Frequency converter 220V output 3 phase

Humanity makes full use of modern technical inventions that are fundamentally new. Life sometimes forces you to study sophisticated layouts and be amazed at the tricks of home-grown techies.

And even if we're not fans, sometimes we just want to be in on things. In fact, to understand the issue, you just need to go from elementary to complex, from beginning to end. And it’s better to start by clarifying unclear things.

What is a three-phase network?

Phase means a change in direction between the magnitudes of the electrical network at the same point in time. In the case of 3 f. current, use three voltages oriented in 3 different directions. Thus, the network voltage is calculated by adding vector quantities, and is not equal to the algebraic sum of all voltages.

Let's look at the example of the same engine. When applying 380 V to the coil, different phase pairs are used in a specific sequence for each winding.

This is actually why the circuit is characterized by 380 Volts, and not by scalar addition (220 + 220 + 220 = 660)V. This explanation is very simplified and not entirely complete, but hopefully well presented.

Yes, and it is written so that it is clear to us, electric “teapots”.

In technical terms, in a three-phase electrical network, circuits of conductors carry three variable values of physical quantities that reach instantaneous peaks at different times.

Taking one conductor as a reference, the other two flows are delayed in time by one third and two thirds of one current cycle.

This delay between phases has the effect of transferring power during each cycle and also allows the production of a rotating magnetic field.

Winding connection methods

Engines in everyday life and in amateur practice drive a variety of mechanisms - a circular saw, an electric plane, a fan, a drilling machine, and pumping equipment. Without knowing how electric motors work, it is better not to get into the weeds with frequency drives. Engines are:

- permanent

- and alternating current (asynchronous and synchronous).

The mechanism includes a rotor and a stator. The principle of electromagnetic induction, studied in school, underlies the principle of their operation. Most of the electric motors produced are “asynchronous”.

Where did this word come from? The rotation frequency of the moving part (rotor) always lags behind the rotation frequency of the magnetic field of the stationary part (stator). The output frequency scale varies - 1000, 1500, 3000... rpm.

And all because the rotor is able to rotate on the shaft at different speeds inside the core.

Depending on the number of poles, the units are one-, two-, or three-pole. In the stator core of the latter there is a winding for each phase, the ends of which are brought out to the terminal box. How can you increase the speed of an asynchronous motor (IM) without losing power? By changing the number of pole pairs.

To move on to other methods, and there are two more of them, we cannot do without the symbols “star” and “triangle”. The three windings of the coil can be connected in two ways: at a point or in a circle, hence the names of the connections “star” and “triangle”.

What happens if a three-phase motor connected by a triangle is connected to a 380 V power supply? In this case, the starting current values can increase seven times, which will lead to network overload.

When dealing with engines, you need to be extremely careful.

When buying a product, be sure to think about whether the nameplates show a triangle/star icon (and not vice versa star/triangle) at the same voltage of 220/380 V.

How to connect a three-phase motor to a 220 V network

The use of a three-pole AD in a single-phase electrical network is of interest to many owners of private houses. The units are increasingly in demand in households. They are quite simple in design and easy to use. However, in terms of connecting the motor to a single-phase network, not everything is so simple.

The pulsating field of a single-phase current is not capable of causing the rotor of an electric motor to rotate - such a current must be converted into multiphase and then only supplied to the unit.

You should not pay attention to rationalization proposals using LATRs and other home-made structures. We are not involved in the field of transcendental nanotechnology and science fiction; we cannot count on fees for the support of “Nobel laureates.” Today, there are two sensible ways to convert single-phase current into multiphase - this is connecting the unit through:

- phase shifting capacitor;

- a frequency converter.

Let's look at them one by one.

- Phase shift using capacitors

In three-phase circuits, creating a rotating magnetic field is not a problem; during energy generation, an EMF is induced in the stator windings due to the rotation of the magnetized rotor.

Some manage to resort to simple “tricks”. Various schemes are used, for the compilers of which the main question is to ensure the operation of electrical equipment without loss of power.

For example, there is a method of shifting the phases in the windings relative to each other.

