Wire and cable for automotive wiring

26 August 2021 12:17

// Tips for buyers

How to choose wires for car wiring? What types of wires are used in cars? How to choose the right section? You will find answers to these questions in our article.

The first and most important requirement for automotive wiring is reliability. In this case, the wires are exposed to a large number of external influences: friction, shaking, shock, oil and fuel getting on them, and strong temperature changes.

Therefore, the wire for car wiring must have copper cores and have sufficient flexibility. Its insulation is to be resistant to both low and high temperatures: it will not harden, crack, soften or spread combustion when ignited.

IMPORTANT!

If these requirements are not followed, a short circuit may occur and a fire may occur!

There are two types of wires used in automotive electrical equipment: high-voltage and low-voltage.

- High voltage conductor is used in ignition systems.

- The low-voltage wire is used to install the on-board network.

Brands of wires for cars

The most common are Russian-made brands, let's take a closer look at them:

PVA is a low-voltage conductor, specially designed for use in car wiring, and has high flexibility of at least class 5. It is resistant to heating up to +105 C, and the period of operation at extreme temperatures declared by the manufacturer reaches 96 hours at +135 C. Satisfies all reliability requirements. The PVAM specification, where M is small-sized, differs in thinner insulation and weight. Used in cars and trucks when installing the on-board network.

PGVA is another low voltage conductor for cars. Not as flexible as PVA (flexibility class 3) and less resistant to high temperatures (up to +70 C). Mainly used in passenger transport, cargo and agricultural machinery. When operating in conditions of electromagnetic interference, its shielded version PGVAE is used.

NVM are universal conductors used for fixed installation. Tinned copper as a conductor material guarantees high-quality soldering, and the permissible operating temperature reaches +105 C. The specifications of NV and NVM differ only in flexibility.

| You can buy wires for your car in our catalog! |

In auto electrics it is also possible to use wires PV3, PV4, PuGV. However, you need to remember that they must be permanently mounted, and their temperature resistance is +70 C. They also need additional protection from external influences. Most often they are used to supply power to car speakers.

Selecting the car wire cross-section

To determine the cross-section of the conductor we will need:

- maximum current consumption of all equipment in the car;

- distance from the mounted electrical equipment to the battery

- rated power supply voltage

Having determined the maximum current in the circuit, you can select the appropriate cross-section from the table, but this is only possible in cases with short electrical circuits.

| Wire cross-section, mm2 | Permissible current (A) depending on the ambient temperature, C | |||

| 20 | 30 | 50 | 80 | |

| 0,5 | 17,5 | 16,5 | 14 | 9,5 |

| 0,75 | 22,5 | 21,5 | 17,5 | 12,5 |

| 1 | 26,5 | 25 | 21,5 | 15 |

| 1,5 | 33,5 | 32 | 27 | 19 |

| 2,5 | 45,5 | 43,5 | 37,5 | 26 |

| 4 | 61,5 | 58,5 | 50 | 35,5 |

| 6 | 80,5 | 77 | 66 | 47 |

The table data is selected for a 12V battery (permissible voltage loss no more than 2%).

| Current, A | Cable cross-section, mm2 | |||||||||||

| 1 | 1,5 | 2,5 | 4 | 6 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | |

| 1 | 7 | 10,91 | 17,65 | 28,57 | 42,86 | 70,6 | 109,1 | 176,5 | 244,9 | — | — | — |

| 2 | 3,53 | 5,45 | 8,82 | 14,29 | 21,4 | 35,3 | 54,5 | 88,2 | 122,4 | 171,4 | — | — |

| 4 | 1,76 | 2,73 | 4,41 | 7,7,14 | 10,7 | 17,6 | 27,3 | 44,1 | 61,2 | 85,7 | 130,4 | — |

| 6 | 1,18 | 1,82 | 2,94 | 4,76 | 7,1 | 11,7 | 18,2 | 29,4 | 40,8 | 57,1 | 87 | 117,6 |

| 8 | 0,88 | 1,36 | 2,2 | 3,57 | 5,4 | 8,8 | 13,6 | 22 | 30,6 | 42,9 | 65,25 | 88,2 |

| 10 | 0,71 | 1 | 1,76 | 2,86 | 4,3 | 7,1 | 10,9 | 17,7 | 24,5 | 34,3 | 52,2 | 70,6 |

