How to understand that the device is faulty

The first signal of a malfunction will be non-stop operation of the motor. Working equipment automatically turns off the compressor for 20 minutes, and in case of extreme heat, the modes are adjusted once every 60 minutes.

Interesting to know! Under normal conditions, the average operating cycle of a refrigerator is 12-20 minutes.

When the device breaks down, users note that the refrigerator does not always turn off and is constantly running, and the sound of the compressor becomes very loud. If measures are not taken in a timely manner, the motor may completely fail.

What to pay attention to

The constant functioning of the refrigerator motor does not always have anything to do with problems. The reason for the lack of equipment stopping may be:

- improper operation - location near heat sources;

- violation of installation conditions - there is no gap for ventilation of 10-15 cm, without which the compressor heats up;

- access to sunlight on the back of the device;

- natural wear and tear of the thermostat of outdated models.

Important! Under conditions of non-stop operation, the service life of the compressor will be about 6 months.

Signs of malfunction and why it is dangerous

The design of a modern refrigerator includes a special timer, due to which the compressor is periodically switched off. In this case, the shutdown time depends on the temperature that needs to be maintained. The refrigerator can work without turning off for a variety of reasons. Symptoms of malfunction are as follows:

- Formation of an ice cushion on the walls of devices. Even in the freezer compartment, a large amount of ice should not form; this sign indicates constant operation. If the compressor runs for a long time, you need to set the temperature to a lower temperature.

- Some residents notice a significant increase in energy consumption. This is due to the fact that refrigerators are equipped with powerful motors. If the refrigerator is constantly running and does not turn off, this will increase costs by 30%.

- Constant operation causes the engine to overheat. It is quite difficult to check this, since the device is located on the reverse side.

- If water is stored in the refrigerator and it freezes, then there is a possibility that the device will operate continuously.

You can only check that the refrigerator does not turn off by monitoring the device. The danger of this phenomenon lies in the following points:

- Overheating of the installed compressor. This element largely determines the cost of the refrigerator, so its failure can lead to large costs. The refrigerator compressor is not designed for long-term operation.

- High energy consumption causes increased costs, as well as excessive load on the electrical cable. Heating it may damage the insulation.

- Incorrect operation of the refrigerator leads to severe freezing of stored food.

- Modern models are also noisy, and constant operation can create discomfort.

In most cases, the fact that a new refrigerator does not turn off is determined only by paying attention to its constant humming. If the problem that arises is not resolved in a timely manner, there is a possibility that the installed compressor will burn out.

Why the refrigerator does not turn off: the main reasons

Your refrigerator works smoothly and does not turn off at all - the following reasons serve as an explanation:

- relay failure;

- thermostat failure;

- malfunctions of thermal control circuits or boards;

- violation of the integrity of door seals;

- freon agent leak;

- clogged capillary tubes;

- installation of equipment in an excessively warm room;

- custom installation of the program.

Each of these reasons requires detailed consideration.

The door seal is damaged

A rubber seal is located around the perimeter of the refrigerator door, ensuring its sealing and preventing cold leakage. If the flap is not closed tightly, the load on the compressor increases. Thus, the motor compensates for excess external heat. The damage can be corrected by replacing the seal.

You have set this mode

When super freezing or express cooling is turned on, non-stop operation of the engine is possible. To troubleshoot:

- a mechanically controlled refrigerator does not turn off, is loud and constantly works until the user turns off the constant cooling program;

- Compressors on electronically controlled models stop after 8 hours.

Advice! When connecting new equipment to communications, immediately check the cooling and freezing modes.

High room temperature

Placing the device near pipes, radiators, air heaters, fireplaces or on the sunny side of the room is contraindicated. Some models work non-stop even at a room temperature of + 30 degrees. The following steps will help resolve the issue:

- installation of air conditioning and ventilation systems in the kitchen;

- moving the refrigerator to another room;

- reducing the heating temperature at the installation site of the equipment.

Important! The optimal temperature of the room where the refrigerator is located is up to +5 degrees. The units cannot be placed on a balcony or left in a dacha without heating.

The thermostat has failed

The thermostat or temperature sensor sends a signal to open the circuit. If it breaks down, the compressor works uninterruptedly - it has already received information about reaching a low temperature and further freezing.

When the refrigerator constantly runs without stopping or turning off, you can determine what the reason is as follows:

- Disassemble the back wall of the equipment.

- Remove thermostat.

- Press the plate next to the center nut.

- If there is no click, replace the part.

The problem can also be identified by checking the resistance with a multimeter.

Important! Work on diagnosing a breakdown and replacing a part should only be carried out by a specialist.

Compressor failure

Failures in the compressor trip relay cause the contacts to stick and cause non-stop operation. With natural wear of the part, pressure in the discharge pipe ceases to form, and the set temperature is not achieved.

The breakdown can only be eliminated by replacing the motor, which is carried out by a specialist. The work is expensive because it includes:

- disassembling the refrigerator;

- compressor installation;

- re-injection of freon;

- starting the temperature sensor;

- testing and commissioning of equipment.

Refrigerant has leaked from the system

The compressor pumps liquid freon into the system. The substance takes heat from the food and removes it outside. If the integrity of the pipes is damaged or bent, the refrigerant leaks out. An increase in temperature and non-stop operation of the refrigerator begins when gas becomes scarce.

The problem can be eliminated by refilling freon, but only a specialist should carry out the work.

Broken evaporator pipes

Why doesn’t a household refrigerator turn off at all if the main parts are working properly? The compressor operates smoothly when an ice clot has formed in the evaporator tube. If the tightness of the pipes is broken, a similar phenomenon occurs.

It is difficult to fix a breakdown on your own - you need to almost completely disassemble the equipment.

Control module failures

The element is responsible for processing the signal from the temperature sensor. During power surges or moisture, the part may break, and the motor may run constantly. To eliminate the breakdown, you need to flash the control module, which will be performed by a technician.

Read also: How to connect an electric stove yourself video

Problems with single-compressor models

If cold is constantly generated and the compressor is not turned off, wear or damage to the sensors may occur. The switch position is normalized manually. If the damage remains, you need to change the compressor or thermostat.

Home refrigerator does not turn off: what to do

Opens a list of reasons why the refrigerator constantly works and does not turn off, a faulty relay or thermostat. The devices responsible for the temperature background are physically unable to objectively assess the current temperature regime. As a result, the equipment decides that there is not enough cooling. Other reasons relate to a breakdown or manufacturing defect, board or thermal circuit.

Regardless of the manufacturer, both devices are present in the device. Their purpose is to control the need for cold.

If, as in the first case, they break down, the Indesit or Stinol unit begins to produce too much or too little cold.

In addition to the reasons listed, experts in the field of refrigeration equipment repair identify a number of others:

- Complete or partial blockage of the main pipes through which the refrigerant circulates;

- If the refrigerator compartment gets very cold without interruption, and the back wall is covered with frost, then the culprit in this case must be looked for among one of the worn out seals;

- User errors associated with improper operation - do not place near the Veko or Indesit device or inside it strong heat sources;

- Refrigerant (freon) is extremely rare - it is necessary to act promptly in such a situation, otherwise the likelihood of freon poisoning increases several times.

Read also: How to connect a breeze car

Most of the reasons as a result of which the Donbass or Zil refrigerator starts working without stopping are great, so you should not try to diagnose it yourself. It is better to seek technical assistance, otherwise the lost time will not have the best effect on the health of the refrigerator.

When uninterrupted operation is not a breakdown

The compressor is constantly active, but there is no breakdown. Is it possible? Non-stop operation of the motor occurs in the following cases:

- increasing the temperature after defrosting. After defrosting is completed, the equipment is connected to the network and operates cyclically. But why then does the refrigerator wear out and not turn off? The phenomenon is associated with the temperature increase by the compressor. After a few hours, the device will return to normal mode;

- The fan of the device with No Frost is noisy. The fan noise of modern models is similar to the hum of a compressor. You need to check the motor, but before that you should study the instructions;

- voltage drops in the network. The vulnerability of the electronic boards causes the microprocessor to malfunction and the motor cannot stop. After detecting the error code on the display, reboot the device. It is advisable to install a stabilizer;

- improper care. Non-stop functionality of the engine will be prevented by regular defrosting and careful cleaning of dirt. Ice and snow coats cannot be removed with a knife. It is contraindicated to place hot dishes for cooling.

Important! For models with No Frost, the evaporator heater breaks and they do not turn off. The part is being replaced.

The difference between No Frost and other systems

The main disadvantage of simple refrigerators is the appearance of a thick layer of frost on the inner wall, which reduces the heat exchange between the cooling zone and the refrigerant moving through the system. As a result, the temperature does not decrease and the compressor is constantly running.

The result is food spoilage and rapid wear of the compressor.

Unlike classic models, the No Frost system has a number of advantages. There is no risk of frost forming on the back wall.

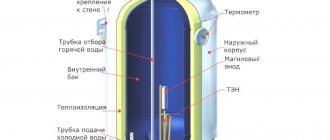

This is due to the special design of the product, which includes:

- electric heating element;

- timer;

- fan;

- evaporator;

- water drainage device.

In the No Frost system, there is a coil in the freezer under the shelf, which looks like a small radiator. It can be installed in any part of the camera. To effectively absorb heat, a fan is installed at the rear of the evaporator.

Its functions include ensuring the movement of air masses through the device and subsequently reaching the products.

Moisture collects on the evaporator, where frost appears. Thanks to the time delay, the accumulated “plaque” is heated and removed using a special system into the tray (located at the bottom of the refrigerator).

When choosing a refrigerator, you need to look at where exactly the No Frost system is provided. Sometimes it only works in the freezer.

The working time coefficient in this system should be up to 0.7. This means that a third of the time, and from an hour this is 20 minutes, the motor must be turned off. The longer the pause time, the better. Reducing this period can lead to a decrease in the service life of components, especially for the compressor.

What measures to take in case of problems

Self-repair is possible only if you have the skills to work with tools and knowledge of the design of your model. With your own hands you can:

- Replace the door seal. The type of part is indicated in the technical documentation. Repair occurs strictly according to the manufacturer's instructions.

- Install the thermostat and temperature sensor. The circuit is pre-tested with a multimeter. The components are selected only for a specific refrigerator model.

- Replace the compressor. Repairs are only possible if the user fully understands the design of the parts and has experience.

- Top up the refrigerant, but only with special equipment and professional skills.

- Having your refrigerator repaired under warranty will save you money or get your equipment repaired for free.

- Call specialists from the brand’s service center who will professionally eliminate simple and complex faults.

A refrigerator is a familiar piece of equipment, but it is quite complex and not insured against breakdowns. Some faults are not immediately noticeable. For example, there are times when the refrigerator does not turn off. The device produces the required amount of cold, the food does not spoil, but the engine runs continuously.

This situation cannot be left unattended; it can get worse very quickly. We will tell you how to independently cope with a dangerous malfunction in the operation of refrigeration equipment. We'll show you how to fix the problem and prevent it from happening in the future.

The Nord refrigerator does not turn off: what to do (video)

The operation of refrigeration equipment is cyclical. As the seals wear out, the quality of the thermostat or relay malfunctions, users note the active formation of ice and a constant hum. All this indicates the system’s inability to analyze the current situation. The sooner a citizen contacts a service center, the less chance of irreversible changes in the cooling system.

Sometimes you may notice that the refrigerator does not turn off for a long time and is constantly running. After some time, no changes have occurred, the engine continues to run without stopping. This indicates the occurrence of a certain breakdown that caused an unnatural operating mode. What factors exist that lead to such malfunctions will be described below.

Read also: Oil-based cutting fluid

Even those who do not understand this technology have noticed that the engine runs intermittently. How long does it take for the refrigerator to turn off? The duration of the operating and disabled states varies. This is influenced by the set temperature of the internal chambers and the ambient air temperature. However, if the refrigerator does not turn off for about seven or eight hours, you should pay attention to the operating mode of the refrigerator compartment. When intense cooling or freezing is set, the engine may not turn off and run without stopping for a long time, and this will be the norm for it. Please remember: later models equipped with electronic displays will stop on their own after a specified period of time, returning to normal operation. As for old refrigerators, they must be removed from freezing mode with their own hands. Otherwise, the motor will run for a long time without stopping.

Reasons for continuous operation of the refrigerator

Poor operating conditions or incorrect settings often cause the engine to run continuously.

Here are some common mistakes:

- the device is installed in such a way that its rear grille touches the wall or is located almost close to it;

- the refrigerator is too close to a hot radiator or other heating device;

- the room where the device is located is too hot, the operating conditions are not met;

- the built-in super-freezing function is enabled, which must be turned off manually or for some reason does not turn off automatically;

- The thermostat is set to the minimum position, and the surrounding air is too warm.

All these situations are associated with a violation of the heat exchange regime.

The device located next to the battery does not produce cold. The principle of its operation is based on constantly removing thermal energy from inside the refrigerator and transferring it to the surrounding air.

If the air is too hot, the heat will not be absorbed. The refrigerator compressor will continue to run, unsuccessfully trying to reach the temperature set on the thermostat. As a result, the main working part of the equipment will quickly exhaust its working resource and become unusable.

Moreover, the greater the difference between the temperature inside the refrigerator and outside, the more thermal energy needs to be moved, and the more difficult it is for the equipment to achieve the required performance. For example, in super-freeze mode, heat exchange must be very intensive.

If the heat does not have time to leave the refrigerator, the temperature sensors will not record the level of cold set by the program, the command to turn off the compressor will not be received, and the equipment will continue to operate.

There are other possible causes of this type of breakdown, related to wear of individual parts of the device. For example, if the integrity of the rubber gasket on the refrigerator door is damaged, this will lead to a violation of the tightness of the internal space.

It turns out that the refrigeration equipment takes thermal energy from the chamber, but the heat seeps inside through inconspicuous cracks.

And although the air inside feels cold, information is received from the sensors that the temperature is not low enough. The compressor continues to run without stopping.

The next reason why a refrigerator can function in this way is a breakdown of the refrigerator’s thermostat, which transmits incorrect information to the control center. Finally, the compressor itself may wear out and work with insufficient power, not providing sufficient temperature reduction.

Another reason why the refrigerator does not turn off is a freon leak. The refrigerant acts as a “carrier” of thermal energy in the system.

It absorbs scattered heat particles inside the refrigerator compartment, then moves it outside. If the amount of freon in the system is insufficient, the cooling rate will slow down, resulting in the refrigerator working constantly.

Don't wait until the sound of the engine running becomes constant. If the intervals between turning off and turning on the compressor have noticeably decreased, and the periods of operation have increased, most likely it’s time to think about refilling the equipment with freon.

It is somewhat easier for owners of modern refrigerators to identify the problem if the unit has a built-in self-diagnosis function. Failures can be reported by marked codes that are displayed on the control panel.

Read also: How to calculate the accuracy class of a device

To decrypt the message, you need to use the operating instructions, which contain detailed information. However, you should not blindly trust this information; sometimes, in order to accurately identify not only the problem, but also its cause, you need to conduct a detailed diagnosis of the device’s condition.

Typically, the compressor operating cycle lasts 10-30 minutes, after which the device turns off for approximately the same period. If the temperature in the room where the refrigerator is located noticeably increases for some time, the operating cycle may be slightly longer.

But if the compressor continues to operate in abnormal mode even after the outside temperature has dropped, it’s time to start diagnosing the condition of the device.

What could cause the breakdown?

First, let's talk about why the refrigerator constantly works, but does not turn off, in order to solve the source of the problem in the first place. Most often, working without a break is caused by the following reasons:

- You installed the refrigerator incorrectly. For example, they did not take care of the air gap between the wall and the housing, or they placed it in a room with a high temperature, next to a heating radiator, etc. The result can be a hot compressor that won't shut off and performs worse, especially in hot weather.

- The equipment is old and the compressor or thermostat has worn out and should simply be replaced.

- You accidentally set the maximum temperature on the thermostat, as a result of which the compressor automatically maintains the set mode for several hours in a row or around the clock. A similar case is that the super-freezing function is set, which implies uninterrupted cooling operation. It is important to know that the average operating time of the compressor should be 10-20 minutes per start.

These 3 reasons are the most common, so it is better to first make sure whether they are or not. If none of the options suits you, you need to move on to a more serious search. Sometimes the problem can be solved by simply defrosting the chambers. If after defrosting no changes have occurred = and the equipment still does not turn off, you need to proceed to repair it yourself. Next, we will look at what to do if the refrigerator constantly works without stopping or taking a break.

Ways to correct the situation yourself

To begin with, you should once again familiarize yourself with the recommendations for operating the refrigerator and check whether the real situation corresponds to what is written in the instructions.

Solving a problem by rearranging

If there is no gap between the refrigerator grille located at the back and the wall, or it is too small, simply move the unit.

The same should be done if the refrigerator is too close to the heat source. Most likely you will have to make a small rearrangement to place the device in a more suitable place. Then you need to check the temperature settings, measure the overall air temperature in the room, and correct the situation.

If after these simple manipulations the refrigerator begins to turn off regularly, you need to observe its operation. The compressor operating periods should not be too long.

Finding a violation in isolation

If the operating conditions are fine, or if the situation is corrected and the engine continues to run without stopping, it's time to look for other options.

First you need to inspect the rubber seal around the perimeter of the refrigerator doors. Over time, the material could become deformed and begin to let air through. If the seal looks new and flexible enough, you can look for damage. A small hole causes many problems.

Replacing the seal is easy. To do this, you need to purchase a new element, remove the old rubber, clean the base and glue the intact gasket using special glue or epoxy resin. Of course, during work the refrigerator must be disconnected from the power supply.

One of the reasons for depressurization of the refrigerator chamber is improper installation of the refrigerator doors. This happens due to the inept actions of the master. This still happens, but happens less often, as a result of using defective elements.

If the seal is in order, you need to inspect the doors and their attachment points. A technician will help you identify and eliminate deficiencies.

Identifying technical faults

Problems often arise from the compressor start relay. This element turns the engine on and off to start the process of circulating coolant and cooling the air. Over time, the moving contacts of the device become welded, “stick” and stop opening.

As a result, the compressor remains energized and continues to operate continuously, regardless of the temperature sensor readings. To detect the presence of such a breakdown, you need to use an ohmmeter.

Installing a new relay is a complex operation; for beginners, it is better to delegate such repairs to a specialist so as not to completely damage the compressor. Freon leaks are not easy to diagnose at home. The refrigerant has no odor or color; it simply evaporates into the environment without causing harm.

This video shows checking for freon leaks and diagnosing the condition of the capillary tube using the example of a BOSCH refrigerator:

It is also better to entrust refilling with freon to a specialist who has equipment suitable for this type of work. The location of the leak is determined by visual inspection of the circuit.

But the damage can be so invisible that to identify it you will have to open the refrigeration circuit and drain the remaining freon from it. Air is then pumped into the tubes under pressure.

It should be small so as not to aggravate existing damage, but at the same time sufficient for successful diagnosis. A soap solution is applied to the surface of the tubes, which will bubble in places where the seal is broken.

The air is bled off, the cracks are sealed, and then the refrigerant is poured into the system. In some difficult cases, when it is not possible to restore the tightness of the circuit on site, the refrigerator is taken to a service center for repairs.

Refrigerator thermostats can have very different designs depending on the model of the refrigerator. If a rod in a device has come out, it is enough to simply adjust its position so that the unit starts working normally.

But it also happens that during defrosting, water gets inside the regulator. This leads to a short circuit in the electrical system; the thermostat will have to be completely replaced. To perform such work, it is better to invite a specialist who can correctly select the element to replace.

A control module malfunction can also only be diagnosed by a technician using testing equipment. An experienced refrigeration technician can fix minor problems right away.

But if the breakdown is complex, its elimination may require work not at home, but in a service center. For example, to flash the firmware, the electronic control board is removed, repaired at a service center, and then reinstalled.

Sometimes the reason for continuous operation of the unit can be a complex blockage of the capillary tube. Usually, to correct this situation, it is enough to simply defrost the refrigerator correctly.

If this measure does not produce results, the master will have to perform significant disassembly of the mechanisms. It is often more convenient to do this at a service center, especially since the procedure may be associated with significant releases of moisture and technical contaminants.

It also happens that in order to restore normal operation of the refrigerator it is necessary to completely replace a worn-out compressor or motor. This is a complex operation that amateur craftsmen rarely manage to perform satisfactorily; it is better to call a professional.

Read also: Device for testing battery capacity

Depending on the refrigerator model, such replacement is performed directly on site or at a service center.

Recommendations for effective prevention

In many cases, problems can be avoided if you use your refrigerator correctly. The advice to read the instructions before starting operation seems banal and obvious, but is not always followed.

Here are a few more recommendations that will help protect your refrigerator from possible breakdowns:

- You need to choose the right place for installation at the very beginning and sometimes check the situation for compliance with the instructions, especially if furniture has been rearranged in the room, new heating devices have appeared, etc.

- The refrigerator should not be located where it is exposed to intense sunlight, even if this does not happen all year round, but only in certain months.

- You should always check how tightly the door seal fits against the body of the refrigerator, whether there is dirt on it, or whether there are other factors that could cause damage or deformation.

- There is no need to lean on the door or otherwise impact it, so as not to disrupt the integrity of the fasteners or damage the sealing gasket.

- You should not store too much food in the refrigerator, as this may lead to poor air circulation.

- It is not recommended to install any heavy objects or household appliances on the top panel of the device.

Defrosting rules are also described in detail in the instructions. Even models with the “No Frost” system need this event. Unless the instructions indicate otherwise, defrosting should be carried out at least once every six months. During the summer, additional procedures may be required.

Once all the ice has melted, thoroughly wipe all surfaces to ensure they are dry. It wouldn't hurt to disinfect it first. To do this, wipe the chamber walls and door with a soda or alcohol solution. Before going on vacation, you also need to defrost the refrigerator and properly preserve it for the duration of your absence.

The door of the switched-off appliance should be left open. Some people simply push an object between the frame and the door to create a gap, but this is the wrong strategy.

This can seriously damage the seal, which will then have to be completely replaced. To prevent unpleasant odors from appearing in your refrigerator, you can leave an odor absorber or an open container of baking soda inside.

Conclusions and useful video on the topic

The reasons why the compressor does not turn off and diagnostic methods are described in detail here:

You cannot ignore the situation when the refrigerator stops turning off. As soon as too few interruptions in the operation of the compressor become noticeable, you immediately need to look for problems and try to eliminate them or call a technician.

If the operating conditions are observed, the likelihood of such breakdowns will be minimal.

Please leave comments in the block form below, post photographs related to the topic of the article, and ask questions. Tell us how you dealt with the problem of a refrigerator that wouldn’t turn off. Share useful information that may be useful to site visitors.

The situation can arise for a number of reasons. A constantly running compressor will certainly fail if measures are not taken to restore the cyclical nature of its operation. Let's look at why the refrigerator freezes but doesn't turn off.

The refrigerator freezes, but does not turn off - reasons

Continuous operation of the cold generator may be caused by external reasons or control malfunctions. First of all, you should check the set mode. Quick freezing may be enabled. It is acceptable if the food freezes in the chamber to a deep minus within 72 hours. Afterwards, the regulator must be switched to its normal position.

The reason may be an incorrect task. If on a hot summer day, in a kitchen flooded with direct sunlight, you set the cooling regulator to maximum, the refrigerator cannot cope with the task, the compressor will work non-stop. He cannot fill a warm chamber with cold. This is the problem with combined refrigerators. After some time, the compressor will break down - in hot weather, the heat removal from the housing is insufficient, overheating or jamming will occur.

Technical reasons for non-stop operation of the compressor

The compressor is included in the system, its activation mode is regulated depending on the readings of temperature sensors. If the readings transmitted to the control element are incorrect, the commands received by the compressor will be incorrect. The compressor runs non-stop, the food in the positive chamber freezes - reasons:

- faulty relay;

- The thermostat has failed;

- the electronic control unit has failed.

But it happens that the reasons why the refrigerator freezes but does not turn off are caused by a malfunction related to the tightness of the circuit. If fresh air is constantly flowing into the chamber, energy is required to maintain operating parameters. In this case, the cavity quickly becomes overgrown with an ice coat.

If there is a lack of refrigerant, the compressor will drive the missing mass along the circuit with gurgling and whistling. But no matter how hard the system tries, the cold removal is insufficient, so the compressor works non-stop until it expels all the freon through the formed crack or burns itself out. The signs are approximately the same if the capillary tube is clogged, but the condenser will be hot on the first leg.