How to prepare the base for the foundation

How to prepare the base for the foundation

Building a house always begins with preparing and laying the foundation. The foundation is the main load-bearing structure that absorbs all the loads from the structures above and transfers them to the base. It is he who is able to protect the walls from groundwater and ground vibrations. Therefore, choosing the right type of foundation and its specialized installation will allow your house to stand for a long time.

continuous (suitable for those types of soils where the water rises quite high);

columnar (great for small, lightweight buildings);

strip (used in low-rise construction).

Selection of materials for foundation construction

The most popular building materials for foundation construction are reinforced concrete and heavy concrete. They provide the necessary strength of the base and are resistant to moisture. The main advantage of these materials is the ability to create a monolithic type of foundation, which will give the structure additional hardness. Concrete foundations are great for block and small brick buildings.

Some people prefer special bricks. However, in terms of its properties and cost, it is inferior to concrete.

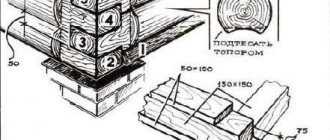

For small wooden structures, you can make a foundation from a similar building material. However, its main disadvantage is minimal resistance to moisture and fungus. In dry places, wood treated in a certain way can become an excellent basis for a future home.

if the soil is weak and the load on it will be quite high, it makes sense to install a pile foundation;

if the soil allows it and you do not plan to create a large load, install a columnar foundation;

if there is fluctuation in groundwater, then make a continuous type of foundation;

if the soil does not float and you are building a house of brick, then consider the option of a strip foundation.

There are cases when, using some construction tricks, several types of foundations are installed. However, for this you need to seek help from specialists.

And remember: it’s better to overpay a little and make the foundation better than to later worry about a crack creeping up the wall.

Foundation depth

Most often, the foundation is laid just below the soil freezing depth - this is done in order to prevent their heaving. The foundation is calculated based on:

climate features of the region;

depth of underground communications;

the nature of the loads acting on the foundation;

depending on the properties of strata soils, etc.

In this case, the laying depth must be sufficient to ensure the stability of the foundation and eliminate the possibility of soil heaving.

In non-heaving soils, when groundwater is located at a large distance, it is allowed to lay the foundation base above the freezing depth of the soil. However, for this, specialists must correctly calculate the average pressure on the foundation and the design features of the building.

The foundations of buildings that are equipped with basements, with an increased groundwater level, must have special waterproofing that can eliminate the possibility of flooding. Dense concrete, lining, coating and other types of waterproofing are also used with certain additives.

Construction of foundations

Most often, before starting construction work, the contractor already has a construction project, which contains calculations of the foundation, linking it to the type of soil, terrain, etc.

The foundation base (pillow) is part of the soil mass on which the foundation itself is located. The durability and strength of the foundation, as well as its susceptibility to shrinkage, depend on the quality of this pillow.

Today, when building houses, many developers use concrete strip foundations. In this case, the foundation on which it must be laid can be of several types:

poured concrete pad;

bulk crushed stone cushion.

Thus, when choosing the type of foundation base, you should definitely take into account the regulations and design calculations, which indicate the depth of the cushion.

Sand cushion for the foundation - when it is needed

Before starting construction, it is necessary to assess not only the condition of the soil in the area where the house is being built (bearing capacity, proximity of underwater waters), but also the climate conditions, as well as the total weight of the structure. It is mandatory to compact heaving soil, which is significantly deformed during the process of freezing and thawing. If you make a mistake with the choice of material for installing a slab under the foundation, most likely the building will shrink greatly, which will lead to the formation of cracks in the walls and the foundation itself. In addition, if the soil in the construction area has a high bearing capacity and the groundwater level is extremely low, you can do without creating a sand cushion.

Of all the materials that are used to create a pillow, sand is the most acceptable. It not only allows you to save a decent amount compared to a slab of crushed stone or concrete, in addition, compacting sand with your own hands is quite acceptable - for example, working with crushed stone is much more difficult. There is only one limitation on the construction of a sand cushion - heavy buildings cannot be built on it (apartment buildings, shopping centers), but for private low-rise construction it is an almost ideal material.

A properly created sand cushion has numerous advantages:

- The foundation created using sand fully complies with all standards used in low-rise construction.

- Complete protection of the entire building from the negative influence of groundwater.

