To select the electrical cable that you will use in the future, you need to know all the abbreviations and designations. After all, every number or letter has a meaning and carries some meaning. The VVGng FRLS cable is fire-resistant, used in fixed locations. Small letters “ng” mean non-propagation of fire. While FRLS stands for: FR (Fire Resistance) index - fire resistance, and LS (Low Smoke) index - low gas and smoke emissions. Such VVGng FRLS wiring is used in buildings with fire safety requirements and in explosive areas; it can also be used at nuclear power plants, provided that it is not laid in a containment zone.

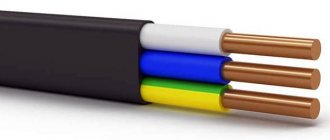

Structure of VVGng FRLS

To understand whether you need this particular cable, you need to know its structure and composition, that is, the materials from which it is made. The choice depends on the purposes for which you need the wiring. The VVGng FRLS cable consists of:

- Copper round conductors of elasticity class 1 and 2.

- The first layer of insulation (mica tapes).

- Second layer of insulation (PVC). There is a special coloring. Due to the fact that they lived monolithic, they are all connected in the core.

- The inside is filled with PVC and PPV plastic compound.

- PVC shells.

- Steel strips as armor.

- Protective layer (hose made of PPO plastic (reduced fire hazard of the casing)).

The VVGng FRLS cable operates with an alternating voltage of 660 Volts, a constant voltage of 1000 Volts and a frequency of up to 100 Hertz. It can be single-core or multi-core (2-5 cores). They may be the same cross-section, or they may differ. For example, in a wire with 3 cores, two may be of the same cross-section, and the third may be different. Can be twisted into 10 outer diameters of single-core wire or 7.5 outer diameters of stranded wire. Installation can be carried out from minus 10 to plus 50 degrees, without heating.

What is FRLS

FRLS is a fire-resistant electrical cable designed to supply electricity to certain consumers in fire conditions over a long period of time. When exposed to open fire, it continues to work for several hours, while releasing a minimal amount of harmful substances into the room.

The main danger of a burning wire is harmful smoke and the spread of fire.

For the abbreviation FRLS, the decoding is as follows: FR - Fire Resistance (fire resistant), LS - Low Smoke (low smoke emission). In addition to the Latin alphabet, it is possible to mark similar cable products in Cyrillic alphabet: KPKVNG, KPSNG, KPSNGA, KPS, KSBNG, etc.

Most often labeled as VVGNG-FRLS. The decoding of VVGNG FRLS is as follows:

- BB – insulation made of PVC plastic compound of reduced flammability,

- G – without protective cover,

- NG – insulation made of non-flammable PVC plastic.

Important! Such cables can have from two to five cores. Their internal structure looks like this:. Structure of FRLS

Structure of FRLS

- Outer shell made of fire-resistant polyvinyl chloride;

- Copper tape or foil, which serves as a shield to prevent both the exposure of the conductor to external electromagnetic interference and the propagation of its own electromagnetic waves;

- Internal insulation made of special fire-resistant plastic, material – polyvinyl chloride;

- Some types of FRLS cable have twisted cores, for which the individual cores must have the same cross-section;

- Special insulation of each core, made of special fire-resistant polyvinyl chloride. Depending on the purpose, each of them has its own color: grounding – yellow-green, neutral wire – white;

- Thermal winding, which is made of mica tape;

- Directly the conductive copper core itself.

Important! In four-wire conductors, the grounding conductor may have a smaller cross-section

Characteristics of VVGng cable

Wiring of this type is used in public spaces or buildings that contain expensive equipment. The VVGng FRLS cable resists high temperatures and open fire, and this is very important to ensure the safety of people exiting in the event of a fire. Its characteristics:

- Operates from minus 50 to plus 50 degrees Celsius.

- At a flame temperature of at least 750 degrees, the cores are stored for 180 minutes.

- Operates at relatively high air humidity (up to 98%).

- At a nominal voltage of 660 Volts, the alternating current is 3000 Volts, and for 1000 Volts - 3500 Volts.

- Has category “A” for non-propagation of flame during installation.

- Resistance from 12 to 50 MOhm.

Service life – 30 years. They are not harmful to the environment and can be recycled. We give you a guarantee that it will last exactly as long. You can buy such a cable cord on our website, and the price will definitely please you.

Classification of VVGNG wires

The abbreviation VVGNG FRLS the following meaning:

- The first letter "B" indicates the presence of polyvinyl chloride plastic as an insulation material inside the wire;

- The meaning of the second letter “B” is that the outer insulating layer is also made of PVC plastic;

- The letter “G” in the product name indicates the absence of an additional protective sheath (metal mesh or a special layer that protects the wire from accidental mechanical damage). Some experts call cables without additional protection bare;

- The presence of the letters “NG” in the name of the wire means that it is fire-resistant, which means it can be used in a fire-hazardous environment;

- The FR marking indicates that the conductor has a special layer that acts as a thermal barrier;

- LS stands for low smoke, that is, it has a low level of gas or smoke emission during combustion.

Thus, the insulation of the VVGNG FRLS cable is made of PVC materials; it does not have additional protection (it is not recommended for use for energy transmission in open space or underground). In addition, it is fire-resistant, able to function at high temperatures and has a low level of smoke and gas emissions.

