One of the main building materials, concrete, is classified according to its strength. Depending on the type of filler, it is divided into light, heavy and super-heavy. Sawdust concrete belongs to the category of lightweight materials because sawdust is used as a filler. Its production was established in the 60s of the last century in the Soviet Union. He received his GOST number 19222-84 called “Arbolite and products made from it” later.

It should be noted that wood concrete is not sawdust concrete, and vice versa. Because in the first one, wood chips of certain sizes are used as filler. In the second, sawdust is used as wood processing waste.

What is sawdust concrete?

The composition of concrete includes: sawdust, cement, sand, lime or clay. Depending on the formulation of the solution, the material is divided into grades, each of which has its own purpose in terms of use in certain building structures.

| Brand | Component proportions | Density, kg/m? | |||

| Cement, kg | Sawdust, kg | Sand, kg | Clay or lime, kg | ||

| M5 | 25 | 100 | 25 | 100 | 500 |

| M10 | 50 | 100 | 100 | 75 | 650 |

| M15 | 75 | 100 | 175 | 50 | 800 |

| M20 | 100 | 100 | 250 | 25 | 950 |

The first two grades of sawdust concrete are used to make blocks that are used for the construction, thermal insulation or repair of the walls of a structure. The last two are used in the construction of the walls themselves (internal and external).

Pay attention to the density of the material, which affects the weight of the products. Maximum density of sawdust concrete – 950 kg/m? (the weight of 1 cube is 950 kg), for brick this figure is 1200, for wood 700, for expanded clay concrete - 1000, for foam concrete - 700. That is, concrete on sawdust is in the golden mean, so blocks made of shavings and cement have a fairly large bearing capacity. But it is necessary to understand that they are used only in low-rise construction, because the raw material is lightweight concrete.

At the same time, blocks made of sawdust concrete, due to the fact that their filler is wooden sawdust and shavings, have low thermal conductivity - 0.08-0.17 W/m K. For example, the thermal conductivity of brick is 0.35, and that of wood is 0. 23, for expanded clay concrete 0.33, for foam concrete 0.16. Therefore, blocks of cement and sawdust are often used as insulation.

Advantages and disadvantages

Considering the pros and cons of sawdust concrete, it is necessary first of all to indicate that the blocks made from it are a wall building material with excellent technical and operational characteristics. The advantages can be added:

- The material is environmentally friendly because it does not contain synthetic components.

- Low water absorption rate of 8-12%. This is when, when exposed to water, the material absorbs a certain amount of it, depending on the weight of the product itself. If a wall built from sawdust concrete blocks is covered with protective compounds, then this technical parameter will be reduced to 3%.

- Blocks made from wood chips and cement (arbolite) and from sawdust and cement belong to the category of non-combustible materials (NG). The stone begins to collapse only at a temperature of +1200C. But this material has one nuance regarding high temperatures. If a large amount of sand is added to the composition of sawdust concrete, then the temperature regime of destruction drops to +573C. Simply, under the influence of high temperatures, sand changes its polymorphic modification. It increases in volume, which contributes to the appearance of deep cracks in the stone.

- The bearing capacity of the blocks is up to 100 kg/cm?, which is a normal indicator for wall materials. In this case, the strength depends mainly on the brand of cement used. Therefore, if the walls are built from sawdust concrete, then it is better to add M500 grade cement to its composition.

- Building blocks made from sawdust and cement are easy to process. They can be cut, drilled, nailed. There is no need to chop or chop them; an ordinary hacksaw can easily handle the stone, precisely adjusting it to the required dimensions.

- Walls made of sawdust concrete can easily be finished or faced with any building materials due to the high adhesion of the surfaces of the blocks.

As for the disadvantages, first of all it must be noted that sawdust, as a reinforcing frame, is inferior to wood chips. Therefore, sawdust concrete products cannot boast of high bending strength. This means that we can talk about the inability of this material to undergo temporary deformation without destruction. Although in the category of lightweight concrete products they are superior to many materials and products.