- Creating a perfectly level site for construction without the use of complex and expensive technologies.

- Possibility of carrying out all work on our own.

- The cost of this important stage of work is quite affordable.

Why do you need a sand pillow?

It is important to find out why you need a sand cushion under the foundation before building a house. This is a very useful element that:

- Helps correct unevenness in pits and trenches. This allows you to save concrete solution.

- Reduces soil load.

- Allows you to avoid soil mobility during spring floods.

- Improves the strength of subsiding and unstable soil.

- Used to replace heaving soil to increase bearing capacity. This will make the foundation strong, holistic, and increases its durability.

- Facilitates the process of building a house in the swamps.

- It prevents melt water from soaking the base of the building and also protects against the penetration of groundwater.

- Makes the foundation resistant to high temperatures.

- Provides stabilization of the structure and does not allow it to settle.

preparation for the foundation

| Page 1 of 2 | 1 | 2 | > |

| 12.04.2008, 13:22 | #1 |

| Pa#MuTyai | |

| View profile | |

| Find more posts by Pa#MuTяй |

12.04.2008, 15:17

| 3 | | #2 |

Geotechnics. Theory and practice

14.04.2008, 21:40

| #3 |

| Pa#MuTyai |

| View profile |

| Find more posts by Pa#MuTяй |

10.03.2009, 16:58

reinforced concrete designer, O&F

| #4 |

| Beginner |

| View profile |

| Find more posts by Beginer |

10.03.2009, 17:28

Design of buildings and parts of buildings

At one time I was confused by searching for information on this topic. There was a question regarding the arrangement of preparation for prefabricated strip foundations on the rock. I insisted on concrete, but the builders wanted 100 mm of crushed stone.

In addition to the joint venture, I also found it in the Guide to the design of concrete and reinforced concrete structures made of heavy concrete (without prestressing)

| 1 | | #5 |

| 3.24. Under monolithic foundations, regardless of soil conditions (except for rocky soils), it is always recommended to provide concrete preparation with a thickness of 100 mm from M50 grade concrete, and under prefabricated foundations - from a 100 mm layer of medium-grained sand. If it is necessary to construct foundations on rocky soils, a leveling layer on the soil of M50 concrete should be provided. |

| Armin |

| View profile |

| Find more posts by Armin |

10.03.2009, 17:36

reinforced concrete designer, O&F

| #6 |

| Beginner |

| View profile |

| Find more posts by Beginer |

07.04.2009, 15:05

reinforced concrete designer, O&F

More on the topic, in TSN 50-302-2004 “DESIGN OF FOUNDATIONS OF BUILDINGS AND STRUCTURES IN ST. PETERSBURG”:

“. 9.6 For monolithic reinforced concrete foundation slabs and pile grillages concreted on the ground, it is recommended to prepare the preparation from compacted crushed stone or gravel 100-200 mm thick, poured with cement mortar or bitumen, or lean concrete 80 mm thick.

Concreting of foundations and grillages without preparation on dry, dense soils is allowed. In this case, the protective layer of concrete increases to 70 mm.

The purpose of preparing lean concrete is allowed in weak water-saturated soils, as well as when it is necessary to waterproof foundations or grillages from below.

When designing the placement of the base of the grillages above the freezing depth, it is necessary to exclude the impact of frost heaving on them, and when placing them below the seasonal freezing depth, this impact should be excluded during the execution of work.”

Device depending on the foundation

All builders know why a sand cushion under the foundation is needed. But not every specialist is convinced of its effectiveness. There is an opinion that it is not suitable for certain options.

Tape

Strip foundations are used with a thin sand cushion only for small buildings.

The calculation of the sand cushion must be carried out so that its width is several tens of centimeters greater than the width of the tape.

To level the ground and avoid liquid penetration into the foundation, as well as for other purposes, all actions must be performed in the correct sequence:

- Place a layer of sand that is necessary for a given type of soil and distribute it evenly over the area.

- Moderately moisten the sand with water so that it settles more tightly and is easier to compact.

- In order to get a dense pillow without voids, and the house does not sag, they resort to special construction equipment for compaction.

- Any unevenness on the cushion is eliminated so that this does not have to be done later during the construction of the foundation.

- Treat the working surface with a waterproofing layer.

