Since electricity was discovered and the first generator was built, humanity has been using various types of cable products to transport electricity. There are simply no other technologies for transmitting electric current over a distance. A cable or drive is the only electrical product that can be used to create electrification networks. These products are available in a huge range. To solve a specific problem, you need a product of the appropriate brand. If the electrical network needs to be protected from mechanical damage, then an armored cable should be used!

Power armored cable is a specialized electrical product, the current-carrying conductors of which are reliably protected from mechanical damage by a special additional sheath made of metal or other durable material. The range of such products is varied and each brand has its own design and technical features. Armored cable is mainly intended for laying underground power lines, but can also be used for installation in open spaces where protection from accidental damage is required.

In this article, we will look at the design, classification, scope of application and installation features of armored cables. The market for electrical products currently can offer consumers a variety of brands of such products, differing in design and labeling, as well as technical characteristics. Therefore, in order to make the right choice, you need to understand all this variety of these products. We will begin our acquaintance with the armored power cable with a description of its design and the features of all its components.

Armored cable design

Cable products with a layer of armor in their design are not much different from similar products that do not have a protective sheath. These conductors of electrical energy have the following components.

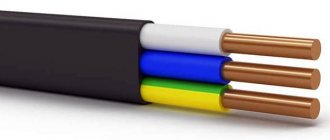

- Conductors are metal conductors of electricity. The number of these elements can be from one or more. According to their shape, the cores can be round, flat, segmental, rectangular or sectoral. They come in either a monolithic design or consisting of many thin wires connected into one structure. The cores are made of copper and aluminum, in rare cases of steel, and for specialized cable products from gold, silver and superconducting alloys.

- Insulation of current-carrying cores - this layer isolates each current-carrying core from each other, as well as from the influence of the external environment. For its manufacture, polyvinyl chloride polymer (PVC), special rubber, polyethylene, impregnated paper and other synthetic materials can be used. In most brands of armored cables, the core insulation is multi-colored. This is necessary to simplify installation work and quickly determine the purpose of each individual core by color. The entire set of current-carrying conductors is protected by belt insulation.

- Internal fillers — seal the internal space between different parts of the cable. Provide additional mechanical strength and rigidity of the entire product structure. Both synthetic and natural products are used as materials for the manufacture of fillers: special cable yarn, impregnated paper, polymers, rubber and even oil. The filler must have high dielectric characteristics and sealing properties.

- Shielding layer - This is an optional element of armored cables. Installed in those brands of products that are designed to operate in conditions of strong external electromagnetic radiation in order to reduce its effect on current-carrying conductors. In addition, screens make it possible to reduce the intensity of the electric field of the armored cable itself, which in some cases is a necessary condition for its operation. Screens are made from metals in a protective shell, conductive paper and other materials.

- The cable sheath with cushion is the outer layer of the product, protecting the entire internal part from moisture and mechanical stress. Various materials are used for its manufacture: PVC, rubber and other polymeric substances, and in special cases the outer layer is covered with a lead sheath. The cushion is necessary to protect the protective outer shell from damage by the metal armor layer. It is made from bitumen or special cable yarn.

- Steel armor is a layer that protects current-carrying conductors from possible mechanical damage during installation and operation. It can be made either from two galvanized steel strips or from intertwined steel wires coated with zinc. Tape armor is more reliable than wire armor, but a product with such protection is more expensive. Depending on the operating conditions, a cable with the armor that is optimally suited for the application is selected.

The advantages of armored cable products include high moisture resistance and strength, durability, excellent anti-corrosion properties and a wide operating temperature range. The disadvantages of these products are low flexibility and high price.

Application of VBShv cable:

The purpose of this brand of cable is to conduct electricity, as well as its distribution in stationary equipment at an alternating rated voltage of up to one Kilowatt and a frequency of fifty Hertz.

It is used in electrical networks with a neutral, insulated or grounded. Moreover, the duration of the working period in conditions of a short single-phase circuit is no more than eight hours, with a total working period per year of no more than one hundred and twenty-five hours.

