Design parameters of the base

If the old plank floor is leaky, it must be replaced with a new

one. The floor is a complex multi-layer structure that provides the ability to walk around the room, as well as thermal insulation, sound insulation, and protection from moisture penetration from below.

Approximate floor design on joists:

- subfloor or base - in a private house it is in contact with a sand and gravel pad or serves as the ceiling of the basement;

- load-bearing beams - logs, massive supports that can withstand the load created by people and furniture;

- thermal insulation - a layer of insulation that prevents heat loss from the room;

- waterproofing – protects the insulation from condensation;

- counter-lattice - a frame made of thin slats on which the flooring is mounted;

- finishing floor

The materials and characteristics of each layer of the “pie” depend on the base. Concrete and wood are suitable for a wooden house.

Concrete floor

If the boards are not rotten, they can be poured over them with concrete.

What is most attractive about this design is its simplicity and economy. The filling process is extremely simple, especially if special mixtures are used. It is enough to place levels on a sand-gravel or earthen cushion and fill with the mixture. After hardening, an absolutely flat, reliable floor is obtained.

The base is strong; finishing and constructing the “pie” will require less time and materials. The floor price is lower.

The disadvantage is the completion time: concrete reaches strength in at least 4 weeks and it is impossible to carry out any other work during this time. In addition, it creates a large load on the foundation.

When pouring a concrete base, it is necessary to install damping elements and divide the base itself into several sections. Otherwise, under the influence of vibrations of wooden walls, the floor will crack.

Wooden floor

An option for replacing a floor is laying new boards on old joists.

Replacing floors in a wooden house often involves using the same material. Wood has excellent heat and sound insulation qualities, remains warm to the touch even when the heating is turned off, does not emit harmful substances and remains attractive throughout its entire service life.

On the other hand, wood requires care and careful preparation, as it is afraid of moisture: it swells, dries out, and rots. Laying a wooden floor is difficult and takes more time. It is quite difficult to achieve ideal evenness of the coating.

There are single and double layer floors. In the first case, installation can be done without beams. In the second, cavities automatically appear in which insulation is placed. Here you can install a “warm floor” heating system.

Features of replacing a wooden floor

Replacing a wooden floor in a country house is not the easiest job and is very dirty. The speed and complexity depend on the condition of the old coating. Other factors also influence this:

- Before removing the flooring, you need to make sure that communications are not hidden under it - wires, pipes, ventilation.

- Dismantling is carried out using steel scrap or crowbar. The work is noisy and requires strength.

- It is necessary to remove not only the top flooring, but also the entire system: joists, insulation, rough flooring. All that remains is a cushion of sand or earth.

- For arranging a concrete base, it is recommended to use self-leveling mixtures, as they significantly simplify installation.

- It is easier and faster to use bitumen mastic as a waterproofing material. However, when laying a purely wooden structure, roll waterproofing will be required.

The nature of the flooring is determined by the style of the room and design features. Laminate or parquet is quite suitable for installation on a “warm floor” system; linoleum cannot be used in this capacity.

Floor coverings in rooms with high humidity

The time has come to consider the installation of floors in rooms such as the bathroom. High humidity levels require a special approach to construction and repair work. This is why there is a need for moisture-resistant floor coverings.

In this case, ceramic tiles and marble chips are perfect. They respond well to humid environments and retain their aesthetic appearance for many years. The same materials can be used for the hallway, kitchen and even balcony.

By the way, about balconies. Clinker tiles have also proven themselves excellent as flooring on balconies.

Simple wood floor repair

Replacing rotten boards with new ones

Complete replacement of floors in a wooden house can be avoided if individual elements are repaired in a timely manner. As soon as chips, cracks, abrasions, or squeaks appear, repairs must begin immediately.

- Deep stains, abrasions, cracks and chips can be eliminated by sanding the flooring.

- Deeper cracks are sealed with putty, a mixture of sawdust and polished.