It is important to check the thoroughness of compaction. If there are no marks on it, then the work was done correctly.

A sand cushion under the foundation is not needed if a monolithic base is used. This is possible provided the soil is not heaving. Also, a foundation cushion without sand is allowed if you plan to build a house on sandy soil.

It is impossible to create a base from FBS without a sand cushion. Such a foundation on a sand cushion without deepening requires preliminary leveling of unevenness formed after removing the loosened layer of soil.

If you place a foundation made of blocks directly on the ground, then voids will form under it and the house will gradually sag unevenly.

Columnar

A column foundation is a solid foundation, but it must be supported with sand and gravel. What sand or crushed stone should be found out first to avoid serious mistakes. First, medium-sized solid fractions of gravel are placed under the pile foundation and all this is diluted with sand. To ensure that the components fit together more tightly, they are filled with a small amount of water and tamped down.

The height of the sand cushion is allowed up to 30 cm.

Finally, polyethylene is placed on the surface to prevent water from being absorbed into the pillow.

Slab

A slab foundation on a sand cushion has the same structure as a strip foundation, but is carried out over the entire area of the pit. To create the correct layer, you need to find out how to do it and whether it is needed for this type of base. The procedure is carried out as follows:

- Dig a hole in the ground under the foundation and carefully level its bottom.

- A certain amount of gravel or crushed stone is placed there. How many centimeters to pour is determined by the density of the soil. If it is small, then fifteen centimeters is enough.

- Sand is poured onto the crushed stone. Which is better, river or quarry, is chosen at your own discretion. If you are planning a small cottage, then 10 cm will be enough. This will distribute the load equally over the entire base area.

- Compact using a vibrating plate.

Shallow foundation for sandy foundations

If a regular belt is installed below the level of seasonal freezing, then a shallow foundation is convenient because there is no need to dig a deep pit or trench under it. The support is placed directly on the ground surface or at a shallow depth - up to 80 cm. For private construction on sandy soils, this is a convenient option, since the main problem for non-buried structures is heaving.

In sandy foundations, heaving is practically absent. If, when constructing a shallow foundation in other foundations, it is necessary to select soil and replace it with sand, then there is no such need.

Shallow foundations on a sandy base are arranged both in the form of strips and slabs. The principle of their construction is similar, only the cost of construction differs.

For temporary buildings, bathhouses, sheds, technical buildings on the site, non-buried foundations are used directly on the ground. To do this, clean its surface from debris and remove the fertile layer.

sand cushion

Foundation for a house made of sip panels

The simplest type of foundation for a foundation, characterized by low cost and simplicity of construction. The sand foundation cushion must be made from coarse sand; the use of fine-grained material is not allowed.

The scope of application of this type of pillow is as follows:

- Areas where groundwater has a significant depth. If they are located at a short distance from the surface, then before installing the cushion it is imperative to install a drainage system, otherwise the sand will be washed away.

- Buildings whose walls will be made of materials having a low specific gravity (frame structures, buildings made of light blocks). The sand cushion does not tolerate high loads and its use in such cases is ineffective.

- That is why you should refrain from using such a cushion when constructing multi-story buildings. The scope of application is limited to buildings of one floor.

The sand for creation is scattered in an even layer, and the thickness of the foundation cushion should be 20-30 cm, while the soil on which it is impossible to install the foundation must first be removed.

Calculation of the amount of crushed stone and sand for the pillow

But how much crushed stone is needed for a pillow?

Typically, a first layer of sand of both medium and coarse grains is laid under the foundation. The density of crushed stone should be from 2.0 - 2.7 g/cm³. There is no need to carry out preliminary work on leveling the trench, since the pad itself is part of the leveling layer.

The thickness of the pillow should vary between ten and fifty centimeters, but may vary due to the load-bearing characteristics of the base. The pillow is poured in layers, each layer should be ten centimeters and very well moistened with water. Then compaction is carried out using a vibrating rammer.

The sand cushion is calculated using the formula.

The first step is to calculate the depth of the foundation. But if the soil is problematic, then it is worth considering replacing it with sand. Next, the width of the fundamental surface is calculated.

There is a simpler way to calculate: To do this, measure the foundation. The width and length of the trench are multiplied. The result is once again multiplied by the total thickness.

You can make a pillow out of crushed stone with your own hands in other ways.