It is enough to connect a capacitor in parallel with one of the windings, first selecting the device rating in such a way as to ensure the necessary phase shift.

This option is not bad if you follow the old rule: the fewer and simpler the parts, the more reliable the system as a whole. The capacitor, of course, is a relatively cheap thing, it can be installed in a minute, but it requires special skills.

But the second method with a converter, although a little expensive, pays off in convenience. Agree, this is a very important factor.

- Frequency generators operating from a single-phase network

The frequency in our network is constant and equal to 50 Hz. The frequency converter is used to convert single-phase alternating current of 50 Hz into three-phase, with a frequency from 1 to 800 Hz. The entire process technology comes down to controlling the rotation speed of an asynchronous electric motor.

Connecting the inverter means choosing the correct cable cross-section, wire types, and additional equipment. Do not think that by opening the page in the instructions, the essence will immediately become clear to you.

You may not even achieve the result by connecting the wires according to the diagram if you do not pay attention to some nuances. For what exactly?

Do-it-yourself converter from one to three phases.

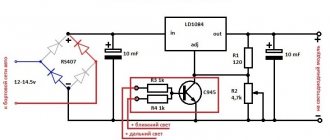

Since the three-pole motor needs to be powered through a state of emergency from a single-phase network, two cables are needed: to the frequency converter, a two-wire one (up to 50 m, you can only use an unshielded cable, shielded - up to 15 m), from the frequency converter to the motor, only a three-wire cable.

One of the wires is grounding, the rest are phase. The cross section is selected according to the technical data sheet for the frequency generator. The required voltage in the wires is obtained from the current and resistance (according to the cross-section) of the cable using the familiar formula: U = R*I.

Calculation data should be taken according to the PUE.

It is recommended to buy a frequency generator with a double margin, at least 2 kV.

Its nominal value is designed only for the power of the machine, which means that at best it will turn off due to heat, at worst it will smoke.

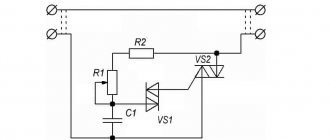

All of them are assembled according to the same circuit, using two thyristors controlled by a multivibrator. The scheme is simple. It is better to choose a simple and more powerful one. Buy where there is a choice and always with a guarantee.

Frequency converter 220-380, whose company is better?

Let's answer the question to the point. There are countless Asian manufacturers on the sales market of such equipment. Let's stop listing. The domestic emergency assembler is a kind of lottery (sometimes it depends on what day of the week the device is assembled).

Frequency drivers from Siemens usually fully meet the requirements. Products produced by ABB or Danfoss are quite easy to set up. It is better than others in terms of price and quality.

Buy without hesitation. Judging by the reviews, they have a very decent device.

Dynamic performance is enhanced by vector control, which also provides high torque at low frequencies during starting and running.

Universal compact CP models do an excellent job of converting network parameters; their obvious advantages are expressed in the following:

- the ability to generate “full” three-phase current;

- no loss in engine power;

- Suitable for any electric motor design;

- The constructivity is very simple.

- own energy consumption is minimal.

Where frequency converters are used single-phase input-output 1 ph. 220 V

Asynchronous motors (AM) are more often used in everyday life than in industry, in particular in the system of single-pole duct fans and water pumps. It is no secret that difficulties arise associated with adjusting the rotation speed of blood pressure. This is the task of single-pole input-output frequency converters 220-220.

Uneven torque may cause abnormal noise and vibration in the unit. To regulate the speed of three-phase electric motors, single-pole 220/380 V frequency changers (input/output) are used, sometimes with a special controller used to control the device.

These types of converters are intended for use in technological applications (pumps and fans, transport mechanisms, extruders, mixers, etc.

) and energy-saving equipment (pump control stations, climate and air conditioning systems, etc.). Models are available with the possibility of mounting on a DIN rail. They have a wide range of output frequency adjustment.

The smart control panel provides a comfortable working environment.