Sawdust is a loose material; it fills a large space, forming pores. To reduce the porosity of the structure, a lot of sand is added to concrete, which leads to heavier blocks. Because of this, the thermal conductivity of sawdust concrete also increases. In this case, the solution can be made without lime or clay, but there is no way to do without sand. The former are usually added if there is a need to save on the use of cement.

Arbolit

Sawdust concrete is often confused with another building material - wood concrete, which is completely wrong. According to GOST, wood concrete is defined as concrete made with cement binder, chemical additives and organic solvents. However, in the classic version, wood concrete involves the use of wood chips. It is this that determines its unique properties.

Exactly like sawdust concrete, wood concrete is an environmentally friendly wall material, characterized by high levels of fire resistance and thermal insulation. Nevertheless, these two materials, despite the similarity in structure, have fundamental differences. The fact is that in the production of wood concrete, instead of small sawdust, which cannot have sufficient strength properties on their own, special wood chips are used, the size of which is strictly standardized. Sawdust, unlike wood chips, cannot sufficiently reinforce (strengthen) the wall block and give it “ductility”. Thus, wood concrete concrete is stronger than sawdust concrete in terms of bending strength and the ability to undergo temporary deformation without complete destruction. To be fair, it is worth noting that sawdust concrete is superior to other types of lightweight concrete in this indicator.

To strengthen the blocks, fill voids and reduce shrinkage, a lot of sand is added to the sawdust concrete composition, and a lot of lime or clay is also added to save binder material. The use of a large amount of sand negatively affects the fire resistance of the material we are considering - at a temperature of +573 ° C, sawdust concrete changes in volume, which can lead to cracking. In addition, due to the significant sand content, the structural characteristics of the blocks are reduced. So, for sawdust concrete to reach the strength of grade M25, its density should be 950 kg/m3. Due to the high density, the cost of the material and its delivery increases, and construction work becomes more complicated.

Wood concrete of a similar brand has a density of 500 to 700 kg/m3. Considering that with increasing specific gravity the heat-saving properties decrease, the thermal conductivity of sawdust concrete and wood concrete differs by more than two times in favor of the latter. This difference is due to the low amount of wood in sawdust concrete compared to wood concrete: approximately 50% versus 80-90% wood chips. This negatively affects such properties as providing passive ventilation of the room. Here, again, it is worth noting that in this parameter sawdust concrete is significantly superior to most wall materials. It is excellent for the construction of low-rise buildings and is second only to its “rival”.

Thus, calling sawdust concrete wood concrete is extremely incorrect, since these are completely different materials. The only similarity between them is the presence of a wood component in the composition.

DIY manufacturing technology

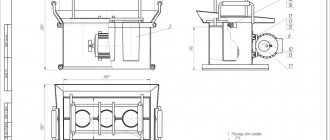

Making blocks from sawdust and cement with your own hands is not a problem. To do this, you will need all the starting materials described above and simple equipment. Namely: a block mold made of boards or sheet metal. If the forms will be used one-time, for example, to make blocks for constructing a shed from sawdust concrete with your own hands, then it is better to use lumber 20 mm thick.

The boards are assembled into one large structure, where they form cells according to the size of the blocks. The number of cells is limited only by the ease of use of the equipment. The form itself must be collapsible, so its elements are fastened together with L-shaped studs bolted to a nut.

It should be noted that the dimensions of the blocks are not established by GOST. Therefore, the work contractor selects these indicators depending on the thickness of the house wall, the width of the openings, installation methods, and other things. Blocks are often produced in sizes: 120x250x140 and 132x275x154 mm.

Attention! During the drying process, the sawdust-based concrete solution undergoes drying out, so the internal dimensions of the form should be 10% larger than the parameters of the blocks being poured.

Preparing sawdust

To make sawdust concrete, it is better to use softwood sawdust, of which spruce sawdust is better than others. Causes:

- The content of water-soluble substances in spruce is 1.12%, in pine 2.6-6.2, in birch 1.3-1.45, in oak 2.5-7.3. The lower the percentage, the faster the solution combines with the wood. There is no rejection of two different materials.