In addition to FRLS cables, VVGNG HF wires are used. The decoding of this name is as follows:

- VVGNG - insulation is made of polyvinyl chloride materials, it does not have additional protection from mechanical damage, the wire is classified as fireproof;

- HF stands for halogen free - the cable insulation is made of materials with a reduced content of halogens, in particular chlorine. Consequently, during combustion (if such a situation does arise), the amount of harmful substances will be released into the atmosphere less, which means there will be less of a poisonous effect for nearby people and the environment.

FRLS and HF cables

The FRLS cable has the following technical characteristics:

- It provides stable transmission of electrical energy in the temperature range from -30 to +50 degrees Celsius;

- The maximum wire temperature at which it retains its operational properties and the combustion process does not begin is 70 degrees Celsius;

- When laying a cable, it should be taken into account that its minimum bending radius should not be less than ten of its diameters. Otherwise, either the conductor itself may break or the insulation may crack, which will lead to the same results (the inability to continue using the wire).

Additional Information. If the recommendations for the order of laying and using the wire are followed in full, then its service life can reach 15 years.

Taking into account the peculiarities of the use of the FRLS cable and its design, it should be noted that it fully complies with fire safety requirements; if it is laid in bundles, the fire between the wires does not spread in the event of a fire due to the presence of special substances in the sheath. The FRLS cable, which means low smoke generation, allows servicing the device where it is installed, even in burning conditions, since the luminous flux is reduced by no more than 50% (a specialist can easily detect the source of fire and quickly take action). In addition, this level of smoke generation makes it easier to evacuate personnel if necessary.

Note! The established fire resistance time (the period when the wire should not catch fire) is at least 3 hours, which allows you to take all the necessary safety measures for surrounding objects and the population.

Cable Specifications

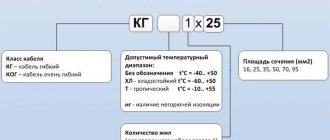

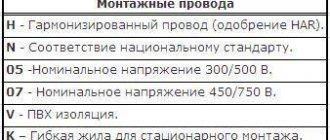

Rules for designating cables and wires

Markings are used to designate various products and help to recognize their features. In practice, there are no great difficulties in understanding abbreviations of names. For example, the decoding of avvg says the following:

- A - the material is core, in this case it is aluminum. If the first letter is missing, then the conductor is made of copper.

- BB - the presence of vinyl covering (1st letter) and insulation on the conductors (2nd letter).

- D - there is no outer layer on top of the metal shell.

Also at the end of the designation there may be an index “a”, indicating that the wire is not capable of spreading fire. Such conductors can be safely twisted into large bundles without fear of fire. Sometimes for similar purposes the index “ng” is used, which can be deciphered as “non-flammable”.

Other letters are also used in the designation of cables, which should also be paid attention to. Here are the basic rules for marking wires:

- The first letter always indicates the core material, and if there is no “A” in the abbreviation, then the conductor is copper.

- K - the location of this letter at the beginning of the marking indicates that the cable is a control cable, for example, kvvg.

- P - parallel arrangement of cores.

- The letters BV indicate the presence of metal armor. If the marking is supplemented with the letter “Ш”, then the cable has another degree of protection - a vinyl hose. An example of such a product is AVBbShv.

- C - the presence of a lead shell.

- 2l - double lavsan ribbon.

- KG - indicates that the wire is flexible.

- E - indicates the presence of an aluminum screen.

- 2 g - double sealed layer of polyethylene insulation.

All the rules discussed apply to both cables and wires. However, some features still apply:

- The presence or absence of the first letter “A” in the wire marking indicates the material of its conductive cores.

- P, V, P - indicate the type of insulating layer - rubber, vinyl and polyethylene, respectively.

- L - can only be at the end of the abbreviation and indicates the varnish coating of the cotton braid.

It should also be remembered that after the letter abbreviation there is a digital designation of the number of conductive wires and an indicator of their cross-section.

Specifications

- Type of climatic modification, placement category 5 according to GOST 15150-69.

- Operating temperature range from -50°С to +50°С.

- Relative air humidity at a temperature of 35°C is up to 98%.

- Gasket without preheating at a temperature not lower than -15°C.

- Minimum bending radius when laying: single-core cables - 10 outer diameters;

- multi-core cables - 7.5 outer diameters.

- from 1.5 to 16 mm2 - 450 m;

Photos, images

Download documentation

- Technical description VVGng-FRLS, VVGEng-FRLS 1 kV (122.7 kB)

Installation work and operating restrictions

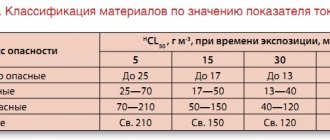

Wire RKGM

If the frls cable is selected, the decoding indicates the possibility of using such products to create power lines in explosive areas (areas). If a fire occurs, combustion is not maintained. This property is checked by special tests according to the methodology approved by GOST R 60332-322-5005. The sample is subjected to prolonged exposure to an open flame. In the same way, using standardized technology, the release of gases and the formation of smoke are checked.

The frls cable is suitable for single and group installation. Given the absence of an armor layer, it should not be used to create routes in the ground. Without preheating, it is permissible to carry out installation work in severe frost (below -15°C). If this condition is violated, a violation of the tightness of the protective shells cannot be ruled out. Allowable bending is up to 7.5 times the diameter (measured along the outer surface).

Permitted performance characteristics:

- air temperature – from -50°C to +50°C;

- maximum relative humidity – no more than 98% (for +35°C).