| 15 | — | 0,73 | 1,18 | 1,9 | 2,9 | 4,7 | 7,3 | 11,8 | 16,3 | 22,9 | 34,8 | 47,1 |

| 20 | — | — | 0,88 | 1,43 | 2,1 | 3,5 | 5,5 | 8,8 | 12,2 | 17,1 | 26,1 | 35,3 |

| 25 | — | — | — | 1,14 | 1,7 | 2,8 | 4,4 | 7,1 | 9,8 | 13,7 | 20,9 | 28,2 |

| 30 | — | — | — | — | 1,4 | 2,4 | 3,6 | 5,9 | 8,2 | 11,4 | 17,4 | 23,5 |

| 40 | — | — | — | — | — | 1,8 | 2,7 | 4,4 | 6,1 | 8,5 | 13 | 17,6 |

| 50 | — | — | — | — | — | — | 2,2 | 3,5 | 4,9 | 6,9 | 10,4 | 14,1 |

| 100 | — | — | — | — | — | — | — | 1,7 | 2,4 | 3,4 | 5,2 | 7,1 |

| 150 | — | — | — | — | — | — | — | — | — | 2,3 | 3,5 | 4,7 |

| 200 | — | — | — | — | — | — | — | — | — | — | 2,6 | 3,5 |

To illustrate, let’s imagine that we need to connect a car radio at a distance of 2 meters, the current strength will be 15A. Substituting the initial values into the table, we find the required cross-section - 6 mm2.

Remember that these are only approximate data and for an accurate calculation it is worth consulting with a specialist.

Source: https://elmarts.ru/blog/sovety-pokupatelyam/provoda-dlya-avtomobilnoy-provodki/

How to choose wires for car wiring - review of brands, prices, characteristics

In the process of selecting wires that are used for installing automotive wiring, it is extremely important to take into account the key factors of the influence of the external environment on them. During operation, vehicle lines will be subject to vibration, become contaminated with fuel and engine oils, and also operate under conditions of temperature fluctuations. That is why the insulating layer of a car wire must be resistant to aggressive environments and withstand both frost and abnormally high heat. Another criterion by which auto wiring is selected is ease of installation, that is, a sufficient indicator of flexibility.

Review of the most popular brands of automotive wires

Below we present the main technical parameters and characteristics that distinguish automobile lines produced by domestic manufacturers:

PVA brand

PVA belongs to low-voltage cables and has a high 5th class of flexibility. This brand is specially designed for use in the industrial production of automobiles. PVA perfectly withstands heating up to +105 C, while the maximum operating temperature can reach +135 C, but not more than 96 hours. The brand withstands the effects of automotive petroleum products, including diesel, gasoline and oils. The minimum service life of the PVA is 10 years.

The small-sized version of this brand, PVAM wire, is characterized by a smaller thickness of the insulating layer and, accordingly, weight. However, there are no noticeable differences in the installation procedure. The main scope of application of the brand is the installation of on-board networks of passenger cars and trucks.

PVA and PVAM brands fully meet European standards.

Brand PGVA

The PGVA brand also belongs to the type of low-voltage wires and has good flexibility indicators (class 3). Its operating temperature range is slightly lower than that of PVA: -40/+70 C. This brand has proven itself well when installing on-board networks of trucks, agricultural machinery and passenger transport. If there is a need to protect the transmitted electrical signal from EMI interference, then a shielded version is used - brand PGVAE.

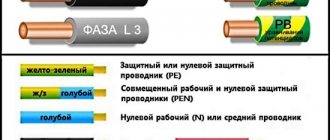

The above brands belong to a variety of auto-tractor conductors and are produced with color-coded insulation. This facilitates installation and subsequent identification of wires when replacing them.

Brands NV, NVM

Brands NV and NVM are universal installation conductors that are used for inter-device, mainly fixed, installation. The wires have a flexibility class and are designed for operation at 600/1000 V AC and 840/1400 V DC. NV and NVM are easy to solder, because their mono- or multi-wire conductor is made of tinned copper. Working heating of wires is up to + 105 C.

How to insulate wires - materials and application features

How and what is the best way to insulate wires?