- If the board begins to rot, become deformed, or become covered with plaque, it must be replaced immediately.

- If the beams are rotting, you cannot see it. To check their condition, the floorboards are tapped with a hammer. If instead of a ringing sound there is a dull sound, the logs have become unusable. In this case, you will have to dismantle the covering and replace the damaged beams.

- Creaks and loud noises mean that the floorboards do not fit together well. It is recommended to tighten them.

- If an unpleasant smell of rot appears in the house, both the finished and rough flooring, joists and even embedded crowns must be replaced.

Repairs will also be required if the floor sag. In this case, the wooden parts may not have any defects. Repair comes down to installing additional supports made of steel pipes or bricks under the floor beams.

Diagnostic work

Before you begin repairs, you should carefully inspect the flooring to determine which part of the boards and joists need to be replaced. Pay attention to both the rotten fragment and the one that was eaten by the bark beetle. Depending on the results obtained, a decision will have to be made on whether to carry out partial or major repairs.

Checking status

The first will cost much less, as it involves replacing individual floorboards and adjusting the spatial position. During a major overhaul, the structure will have to be dismantled. After this, the damaged elements will need to be replaced. Having decided on the type of repair, calculate how much material will be needed.

Attention! If the flooring itself looks perfect, check the condition of the subfloor.

To make sure the wood is intact, take a hammer and knock. A rotten board has a characteristic dull sound. The nails show signs of corrosion. You will have to get rid of such shabby boards by cutting out the damaged areas or replacing the floorboards.

The following signs indicate the need for repair work:

Floorboards creak when walking on the floor.

- Deflection of the finished floor under the weight of furniture or other heavy objects.

- Presence of slope. A small amount of water will help determine. If the level difference is significant, the liquid will flow in a certain direction.

- Gaps or cracks between boards.

- Wood crumbling with minor impact.

Removing old floors and preparing the base

Insulation of the floor when replacing the covering

Replacing floors in a private house begins with removing the old covering.

- Wooden deck boards or other material are removed using suitable tools. Boards, joists, and all construction waste are removed from the house.

- The new base is laid on a layer of crushed stone and sand or on an old screed, if the latter is strong enough and has not suffered from mold. Level the surface as much as possible. If this fails, fill it with screed.

- Before laying, the base is treated with a primer with an antiseptic effect. Its task is to improve the adhesion of the base to concrete.

- Waterproof with bitumen mastic. To proceed to the next stage of work, you need to wait until the mastic dries. If necessary, duplicate waterproofing with roll materials. All joints are treated with mastic.

- Insulation is laid on the waterproofing layer. Under the concrete floor, slab materials are used - polystyrene foam, penoplex, and less often mineral wool. If the floor is installed on joists, expanded clay, basalt and mineral mats are used.

Dismantling an old concrete base is extremely rare. To remove it, you need to use a hammer drill.

Dismantling the floor.

In a private home, from time to time you have to make efforts to maintain it in good condition.

The floor requires special attention, and if its quality leaves much to be desired, it needs to be replaced. In this article we will tell you in detail how to do this. Changing the floor is not an easy task, but necessary when it is worn out.

The main criteria for checking field strength are:

- the floor creaks under load;

- boards on the floor sag under the furniture;

- differences in floor level;

- gaps and cracks between boards;

- the quality of the material deteriorates (the wood crumbles and becomes rotten).

If you observe several items from the list presented, then it’s time to change the gender.

Work is usually carried out in several stages:

- preparation of necessary tools and materials;

- dismantling the old floor;

- installation of a new floor;

- finishing coating.

Any construction job requires a number of tools.

To lay the floor we will need:

- screwdriver;

- drill;

- saw or jigsaw;

- building level;

- axe.

It is also necessary to prepare materials for installation of the coating:

- timber for logs;

- boards;

- insulation;

- substrate;

- nails, screws.

Having prepared all the materials and tools, you can begin to work.

