What is important to know

A typical situation where it may be necessary to connect a self-supporting insulated wire with a copper cable occurs when connecting a private house or cottage to a power line made with a self-supporting insulated wire. Here, first of all, you must comply with the received Technical Conditions issued by the energy supply organization. This document usually contains detailed information on how and with what conductor the power circuits to the meter must be connected. It may also indicate how to connect the wires. As a rule, the requirement is that the conductor from the overhead line to the metering panel be visible and solid.

Connection options

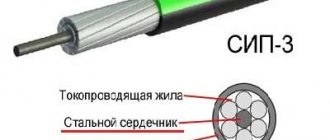

Depending on the location of the metering board, options arise to connect the SIPs to each other or to a wire of another type. Next, we will consider in what situations and how exactly it is necessary to connect a self-supporting insulated wire with other conductors.

The metering board is located on the line support

The connection of the line to the metering board is made with a solid conductor, which is connected directly to the input circuit breaker in the board. To connect the conductor to the line, you should use a standard piercing clamp specifically designed for SIP lines. A version of such a connector is shown in the photo below. The piercing clamp is designed for connecting taps to main lines. This instance can connect a line with a cross-section from 16 mm 2 to 120 mm 2 with a tap with a cross-section from 6 mm 2 to 50 mm 2. SIP or ordinary copper cable, for example VVG, can be used as a tap.

The main compression elements are two steel plates with pointed teeth, which, when the mounting bolt is tightened, come closer to each other and, piercing the insulation of the line and soldering wires, ensure reliable contact and tightness of the fastening point. The bolt is tightened until it breaks, designed for a certain compression force. The design is disposable.

The video below clearly shows how to use piercing squeezes:

If the connection from the metering panel on the pole to the house is made using SIP, standard fittings should also be used for its installation. The best option is to run the wire directly into the distribution box, connecting it to the input circuit breaker in the panel. In this case, it will not be necessary to fasten it to the cable. If for some reason the SIP and copper cable need to be connected, this can be done on the street, at the entrance to the house. The connection can be made with a piercing clamp. In addition, the connecting installation can be performed using die compressions, which are called nuts for their shape. You can learn more about the nut clamp from our article.

Both types of clamps can connect current-carrying conductors made of different materials, for example, a self-supporting insulated conductor can be connected to SIP, VVG, VVGng, AVVG or AC. This is made possible by the design of the connector, which ensures that there is no direct contact between aluminum and copper. Each of the connected conductors is in contact only with the steel plates.

How to use nuts is described and shown in the video:

The connection of SIP with uninsulated wires (bare) is carried out using a clamp of a special design that does not have sharp teeth on the side where the bare wire is attached. This type of compression is shown in the photo below:

It remains to add that it is not allowed to twist copper and aluminum wires together due to the occurrence of electrochemical corrosion! This issue is discussed in more detail in the article: https://samelectrik.ru/kak-soedinit-alyuminievyj-provod-s-mednym.html.

The metering board is located on the wall of the house

In this case, the tap, connected to the main line by a seal clamp, is inserted directly into the metering panel and connected to the input machine. If the tapping conductor is a self-supporting insulated wire, anchor clamps are installed on the line support and on the wall of the house to secure the wire. If a copper cable is chosen to connect the line and the metering board, it is necessary to tension a steel cable on which the cable should be secured, since it is not designed for tensile loads.

Connecting SIP and copper cable in this option may be necessary if there are several buildings on the site and power distribution through them is carried out using SIP. Installation in this case can be performed in the same way as described above, using a piercing or die clamp.

Sometimes you can see how the connection of a self-supporting insulated wire with a copper cable is made with a sleeve that requires subsequent crimping.

This is unjustified for several reasons:

- Installation of sleeves requires special equipment.

- MJPT sleeve clamps are designed for end-to-end connection of SIP wires of the same cross-section during repair or installation of trunk lines. The technology used ensures the mechanical strength of the bonding point, which is necessary for the repaired wire to maintain its load-bearing properties. The connection of the cable to the SIP at the house power input does not carry a mechanical load.

- Bare copper sleeves are used to restore the cores of a conventional cable, after which a coupling is mounted in this place.

The connector installation technology is shown in the video:

Connecting SIPs to each other

The methods of such connection depend on the purpose being pursued. There can be two types of fastening of wires to each other on a support:

- connecting the main line end-to-end during repair or installation, when the length of the solid wire is not enough;

- branch from the main line to power the consumer.

In the first case, MJPT clamps are used, this was mentioned above. In the second case, it is enough to connect the wires with a piercing clamp.

Types of fasteners for SIP

To lay a self-supporting wire, use the following fasteners:

- intermediate support clamps;

- brackets for fastening anchor clamps;

- brackets for fastening intermediate clamps;

- anchor brackets for power consumer wires;

- anchor clamps for insulated load-bearing neutral core;

- anchor clamps for power consumer wires;

- mounting hooks;

- fastening tape (the tape must be made of stainless steel);

- stainless steel clamps;

- stainless steel yokes;

- fastening ties;

- facade fastenings for SIP;

- Spiral knits.

Clamps

Many clamps allow you to attach two self-supporting cables at once. To do this you need to use another clamp. In this case, fastening the SIP will save not only materials, but also free space. Do not use simple cable ties for this purpose. You only need to install clamps for the self-supporting wire - they are wide. In addition, they are made of high-strength plastic, so they are more durable.

Anchor clamps

Using these clamps, SIPs with an insulated load-bearing neutral core are secured. The anchor clamp consists of a body and self-adjusting wedges that allow you to carefully clamp the neutral core.

Thanks to the flexible cable, you can install up to three clamps on one bracket.

Facade and pillar brackets

The brackets securely hold the anchor clamps on the facade. They differ in design. When choosing these fasteners, you need to consider the purpose for which the cable is used, because power wires often get very hot (heating of the cores up to 90°C is allowed). Such fittings for fastening SIPs must provide a large gap between the walls and the cable so that it is well cooled.

For installation with tape, use brackets with large limiting projections. During the operation of power lines, a backlash appears in them, which is associated with the stretching of the tape. If these SIP fastening units are on supports with small protrusions, then it can jump off the fastening point.

A drawing of an anchor fastening of a self-supporting cable to a reinforced concrete support is shown below.

How to connect SIP with copper?

Good afternoon I will delete the post immediately after receiving a response.