How to insulate wires so that the contact connection serves you as long as possible, and the insulation resistance in this place is equivalent to the “native” insulation of the cable or wire?

This is especially important if we remember the fact that more than 90% of all damage to cable and wire products, and electrical equipment in general, occurs at contact connections. That is why the closest attention should be paid to the application of high-quality and correctly executed insulation.

Types of connections

But before we look at the types of insulating materials and how to use them, let's look at the types of wire connections in everyday life. After all, the type of insulating material largely depends on this factor.

- Most often in everyday life we are faced with the need to connect several wires. But connection is different from connection. After all, according to PUE standards, wires can be connected by welding, soldering, pressing and bolting. Please note that the popular method of twisting wires is not on this list. And this is no coincidence. After all, twisting wires does not guarantee the quality of connections and its reliability during operation.

| Welding connection |

The essence of this method comes down to the fact that the conductive strands of the wire are twisted, and then, using a special welding machine for wires, the ends of this twist are welded into a single whole. The main limiting factor in the use of this method is the price of the welding machine, which, if you are not doing this professionally , you don't need it at all. |

| Connecting wires by soldering |

It has found wide application in low-voltage networks as one of the most reliable and easy-to-implement connections. At the same time, with large cross-sections of wires, this method is practically not applicable. Indeed, with large cross-sections, contact connections can heat up to significant temperatures, which can lead to destruction of the contact connection. |

| Connecting wires by pressing |

It requires special equipment in the form of sleeves and presses. Of course, for small cross-section wires there are sleeves that can be compressed with ordinary pliers, but they are not widely used. |

| Screw connection of wires |

Special terminals, which already have insulation, allow you to connect the wires quite reliably. The disadvantage of this method is the increase in the size of the contact connection, and their extremely low protection against moisture penetration. |

Types of insulating materials and their scope of application

We've decided on the contact connections - now let's figure out how to insulate the wires? For household use, there are usually two options - insulating tape or heat shrink. But each of these materials has a lot of varieties and areas of application. So let's look at them in more detail.

Insulation tape

Let's start with the most common and time-tested material - insulating tape. This material is applied to the conductor by winding it around the conductive part. But the properties of this product depend on the material of manufacture. And there are not so few of them.

So:

- The most common option is PVC electrical tape. It is made of polyvinyl chloride film, on the surface of which a special adhesive composition is applied. This solution should ensure good adhesion of the tape to most types of materials.

- In our country, PVC electrical tape with a thickness of 0.1 to 0.2 mm is produced. The composition of the adhesive solution and the base of the sleeve also differ. In addition, the color range of such electrical tape, which in Soviet times was only blue, has recently expanded.

- This material can be used to insulate any type of connection. The insulation resistance of such electrical tape, according to standards, is tested at a voltage of 1000V.

Note! In practice, when insulating high-voltage installations, it is generally accepted that one layer of such insulating tape provides protection up to 660V. That is, to insulate a cable under voltage of 6 kV, at least 6 layers should be applied.

- Cotton duct tape is another option. It is made on the basis of fabric on which a special adhesive solution is applied. In our country, raw rubber production waste is often used for this. This gives the product additional tightness after drying.

- CB insulating tape is used as the main insulating material in electrical installations up to 1000V. In electrical installations above 1000V, it is often used to give the connection additional properties. For example, if we need frost-resistant insulation on a wire.

Note! PVC, CB and many other types of insulating tapes must be applied at a temperature not lower than -10⁰С. But for some types of electrical tape, operation after the adhesive solution has dried is allowed at lower temperatures.

- There are also so-called epoxy tapes. They are elastic, wear-resistant, but their main advantage is high temperature resistance. This tape can normally withstand temperatures up to +155⁰С.

- Mica tapes have even higher heat resistance. They are often used to insulate parts and assemblies of electrical machines. In addition to thermal resistance, such tapes are also fire resistant.

- Fiberglass tapes demonstrate maximum temperature resistance. They are able to withstand temperatures up to +200⁰С.

- In addition, there are other types of electrical tape. But in everyday life they are used extremely rarely, so we will not dwell on them in more detail.

Heat shrink

Now let's talk about heat shrink tubing. The peculiarity of this material is that it compresses under the influence of temperature. This ensures reliable fixation and uniform adhesion of the material over the entire surface.

