The standard household voltage is 220 V 50 Hz, but some home craftsmen use three-phase electric motors in their garages and workshops. This power supply can also be used in pumps that supply water from wells or reservoirs to personal plots and private houses.

There are various ways to connect these electric motors to a household network, but this reduces the power of the device, so many owners of these devices are wondering how to make 380 volts from 220 volts?

How does three-phase voltage differ from single-phase

Modern residential buildings and the vast majority of industrial enterprises are connected to the network using a three-phase, four-wire power supply circuit.

According to the new standards, to improve consumer safety, a fifth grounding conductor is added, which is used only in an emergency and does not serve to supply voltage, but to protect against electric shock.

All conductors in a three-phase network have their own designation:

- L1, L2, L3 - linear (phase) wires through which voltage is supplied;

- N or PEN - working neutral, used to connect consumers to the solidly grounded neutral of the transformer;

- PE - protective grounding.

In such a power supply circuit there are two voltage values:

- Linear. It is measured between two linear wires and reaches 380 V. At transformer substations and distribution centers it is designated 0.4 kV. It requires four conductors - three supply wires L1, L2, L3 and neutral N, through which the equalizing current flows.

- Phase. It is measured between one of the linear conductors and the neutral. It is 220 V. This is what is necessary for most household electrical appliances and is supplied to the apartment via two wires - phase L and neutral N.

Single-phase voltage is a special case of three-phase voltage and is obtained by connecting the consumer to the phase and neutral wires. Apartment buildings and garage cooperatives are connected to a four-wire, three-phase network (with a five-wire PE grounding wire), and only two wires are supplied to individual consumers.

For private houses and cottages, this separation is carried out on power lines, from which two or three wires extend. The third conductor in household electrical wiring is grounding (protective) and is not involved in powering electrical appliances.

| Important! If the neutral conductor breaks, the voltage in the outlet can fluctuate from 0 to 380 V, which has a detrimental effect on electrical appliances. This also applies to electric motors connected to a three-phase network. To protect against equipment failure, it is advisable to install a RN voltage relay that turns off the power in an emergency. |

However, the main difference between three-phase and single-phase networks is not the voltage value and the number of wires. The main feature of a three-phase network is that the voltage in the supply conductors is shifted relative to each other by 120°.

This shift is provided by the arrangement of the windings in the generators in the power plant and is necessary to provide torque to the electric motors. In addition, the phase shift allows you to reduce the cross-section of the neutral wire.

In a three-phase network, not the full load current flows through it, but only equalizing currents, which are smaller the more evenly consumers are distributed among the individual phases.

Security measures

Basic safety rules for energy conversion:

- It is necessary to work only with tested and technically sound devices to avoid short circuit or fire;

- The minimum power in devices must be more than 400 W for correct voltage conversion;

- During the conversion process, you must use a multimeter in order to monitor the result;

- It is necessary to install a residual current device in the panel so that household appliances do not fail during power surges;

- When working on the connection, all rooms must be de-energized and the panel turned off;

- If there are twists on the wires, they must be replaced so that they do not short out during operation;

- There should be no exposed insulation in the wires, as contact may result in a short circuit or electrical injury.

DIY 220 to 380 converter with capacitor

Attention! Safety rules must not be neglected, otherwise this can lead not only to failure of household appliances, but also to fire, damage to wiring and equipment panels.

You may be interested in this Determination of short circuit current

Such work should only be carried out by an experienced electrician or a person with sufficient knowledge of electrical engineering. To understand how to take 220 from 380, you need to study the principle of operation of all energy conversion devices. Experienced craftsmen recommend using only transformers or motors with capacitors. Even a beginner can handle these devices, provided all safety rules are followed.

Residual current device

So, several current conversion techniques were considered. In conclusion, it should be noted that this process is quite complex. In some cases, special permission and permission to work is required. Poorly performed work can lead to short circuits and fires, and damage to the integrity of the insulation. It is believed that 220 V is sufficient to connect standard electrical appliances in apartments.

Use a voltage converter (inverter)

The easiest way to make 380 Volts is to purchase and install a three-phase voltage converter (inverter). A single-phase voltage of 220V is supplied to the input of this device, and three phases of 380V appear at the output terminals of the device. This is the best, although the most expensive, method of obtaining three-phase power.

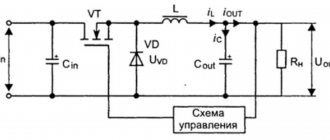

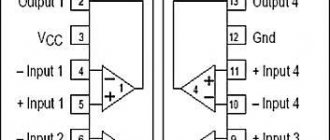

Structurally, the inverter consists of four units - a rectifier and three converters that convert 220 V DC into AC. Due to the appropriate settings and connections of the nodes, the individual phases are shifted by 120°, which ultimately gives a linear voltage of 380 V.

Most inverters have a built-in voltage stabilizer and various types of protection that turn off the power in case of overload, short circuit or high input voltage.

| Information! In addition to voltage converters that connect to a 220 V 50 Hz network, there are inverters that operate from a = 12 V car battery. |

How to make a converter from 220v to 380 yourself using a transformer

An energy converter is one of the most common devices that can be used by both beginners and experienced craftsmen. Using transformers, you can achieve any voltage within the permissible service life of the device, including 380 Volts. As for the use of a capacitor for energy storage, its necessity always remains at the discretion of the consumer.