When choosing materials, the question arises: what to prefer: edged or floorboards. To begin with, it is necessary to characterize each species. An edged board is a woodworking product with a rectangular cross-section with specified dimensions. It is obtained by processing the log from all sides.

The following tree species are used to make boards:

- conifers (spruce, pine, larch);

- hard deciduous (oak, beech);

- soft deciduous (birch, aspen).

The cost of timber will depend on the type of tree. For example, a larch board, due to its durability and resistance to moisture, will be more expensive than its pine counterpart. True, edged boards have one drawback: a large number of knots. This material is suitable for installing subfloors or flooring in non-residential premises.

The floorboard is another matter. It is made of wood and carefully processed on all sides. This material is ideal for flooring. And most importantly, you don’t have to additionally dry and treat the surface of the boards, achieving a nasty coating.

Construction timber is widely used in construction and repair. It is made from coniferous and deciduous wood. The beam can have a square or rectangular cross-section. It is obtained by processing a log from four sides. Material measuring 50*100 mm is widely used in repairs. It can be used to make lathing for wall cladding or floor joists. Its cost can vary between 4 – 10 thousand rubles.

When dismantling the floor, you need to prepare tools. To do this you will need a nail puller, a crowbar, pliers and a saw.

Next, you need to perform a number of preparatory work:

- we clear the room of furniture;

- remove old baseboards;

- remove the floor covering;

- remove the subfloor;

- We take out the trash and clean the room as much as possible;

- We do wet cleaning of the premises.

It is quite difficult to cope alone, so ask for help in advance. Next, armed with a nail puller, we try to remove the nails with which the boards are nailed. This will make it easier to remove them. If it doesn’t work, you can lift the boards with a crowbar. If necessary, you can saw the covering and dismantle the boards in parts. This will make it easier to take them out. After this, you need to remove the lags. This way we will get a completely cleared space for installing a new floor.

First you need to level the surface for installing the logs.

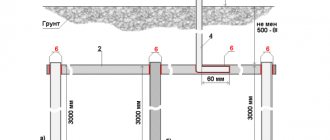

To do this you will need to perform the following sequence of actions:

- level and compact the ground;

- in the place where the supports are installed, we make recesses measuring 20 by 20 cm and up to 50 cm deep;

- after that, we fill them with layers of sand, crushed stone and rubble chips, each 6 cm thick;

- fill them with concrete solution;

- We erect brick columns on concrete for laying beams;

- after that, logs are laid on the beams in increments of 50 - 80 cm;

- the space between the joists can be covered with boards or particle boards.

This way we will get a frame for laying the finishing coating.

But, we still need to insulate the floor. Mineral wool is suitable for this; it is placed in the spaces between the joists and covered with a waterproofing film. The level installation of the logs is checked with a level, or checked with a cord that is pulled between the two outer boards.

If the floor is being replaced on a concrete base, it is enough to replace the logs and lay insulation. And then comes the laying of the boards.

First you need to decide on the direction of installation. It is best to do this from the windows, this will achieve the effect of increasing the space. We start laying from the wall. In this case, you need to leave a gap of 1 cm at the ends and side surface of the wall.

This is necessary because wood can expand when moisture increases and contract when dry. We secure it with self-tapping screws. Next, we sequentially install the floor, securing them with self-tapping screws into the grooves of the boards. When installing the last board, it is necessary to measure the distance taking into account the gap. You can trim it if necessary.

To prevent the coating from deforming, you can insert pegs between the boards and the wall. Now you can varnish or paint the floor.

Many people will wonder why lay fiberboard when you can lay linoleum on boards. The fact is that sheets of this material are a good thermal insulation material. And keeping the house warm is the most important task. Also, a completely flat surface allows you to achieve an even coating. Before installing the fiberboard, it is necessary to fill all the cracks between the boards with acrylic sealant and any uneven areas with putty.

Now you can fasten the slabs using nails or self-tapping screws. The disadvantages of such methods may be the fastener caps protruding above the surface. To eliminate this problem, we make recesses at the fastening points so that the caps are completely submerged and flush with the plane of the floor. Before installing the slabs, you need to leave them in the room for a couple of days. After this, we lay fiberboard starting from the far corner of the room, gradually moving towards the door.

Now fill the gaps between the plates with putty.

Now you can lay linoleum; it is also left indoors for two days to adapt to temperature and humidity. Next, we spread the material and give it time to rest. After this, you can secure it with baseboards. Since this coating dries out over time, it must be laid close to the walls.

Another option is to glue it to the surface of the fiberboard. Apply the adhesive composition to the floor with a notched trowel and wait until it thickens. Next, it is applied to the back side of the linoleum and glued to the floor. To ensure that the coating is even, it is straightened from the center to the corners.

This way we will get a smooth and warm floor covering.

This article tells you how to replace a wooden floor in a private home. Talk about what tools and materials will be needed. Using the advice in the article, you can prepare the necessary tools and carry out the work yourself. Good luck.

The first step when replacing and/or insulating floors with your own hands will definitely be to dismantle the baseboards around the perimeter of the room and the existing floor covering, and, possibly, transfers. No special skills are required here, the main thing is accuracy in work and attentiveness when disassembling, so as not to disrupt communications (mainly electrical wiring and sewerage, possibly plumbing with heating).

We invite you to familiarize yourself with the storage tank for water from a well

After all this, the accumulated construction waste should be removed (there will be a lot of it, so prepare a place for its disposal in advance). Often, it is no longer possible to carry long boards and translations through the doors, so we either cut them right in the room (inconvenient, and when using a chainsaw, the smell of exhaust fumes remains) or we feed them through the windows (most often this is what they do).

Redevelopment

Redevelopment means any change in the configuration of a room. This fully includes changing the floor design. For such work you need to obtain permission.

You need to figure out what these changes are:

- Repairing the floor in a country house with your own hands, if it does not belong to the category of residential buildings, does not require permits.

- Changing the flooring - boards or insulation - does not change the configuration of the room and is done independently.

- If during the renovation process new communications are laid and old ones are removed, you will need to create a project and have it approved by the relevant authorities.

- Replacing a wooden floor on joists with a concrete base with a “warm floor” system also requires permission. Concrete floors are much heavier, putting additional stress on the foundation and reducing the height of the room.

Current repairs and redevelopment that do not change the living space do not require permission, but are recorded in the technical passport of the building.

Replacing the floor in a private house with your own hands

OSB boards under a wooden covering

Most often, a wooden floor on joists is replaced with the same one. Such a foundation is lighter and does not require additional strengthening of the foundation.

- The base floor is leveled, cracks are sealed with polyurethane foam and cement mortar. If the base is wooden, use a mixture with sawdust. Treat the surface with antiseptics.

- Waterproof the floor with bitumen mastic. The material is applied not only to the base, but also to the walls to a height of 10 cm.

- The logs are laid in increments of 50 to 80 cm. The distance depends on the flooring material.

- Insulation is laid between the joists. You can take expanded clay, it is much cheaper. More often, mats made of mineral and basalt wool are used.

- The thermal insulation layer is covered with rolled waterproofing material. It is better to use a special film, since polyethylene does not allow steam to pass through. The joints are treated with mastic or other composition with similar properties.

- If the logs form a flat surface, the finished floor can be mounted directly on them. However, it is better to make a counter-lattice from thin slats placed in the opposite direction to the beams.

- Lay the finishing flooring: boards, parquet modules, laminate.

If the covering is a soft material, such as linoleum or cork boards, sheets of plywood are placed on the sheathing.

Replacing the flooring in a private house is a difficult, dirty and time-consuming job. The timing and costs depend on what the new foundation will be, what material is used for the flooring, and whether a floor heating system will be installed.