- But if you think that heat shrink is no different from each other, then you are deeply mistaken. The most common heat shrink, with double shrinkage. It is mainly used for insulating wires.

- If it is necessary to ensure more reliable fixation of heat shrinkage to the surface, then materials with glue on the inner surface can be used. This glue is also hot-melt, and when heated, it fills the smallest voids between the tube and the surface.

- If you don’t know how to insulate the wires in a car, then there are special oil- and gas-resistant tubes. Regular PVC electrical tape may be useless in this case. She does not tolerate exposure to chemically active substances well. But chemically resistant heat shrinkage copes with this perfectly.

The photo shows heat shrink with glue

- For use at elevated temperatures, special high-temperature tubes are used. Depending on the material of manufacture, they can withstand temperatures up to +260⁰С. For comparison, conventional heat shrink is intended for operation at temperatures from -50⁰С to +125⁰С.

- By the way, heat shrinks are successfully used not only for low-voltage networks. There are special high-voltage heat shrinks. They can be used in electrical installations up to 110 kV.

High Voltage Heat Shrink

In addition, there are also various types: non-flammable, anti-tracking, semiconductor, self-extinguishing, fluorescent, with increased strength, with a corrugated surface - and many other heat shrinks. The list of such materials is constantly growing.

Rules for applying insulating materials

All these additional properties are of course good. But first of all, we are interested in ensuring that the wire insulation at the connection point is not inferior in resistance to the main insulation. To achieve this, the insulating material must be applied correctly.

Method of installing insulating tape

The method of applying insulating tape largely depends on the type of connection and, of course, the shape of the object - but there are general rules.

Let's look at all these aspects:

- Before applying electrical tape to the surface, it should be prepared. To do this, the wire should be wiped. The insulation and live parts must be free of moisture, oil and dust. All this reduces the adhesion of the tape to the surface.

- Our further actions depend on the type of wire connection. If the wire is connected by soldering or pressing, and does not have twisted branches, then apply electrical tape as follows. We attach the edge of the electrical tape to the part of the conductor that has insulation. The instructions advise doing this at a distance equal to the width of the electrical tape. Then, wrapping the wire with insulating tape at a slight angle, we pass to the edge of the wire with insulation opposite from the junction.

- Here we securely fix the electrical tape with one or two turns around the wire, without an angle of rotation, and then go in the opposite direction. With one or two wraps we fix the tape on the original side and cut off the excess. After this, we press the place where the insulation is applied with our hand to level the surfaces and remove air.

Applying electrical tape to a wire

- If we have a connection made by welding with a twisted branch. In this case, with one or two turns, tightly fix the electrical tape on the insulated surface of the wire. Then, using rotational movements around the wires, we isolate the connection at an angle to the edge and above. We need the electrical tape to extend at least half its width beyond the joint.

- After this, we bend the protruding edges and fix them with the next turn along the edge of the connection. Using rotational movements at an angle, we return to the edge of applying the electrical tape. We fix it with one or two turns and trim the edges.

Applying electrical tape to a twisted connection

Heat shrink installation method

With heat shrink everything is much simpler. It is used only for connections by pressing and soldering. If welding is used, the connection point must be pressed tightly against the wire with the existing insulation. But let's talk about everything in order.

- So we have two wires. Before connecting them, you should cut the heat shrink to the required length and put it on one of the wires. The length of the tube must be such that after making the contact connection and moving it to this place, the tube protrudes at least 3 to 5 wire diameters beyond the insulated surface.

- After making the connection, move the tube and securely fix it in the required position, as in the video. After this, using a special hair dryer or just a lighter, heat the tube.

Heat shrink for twisted connection

During the heating process, the tube decreases in size and tightly fits the contact connection. We check that after shrinking the tube, its edges lie on the surface of the wire insulation, and there are no exposed parts. This completes the installation of heat shrink.

Conclusion

Now you know how to insulate wires and how to do it correctly. And you probably have a natural question, so what type of insulating material is better?

There is no clear answer to this. Heat shrinkage performs well during operation, and its installation is much faster.

At the same time, not in all cases it is possible to perform insulation with its help, and the cost of such a connection is a little more expensive. Based on this, you can independently choose how to insulate the wires.