- Concrete drying speed. If spruce sawdust was used, then it takes up to 12 hours for the blocks to dry. If hardwood waste was used, the drying time may take up to 90 hours.

To reduce the amount of water-soluble substances in wood, various methods and technologies are used. Eg:

- spread the sawdust in the sun, thereby reducing its humidity due to evaporation;

- soak the raw material so that water-soluble substances come out of it with water;

- treat sawdust with calcium chloride or liquid glass.

The first two methods are a long process that can take 2-3 months. The latter has certain nuances: liquid glass makes wood brittle; calcium chloride can only be used if the wood has been thoroughly dried beforehand.

Screenings must also be added to the preparation of sawdust. It is optimal if the material is homogeneous. Blocks made from small sawdust will have high thermal conductivity, while blocks from larger ones will have low strength. Therefore, the ideal size of sawdust is within 1-2 cm. Experts recommend taking sawdust from a sawmill (belt or disk), from calibrating and rounding machines, shavings for sawdust concrete are not suitable, they are too large.

Concrete production

What is sawdust concrete? It is ordinary concrete, into which sawdust is added as a filler. Therefore, it must be made in exactly the same way as in the case of ordinary concrete mortar. The main thing is to strictly follow the recipe and sequence of ingredients added. It is better to use a concrete mixer for preparation.

- Cement and sawdust are poured into the concrete mixer drum.

- Then add sand in small portions so that it mixes well with the main components.

- Next, strictly according to the recipe, clay or lime dough, which must be prepared in advance.

- After thorough mixing, water is added in small portions.

Attention! The finished concrete solution is determined by the method of compressing a small part of it in a fist. A plate mass should form, on the surface of which, after compression, fingerprints will remain. At the same time, no drops of water.

Molding

The finished solution is placed in molds where it will be stored for several days until maximum drying. The main task of the work producer is not to procrastinate. The concrete solution “lives” for 1.5-2.5 hours, after which it begins to harden.

The cells are filled with the solution and compacted. After 2-5 days (depending on the drying temperature), the molds are opened. In this state they have 30% strength. Further drying is carried out outdoors, which can take more than one month.

If the form was made of boards, then the internal planes of the cells are covered with plastic film, which prevents moisture from passing from the concrete into the wood. In this case, the film separates the solution from the mold, which will help when disassembling the structure without affecting the integrity of the blocks. If the mold is made of sheet iron, then the inner walls must be coated with processing.

If you want to make blocks with holes, thereby lightening the wall material, then you need to prepare wooden or metal pins. They are installed either before pouring the solution into the cells, or after, sticking them into the solution at the same distance from each other.

Final drying

Sawdust concrete blocks should be dried in the air, preferably not in a draft, by placing them under a canopy and covering them with plastic film. It is important to leave gaps between them for ventilation. Usually the blocks are assembled into pillars of two stones. The bottom two are laid on bricks, the top two across the bottom ones, and in this sequence to a height of up to 10 stones.

After three months, the sawdust concrete mortar in the blocks will gain 90% of its brand strength. Stones can already be used in construction. Finished products must be durable and free from defects in the form of cracks. To check how strong a block is, it must be dropped to the ground from a height of 1 m. If it does not break, then the strength is sufficient.

How to make sawdust concrete with your own hands

Initially, the so-called dough is mixed from:

It is best to carry out the mixing process in a concrete mixer. Gradually add all ingredients. The consistency of the mass should be homogeneous. This will have a beneficial effect on the structure of houses, since the surface of the material will be smooth.

After this, the solution is poured into pre-made wooden molds of any size, lined with linoleum or special polyethylene tape. It will dry quite quickly. But for the material to get stronger, it will take more than 3 months. The finished sawdust concrete blocks are laid out under a canopy on the street. Moisture will come out of it gradually, which avoids the appearance of internal deformations.

Note. A house made of sawdust concrete, which has acquired natural strength, will be of higher quality.

Project of a two-story house built from sawdust concrete

Technology for constructing sawdust concrete walls

Construction from sawdust concrete makes it possible to save a lot of money. After all, there is no need to build a large and complex foundation for a structure made of this material. Usually a shallow belt is chosen.

