Short description

ASKUE is an automated system for commercial electricity metering. It was created by experts to make your workflow easier. If a person has just encountered this industry, then in order to perceive and understand the meaning, it is better to consider all the data using the example of an apartment building. Correct installation of ASKUE opens up the possibility for specialists to remotely take readings of electricity meters from each apartment. Data reaches its destination through special lines that are reliably protected by encryption. A special server processes the information.

Skillful use of ASKUE allows you to make important decisions in a short time about changing the operating mode of installed electrical equipment, monitor the current balance, and also carry out operational calculations of energy consumption. The experts themselves claim that the installation of such a system will also be useful at those facilities where numerous points of current consumption are scattered in different places, but are united into one network. A striking example is garage cooperatives, apartment buildings, as well as various suburban villages.

In addition to the household industry, it is impossible to imagine large transport and industrial enterprises, railways and ports, airports and transshipment terminals without ASKUE. If a specialist is only interested in recording readings, then the automated electricity metering system provides an excellent opportunity to collect current data from all installed meters separately within a specified period. Thanks to this, errors in manual rewriting of testimony are eliminated, and there is no need to recruit additional staff who will process the information.

Operating principles of ASKUE

Nowadays, many processes are based on electricity metering. Various speakers help perform functions ranging from monitoring the balance of each consumer to making various decisions regarding changes in power consumption patterns.

Askue - transcript

ASKUE is an automated electricity metering complex.

This system is the main option for quickly solving problems.

The main purpose of such a complex is to implement an automated process related to accounting for electricity consumption in order to make payments to consumers.

The information collected is needed to generate reports that are used to generate electricity consumption forecasts, as well as for calculations regarding maintenance costs.

Conditions

To carry out important functions aimed at controlling energy consumption, the necessary operating conditions must be provided.

The consumer must have:

- ASKUE device for accounting.

- A communication system that ensures signal transmission from devices to the central processing part.

- Centers created for receiving and processing information.

- Special devices installed to accumulate data when sending it to various servers.

Types of ASKUE

Since electricity prices are constantly rising, experts are trying to develop new effective metering measures in a timely manner. Due to this, the scope of application of universal automated control systems is constantly expanding. The introduction of new technologies helps to effectively and continuously control and optimize the amount of costs. Statistics have shown that automated accounting systems are used in the following industries:

- In residential sectors, private and commercial real estate.

- Collective accounting systems that allow you to service up to 50 subscribers.

- Consumer industries.

- Large systems serving up to 1 thousand people.

- In country houses and dachas, as well as in gardening partnerships.

The main part of information and measurement systems is based on a computer complex installed in individual accounting sectors, as well as processing various information at substations, oil and gas organizations, power plants, as well as at large manufacturing and industrial enterprises.

Explanation of the abbreviation ASKUE

The name is deciphered as follows:

- A – automated.

- S – system.

- K – commercial.

- U-accounting.

- E – electricity.

Sometimes a clarification is added to the name to describe the nature of the complex - “information-measuring”. In this case, the abbreviation is transformed into AIIS KUE or AISKUE.

Among the accepted abbreviations you can find consonant names, for example: ASDUE or ASTUE, but these are completely different automation complexes. The first provides dispatch control of power supply (DUE), while the second, although it is an accounting system, has a technical rather than a commercial component. The differences between these speakers will be discussed in detail below.

Key Features

The ASKUE system cannot function normally without digital electricity and power metering devices, communications, computers, and software. The collection and transmission of information occurs thanks to microprocessor devices that are located in a certain sector. The main advantages of such units include the ability to take into account active and reactive energy in accordance with the current tariff. The equipment calculates the power indicator in all directions.

You might be interested in Transformer substations KTP and KTPT for power supply

The system is designed to record the load in a certain time period and the maximum load; all information is stored in the ASKUE memory. Some devices are capable of measuring quality parameters of electricity: voltage dips, frequency. The transfer of all collected information can only take place if a connection has been established. Otherwise, the data will be archived in kilowatt-hours. Such information can be stored in the memory of the metering device for some time.