Source: https://Elektrik-a.su/energii/provodka/kak-izolirovat-provoda-223

Wiring in a car cannot be soldered. Or is it still possible?

The easiest way to collect clicks is by drawing attention to some very simple, ordinary and ordinary thing, playing with it in the “yellow” style. Cunning people create pseudo-sensations and “revelations” from the most ordinary things, and the automotive topic is no exception. A lot of car bloggers “open the eyes” of readers to the imaginary danger of a completely ordinary everyday thing, luring them with vulgar headlines. Recently, I have often come across the topic of the dangers of connecting car wiring using soldering. Many hosts of applied blogs and channels about car repair and maintenance commented on the topic in the spirit of “if you do this, the car will catch fire, explode, and everyone will die!”, often without any skills in electrical engineering and electrical installation and acting on the principle “I heard a ringing…” . We will try to figure it out without cheap sensations and thoughtfully.

Start over. In the practice of repairing an older car, the owner of which maintains and repairs it with his own hands, there is often a need to work with electrical wiring. A lot of cars, which due to their age are not expensive “computers on wheels,” fully allow free intervention in the electrical wiring if you have basic electrical installation skills. Repair faulty standard electrical circuits by replacing rotten or broken wires from age and restoring contact, connecting some additional equipment, which requires installing an intermediate relay, inserting a fuse, removing a connector, etc. The main and most common activities in practice that require connecting wires look like this:

All these connections in garage conditions are often made by twisting wires. Sometimes very vulgar and rude. And, despite the fact that a twisted connection, done carefully and carefully, is generally workable and has a right to exist, it still has a lot of disadvantages. The contact in the twist can deteriorate over time due to oxidation due to natural fat from the fingers applied to the copper veins (if the hands are clean), various grease oils (if the hands are dirty from repairs), and from moisture easily entering from outside. It is quite difficult to use twisting to ensure high-quality contact in wires with a large cross-section, with flowing currents of 10 amperes and above - you have to strip the twisted conductors of insulation over a very significant length, which is not always possible. There are other similar nuances, and if you are delving into the car with love and for yourself, and not hastily eliminating faults before selling, then it is advisable to avoid twists if possible.

In the conditions of a car factory or workshop, a good level of connection and connection in electrical wiring is made, of course, not with twists, but by crimping through bushings/sleeves/brackets or using ultrasonic welding. An ultrasonic device for welding wires is a professional device, and it is not found in the arsenal of a garage technician. But crimping with sleeves or staples is a simple procedure, the tools (crimping pliers, crimper) and consumables are inexpensive, and you can connect the wires using this method no worse than at the factory.

However, many have soldering skills and deftly use a soldering iron, solder and rosin. Solder the connection instead of crimping it with a sleeve - why not, if you have a soldering iron at hand, but don’t have a crimper? However, the opinion is often heard that soldering in the electrical wiring of a car is unacceptable. What is the reason? Let's explain!

In preparation for soldering, copper wires are tinned - covered with a layer of solder using flux (which, even in the 21st century, good old rosin still works best), which gives the solder fluidity and insulates the soldering points from oxidation with oxygen from the air. However, tinned copper wire at the junction of the bare part impregnated with solder and the unimpregnated part hidden under the insulation loses its elasticity and acquires a certain fragility. To put it in the dry language of science, in the process of heating wire made by cold deformation (and this is the method by which almost all wire used for electrical wiring is produced), recrystallization processes occur, which lead to a change in the physical and mechanical properties of copper, reducing bending resistance.

Tinned and then soldered conductors at the points indicated by arrows become more brittle than the original wire. In order to break a stranded copper wire stripped of insulation with your hands, you need to bend it up to a hundred times in a row, and a soldered wire is enough to bend at the above-mentioned breaking points twenty times, and it will fall off...

Agree, it sounds convincingly not in favor

using soldering to connect wires in a car? However, not everything is so scary, and those who have an understanding of the processes and soldering skills use it in automotive wiring easily, without problems and with virtually no restrictions!

Yes, a car in motion experiences endless vibrations, often very intense. And if a soldered wire is suspended freely under the hood at a length of half a meter, like a rope bridge over a river, after some time of wobbling and dangling it can actually break at the boundary of soldering and insulation. But even in such unrealistic conditions this will not happen soon, and it is not a fact that it will happen at all.