You might be interested in: Features of static electricity

In order to ensure stable power supply on three phases, a special three-phase transformer should be used. The main function of the unit, in addition to changing the voltage, is to convert single-phase current into three-phase. Similar devices are available in most electrical stores.

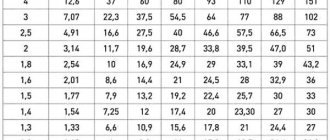

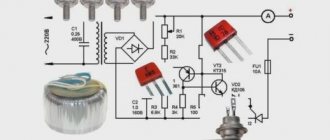

The voltage converter coils are fastened with a triangular clamp. Voltage will be supplied to both primary coils directly, and to the latter using a storage device. The capacitor should be selected based on 7 uF, which falls on every 100 watts of power.

Operation process without capacitor

Attention! It is important that the minimum factory power of the device is at least 400 watts. In addition, it should be noted that such devices are prohibited from being put into operating mode without load.

If this happens, then the required voltage will be achieved, but the power of the electric motor will be reduced, and the efficiency, in turn, will begin to sharply approach zero.

Three phase method

Another way to obtain three-phase voltage is to replace the input cable and electric meter. In this case, the single-phase power supply of an apartment or private house is changed to three-phase with the connection of additional phases from the access panel or street power line.

This work can only be performed after agreement with the electric company; unauthorized connection is considered theft of electricity and entails a fine.

It is advisable to replace the power supply when installing an electric stove or electric heating and is performed to divide the load into different phases and reduce the current consumption and the cross-section of the supply cable.

Connecting electric motors to a three-phase network in this case will be an additional bonus. Supplying power to a single electric motor is not financially viable.

Connecting an electric motor via a capacitor

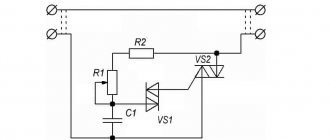

Most often, the question of whether it is possible to get 380 Volts from 220 is asked by owners of small three-phase motors. Such electric machines can be connected to a 220V network through two capacitors - starting and working.

To do this, the windings of the device must be connected in a triangle. The coils of most motors are connected in a star configuration, with all the beginnings of the windings connected together and a supply cable attached to the ends.

When switching to a delta circuit, the end of each coil is connected to the beginning of the next one. This scheme is used for electric machines with a power of up to 5 kW and leads to a drop in power and torque by half.

When such a 220 V motor is turned on, power is connected to one of the windings, and a working capacitor is connected in parallel to one of the remaining windings. To reverse it, it must be connected to another winding.

The capacity of this capacitor is calculated by the formula:

Srab(uF)=70*Rmot(kW)

These items must only be used on AC power. During the start-up of the electric machine, a starting capacitor is briefly connected in parallel to the working capacitor:

Spus=(2-3)Slave

| Advice! Electrolytic capacitors can be used as starting capacitors. |

Application of three-phase transformer

In the event that only three terminals come out of the electric motor, it is impossible to switch the windings to a “triangle” without disassembling, and with a “star” circuit the power losses are too large. In this case, a step-up three-phase transformer or autotransformer is used to obtain a voltage of 380 volts.

In this case, single-phase power is supplied directly to two terminals of the primary winding, and to the third through a capacitor. Its parameters are calculated in the same way as connecting a three-phase electric machine to a single-phase network.

This scheme is used quite rarely due to the need to use an additional device.

Is it possible to make 380V from 220V

At various industrial enterprises or in premises with special functionality, generators produce mainly three-phase current, which makes it possible to increase its voltage several hundred times when using special equipment. According to DEP installations, energy is supplied to consumers, but before that it must go to a power transformer, which will increase the voltage to 380 V. From the distribution substation, the energy will move to the consumer line.

Motor connection

In three phases, the current is transmitted in such a way that its particles move along perpendicular trajectories. Inside the conductor the voltage is 380 Volts, and between the phases - 220 Volts, which is a normal value for residential premises. Considering that the vast majority of apartments are electrified using a single-phase scheme, the two missing phases can be brought into the room from the nearest distribution board.

Attention! Today, there are many converters available on the market that can increase the power of electric current. But when working with them, you must adhere to certain safety rules.

Many ordinary people who have not studied the features of converting electric current are concerned with the question of how to get 220 volts from 380 volts and vice versa, what types of adapters should be used? The modern electrical engineering market offers a lot of devices for voltage conversion. Depending on the power of the connected equipment, each consumer can choose either a simple household inverter or a high-tech industrial installation.

You may be interested in this: How to calculate grounding

Electric motor as generator

In addition to the different methods of transformation, there is another method of making 380 from 220 Volts. This is obtaining such power through the engine-generator system.

In this case, a single-phase machine is used as a motor, for example, from a washing machine or a vacuum cleaner, and a synchronous generator or motor must be installed as a generator. Instead of a synchronous machine, you can use an asynchronous one, but for this it is necessary to place high-power permanent magnets in the rotor.

This method is quite difficult to implement due to the difficulty of matching the rotation speed of electric machines and the impossibility of adjusting the output voltage.

In practice, it is much easier to take a ready-made diesel or gasoline generator designed for backup power during a power outage, and if you have such a device with a faulty engine, simply replace it with a new one or repair it.