It is used when laying various routes, in particular in vertical sections.

VBShv is used when laying single lines both indoors and outdoors under various conditions, including unfavorable ones. It is indispensable in the construction of high-voltage lines and is used in trenches and mines.

If a group gasket is installed, the presence of fire retardants is mandatory.

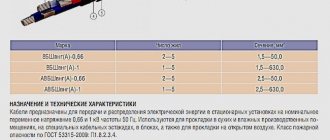

Marking of cables with a layer of armor

Armored cables are available in various designs, which are indicated in the product labeling. The marking standard is the same for all types of cables and wires. The marking code consists of a set of letters and numbers, where each letter symbol indicates a specific design feature or technical characteristic of the product. The absence of a letter can also indicate certain properties of the product. So, below we will look at the letter and number markings of armored cables.

- Metal of current-carrying conductors: if it is “A”, then this is an armored aluminum cable, and if there is no letter, then this is an armored copper cable.

- Type of outer shell: “B” - made of PVC (polyvinyl chloride); “P” - polyethylene; “Shv” - in a PVC hose; “Shp” - polyethylene hose; "C" - lead sheath.

- Presence of a screen: the letter “E” in the marking indicates that this cable has a shielding layer, and its absence indicates the opposite.

- Insulation of current-carrying conductors: “B” - made of polyvinyl chloride (PVC); “Pv” - stitched polyethylene; “P” is a polymer composite material.

- The presence of a layer of armor: “B” - armor made of two steel strips, and an additional letter “b” for the absence of a bitumen cushion; “K” - armored with round wires.

- Cable cut shape: indicated by the letter “P” if it is flat; marking is not provided for a round product.

- According to the shape of the cores: monolithic ones are marked with the letter “o”, and stranded ones are marked with the letter “m”; segmental “s”, and round “k”.

In addition, the marking may contain other letters that determine the fire-fighting properties of the product. After the letter code there is a digital code, where the first digit indicates the number of cores, the second the cross-section of the current-carrying wires in mm² and the third the rated voltage.

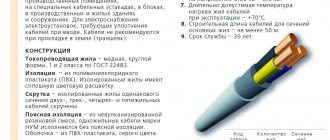

VBBShv cable design

The VBBShV cable has mechanical design features. For example, it is worth considering that copper conductors can be either single-wire or multi-wire. Cores from 1.5 to 50 mm2 can be single-wire. From 16 to 1000 mm2 cores are produced in more flexible stranded variations.

General cable design:

- The conductor is made of copper.

- The core insulation is made of PVC plastic. Each core has a color or digital marking.

- Belt insulation made of extruded polyvinyl chloride, filling the free space between the cores.

- Armor made of two spirally applied steel strips.

- The outer shell is in the form of an extruded polyvinyl chloride hose.

Cores with a cross-section from 1.5 to 50 mm2 are most often made single-wire. Conductors with a cross-section from 16 to 1000 mm2 are produced stranded, which increases their flexibility.

Laying and cutting of armored cable

The laying of armored cables in the ground and in open space is carried out in compliance with the requirements of the PUE (electrical installation rules) and building codes. To lay the product in the ground, it is necessary to properly prepare a trench with a depth of at least 50 cm. The bottom of the trench should be equipped with a sand cushion. A cable with armor can be laid in the ground without a protective sheath, but it is best to pass it through a pipe and cover it on top with signal tape, which will ensure the safe carrying out of various excavation works in the future.

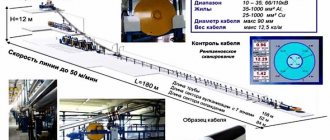

Particular attention should be paid to cutting the ends of the armored cable, which is necessary to connect individual parts of the product and connect it to input distribution devices. In industrial conditions, this operation is performed using special machines. In everyday life, when connecting private houses or summer cottages to electrification networks, cutting is done manually, carefully removing each layer of cable down to the current-carrying cores. The cable parts must be connected using special couplings. During installation, it is necessary to ground the armor layer.