In fact, there are no hanging conductors in the electrical equipment in the car. The wires are bundled, tied, laid along the body elements and secured. Sagging and unsupported sections such as outputs to sensors or headlight bulbs are usually very short. If repairs are carried out, and the wires are lengthened, joined, or new ones are inserted, replacing and duplicating the standard ones (in which the contact is lost and it is more difficult to find it than to insert a “double”), then all these new wires are also either tied with electrical tape or plastic ties to the original harnesses , or are placed in protective electrical installation corrugated tubes, secured with clamps. Therefore, significant vibrations of the wires, which can destroy the solder joint by vibration, are practically excluded! And you can connect wires by soldering!

There are two main conditions for a reliable solder connection. The first is the generous use of heat shrinkage, which, in addition to electrical insulation of the connection, provides equally important mechanical protection against sharp bending and the risk of that same break at the border of the tinned and untinned part. The heat shrink tube should cover not only the junction, but also have an allowance of a couple of centimeters on both sides of it. And for rigid conductors with a large cross-section, it is advisable to tighten the solder joint with a double or even triple layer of heat shrink, one on top of the other.

Let us also note this: the use of expensive and not always accessible special heat shrink with an adhesive layer inside to protect soldering from moisture, which is often recommended by the same autobloggers, is not at all necessary even for engine compartment connections. Yes, such protection is very useful for twisting, because penetrating moisture oxidizes the conductors at the points of pressure against each other. Soldering, on the other hand, is not afraid of moisture in principle, and sections of the wire outside the soldering, going into the insulation, are impregnated with rosin during tinning and do not allow moisture under the insulation, inside the wire. Therefore, to protect the soldering, the most common cheap heat shrink is enough - as long as it fits optimally in diameter.

In the same way, using soldering, wire branches, wire joints, soldering of connectors, etc. are also performed:

And the second, even more important condition is the careful fixation of conductors in which soldering is used, with clamps or electrical tape to standard harnesses or other fixed elements under the hood, dashboard, etc. The red wire in the photo has a heat-shrinkable solder in the middle, the place of which is secured with ties to a thick and rigid harness above and below the connection and is thereby completely protected from vibrations that can lead to breakage:

Are the horror stories about the inadmissibility of soldering electrical wiring based on nothing at all? It is very likely that rumors about the extreme brittleness of solder wires arose due to the use of so-called “soldering acid” as a flux, which is usually zinc chloride (zinc dissolved in hydrochloric acid).

Acid is used for soldering various coarse ferrous metals; it is not customary to use it for electrical connections. However, it is often used by small Chinese manufacturers of all kinds of household electronic crap, with manual installation predominating in the production process. “Soldering irons” tin the ends of the wires before soldering for maximum speed of the process, not with a soldering iron and rosin, but by alternately dipping into a cup with a solution of zinc chloride and a cup with molten solder.

At first, this may not cause any problems, but over time, the wire at the junction of the tinned and bare copper part begins to be destroyed by acid residue, the wires turn green, become thinner and break even from slight bending. But, frankly speaking, in the soldering of automobile wires such a situation can only occur if the solderer is catastrophically illiterate, and indiscriminately extending the “acid problem” to soldering in general is the same as scolding a gasoline car for not running smoothly. filled with diesel in the tank...

How to insulate wires in a car?

Looking at imported cars, many domestic car owners note the high quality of communications of electrical components.

Whereas the products of the Russian automobile industry cannot boast of the same condition of the wires.

Photo of independent work on protecting corrugated wiring

For reference: a corrugated or corrugated hose is a hollow plastic product designed to protect electrical wires. The special shape of the corrugation prevents the wires from being bent (protects against fractures) and also prevents them from getting wet.

Electrical tape for automotive wiring

Insulating tape is well established in everyday use, representing a raw material for sealing and insulation. It must protect from sources such as humidity, ultraviolet rays, various substances, etc. It can be used to isolate exposed wires that may come into contact with each other and cause a short circuit.

https://www.youtube.com/watch?v=ZFCv1V-8-bk

There are several types of electrical tape, each of which has its own advantages and disadvantages.

