in 3 bricks:

- The outer row rises to its height.

- The internal brick is installed in one layer.

- Then a rubble row of broken bricks is laid.

- After this, the third row of bricks is raised.

The height of the rubble should be such that the final row is level with the initial step.

Next, stepping back 0.3 m from its edge, begin laying out the second step. Then the third, etc. Following the front rows, lift the backfill.

Construction of the side part of the structure.

Lay out the sides of the porch in the same way. So bring the masonry to the required height, constantly checking its evenness using a level.

Arrangement of blocks in rows.

Place the bottom rows of bricks on the steps lengthwise, and the top rows across. In this case, the masonry will be stronger and more durable.

The top of the structure is covered with broken stones and filled with concrete mixture.

Lastly, pour a 30-centimeter layer of crushed stone, brick fragments, and small cobblestones inside the well of the future upper platform. Fill everything with concrete so that the solution is level with the edge of the upper step.

Lastly, the porch is covered with tiles.

To make the appearance of the brick and concrete porch more aesthetically pleasing, it is tiled. It can be porcelain tiles, ceramic, clinker or stone tiles.

Work methodology

At the next stage, materials are prepared for pouring concrete under the site. The thickness of this layer should be from 5 to 10 cm. Here you will need to use construction reinforcement that will connect the slab to the facade wall and steps. The sand will serve as permanent formwork. Over time it will settle. This is where the masonry ends. At the final stage, you will need to finish the structure with tiles.

Creating a semicircular porch

Entrance staircases made of semicircular brick are more beautiful, but difficult to implement. The calculation of the length of steps and height does not differ from that described above, but the technology will be different. For such a porch, a solid facing brick is used, which is laid on the edge with the butt facing outwards. The size of the bricks allows you to make steps with standardized parameters, so the work is simplified and accelerated.

The cladding here will be more difficult. The brick should be laid on the edge, since due to this method the circle is more even and the degree of adhesion of the bricks will be increased. The steps will be more beautiful and durable.

If you want to finish such a porch with tiles, then the brick can be laid in the usual position, but the poke should face outward. Before building a brick staircase, you must remember that during the installation of the material you will need to learn how to control the turning radius of the step. First, decide on the width of the site. Its dimensions should not be smaller than the space in front of the door. Moreover, this distance should be 50 cm greater. This will allow two people to separate without problems.

You should find the center of the semicircular steps. In the standard position it is in the middle of the doorway. But you can shift the center in one direction or another. A vertical stand is fixed in this place, which can be a pipe. The element is attached with dowels and clamps to the wall or foundation. After determining the width, height and number of steps, it is necessary to prepare a rope of the appropriate length. One end of it is tied to the stand, and chalk is attached to the other. Using this design, a circle is drawn. Next, you can begin laying the steps.

You need to start from the center, moving in both directions. If the product does not fit into the corners, it must be cut, where the cut will be less noticeable. As soon as the first step is ready, you can start marking the 2nd. To do this, the length of the rope is reduced by the width of the step. Using chalk, you need to draw a circle along the bricks of the first stage.

The seams should be well filled. The load will be large, so failure to comply with this rule may eventually cause the structure to loosen. In this case, products sometimes even fall out. Don't forget about bandaging. Any waste construction materials should be used for backfilling.

Why can't you make steps out of brick?

The life of steps made of red brick is short, 2-3 years. This is the most optimistic forecast.

To verify this, you need to walk along the streets of your city and see what the collapsed porches are made of.

There are especially many of them in early spring, when the frosts have already passed, and the warmth necessary for repairs has not yet arrived.

The main reason is the freezing of water in the pores of the red brick.

How does water get under the tiles and saturate the brick?

- The first reason is filling the joints between ceramic tiles with cheap grout that is not intended for outdoor use.

- Lack of waterproofing at the base of the porch.