As for masonry mortar, there are several options:

- mortar based on sand and cement;

- ready-made heat-insulating mortar with perlite;

- adhesive composition for laying cellular concrete blocks.

The second option is preferable because the seam is filled with a solution that will not act as a cold bridge. And for a house made of concrete blocks, this is an important factor.

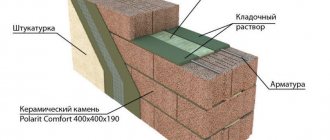

The masonry process itself is carried out using identical technology, associated with other block materials. Namely:

- assembly begins from the corners of the building;

- the first row of blocks is laid on sand-cement mortar, as the most durable;

- vertically stacked stones are checked with a plumb line or building level;

- in the horizontal plane, verification is carried out using a thread stretched horizontally;

- the masonry is carried out with a band (offset to the floor or a quarter of the stone), the main thing is that the vertical seams should not coincide;

- To strengthen the wall structure, a synthetic reinforcing mesh is laid between the blocks.

If the masonry row is not to be filled with a whole block, the latter is cut to the required size. In this case, the thickness of the masonry mortar (seam) is taken into account.

Wall decoration

Material made from sawdust and cement does not shrink because it is well dried before installation. Therefore, finishing can be carried out immediately after the construction of the walls and the construction of the roof.

There are no restrictions in this regard. This can be plastering followed by painting, installation of siding, block house or lining, lining with brick, stone, etc. As for interior decoration, plaster with perlite is most often used to increase the thermal insulation properties of the wall.

Disadvantages of construction from sawdust concrete

As in any business, building with your own hands, in addition to the advantages, also contains the following disadvantages, which, rather, are simply features:

- you need to clearly select the composition of sawdust concrete for building a house, since it can be of different densities and, accordingly, different load-bearing capacity and thermal conductivity. Correct calculation will help you obtain a material with the required load-bearing capacity with the lowest possible thermal conductivity, whether for block or poured walls;

- it is necessary to carefully study the technology chosen for the construction of walls, be it a block or monolithic version, since due to inexperience you can get very crooked walls that will barely bear their own weight, or errors will lead to very difficult wall cladding, this also happens;

- again, you need to strictly adhere to the technology regarding the introduction of sawdust mineralizing substances into the material, otherwise the high water absorption of sawdust concrete will significantly reduce the service life of a house built from it and will negatively affect the comfort of its operation.

To summarize all of the above, sawdust concrete is almost the best thing you can choose for building a house with your own hands, especially alone. The advantages of both the flood method and the block method are simply undeniable, but the disadvantages can only conditionally be called such and with the proper approach they are simply eliminated.

Additional properties of sawdust concrete

The good thermal insulation qualities of sawdust concrete have become the reason for its use for cladding load-bearing structures of houses. In this case, it is used as insulation. To insulate the ceiling or ceiling, thin blocks 100 mm thick are used. They are either poured into specially prepared molds or cut from standard blocks. For wall cladding, stones of standard sizes or with reduced parameters are used. Thermal insulating masonry mortars are used for installation.

We build a house from sawdust concrete

Before choosing sawdust concrete as a material for constructing a building, you need to understand what properties it has. Sawdust concrete is a cheap building material. It has increased heat-insulating and sound-absorbing characteristics. But its shortcomings require deep thought when choosing a composite as a material for building a house from sawdust concrete with your own hands.

The special components of the product and its characteristics give it a lot of advantages in the eyes of consumers

The main disadvantages include:

- Low moisture resistance of the material, requiring additional processing.

- Unpresentable appearance requiring decoration.

- Short service life due to reduced strength.

Considering the disadvantages, the use of sawdust concrete is limited to the construction of small buildings. The main application is country houses, auxiliary buildings that do not require high strength load-bearing walls. At a density of 300–700 kg/m³ it is used as insulation. When the density increases to 700–1200 kg/m³, it is used in the construction of load-bearing walls with subsequent moisture-proof treatment.