Communications are represented by specialized telephone channels, as well as telecommunications equipment (multiplexers, modems, radio modems). The final works always depend on computers. To automate the process, specialists have developed universal interfaces for transmitting collected information:

- Pls. All data is transmitted via the meter's power wires.

- RS-485 interface. The system is presented in the form of a cable that supports the connection of up to thirty devices. Thanks to this, specialists can increase the data transfer speed several times. But this option is only suitable for small objects.

- Mobile interface. Information can only be transmitted using a high-quality modem.

Particular attention should always be paid to the software, since this is what allows exchange with other suppliers and enterprises.

ASKUE: providers should think about it

This system, when viewed through the eyes of a communications operator, represents another option for using an Internet provider network to transmit data.

Accounting for consumers

Massive interest began to emerge with rising electricity prices and the simultaneous proliferation of compact computers and data networks.

Modern electricity meters with a digital interface can provide much more benefits if they are connected to the network.

It is enough to install specialized software, and it will not only provide remote automatic electricity metering, but will also show the company’s power engineers almost all the main power supply parameters in real time.

Accounting for suppliers

Electricity suppliers themselves are also showing interest in accounting automation.

There is nothing illegal in the recommendations for installing ASKUE. The fact is that, according to Government Decree No. 442 “On the functioning of retail markets for electrical energy, full and (or) partial limitation of the mode of consumption of electrical energy,” for organizations that consume electricity at maximum power (at least 670 kW), the price category of consumption is assigned by the supplier .

Energy optimization

- Accurate measurement of electricity supply/consumption parameters;

- Diagnostics of data completeness;

- Integrated automated accounting of energy resources and control of their parameters;

- Control of energy consumption for all energy carriers, points and metering objects in specified time intervals (5, 30 minutes, zones, shifts, days, decades, months, quarters and years) relative to specified limits, as well as operating and technological restrictions;

- Recording deviations of controlled parameters of energy resources;

- Alarm (color, sound) about deviations of controlled values from the permissible range of values;

- Forecasting (short-, medium- and long-term) energy metering values;

- Automatic control of energy consumption based on specified criteria and priority schemes for switching on/off consumers-regulators;

- Maintaining a single system time (i.e. ensuring synchronous measurements).

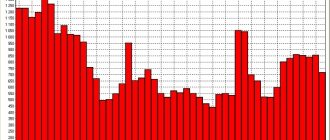

Data can be processed using special software. It makes it possible to create charts and track consumption dynamics in real time.

Construction options

There is no connection between the meters and the data collection center. All counters are queried sequentially as the operator walks through them. The survey is carried out through the optical port using a program located on a laptop computer.

The disadvantages of this method of organizing ASKUE is the high complexity of data collection.

Meters, united by a common RS-485 bus, or via a “current loop” interface, can be located in various distribution devices and polled through a common USPD once or several times a month using a program located on a laptop computer, which generates a file of polling results. There is no permanent connection between the meters and the data collection center. The time of the counters is synchronized during the polling process with the time of the laptop computer.

Meters are constantly connected to the data collection center through direct communication channels and are polled in accordance with a specified polling schedule. Primary information from meters is recorded in the database. The counters' time is synchronized during the polling process with the time of the data collection center computer. A local PC is used as a data collection center computer. It is where data processing and database maintenance takes place. Data collection into the database occurs periodically at specified intervals.

Areas of application

The operating principle of ASKUE is to timely collect data on all consumers, both in terms of voltage and power. Only after this the automated program processes all the information, on the basis of which a detailed report is compiled. Experts are required to conduct an analysis and also make a forecast for the coming period. In addition, further coordinated work is impossible without studying the cost of certain parameters and drawing the final price for the energy consumed.

In order for the system to work smoothly according to this principle, a number of mandatory requirements must be met:

- Install innovative metering devices - meters - at all areas of electricity consumption.

- Absolutely all digital signals coming from meters must be stored in special blocks - adders, with a large memory.