- The laying of ceramic tiles on the steps and landing is done without a slope. This leads to the formation of puddles on the steps after rain or melting snow. Snow that melts during the day becomes ice at night. Water, as you know, expands when it freezes.

- of framing corners for tiles on steps

- No canopy over the porch.

In addition, the strength of the brick is lower than the strength of the cladding (adhesive + tiles). This alone can lead to the plaster or tile coming off:

Concrete steps are also vulnerable to the above factors.

But if the strength of the concrete complies with the standard - M200 and the screed under the tiles is made according to the rules, then the tiles on such a porch can last a long time. Everything will depend on the number of other negative factors that simultaneously fall on this porch.

In the bottom photo, the base of the porch was also made of red brick. But this was not enough for the builders. They also made a pit for water - so that it would certainly crumble.

ANOTHER BRICK PORCH.

Typically the first stage of construction goes like this:

What's interesting in this video?

- The bricks I use for masonry are different. Mostly silicate, but there are red inserts. Different materials have different thermal expansion. In a year, cracks will appear around the red brick.

- Sand-lime brick is a poor material for subsequent finishing. Plaster or screed can only be secured to it using a contact layer.

The fact that tile cladding in most cases does not protect the brick from getting wet can be seen from a short excerpt:

Brick absorbs water more strongly than screed, and its strength is 2-3 times less. When frozen, separation into plates occurs. In the first year of destruction, you can still fill the mesh, make waterproofing and slow down the process of destruction. After two or three winters there is no need to attach the net. The brick is destroyed when the dowels are driven in.

A porch made of foam blocks and expanded clay concrete is also short-lived.

Porch made of foam blocks.

Porches made of clinker bricks.

You can find many photographs where red brick porches look decent for many years. These examples are confusing.

Such brick steps really exist for a long time, but they are made of clinker bricks:

CLINKER BRICK ON STEPS.

Clinker bricks are similar in properties to clinker tiles, which have been lying on garden paths for decades without damage.

It's all about structure. Clinker does not absorb water well. And having absorbed it, it easily gives it away. Real clinker bricks comply with the following standards:

- DIN 1344 – Paving bricks, July 2002 (Germany).

- DIN 18 503 – Road clinker, August 1981 (Germany).

The certificate of conformity guarantees that the hygroscopicity of the product is no more than 6% and the density is about 2.0 kg/dm3.

How is ordinary red brick different from clinker brick?

– the grade rarely exceeds M100. Most often M50, M75.

– presence of cracks and high porosity (a dull sound is heard when struck with a hammer).

Externally, such a brick can look very high quality. But this is still the same ordinary red brick:

In addition, it is necessary to take into account the special technology for constructing porches made of clinker bricks, which is similar to laying road clinker:

- A drainage layer of fine crushed stone and sand with a grain size of 0/5 - 0/8 mm is laid at the base. The depth of the permeable soil layer is at least 1 m. This guarantees rapid drainage of water and insulation from moisture of the base.

- The seams are quite wide and filled with drainage material. Filling can be from ready-made mixtures mixed with a small amount of water.

- The clinker brick steps are not lined with anything. If such porches are faced with porcelain stoneware, then other processes will begin.

Stairs in the house

The brick staircase in the house is built using the same technology as outside. Foundations cannot be connected here either. Such a heavy structure is laid at the design stage of the main building. The foundation must be deepened to the same level as the main one for the house. Step-by-step instructions for creating any staircase in general terms look like this:

- Creation of a project indicating all dimensions and materials used.

- Preparing the foundation for construction.

- Carrying out waterproofing.

- Construction of the foundation.

- Construction of stairs.

- Finishing with tiles or other materials.

Brick steps inside the living space can be tiled. In this case, you should not forget about waterproofing. It is best to use anti-slip material. If a whole tile does not fit on the step, then the pieces are laid only on the side of the riser. The whole product is placed on the ledge. The adhesive strength of a whole tile is greater than that of a small piece. During ascent, the maximum load will be applied at the very beginning of the step.