Brief contents of the article:

Types of insulating tape

Despite the fact that the purpose of different types of electrical tape is the same, it still differs from each other.

PVC electrical tape

It was invented in the United States of America in 1946. The width of such insulating tape can reach from thirteen to twenty millimeters.

It has the following qualities:

- Withstands high voltages

- Is very heat resistant, withstanding extreme temperatures

- Has excellent adhesive properties

- Durable

- Withstands stretching well

- Has good fire retardant properties

PVC insulating tape: application

To see what this product looks like, you can find a photo of electrical tape on the Internet.

It has wide application in the following areas:

- Electrical work;

- Household works;

- Repair of cars and vehicles;

- Packaging of goods;

- Pipeline repair work;

HB electrical tape

It is made as follows: an adhesive solution is applied to rubberized cotton fabric or fiberglass.

The width of the tape can start from fifteen and reach up to fifty millimeters. She has the following qualities:

- High wear resistance

- Excellent durability

- Withstands voltages of a thousand volts

- May ignite if heated too much

- Not moisture resistant. It cannot be used in rooms where humidity levels are high.

Main characteristics of HB electrical tape

Cotton insulating tape has high abrasion resistance; fiberglass insulating tapes have the highest level of heat resistance.

There are also electrical tapes reinforced with fiberglass. They have a low level of elongation and are resistant to rupture and mechanical damage.

Before starting work, you need to carefully study the characteristics of the electrical tape and choose the one that is suitable for repair.

Pvc or cotton?

If we compare the technical properties of these products, then PVC insulating tape is undoubtedly the leader. It never ignites and is suitable for use even in the most aggressive environments.

But cotton tape also has one important advantage - it is very resistant to abrasion throughout its entire service life, and it also does not freeze in severe frosts.

How to insulate wires so that the contact connection serves you as long as possible, and the insulation resistance in this place is equivalent to the “native” insulation of the cable or wire?

This is especially important if we remember the fact that more than 90% of all damage to cable and wire products, and electrical equipment in general, occurs at contact connections. That is why the closest attention should be paid to the application of high-quality and correctly executed insulation.

Source: https://auto-dig.ru/chem-izolirovat-provoda-v-avtomobile/

Car device

Wires used in cars to transmit electrical energy from sources to consumers during operation experience significant thermal and mechanical loads, and are also susceptible to chemical and corrosive influences.

These include significant temperature changes, vibration and shaking, the negative effects of petroleum products, moisture and pollution. Some wires are designed to carry small amounts of current, which can be affected by various radio interference and electromagnetic fields.

For these reasons, high technological and operational requirements are imposed on electrical wires used for installation of electrical circuits of automobiles.

The electrical system of automobiles can use wires designed to transmit low and high voltage current, while high-voltage wires are usually used in ignition systems of automobile engines with forced ignition of the working mixture.

***

Automotive low voltage wires

Low voltage wires are used for connections in the on-board network. They consist of copper conductors with PVC or rubber insulation. The cores are made of tinned or untinned copper wire, which has high electrical conductivity, elasticity and is technologically simply connected to terminals with plugs and other connecting elements.

For convenience when installing and repairing electrical equipment, alphabetic and numerical designations of terminals and color markings of wires are used. Marking wires by insulation color creates convenience during their installation, maintenance and repair. Solid coloring of wires uses ten colors; with combined coloring, stripes or rings of white, black, red or blue are additionally applied to the solid coloring. Thus, the color palette used to mark wires is significantly expanded.

Source: https://autotok66.ru/chem-izolirovat-provoda-v-avtomobile/

Connect the wire to the car

One of the options for connecting wiring in a car is to use a specialized connector. In addition to this, you will also need regular pliers.

Connecting wires by twisting

The method of connecting wires by twisting is most common among motorists and car service stations.

The widespread use of this method is due to its simplicity, fairly good mechanical strength and, with proper insulation, good protection from moisture. To make such a connection, we do not need any tools.

The only consumable for such a connection is electrical tape, which needs to be selected correctly (we'll talk about this later).

Such a connection can be used when repairing automotive electrical wiring, where mechanical strength is not required, in places that are difficult to access for special tools, and where there is no digital CAN bus signal. Advantages: quick connection of wires, good contact, flexibility. Disadvantages: low mechanical strength of the connection.