- Set up centers where all received data will be processed. Management must equip companies with powerful computers and modern software.

- It is imperative to tie the entire system with communication lines, through which all reports will be sent to consumers and reporting enterprises.

You might be interested in this: How to decipher the abbreviation KIPiA and what does a Kipovets do?

Basic elements of ASKUE

As you can see, the automated accounting system includes a number of elements (divisions) that perform certain tasks. Such a structure is usually divided into three levels. Let's talk in detail about the purpose of each of them.

First level elements

These include electronic metering devices that have a special module that allows you to send signals to the collection center. In Russia, the practice is to use the RS-485 interface; this is a standard for asynchronous data transfer used in automation systems. Its simplified organization is presented below.

Organization of the RS-485 interface

The main disadvantage of such a device is the limitation on the number of transceivers; there cannot be more than 32. A way out of this could be cascading the system, namely the installation of adders that “accumulate” data from various sources. An image of such a device is shown in Figure 7.

Figure 7. Data acquisition and transmission device (DCD)

Please note that the development of speakers based on the RS-485 interface was carried out at a time when the use of GSM was not economically justified. Currently the situation has changed radically

Connecting link (second level elements)

This level is used to organize data transportation to the processing center. Currently, most metering devices use the RS-485 interface, despite the fact that this method is clearly outdated. The current situation is caused by the inertia of the structures responsible for standardization, which somewhat slows down the implementation of the new technical base.

Processing center (final link)

This element is an automated complex into which information signals are received and processed. Its characteristics directly depend on the volume of incoming data and the availability of additional system functions. Based on these technical conditions, computer power and software are selected for the NPP complex.

The purpose of creating the ASKUE and AIIS KUE system

The implementation of the ASKEU system will allow any consumer to:

- Measure the amount of electricity consumed without manually taking readings. Simply put, after the implementation of ASKEU, you will not need to come every month on the 30th and record meter readings. The system will do this automatically.

- Monitor hourly, daily, weekly electrical energy consumption;

- Carry out automatic collection, processing and storage of data on the volume of electricity consumed;

- Calculate electricity balances and control “leakage” of electricity;

- Analyze electricity consumption;

- Receive instant information about all metering faults.

All of the above allows the consumer to significantly reduce their costs for electrical energy.

How and due to what does this happen? Let's figure it out.

Components

To study the structural diagram of ASKUE, you need to mentally divide it into three general blocks. This is the most common, generally accepted layout and forms the basic part of the entire system. Block number one includes powerful energy metering units, represented by induction or electronic electricity meters. Such devices are installed exclusively at the consumer’s premises. If an innovative meter has been installed, then the necessary information will be collected through the built-in communication port.

It is also worth considering that today the main percentage of devices are equipped at the factory with a powerful interface for inclusion in ASKUE. If an old-style meter is used - an induction meter, then specialists additionally equip it with a reading device, due to this, data is transferred.

The second block performs all communication functions. Those testimonies that were successfully collected at the first stage must be transferred and reliably protected from hacking by fraudsters. This idea can be implemented in several ways:

- Via regular telephone lines.

- Transmission over the World Wide Web.

- Mobile communications of different standards (3G, GPRS, Wi-Fi).

- The set of all existing methods for guaranteed trouble-free operation of the system.

The third block combines specialized means of computer processing of the received data. At this stage, all collected information is processed and analyzed. From the technical side, the third block necessarily consists of a powerful server or computer with up-to-date software. Thanks to this, experts can configure all system components as correctly as possible.

Operating principle of ASKUE

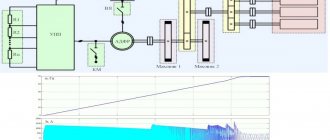

The operating algorithm of the complex can be described as follows:

- Electronic meters (Mercury, Energomera, etc.) send a signal simultaneously. The frequency (periodicity) of data transmission is determined by the AC.

- Data is archived in adders, from where they are transferred to the collection and processing server. In an unloaded AS, transmission directly to the server is allowed.

- Processing of agro-industrial complex data.

Actually, this operating algorithm is used in all energy metering and control systems. The difference between automated complexes lies in their functional purpose, which is reflected in analysis and processing. As an example, here are the differences between commercial and technical systems (ASTUE):

- The data processing algorithm for settlements with consumers is maximally optimized for this task.

- The data received by the commercial processing center is used to generate bills for consumers, that is, in essence, it is an internal “product” of the energy company.

- According to the law, all consumers are required to have metering meters, while the ASTUE system is being implemented to solve the internal problems of a particular business entity. For example, to monitor energy consumption, analyze its structure and develop a general energy-saving program and other tasks of automated process control systems.

To understand the structure of commercial accounting systems, we provide several examples of implementation schemes.

ASKUE scheme in SNT

As you can see in this diagram, the metering devices installed at each consumer transmit signals to the adder, from where transmission is carried out to the processing center. This implementation is practiced in holiday villages and gardening

Please note that such an AC can be used both to measure the consumption of electricity (electric current) and cold and hot water. An example of such an implementation in a residential building is shown below

Scheme of the ASKUE system at home

Installation requirements

Any system implementation must begin with design. The successful installation and connection of ASKUE depends on the correctness of all calculations. Professional design must take into account the characteristics of the facility, resources, as well as the company’s production volumes. Based on the calculations obtained, the final quantity and type of equipment used when installing the system may be subject to changes. Thanks to this, additional time is available for selecting the necessary devices that will exactly meet all the stated requirements.

You might be interested in this Protection against differential currents using a differential circuit breaker and an RCD

Only after all calculation and design work has been completed, specialists can begin installing ASKUE. This procedure consists of several main steps:

- Installation of required equipment (modems, meters, computers, servers).

- Laying and subsequent installation of cable lines.

- Connection of purchased equipment.

- Final setup of the system.

It is worth noting that all work on installation and connection of ASKUE can be performed exclusively by contract companies. The responsibilities of experts include the following activities:

- Careful study of the object. Selection of the most suitable equipment, as well as step-by-step preparation of project documentation.

- Mandatory approval by the Energosbyt authorities. After approval of the plans, specialists can begin installation and commissioning work.

- Setting up computer equipment, consulting consumers. During the period specified in the documents, the client can apply for warranty service for the equipment free of charge.

If during operation any problems, malfunctions or malfunctions in the operation of ASKUE arise, then users can contact any contractor who has the necessary experience in building such systems.

The installation of an innovative ASKUE system must be carried out in strict accordance with the clear requirements and wishes of the customer. The expert himself must also rely on the specific data of the object. The final result depends not only on the design and installation, but also on the settings. The final step is to set the correct options.

AIIS KUE

Recently, in the wholesale electricity market, instead of the term ASKUE, the abbreviation AIIS KUE (stands for: automated information-measuring system for commercial electricity metering) has been used. The concept of ASKUE does not contain the word measurement, which means that it is outside the legal field of the main regulations. By accepting documents related to electricity trading, the parties undertake to comply with all requirements regarding compliance with regulations, therefore, inaccuracies in the writing of documents are not allowed. This concept has not yet taken root quite firmly among energy workers. AIIS, just like ASKUE, is a hierarchical system and carries out the same operations.

The estimated cost for organizing and constructing an AIMS KUE with various functionalities is:

- Drawing up project documentation 330,000 rub.

- Operational documentation costs 140,000 rubles.

- Metrological documentation RUR 380,000

- Documentation for establishing compliance RUB 100,000.

- Counters, collection network, and data transmission RUB 340,000.

The final result depends on whether the AIMS KUE is budgetary, functional or retail; they are calculated per measurement point and range from 870,000 to 3,990,000 rubles.

Technical specifications

Since the reliability of the ASKUE system directly depends on the first block, all basic requirements must be applied exclusively to metering devices. The accuracy of the determination indicates the veracity of the data obtained. An equally important indicator of the system is the maximum permissible error in the data transfer process. This point requires a little clarification. The final telemetric output of the unit broadcasts a sequence of pulses with a frequency that corresponds to the power consumption. Thermal noise and interference can introduce serious errors into the final data, which affects the report.

Common problems can be avoided if all collected information is transmitted in binary code. The high and low impedance of the signal must correspond to "1" and "0". Experts also use checksum encoding, which allows them to verify the authenticity of the data. Many experts mistakenly believe that the digital form of information transmission is protected from errors, but it lacks specifics. This is due to the fact that the protocol always allows for a certain probability of error. This disadvantage is inherent to one degree or another in any data transmission system.

Requirements for technical electricity metering systems (ASTUE) at enterprises

Technical accounting systems are created on the basis of individual meters installed for internal accounting in the production divisions of the enterprise (for example, in workshops). But commercial electricity metering systems must also have the ability to solve technical problems.

Requirement 6: The system must provide collection and analysis of consumption parameters.

The meters allow you to obtain data on consumption parameters (voltage level by phase, phase currents, power and other characteristics). Typically, this data is not accumulated by the counter in internal memory, but is issued upon user request (instantaneous values).

To track consumption parameters over time and record their deviations, the system must collect them automatically. The polling frequency is set by schedules and selected for specific tasks. Taking into account the time of sending a request, processing the request by the counter, and delivering the results, data is usually collected once every five minutes. There are systems with the ability to receive data more frequently.

Requirement 7: The system must warn the user of emergency threats

The threat of an accident can be judged by a variety of data: voltage drops, current overload, phase loss, ... Modern meters can collect the necessary data to warn the user about the occurrence of such events.

The system should allow you to set settings for various parameters and send messages to the user about violation of the set settings. Alerts should be displayed on a computer or smartphone screen, and also sent by email. via instant messengers or SMS messages.

Requirement 8: The system must collect power quality indicators and warn about violation of supply conditions

Poor quality power supply can also lead to equipment damage and significant damage. Many modern counters keep records of key quality indicators and record in their memory all events when indicators did not correspond to standard values.

The system must ensure that such data is read from meters and generate reports of violations of the terms of electricity supply. so that there is an opportunity to present them to the electricity supplier, report violations and demand high-quality electricity supply.

How it works

Let's start with the tasks performed by an automated system for monitoring and accounting for energy consumption:

- Collection of data from each individual consumer (group of consumers) about the consumption of electrical energy at the current time and for a certain period.

- Transfer of data from monitoring devices to a unified information processing center (IPC). Information channels cannot be intercepted or bypassed, since communication through them is encrypted.

- Processing the received information, systematizing it, obtaining summary reports and a current picture of energy consumption in real time. Performed using computer technology.

That is, ASKUE allows you to collect information about energy consumption from an object (group of objects) with a high degree of reliability. At the same time, possible errors and deliberate distortion of information are minimized, which is often encountered during manual data collection (the notorious human factor is eliminated). This helps prevent unauthorized connection and illegal extraction of electricity. Therefore, large energy operators welcome the introduction of such technologies.

In addition, installation of ASKUE throughout the entire chain from the power plant to the end consumer ultimately provides significant savings in energy resources. Not to mention the reduction in costs of energy supply companies that arise when the transferred capacities do not correspond to the readings of the consumer’s internal metering devices.

Problems solved by the producer and consumer of electricity

- Energy supply companies do not spend much time or money identifying unauthorized electricity withdrawals. In addition, by systematizing data on consumption levels, unified energy systems of regions and the entire country can timely distribute power to eliminate critical points of excess load.

- The consumer controls his expenses, thereby saving money. Automated accounting allows you to credit money without the need to take readings from electricity meters, calculate the cost of tariffs, or manually pay bills. It is enough to install software on the organization’s computers to account for and generate payments for electricity.

- In addition, working with automated control allows you to analyze cost parameters and select prices for consumed electricity with different tariffs: including differentiation by time of day.

Technical support for automated commercial electricity metering systems

- Installation of modern electronic electricity metering devices at all group consumption points, with the ability to remotely read parameters in real time (computer or specialized network).

- Development and connection to metering devices of special adder modules with internal memory, which will accumulate data and separate them according to tariff classification. These modules must be provided with autonomous (backup) power.

- Laying wired communication lines between metering devices, data storage devices and information processing centers. Data exchange can be organized using wireless networks or using the Internet. Communication lines must provide for sending reports in real time to the consumer's subscriber device to ensure control over the formation of summary data. Channels are protected from unauthorized connection (encoding). First of all, this is done to protect against hacking and the provision of distorted information.

- Arrangement of information processing centers (IPC), equipped with high-speed computing systems (servers). It is also necessary to provide for the possibility of connecting remote access systems to the COI, so as not to tie operators to a physical workplace.

- Equipping servers and computerized workstations with specialized software. When using remote access, it is necessary to install programs running under mobile operating systems.

- Ideally, the energy sales company should have access to the information. For efficient operation of automation, autonomous equipment is also installed at transformer substations.

Functions of the ASKUE system

This system, which allows you to control electricity, has many functions. Thus, it allows you to automatically perform operations on processing information that belongs to the company involved in the transmission of electricity.

Another important aspect is the ability to calculate the amount of electricity and heating supplied to objects of various uses: from residential buildings to industrial warehouses. This system can take into account the consumption of energy resources at the level of a house, district, city and even an entire settlement.

The main functions of the system include:

- Constant monitoring of energy use.

- Accounting for electricity use according to numerous tariffs.

- Providing digital characteristics upon request of the dispatcher.

- Management of the time system with the possibility of its adjustment.

- Saving digital characteristics in the main database.

Automatic preparation of information on electricity consumption for each metering point at specified commercial intervals is carried out every thirty minutes.

Video: Example of developing ASKUE for SCADA TRACE MODE

Advantages and disadvantages of ASKUE

An automated commercial metering system is an effective means of reducing commercial electricity losses. It comprehensively solves the issues of reliable remote data acquisition from each measurement point. In addition, it complicates unauthorized energy consumption, promptly notifies about cases of interference in the operation of metering devices, and simplifies the identification of sources of commercial losses in the shortest possible time and at minimal cost. This is the economic efficiency of ASKUE.

Digitalization of accounting is not a fantasy of the future, but a necessity of today. A digital network means reducing losses, operating and capital costs by 30%. Digital solutions make it possible to demonstrate the operational efficiency and reliability of a company without raising tariffs.

Pavel Livinsky, Chairman of the Board of Directors of PJSC Lenenergo

Electricity metering system for apartment buildings

How ASKUE "STRIZH" works

In a residential building, “A1” electricity meters are installed for single-phase subscribers, and “A3” for three-phase subscribers. Meters transmit readings and electricity parameters according to a customizable schedule or standard patterns: hourly, daily, monthly. Data is transmitted wirelessly to a base station, which acts as a data collection and transmission device (DCT). The station transmits data via a secure channel to the dispatcher’s personal account.

The capabilities of the STRIZH technology and radio protocol make it possible to collect data from millions of smart meters without the use of concentrators or repeaters within a radius of 10 km from the station in urban areas. High signal penetration ensures transmission from basements and electrical cabinets located inside buildings.

A three-phase meter “A3” is installed in the MKD as a collective electricity meter. Its task is to transmit readings of general house consumption for subsequent balancing of the house and calculation of electricity consumption for general house needs (GDN).

Single-phase electric meter “A1”

“A1” is a “smart” meter designed to account for electricity from single-phase subscribers in an apartment building. It has 4 built-in tariffs for economical multi-tariff accounting in MKD.

Installed plug-and-play without additional settings by an ordinary electrician.

The electric meter measures the amount of electricity consumed, records power profiles and electricity parameters. The built-in radio module transmits accumulated data via an 868 MHz LPWAN radio channel to the nearest base station at a specified frequency.

The reverse communication channel provides remote control of the electric meter. The built-in load relay solves the problem of remote limitation or complete power outage.

Three-phase electricity meter “A3”

“A3” is a “smart” electricity meter, designed to account for the energy of three-phase subscribers and performs the functions of a collective metering device in an apartment building. Capable of working in single or multi-tariff mode.

The meter, through the base station, sends consumption data and electricity parameters to the dispatcher’s personal account via an 868 MHz LPWAN radio channel according to the configured schedule.

The built-in load limit relay effectively solves the problem of dealing with defaulters. Limit load or turn off power remotely.

Personal account of ASKUE dispatcher in MKD

Electricity consumption statistics for each subscriber and common household appliances are available in your personal account in the form of hourly, daily and monthly reports. Compile the electricity balance for a residential building and generate summary reports in two clicks.

Remotely manage, program and remotely limit the load of debtors without the need for a team to travel directly from your personal account.

The system integrates and loads data into 1C and GIS Housing and Communal Services automatically. There is no need to transfer readings manually.

View demo

User workstation capabilities

Specialized software, including a set of application programs “automated power engineering workstation” allows for a detailed analysis of electricity consumption both for the enterprise as a whole and for each division or technological chain separately.

The operating principle of application programs makes it possible to build a variety of graphs that clearly demonstrate the power consumption of individual technological units by day, and to generate real daily consumption graphs for both the enterprise as a whole and any of its divisions separately. This allows you to draw up real forecasts of electricity use, which will help plan the financial activities of the enterprise, as well as submit reasonable requests for electricity consumption volumes for future periods.

ASTUE data may be indispensable in determining the norms of electrical energy consumption per unit of output, or for any closed technological cycle. The need for such calculations very often arises when carrying out a financial analysis of an enterprise's activities.

Application of ASKUE

An information processing center (IPC) is installed in the control room; a separate room is not necessary; data on current energy consumption from each group of consumers flows into it.

Over time, an automated metering system began to be implemented at facilities with lower power consumption: for example, in residential neighborhoods. Serial production reduces prices, and the introduction of ASKUE has become possible even at the level of small housing cooperatives. In this case, the information processing center can be located both in the control room of the energy supply company and in the office of the board of housing cooperatives.

Modern technologies make it possible to organize a data exchange network not only through specially equipped networks. Your own wiring is quite expensive: the cost of the cable, labor costs for installers, rental of load-bearing supports, project approval. With the advent of publicly accessible means of communication, it has become possible to reduce the costs of operating automation of accounting systems. Wireless communications, cloud networks, free access to the Internet allow you to control energy consumption on mobile devices and computers, which there is no need to buy specifically for ASKUE.

Any user, or designated operator, controls the equipment of an individual or public ASKUE from a virtual workplace, or even from a smartphone. The main costs come down to the purchase of subscriber control devices and software. Today, Smart Home technology is being actively implemented, within which it is possible to set up electricity metering in small rooms. The owner of a home or office can automate energy consumption while being at any distance from the control object.

We’ve sorted out accessibility and convenience, let’s look at the operating principle of ASKUE.

ASTUE - what is it, requirements for the structure of the system

The system is an open system with a high degree of unification of design solutions for the purpose of further modernization and increase in functionality.

Scheme of structural organization and data transfer of ASTUE at the enterprise

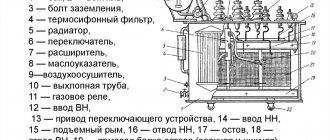

The hierarchical structure of the ASTUE system includes:

- Designed field equipment: electricity meters installed in the cells of working units and machines, auxiliary transformers, transformer transformers intended for the needs of technological installations, as well as at the inputs of switchgear devices. The meters are designed to collect information about active and reactive power in AC networks.

- Pressure and flow sensors, power supplies.

- Designed ASTUE cabinet with equipment for control and for collecting information and transmitting data.

- Necessary equipment for transmitting information via existing communication channels.

The ASTUE system should include a mathematical model for calculating productivity, efficiency and unit costs of equipment.