Cable for laying in the ground - review of power cable brands

| The most common and frequently used brand of armored cable for laying in the ground is VBBbShv, according to the new standard (GOST R 53769–2010) VBShv or a similar aluminum cable AVBbShv. VBBShV cable is produced for voltages of 0.66 kV, 1 kV, 3 kV and 6 kV. Thanks to the armor made of steel strips in the design of this brand, cable laying is carried out without protective pipes. armor protects the cable from mechanical influences and rodents. In addition to laying cables in the ground, VBShv is used for laying by air, in special cable structures, damp places, etc. The peculiarity of the installation of VBBShV is that the steel armor must be grounded. Go to the catalog of armored PVC cable |

| Other popular brands are armored cables for laying in the ground with paper insulation: copper, SBL, SKl, as well as aluminum with a similar design. In the design of paper-insulated cables, in addition to armor, there is always a metal sheath that protects the paper insulation from moisture. The sector shape of the cores of these cables significantly reduces the overall weight of the cable and saves space. The disadvantage of such cables is that if, when laid in the ground, the difference in the level of the route exceeds 15 meters, then a paper-insulated cable cannot be used. This is due to the viscous flowing impregnation of the paper insulation. in case of height difference, it is better to use cables with polyethylene insulation or cables with paper insulation with non-drip impregnation based on ceresin: TsSP, TsSB, TSKL, etc. Paper-insulated cables are most often designed for voltages of 1 kV, 6 kV and 10 kV. Go to the catalog of armored cable with paper insulation |

| An excellent replacement for paper-insulated cables are cables with cross-linked polyethylene (XPE) insulation. Popular brands of cable for laying in the ground: PvBbShv (produced at 0.66 kV and 1 kV), PvP, PvPg (10, 20, 35 kV). Despite the more expensive cost (by 5-60% depending on the voltage), cables with XLPE insulation have their advantages: the possibility of laying at subzero temperatures without additional heating, there are no restrictions on routes, etc. Go to the catalog of cables with XLPE insulation |

Explanation of markings

- the first capital “B” indicates that the current-carrying conductors are covered with an insulating layer of polyvinyl chloride;

- “B” literally stands for “armor,” that is, it means that the cable is protected by a layer of armor made in the form of a steel strip;

- the letter combination “Shv” informs that the outer cover of the cable is a hose made of polyvinyl chloride (vinyl) plastic;

- The absence of the letter “A” at the beginning of the abbreviation indicates that the cable cores are made of copper.

Thus, VBShv is a cable with copper conductors in PVC insulation, protected by armor coated with a polyvinyl chloride hose. The marking may contain additional symbols, for example, “ng”, indicating that the product does not support combustion, or LS (Low Smoke) - low smoke formation when exposed to high temperatures.

The purpose of the VBShv cable is the transmission and distribution of electricity to objects located at various distances, under conditions where the use of bare or unprotected conductors is impossible due to an increased fire hazard or the likelihood of external mechanical impact on them.

The working life and design of the cable allows its installation in trenches.

Rules for laying VBBShv

When laying the VBBShV product, you must follow certain instructions:

- the cross-section of the wire must be equal to the load on the electrical network;

- when wiring a group of wires in one trunk, they must be laid at an equal distance of at least 150 mm;

- the distance from the wire to the sewer drains must be at least 650 mm;

- the distance from the wire to the gas pipes must be at least 1000 mm;

- VBBShV type products must be laid 600 mm or more in depth from the ground level.

The VBBShV cable laying scheme is based on data on the area in which the work needs to be carried out. If the wire runs in an area far from sidewalks and asphalt, in the ground, then no preparatory measures are needed.

You might be interested in Choosing a speaker cable

The wire located in the trench is initially covered with sand, and then with fine soil (25 cm layer), and again with sand (about 20 cm). A warning tape is placed on the ground, a dusting is applied and the soil is compacted.

Cable storage drums