Twisting two wires (cables) as a continuation of each other

Despite all the seeming anachronism, twisting wires in a car is a completely decent and high-quality connection, especially if it is soldered and well insulated. One of the options for the jacket could be extending the wire, when one wire continues the other. In this case, twisting can be done as follows.

As you can see, the wires first unravel and then twist together. It is this strategy that provides the largest contact area and connection reliability. Of course, then twisting - the connections must be insulated. For this, a thermal tube is suitable, which must be installed on one of the wires before twisting, or electrical tape.

Connecting wires by soldering

You can increase the strength of the connection by soldering the wires. Although the disadvantages of such a connection for automotive wiring are more than the advantages. Advantages: mechanical strength of the connection, excellent electrical contact in the connection. Flaws:

Twisting two wires (cables) as a branch of one another

By using a twist connection, you can not only extend the wire in the wiring, but also make a branch from it. In this case, the process of branching wires from one another is carried out according to the following algorithm. We strip the cable section down to the conductors...

...and separate them, dividing them in half to the sides.

We thread the second cable into the resulting ring and twist it together.

Just like in the previous case, everything needs to be soldered and insulated.

This will guarantee reliable contact.

After the connections have been insulated, you can connect the wires together with a plastic clamp to reduce the effort on the electrical connection if the wire is pulled.

Connecting wires by crimping No. 1

Using widely used female and male connectors, you can make a strong electrical connection to car wires. It’s true that to make a strong connection of wires you will need special tools.

Advantages: mechanical strength, good electrical contact, excellent flexibility, since the connection length is 8-10 mm, the ability to connect an additional wire to the standard car wiring with minor damage, low cost of connection.

Disadvantages: it is very difficult to choose a suitable tool, the cost of the tool.

Quality of wiring in the car

All the huge coils of wires connected with clamps that you see under the hood perform a single task - supplying impulses to various components. And if at least one of them breaks or the contact oxidizes, then the operation of the entire system may be disrupted, sometimes the entire computer component completely fails.

It will not be particularly difficult to replace any wire; the most difficult task is that you still need to find it. And this is quite difficult to do, so to help you we will look at the following questions:

Wire connection No. 2

Connecting the car's electrical wiring in this way is not difficult. For such a connector, there is no need to even strip the wires; this function will be performed by the connector, cutting through the insulation of the wires to the copper. However, it is not advisable to connect wires with a large current in the load, because

because the connection is not made over the entire cross-section of the wire and the contact area is very small. Advantages: ease of connection, the ability to connect an additional wire to the standard car wiring with minor damage.

Disadvantages: low mechanical strength, low protection from moisture (due to the large size of the connection, it is not possible to properly insulate the connection, so the scope of application of such a connection is limited), satisfactory electrical contact (a small contact area in the connection is used). Connection Rating:

Pros and cons of connections using specialized connectors (clips)

Such contacts look aesthetically pleasing, compact and easy to install. Providing a relatively, here it is important to note again the word relatively, a reliable connection of wires. The disadvantages include the fact that the contacts can oxidize, and eventually the contact will disappear.

To prevent this, when crimping such “clips,” use a grease, such as lithol or a lubricant specialized for contacts, which can be purchased at specialized electrical goods stores.

This lubricant is also used for connectors used to connect wiring in an apartment (such as Wago). Also, due to the small contact area, you should not use such connectors for power circuits. This connection method is more suitable for control signals.

For power circuits, it is still better to use a banal twist, but if you solder it well, then this is an ideal option. It is about variations of twists that we will talk further...

Wire connection No. 3

This wire connection is easy to use and will provide good electrical contact, but unfortunately has low protection from moisture. Advantages: ease of connecting electrical wires, good electrical contact, cheap and common tool. Disadvantages: low protection against moisture (difficult to insulate the connection).

What kind of soldering of electrical wires can be used in a car?

Experienced auto electricians say that in rare cases it is still possible to solder auto wiring, but this must be done with a special soldering iron and not use electrical tape, but use soldering or heat shrink.

This is a complex method, but it guarantees safety and reliability. Electrical wires connected using heat shrink do not oxidize or break, maintaining good contact at all times.

The principle of this method: