Setting up and preparing the multimeter

To use the multimeter correctly, you need to configure it. This means that you need to select the value to be measured and the limit of its operation, that is, the value beyond which it will not go.

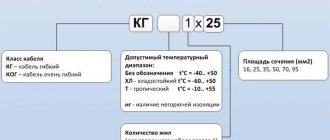

Symbols on the front panel of the meter

A multimeter can be used to check various electrical quantities: current, voltage, resistance, frequency. It is also used to test the performance of various radio elements: resistors, capacitors, diodes and transistors. The very part of the word “multiple” implies the presence of several types of measurements. To select these types, there is a knob on the front panel of the tester, by turning which you can select the required value.

In most cases, the symbols depicted on the body of the multimeter represent designations of electrical quantities accepted in physics or conventional graphic designations of radioelements intended for testing. On the front panel you can find the following symbols:

- U - voltage symbol;

- V - stands for volts, this is also a measure of voltage;

- I is the current; when you set the knob to this designation, the current strength will be measured;

- A - amperes, a measure of current strength;

- Ω, R - symbol of resistance;

- Ohm is a measure of resistance, Ohms;

- -| |- - this icon indicates a capacitor, the multimeter will measure its capacitance;

- Diodes and transistors are also marked on the tester body with their symbols.

But not only the measured values are indicated on the front panel of the tester: the holes for connecting the probes also have their own designations. One of the meter slots will always be occupied by the black probe. This is a common hole, it is usually marked with the inscription COM, which means “common”. In addition to it, the multimeter has two or three working holes, designed respectively for measuring voltage, low current and high current.

The socket marked U, Ω, Hz is intended for measuring resistance, voltage and frequency, as well as for testing various radio elements. You also need to install a probe here to test wires and cables for breaks.

https://youtube.com/watch?v=DU1hvRCR2Rw

The hole marked mA (mA) is used to test low currents (up to 1 ampere), and the hole marked A (10 A) is needed to measure high amperages.

Limits of measured values

In addition to designations of the values of the parameters being tested, designations of measurement limits are printed on the front panel of the multimeter. In more advanced equipment, these inscriptions are not present, since the tester electronics itself selects the limit based on the signal supplied to it at the input. However, most multimeters require manual adjustment of measurement limits.

Typically, limits are given by numbers that are multiples of 2: 2, 20, 200... Thus, when choosing a limit, you should be guided by the rule: choose a limit higher than the one being measured, but of the same order. For example, to measure the voltage in a home electrical network (in an outlet), you need to select the AC voltage measurement mode and the measurement limit of 2000 volts. And to test the wires with a multimeter, you need to select the resistance mode and the minimum measurement limit of 2 ohms. However, long cables require a higher measurement limit of 20 ohms. Additionally, you can turn on the button with a sound signal that sounds when a short circuit occurs (circuit presence).

Connecting the tester

To check the parameters of electrical circuits and the continuity of wires and cables with a multimeter, you must correctly connect the meter to the circuit being tested. When checking for circuit integrity, the required area between the meter leads is checked. Therefore, the tester is connected to the terminals of the circuit. If voltage is being measured, the multimeter must be connected in parallel to the section where the voltage is being tested.

When measuring current, the multimeter must be connected in series to the open circuit of the circuit being tested, for example, between the power supply terminal and the load terminal.

Procedure for setting up the device before testing

To check the wire for a break with a multimeter, you will need:

- Set the switch to the dialing mode “-{amp}gt;Ι-” and activate the buzzer.

- Place the ends of the measuring probes with probes into the sockets. Red is located in the hole VΩmA, black - in COM. This is necessary to maintain the polarity of measurements.

- Test the device itself for malfunctions by short-circuiting the red and black probes to each other. A beep will be heard and the display will show 0 or a value close to it.

You can use a multimeter not only for cable measurements. Experts use it to measure electrical equipment.

Fuse

Checking the fuse by resistance

Devices in the form of a small box with a thin internal cable prevent overheating and fire of circuit elements. Models without wiring are tested as follows:

- The device is switched to dialing mode.

- The probes are applied to both sides of the fuse.

- When the resistance is 0 Ohm and there is sound, the device works.

- The number 1 appears, there is no sound - the fuse is broken.

Diodes and LEDs

Checking the LED with a tester

The polarity of diodes is represented by a positively charged anode and a negatively charged cathode. For this reason, it only allows current to flow in one direction. When testing, the multimeter is switched to a special mode:

- Probes are placed on anodes and cathodes without reference to color.

- The tester is activated.

- The probes are swapped and the tester is turned on again.

The serviceability of the diode backlight is determined based on the appearance of voltage in the first case and the number 1 in the second.

The polarity of the LED is opposite. It works when there is a plus on the anode and a minus on the cathode. Probes work in a similar way. If the voltage appears and then disappears, the LED is working.

After switching the tester to dialing mode:

- Place the first probe on the central contact of the light source.

- Place the second probe on the side contact.

- A malfunction is determined by a buzzer and a 3-200 Ohm indicator.

Testing wires with a multimeter

Manufacturers make different types of multimeters, but the measurement principle remains the same, only the location of the controls and measurement limits differ. To check the integrity of the wires, the measurement mode switch is placed in the continuity position; this is marked with a diode or buzzer sign. After which the dialing process is carried out using the methods described above. The integrity of the conductor, in addition to the display of zeros (no resistance), is accompanied by an audible signal or an LED indicator, this depends on the brand of the multimeter. article: → “How to use a multimeter for dummies?”

Multimeter GE 2524 in dial position

The probe with the black wire is inserted into the connector with the ground symbol (case), the red one above, into the connector for measuring resistance with the Ohm symbol “Ω”. The disadvantage of many digital multimeters in dial mode is the delay in the sound indicator signal when touching the contacts. It is necessary to fix the probes on the wire for 2-3 seconds to make sure there is contact. This inertia in operation creates some difficulties in checking the integrity of the wire.

Multimeters of the UNI-T type have good performance in dialing mode; the sound indicator operates almost instantly when the contacts are closed.

In other parameters, UNI-T is not inferior to other models in measurement accuracy and number of options. article: → “Checking circuits with a multimeter or tester.”

Comparison table of characteristics of Fluke-179 and UNI-T UN61 multimeters

Please note that for all instruments it is advisable to use probes with gold-plated rods. Unlike steel ones, they are not subject to oxidation and provide reliable electrical contact.

Multimeter readings when dialing

When checking the integrity of the wire, first of all you need to make sure that its ends are cleared of insulation. By touching the multimeter probes to the bare ends, you will get a certain result:

- The wire is intact . In this case, a signal will sound, and the device reading will be equal to zero ( 0 ) or the value of the conductor resistance (it should tend to zero, for example 0.01).

- The wire is damaged . This is indicated by a unit ( 1 ) displayed on the screen and the absence of a buzzer signal. A unit indicates that the resistance level between the probes is higher than the measurement limit.

Program for checking access to the Internet Network Traffic Monitor

Search engines often search for the answer to the question: “a program for testing twisted pair cables.” A computer with Windows installed already has a program that displays the message “The network cable is not connected” if the twisted pairs in the cable are broken or shorted. You will have to look for the location of the break or short circuit yourself; there is no program that would indicate the exact location and cause of the malfunction. There are special testers for this, for example MicroScanner Pro.

It’s another matter if there is a connection to the Internet, but it is unstable or the download speed has suddenly dropped. To monitor network traffic, there is an excellent free program, or rather a utility called Network Traffic Monitor.

It allows you to measure data transfer speed in real time, observe changes in speed over time, save data on a hard drive, rubber windows, extensive customization options and many other useful services. Supports many languages, including Russian.

Installing the program on your computer is simple, just run the EXE file and press the confirm button several times. Network will automatically be added to startup and will monitor and save all data. To display any of the windows on the monitor screen, just right-click on the tray icon and select the desired window. Network Traffic Monitor is the best utility for analyzing and diagnosing network quality that I came across during my search. I have tested the functionality of the Network Traffic Monitor program with Windows HP and Windows 7. You can use the Network Traffic Monitor program with one click of the mouse from my website.

Safety rules when making calls

Any electrical work, including diagnostics of conductors, requires compliance with all precautions and electrical safety rules. The main rules, the observance of which will save your life and health, are as follows:

Always operate with power off. Post a sign that says “DO NOT TURN ON”

PEOPLE WORK!” at a switch or machine; Do not touch exposed conductors with bare hands, use special clothing and special tools; Use power tools with sharp edges carefully: use gloves and do not damage the cord; At the end of the work, all faulty systems must be de-energized, and exposed wires must be properly insulated.

Take care of yourself and remember, if you doubt that you are capable of working with electrical networks, entrust this task to professionals.

Dialing methods

There are several ways to ring wires at home:

Using a light bulb and battery. This is the simplest and fastest method. In order to construct such a device, you need to have a light bulb and a battery (several batteries can be connected together), as well as connecting conductors and a probe. In addition, do not forget that the voltage of the light bulb and the battery should be the same, or the battery should have more, but not vice versa. The connecting wire must be long enough to ring the wire from a distance.

In order for the dialer to work correctly, it is necessary to mark the cable in any order. The operating method of such a device is as follows: a wire that comes from the battery is connected to one core, and a light bulb is attached to the probe. Use this probe to touch the conductors at the opposite end of the cable one by one. If the light comes on, it means this wire is connected to the battery.

You can learn how to ring the wires of a light bulb and a battery from this video lesson:

Using a multimeter. This device measures various parameters of the electrical network (for example, voltage, current, resistance). In the house, such a device will be indispensable if you need to check an outlet or switch, check for a break, or find out where the wire goes.

You can test the cable with a multimeter using the following method:

- The dialing function is installed. Depending on which model of device is used, this mode is designated differently. As a rule, it is indicated by a diode.

- Then you need to find the phase in the distribution box. This is done as follows: you need to turn on the power and use an indicator screwdriver to check each cable. We mark the one we need with tape or tape and then determine zero.

- After this, you should find the voltage. To do this, set the multimeter to the “voltage measurement” mode. Using a probe, we check each wire. If the next time you touch the probe, it lights up around 220 V, then the right one has been found.

To check the electrical wiring in the wall for integrity, you need to disconnect the cable from the power source. Set the multimeter to resistance measurement mode. When the probes are closed, zeros should appear on the screen.

The video below clearly demonstrates the technology of testing a cable with a multimeter:

These two methods are convenient if the dialing is carried out over a short distance and can be done by one person. If the cable is long and its ends are in different rooms in the apartment or outside, then use a different method.

Using telephone handsets. Dialing with telephone headsets is carried out as follows: the capsules in the handset are connected to each other and a battery is connected to them, the voltage of which does not exceed two volts. Thanks to this technique, workers can talk to each other over the phone and coordinate their actions.

Cable wiring diagram using telephone handsets:

You can ring as follows: the cable on one side is connected to the tube conductor, and the other conductor is connected to any core. On the other hand, the cable connects to the tube conductor, and the other to each core in turn. If workers can hear each other on the handset, it means they are connected to the same conductor.

You can see the entire technology of work in this video example:

Using a transformer. There is another way in which you can ring cable lines - this is ringing using a transformer, which has several taps coming from the secondary winding. The technique is as follows: the beginning of the winding is connected to the grounded shell of the conductor, and the transformer taps are connected to the cores and power each of them. If you measure the voltage that exists between the shell at the other end and the conductors, you can determine whether the end belongs to a specific conductor. The dialer will allow you to identify and mark the necessary cores. You can learn how to correctly mark wires from our article.

Measurements

Using an electronic tester is convenient because you don’t have to look for the right scale, count divisions, and determine the readings. They will be displayed on the screen accurate to two decimal places. If the measured value has polarity, then a minus sign will also be displayed. If there is no minus sign, the measurement value is positive.

How to measure resistance with a multimeter

To measure resistance, move the switch to the area indicated by the letter Ω. Select any of the ranges. We apply one probe to one input, the second to the other. The numbers that appear on the display are the resistance of the element you are measuring.

How to use a multimeter to measure resistance

Sometimes what appears on the screen is not numbers. If 0 “jumps out,” then you need to change the measurement range to a smaller one. If the words “ol” or “over” are highlighted, the value is “1”, the range is too small and needs to be increased. That's all the tricks for measuring resistance with a multimeter.

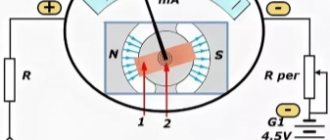

How to measure current

To select a measurement mode, you must first determine whether the current is direct or alternating. There may be problems with measuring AC parameters - this mode is not available on all models. But the procedure is the same regardless of the type of current - only the position of the switch changes.

Read also: How steels are classified according to carbon content

D.C

So, having decided on the type of current, we set the switch. Next, you need to decide which socket to connect the red probe to. If you don’t even know approximately what values to expect, so as not to accidentally burn the device, it is better to first install the probe in the upper (leftmost in other models) socket, which is labeled “10 A”. If the readings are small - less than 200 mA, move the probe to the middle position.

The situation is exactly the same with the choice of measurement range: first set the maximum range, if it turns out to be too large, switch to the next smaller one. Do this until you see the readings.

How to connect a multimeter to measure DC current

To measure current, the device must be connected to an open circuit. The connection diagram is shown in the figure. In this case, it is important to install the red probe on the “+” of the power source and touch the black probe to the next element of the circuit. When measuring, do not forget that there is power, work carefully. Do not touch the bare ends of the probe or circuit components with your hands.

Alternating current

You can try the AC current measurement mode on any load connected to a household electrical outlet and thus determine the current consumed. Since in this mode the device must be connected to an open circuit, difficulties may arise with this. You can make a special cord for measurements, as in the photo below. There is a plug at one end of the cord, a socket at the other, cut one of the wires, attach two WAGO connectors to the ends. They are good because they also allow you to clamp the probes. After the measuring circuit is assembled, we proceed to measurements.

Measuring AC current with an electronic multimeter

Move the switch to the “alternating current” position, select the measurement limit. Please note that exceeding the limits may damage the device. At best, the fuse will burn out, at worst, the “filling” will be damaged. Therefore, we act according to the scheme proposed above: first we set the maximum limit, then gradually reduce it. (don’t forget about rearranging the probes in the sockets).

AC current measurement circuit

Now everything is ready. First, connect the load to the outlet. Maybe a table lamp. We insert the plug into the network. Numbers appear on the screen. This will be the current consumed by the lamp. In the same way, you can measure the current consumption for any device.

Voltage measurement

The voltage can also be variable or constant; accordingly, select the required position. The approach to choosing a range is the same: if you don’t know what to expect, set it to the maximum, gradually switching to a smaller scale. Do not forget to check whether the probes are connected correctly and into the correct sockets.

In this case, the measuring device is connected in parallel. For example, you can measure the voltage of a battery or a regular battery. We set the switch to the DC voltage measurement mode position, since we know the expected value, we select the appropriate scale. Next, use the probes to touch the battery on both sides. The numbers on the screen will be the voltage that this battery produces.

How to use a multimeter to measure voltage

How to use a multimeter to measure AC voltage? Yes, exactly the same. Just choose the right measurement limit.

Testing wires using a multimeter

This operation allows you to check the integrity of the wires. On the scale we find a continuity sign - a schematic representation of the sound (look at the photo, but there is a double mode, or maybe there is only a continuity sign). This image was chosen because if the wire is intact, the device makes a sound.

Dial mode on the multimeter measurement scale

We put the switch in the desired position, the probes are connected as usual - into the lower and middle sockets. We touch one edge of the conductor with one probe, and the other with the other. If we hear a sound, the wire is intact. In general, as you can see, using a multimeter is not difficult. Everything is easy to remember.

If the task is to check the electrical circuit for breaks (leaks), then you need to familiarize yourself with how to test the wires with a multimeter. A specialized measuring device is indispensable when testing wiring. And even if you are not a professional electrician, once you understand the basic rules for safe use of a multimeter, you can easily identify problem areas in your home electrical network.

Cable testing devices

To test wiring, there are several devices that can help you complete the task.

There are devices of the E-121 series, popularly called Woodpecker. Using this device, you can determine the location of a hidden wiring break. Testing a power line using Woodpecker is very easy. In this case, it is necessary to guide the tool along the wall along the electrical network. If the Woodpecker made a sound signal, there is a break in this place.

Testers are able to determine the integrity of the cable, as well as the correctness of its connection. Some types of more expensive testers have a built-in multiplexer, as well as an analog-to-digital converter.

Tone generators are used to test cables. These types can more accurately determine the location of the break and determine the location of hidden wiring. In this case, the generator operates in a de-energized network, otherwise the device may fail.

The device is capable of testing various types of cables: from multi-core power cables to thin radio wires. However, tone generators cannot determine whether electrical connections are correct.

You can also ring an electrical circuit using telephone handsets or a transformer.

Methods for checking cables for breaks

Today there are a lot of techniques that use not only a multimeter, but also an ordinary incandescent lamp. With the help of a multimeter, these tasks can be completed faster.

To check you will need to perform the following sequence of actions:

- set the multimeter mode to test resistance;

- use a probe to check each wire strand one by one;

- correctly classify multimeter readings.

Everything is probably clear with the first two points. The latter requires some clarification. If the resistance is around 2 ohms, then the wire is absolutely intact (intact). Exceeding the 10 ohm mark is an alarming sign. There is probably a partial break in the line.

Perhaps the wire burned out in the wall and as a result, power supply to the apartment became impossible. Naturally, there is no direct access to the wire. And hammering a wall because of one wire is, to put it mildly, not an option.

Point it at the location of the suspected cable break. The fact is that in this place, when power is applied, electromagnetic anomalies and turbulence will form. The device detects them at once and signals a break.

You can detect a break using the old “old-fashioned” method. However, this requires an ordinary radio receiver. You need to set it to a frequency of 100 kHz. The noise will increase where the break is located.

We check the wiring in the apartment with a multimeter

Let's take as an example a modern apartment in which the wiring is done in accordance with current requirements and standards. This means that when laying the lighting lines and power outlets, they were separated, and separate wires were laid for them in each of the rooms. Each of these circuits is powered from the apartment panel through a separate circuit breaker.

If the light has gone out in one of the rooms, you should first check that the lamp is working properly. Before starting work, it is necessary to turn off the power to the room/apartment depending on the power supply. When using an opaque incandescent lamp in a lamp, the integrity of the filament is difficult to visually determine, so you will need a multimeter and its continuity function. Let's figure out step by step how to do this correctly.

First you need to check the shield for triggered circuit breakers. In the first case, they will be in the on position (then the fault may be hidden in the room switch, lamp or socket). The likelihood of damage to the wiring in such a situation is low. If the device works, you will need to check everything except the room switch, including the switchboard itself.

If the machines don't work

- Make sure there is voltage at the input and output of the machine. If it is, you can proceed to further verification.

- Prepare the device for operation and check its serviceability by short-circuiting the measuring leads.

- Unscrew the lamp from the socket.

- Touch one of the measuring probes to the base (the metal part of the lamp with threads), and the second to the central contact of the lamp (the insulated center of the end part of the base).

- A sound signal and instrument readings that are different from 0 or 1 mean that the lamp is working. If it is faulty, you need to replace it, which will solve the problem.

- We check the cartridge for serviceability. To do this, you need to disassemble the lamp, make sure that the connected wires and contacts are intact. If everything is in order, then the cause of the failure is not in the cartridge. If malfunctions are detected, they must be eliminated. The lamp cannot be screwed in yet.

- We check the serviceability of the room switch. To do this, remove the plastic cover, unscrew the screws and take it out of the mounting box. We inspect the equipment for the appearance of carbon deposits and check the tightness of the fasteners. If everything is in order, you need to install the measuring ends of the tester on the contacts of the switch. The appearance of a sound signal when dialing in the on position will indicate that the equipment is working properly. The wires do not need to be disconnected.

During such a check, as a rule, a malfunction is identified, which becomes the cause of all the troubles. Eliminating it allows you to quickly solve the problem.

If the machine worked

To ensure electrical safety during work, in this case the voltage is turned off using a general apartment circuit breaker. Next, the serviceability of the socket and the wires connected to the lamp is determined according to the algorithm described above. If there are no faults, you need to check the wiring itself using a multimeter and the continuity function. Such malfunctions happen quite rarely, but they still happen, for example, when installing suspended ceilings or decorative interior elements.

The wiring in this case is performed as follows.

- Using a screwdriver, disconnect the connected conductor (if installed correctly, it is located at the bottom) and move it to the side. The “zero” of this group is, as a rule, located at the zero clamp under the machines.

- Unscrew the incandescent lamp from the socket. Using a ready-to-use tester, we check the line by connecting one of the measuring probes to “zero” and the other to the disconnected conductor. If the device beeps, it means the wiring is shorted.

- In this case, in the room under the ceiling above the switch, we find and open the junction box. We disconnect the wires.

- We check all groups of wires for short circuits. To determine the section of the circuit in which there is a short circuit, we again check the circuits on the apartment panel with a multimeter. If the signal sounds, it means that it is the wire laid from the switchboard to the box in the room that needs to be repaired. Otherwise, the search will need to be continued until a result is obtained.

Using improvised means

Testing wires with a multimeter is not the only possible option for testing them for continuity or breakage. You can verify the serviceability of any linear conductor without the help of this universal device.

To carry out such a check you will need:

- a regular battery (preferably a 4.5-volt square one);

- a 3.5 Volt light bulb, with which the linear section of the wire being tested is checked (monitored);

- a pair of connecting wires and a gripping type connector (the so-called “crocodile”).

After preparing all the necessary elements, a simple measuring chain is assembled on their basis, consisting of a test light, a battery and the conductor being tested. If the circuit is correctly assembled and if the tested area is in good condition, the control light will light up. The absence of a glow even though all circuit elements are working properly indicates a break in the conductor itself.

When testing in this way, the same principle is used as when checking with a multimeter turned on in the dialing mode.

In what cases is wire testing carried out?

This question can be answered in a few words - if the current-carrying core breaks or the integrity of its insulation is compromised.

Let’s clarify this answer and consider typical situations:

- Let's say an outlet or switch stops working. After you have made sure that the problem is not in the connections (including the junction box) and not in the light bulb (lamp), it is advisable to ring the wires in this area. If the integrity of the wiring is compromised, the multimeter will signal this.

- Developing the first example, it can be noted that such situations are not uncommon during repair work (drilling holes) and short circuits due to dilapidated wiring and network overloads.

- An atypical, but quite effective use of multimeter testing is to determine the required conductors on large sections of wiring. This method is appropriate when the color marking of the wires does not allow you to accurately identify the desired conductor.

- Also, in everyday life, dialing allows you to determine the integrity of electrical appliances (lamp, iron, switch, fuse). And if you are well versed in electronics, then when soldering, repairing printed circuit boards and other devices, testing circuits is a mandatory step.

How to check wire continuity in resistance detection mode

In multimeters that do not have a continuity function, checking the integrity of the wire can be done in the resistance measurement mode.

Read also: Pinout of American towbar socket

In this case, the probes are connected in the same way as during dialing, and the device is set to resistance determination mode ( Ω ).

You need to start measuring at the very minimum threshold of the instrument scale - for example, 200 Ohms. All actions are the same as when calling. You just need to monitor the readings of the device. If the wire is intact, the display will show its resistance value. If there is a break, then the resistance will not be displayed (OL - overload condition).

Checking the electric heating element

You can also ring an electric water heating element with a multimeter. To do this, the probes of the device must be attached to the contact plates of the heating element. If the resistance reading is small, then the heating element is working. With very large values or one (depending on the model), the heating element is damaged and requires replacement.

Note! Sometimes one housing may contain two heating elements connected to voltage in parallel. In this case, you need to ring them separately, having first removed the jumper between them

It is very important for boilers and other water heating devices to ring the contacts of the heating element for penetration into the body

To do this, the probe is connected to one of the contacts, and the second - to the body of the heating device

It is very important for boilers and other water heating devices to ring the contacts of the heating element for penetration into the body. To do this, the probe is connected to one of the contacts, and the second to the body of the heating device. If the tester shows a certain value, the internal insulation has been damaged in this heating element.

To prevent electric shock, the heating element must be replaced.

If the tester shows a certain value, the internal insulation has been damaged in this heating element. To prevent electric shock, the heating element must be replaced.

Cable phasing

Phasing is the ability to determine in what order the phases alternate when connected in parallel. This is necessary in order to avoid short circuits. Indeed, in order to increase the reliability of power supply, sometimes one conductor is not enough (or if the consumer’s power is too high). In order for the electrical installation to work normally, another wire is placed in parallel. In this case, it is necessary to take into account the phase rotation. The phasing diagram is shown below:

Phasing can be done in several ways: using a voltmeter or an incandescent lamp. A voltmeter is used for 380/220 V installations. The technique is as follows: cable 2 in the first installation is connected using a switch, and in the second, thanks to a voltmeter, it determines the voltage between the core and the bus to which it is planned to be connected.

If the voltage is linear, then the core and bus have unequal phases, so connecting them is prohibited. If the voltmeter displays zero, then this indicates that the wire and the bus have the same potential, respectively, they have the same phase and can be connected. Other conductors are tested using the same method.

If there is no voltmeter, then phasing can be done using two incandescent lamps that are connected in series and have a rated voltage of 220 volts. If the lamps do not light, then the wire and bus belong to the same phase.

You should also take into account the fact that after such actions a certain voltage remains on the cable cores, which is associated with a residual capacitive charge. Therefore, the cable should be discharged after the next passage of voltage. This is done by connecting the conductors to grounding.

So we looked at the main methods of testing wires and cables, as well as devices that can be used for such work. We hope the information provided was useful and interesting for you!

We also recommend reading:

- How to use a multimeter correctly

- What is phase rotation

- How to detect a short circuit

Checking in the absence of testers

A multimeter and tester may not be at hand. In this case, you can use the manual verification method. To do this, you need to cut off pieces up to 15 cm long from each end of the cable. Next, you should remove the winding by 5 cm. And expose the cores by a couple of cm.

After this, prepare a container with water, which should be made of glass or plastic. Ordinary table salt weighing 1/4 of the weight of water is added to the liquid and mixed until completely dissolved. The cable cores are conductors and their contact must be avoided.

The other side of the cable section must be connected to a power source with a voltage of more than 3 Volts. A regular battery, a smartphone battery, and other safe sources may also work.

After applying voltage, you should monitor the wires in the water. The negative conductor should be covered with white bubbles, and the positive conductor should be covered with yellowish-green ones. If everything is so, then the twisted pair is in good condition and no short circuit has occurred. If there was a short circuit, then bubbles will come from the other vein.

How to connect wires

Before measurements, it is important to strip the ends of the wires from insulation and remove oxide from the cable cores. The oxide on the wires may have high resistance, which will be higher than the value limit of the selected resistance mode of the device, which will give incorrect readings

Before making the call, you need to remove the mains voltage from the electrical wiring and remove the terminals from the battery in the car. If there are capacitors in the wire continuity circuit, then they need to be discharged by short-circuiting the terminals. All these precautions will help avoid damage to the multimeter and give more reliable results.

For convenience, when making calls, use special wire clips - “crocodiles”. The “crocodile” is put on the probe and clamped onto a section of the wire. The use of such clamps increases the convenience of working with wires, as your hands are freed.

Short cables and wires can be tapped at one end, while long wires must be thoroughly cleaned of oxides and twisted together on one side. Then the dialing process is carried out only on one side. You can ring the wires without a multimeter. For such purposes, electricians use a specially made “dialer” consisting of a battery and a light bulb. A sound generator and headphones are also used to check cables and wires.

Battery-powered bell with light bulb

Rules for safe calling using a multimeter

testing the network cable with a multimeter

Working with electricity does not allow for unprofessionalism, so a certain list of rules has been developed that make it possible to make it as accurate, fast and safe as possible.

- When making calls, it is most convenient to use special tips at the ends of the measuring wires, which are more commonly known as “crocodiles”. They will make the contact stable and free your hands when taking measurements.

- When testing, the circuit being tested must always be de-energized (even low-current batteries must be removed). If there are capacitors in the circuit, they must be discharged by short-circuiting. Otherwise, the device will simply burn out during work.

- Before checking the integrity of a long length of conductor when taking measurements, it is important not to touch its bare ends with your hands. This is due to the fact that the resulting readings may be incorrect.

When testing a multi-core cable, it is necessary to separate and strip all existing cores from both ends. After this, you need to check the circuit for the presence of short circuits in it: to do this, a “crocodile” is attached to each core in turn, and all the remaining ones are touched with the other measuring end in all possible combinations.

Check to see if there is a short circuit between the cable cores. If the indicator shows “1” and there is no sound signal, then everything is in order, otherwise there is a short circuit.

In this case, a sound signal will indicate the presence of a short circuit between the tested wires. This may not be of practical importance for small cross-section multi-core cables operating in low-current networks, but when working with high voltages it is fundamentally important.

We call the cable cores. There is a sound signal - everything is fine, otherwise the core is damaged.

To determine the integrity of the cores, the same operation is performed, only at one end of the cable all stripped cores are twisted together. When searching for a break, it is important to consider that the absence of a sound signal at either end will indicate a violation of the integrity of the conductor.

Checking electrical circuit parameters

When testing electrical circuits, you can test many of their parameters. This includes current, network voltage, and signal frequency. But to determine serviceability, you only need to ring the circuit for integrity and check the insulation resistance. Both can be done with a multimeter.

In order to know how to test electrical wiring with a multimeter, you need to correctly configure the measuring device and correctly perform the measurement steps. To check the integrity of the wire you need:

- Connect the black probe of the multimeter to the socket labeled COM, and the red one to the socket labeled U, Ω, Hz;

- The meter knob must be set to the 20 Ohm position;

- Connect the measuring contacts to both ends of the wire. If the ends are in different places in the room, you need to use a previously tested extension wire;

- The tester screen will display the value. If the value does not exceed 2 ohms, it means that the integrity of the wire is not compromised. If the readings are not at the same level or more than 8-10 ohms, then there is a break in the circuit.

In the same way, wires in a car and cables of various electronic devices are tested.

In addition to checking integrity, wires are tested for insulation resistance. This can also be done with a multimeter:

- The probes remain in the same holes as when checking integrity;

- The measurement mode selected is the same - resistance test;

- The measurement limit must be selected as large as 20 or 200 megaohms;

- Touch the probes to opposite conductors of the cable: phase and neutral or phase and screen. In a car, this is ground and signal wire;

- The screen should remain displaying infinity; if there is any value instead, it means there is a short circuit somewhere. Changing values indicate interference in the network.

In addition to ordinary wires, there are high-voltage wires that can withstand high current and voltage loads. These include spark plug wires in cars. The current that is required when starting the engine flows through them; this current reaches 80-150 amperes. Knowing how to test high-voltage wires with a multimeter is required when diagnosing car electronics. The ringing of these wires occurs according to the specified scheme, with the difference that it is necessary to set a larger resistance measurement limit. Typically this limit should be set at 20 kilo-ohms.

In trucks, as well as in networks located in places subject to constant mechanical stress, conductors with a screen - armor or armored wires - are placed. The only special feature of the armored wire is the screen, made of durable metal. You can check the integrity and insulation of the armored wire in the same way as a regular one, you only need to have access to its ends and the screen outlet.

The principle of testing and determining resistance

If you carefully examine the multimeter, you will notice that the continuity mode (diode testing) is in the resistance measurement zone. In simple words, continuity testing combines the determination of conductor resistance, analysis of the data obtained and output of the result with an additional sound signal.

Read also: Attachment for Makita jigsaw

To understand the principle of dialing, it is enough to first know Ohm's law. It states: “the strength of the current in a conductor is directly proportional to the voltage at its ends (potential difference) and inversely proportional to the resistance of this conductor.” Based on this rule, resistance R = U ⁄ I, where I is the current strength, U is the network voltage.

Knowing how resistance is determined, it remains to understand where the current and voltage come from during measurements (for safety reasons, the circuit being tested must first be de-energized). It's simple. The multimeter has a power source that creates voltage and supplies current. By comparing the initial data with the amount of loss caused by connecting to the measured resistor, wire or light bulb, the final result is calculated (unit of measurement - Ohm).