The direct purpose of VVG power cables with indices (ng) and (-LS) is energy distribution of any stationary type installations. As a rule, the latter work on:

- Base voltage – from 660 V to 1000 V.

- Constant voltage up to 1000 W.

Note! VVG is a cable that has its own insulation and sheath made of polyvinyl chloride plastic. The differences between the above-mentioned cables lie precisely in the indices assigned to them - ng and LS.

Main differences between VVGng and VVGng-LS

Application:

The VVGng cable is used in laying:

- Cable routes in premises. Mainly in business.

- Cable trays.

- External works.

VVGng-LS, on the contrary, is actively used in residential premises, offices and crowded places. External installation is also acceptable. The latter cable, which has the LS index, due to its design and materials, has minimal smoke and gas emissions in the event of ignition of its sheath. VVGng is a cable that prevents the spread of fire, especially if we are talking about group laying of the route. A possible local burning of the bundle gasket, and it is quite insignificant, will release more smoke and gas, which can complicate the evacuation of people.

That, in fact, is the fundamental difference in the intended use of the cables in question, as well as the principle of assigning the corresponding indices to them.

Core cross-section

Unlike VVGng-LS, the VVGng cable has a smaller core cross-section, exclusively in relation to four-core and five-core power conductors. For example, four-core VVGng-LS has a cross-section of 70 mm2, and VVGng - 90 mm2. The same, but already five-core conductors, have the following cross-sections - 185 mm2 and 120 mm2, respectively.

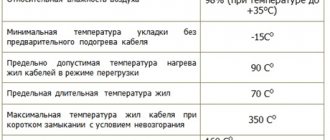

Laying conditions

Installation of the VVGng-LS cable is allowed even at 25 degrees below zero, while for VVGng the permissible limit is considered to be -15°C. It is also worth noting that lower temperatures require the use of special equipment that will heat the cable every 100 - 150 meters. Otherwise, the installation - the formation of a bundle gasket - will not be of high quality. The latter will reduce the coefficient of protection against fire due to the fault of a third-party source, if we are talking about the VVGng cable.

Price policy

Of course, price is the main difference and the reason for choice. Pricing depends on the quantity and quality of materials used. In the case of the power cables under consideration, high-quality materials are used, up to tubular PVC braid, but their quantity is different. In the case of VVGng-LS there are more of them, and the production method is more complicated. These two factors influence the price, which, by the way, is higher, by approximately 12%, in relation to the above-mentioned VVGng.

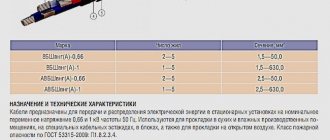

VVGng(A)-LS

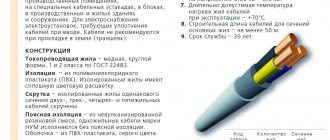

Technical characteristics of VVG cable

The features of using different types of VVG cable were discussed above, and now we will talk about the technical parameters of conductors of this brand.

- Can be laid at temperatures down to -15°C. At lower temperatures, it is necessary to heat the cable, which is not easy to organize (the sheath becomes too rigid and is very difficult to bend).

- Operating temperature range - from -50°C to +50°C. At the same time, when installing outdoors on the street, additional protection from ultraviolet radiation is required.

- Bending is possible with restrictions: VVG with single-core conductors; minimum bending radius is 10 radii;

- with stranded ones - 7.5 radii (due to greater flexibility).

There are flat options (two and three wires)

- for a short circuit in which the conductors remain operational depends on the manufacturer and can range from +160°C to +250°C.

It must be said that the technical characteristics of the VVG cable depend not only on the specific type, but also on the manufacturer. Therefore, before purchasing, look at the cable passport (you can ask the seller). The above are parameters common to all brands of VVG cable.

It is not surprising that these conductors are very popular - with good technical indicators, they cost relatively little, and can be used almost everywhere - both in enterprises and offices, and in houses and apartments.

Section and number of cores

The cross-section of the VVG cable cores of any brand can be from 1.5 mm2 to 240 mm2. Conductors with conductors up to 35 mm2 are usually on sale; other, larger sizes must be ordered.

As already mentioned, there are VVG cables with 2, 3, 4 and 5 cores. The number of cores is written immediately after the abbreviation: VVG 2 x 3.5; VVGng 4 x 4, etc. The first number is the number of cores, the second is the cross-section of the conductor.

Approximate range of VVG cables

There may be VVG cables with “neutral” and “grounding” conductors. Moreover, there are options in which the protective wires are of the same cross-section, and others with a smaller diameter (to save copper and lower cost). Most often, the “ground” conductor is made smaller; in some cases, the “neutral” is also made a little smaller. If the protective conductor has a smaller diameter, it is designated as +1. For example, VVGng 4 x 4.0+1 (read as 4 wires with a cross-section of 4 mm2 and 1 step less than 2.5 mm2). These VVG cable options are also standardized, their parameters are given in the table below.

Parameters of VVG cables with cores of different diameters

Continuous current

When selecting a cable cross-section, a more correct method is based on the maximum current. In this regard, such a characteristic as long-term permissible current is standardized. It depends on the number and cross-section of the cores, as well as on the method of laying - open or closed.

| Core cross-section | Continuously permissible current | ||

| with two main cores | with three main cores | with four main cores | |

| 1.5 mm2 | 24 A | 21 A | 19 A |

| 2.5 mm2 | 33 A | 28 A | 26 A |

| 4 mm2 | 44 A | 37 A | 34 A |

| 6 mm | 56 A | 49 A | 45 A |

| 10 mm | 76 A | 66 A | 61 A |

| 16 mm | 101 A | 87 A | 81 A |

| 25 mm | 134 A | 115 A | 107 A |

| 35 mm | 208 A | 177 A | 165 A |

Two modifications of VVG cables are produced - with a rated voltage of 0.66 kW and 1 kW.

Conclusion

Thus, it turns out that the use of VVGng-LS power copper cable is rational in those premises where people live and work. The VVGng cable, although it is fire-resistant (does not propagate combustion provided it is laid in bundles), is best used in outdoor installations, as well as stationary installations outside buildings, even if we are talking about industrial production. Excessive release of smoke and gas can be fatal, both for humans and for manufactured/stored products.

Hi-techComment

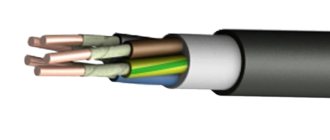

Decoding and structure of the VVG wire

To do this, let's first understand the structure of the wire. Deciphering its abbreviation, as well as a detailed analysis of the cable structure, will help us with this.

Decoding of VVG cable

Let's start by deciphering the abbreviation of the cable name. GOST 53762-2010 will help us with this, to which our guide must comply.

Differences between AVVG and VVG cables

So:

- The first letter that can appear in the abbreviation is A. It denotes the use of aluminum conductors. In our case, it is not there - this means that our cable has copper conductors.

- The next letter indicates the cable insulation material. In our case it is "B" . It stands for vinyl, or, as it is more correctly called, polyvinyl chloride.

- Our next letter is again “B” . This means that our cable has another layer of insulation. As you probably already guessed, this is vinyl again.

- Our third letter is “G” . It means the cable has no armor. Due to this, the VVG cable turns out to be, although less stable, but much more flexible. It is this property that has ensured that this type of conductor is widely used.

VVG cable structure

- But we were interested in the VVGng cable. “NG” means that the cable does not propagate flames when laid together. The fact is that when laid alone, almost all wires do not spread combustion. But to prevent the cable from spreading fire when laid in groups, it is coated with a special solution.

VVGng cable marking

- But in addition to the abbreviation “ng”, the cable designation may also contain symbols such as “A”, “B” or “ls”. The symbols “A” and “B” indicate cable resistance categories. And the presence of the “hp” symbol tells us that when burned, the cable emits a reduced content of smoke and harmful gas.

VVGng cable structure

- In addition to the above symbols, after the symbol “ng” there may be “HF” . This indicates that the cable does not emit corrosive gaseous products when burned. The abbreviation “FRLS” means that the conductor is fire resistant and has reduced smoke and gas emissions. Well, “FRHF” will tell you that the cable is fire-resistant and has a reduced emission of corrosive gaseous substances.

VVG cable structure

The characteristics of the VVGng wire are ensured by its structure. Therefore, you cannot ignore the cable structure. Moreover, this concerns not only its mechanical and electrical characteristics, but also simply its appearance.

| As we have already defined above, the conductors of our cable are made of copper. The number of cable cores can be from one to five. In the marking, the first number indicates the number of wires, and the second number indicates the cross-section of these wires. For example, VVGng 3x1.5 means that the cable has three cores with a cross-section of 1.5 mm2 each. |

| Each individual core can be made of one wire of the appropriate cross-section, or of several wires twisted in an appropriate manner. This can also be determined from the cable designation. “o” denotes cables in which each core is made of one wire. Multicore products are marked “m” accordingly. |

| It is clear that cables with a small nominal cross-section have a single-core structure. But multicore cables have one more difference. Each individual core can have not only a round shape, which is not very convenient for large sections, but also a so-called sectoral, or, as it is also called, segmental shape. In this case, each individual core has the shape of part of a sector of a circle. |

| Cables that have a conventional round shape are designated by the symbol “k”. Conductors with a segmented arrangement of cores are designated “c”. |

| But, as you can see in the video, there are also VVG flat cables. This is when all the cores are laid along one plane. This form is usually used for cables with a small cross-section. |

| We talk and talk about the cross-section, but we have not yet identified its denominations. For VVG cable, the nominal range starts from 1.5 mm2 and up to 50 mm2. At the same time, sometimes you can find products with a rating of up to 400 mm2, but such cables are usually produced on special order. |

| And here it should be clarified that if the cable rating is, say, 4 mm2, this does not mean that all cores have this cross-section. As an example, let's take a five-core conductor of this cross-section. According to PUE standards, the neutral conductor and grounding conductor may have a smaller cross-section, which is why the price of the cable may be lower. And in our case, they can be 2.5 mm2 each. |

Note! In our case, the neutral conductor and the grounding conductor have the same cross-section. But this is not the rule. As you can see in the photo, the neutral conductor can be an order of magnitude lower than the nominal cross-section, and the grounding conductor can be one order of magnitude smaller.

- But what are we talking about veins and veins? An important part of the cable is the insulation. And here everything depends on the nominal cross-section and rated voltage for the work for which the cable is intended.

VVG cable insulation thickness

- So, for voltages up to 660V, the nominal insulation thickness of a wire with a cross-section of 16 mm2 will be 0.9 mm. And for a wire of the same cross-section, but for a voltage of up to 2.5 kV, it will be 1 mm. In this case, not only the nominal thickness is standardized, but also the minimum thickness, which allows for some deviation.

- As we remember from the transcript, the VVG wire also has a second layer of insulation. It depends on the rated voltage and the diameter under the sheath. So, for our three-core cable of 16 mm2, the nominal sheath thickness will be 1.7 mm.