In order to avoid complications that are often encountered during the operation of 3-pole electric motors in single-phase networks, you should adhere to the following rules:

- the power of the engine used as a state of emergency is selected greater than the power of the electric drive connected to it;

- in practice, 4 kW converters are capable of solving all existing economic problems in a private home. You can focus on a load of 2-3 kW, which is acceptable for the power grid;

- the operating current of the converter in normal mode must be greater than its value indicated in the passport of this type of electric motor (otherwise the power supply will simply burn out);

- The converter is connected in a strict sequence: the emergency starts first, then the 3-pole consumers. The equipment is turned off in the reverse order.

Conclusion

Today is not yesterday, but if it happens that you need to connect a three-pole 230 V motor, we think you can handle it. After all, in fact, everything should be clear. You will need a regular 1-pole frequency converter 220-380 V.

Frequency generator 0.75 kW from China - converter 220 to 380 3 phases

Source: //chistotnik.ru/chastotnyj-preobrazovatel-220-v-vyxod-3-fazy.html

How to make 380 from 220 Volts?

In a private house, apartment, country house, that is, in domestic conditions, the most common standard single-phase voltage is 220 Volts, which is obtained by connecting the consumer to one phase and a neutral conductor.

This voltage is called phase voltage; its generator is mainly a 6 kV/380 V power transformer installed at the distribution substation that supplies the given consumer.

Sometimes, especially in a private home, it becomes necessary to start and operate an asynchronous three-phase motor designed for 380 Volts.

There are schemes that make it possible to connect this motor to a single-phase 220 V network, but in this case the power of the electrical asynchronous machine is greatly lost. Accordingly, the question arises of how to get 380 Volts from 220 at home, for efficient operation of the electric motor.

What is important to know

In a three-phase network, all three phases have a shift of 120 degrees.

If it were necessary to convert three-phase 220 Volts to 380V, or single-phase 220V to the same, but with a voltage of 380V, then this can be done very simply using a conventional step-up transformer. In this problem, it is necessary not just to increase the voltage, but to obtain a full-fledged three-phase network from a single-phase one.

There are three main ways in which this manipulation can be done:

- using an electronic converter (inverter);

- by connecting two additional phases;

- due to the use of a three-phase transformer, but the power is still reduced.

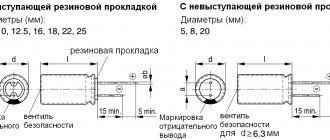

Before converting the mains voltage, you need to consider whether it is possible to connect the motor to a standard single-phase network without loss of power. First you need to look at the plate on the engine itself, some of them are designed for both of these voltages, as shown in the first photo. You just need a capacitor for starting.

The second plate shows that the machine is designed exclusively for star connection of windings and a voltage of 380 Volts:

You can, of course, disassemble the engine and find the ends of the windings, but this is already problematic. Let us dwell in more detail on the creation of a high-quality three-phase network of 380 V from 220.

Voltage transformer

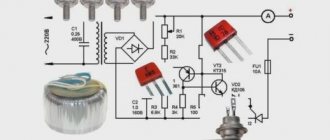

This device is more widely known as an inverter, and it consists of several blocks. To begin with, the device rectifies this single-phase voltage, and then inverts it into an alternating voltage of a given frequency.

In this case, there can be any number of phases shifted by a certain degree, but optimally for the operation of generally accepted standard electrical equipment it is three and, accordingly, their shift is 120 degrees.

Making such a complex device at home is very problematic, so it is recommended to simply buy it; besides, the market for these products is very developed.

Here is the schematic diagram of the inverter:

And this is what it looks like in the factory case:

Often, these devices not only convert single-phase to three-phase voltage, but also protect electric motors from overloads, short circuits and overheating.

Three phase method

This method must be agreed upon with Energonadzor or the electrical energy supply company, since this requires the connection of two additional phases from the panel, which are on each floor of apartment buildings.

Here the question is not how to convert single-phase voltage, but how to connect it, and for this you only need a three-phase extension cord, and if everything is done legally, then a meter.

Three-phase transformer

To turn 220 Volts into 380 Volts, you need a three-phase transformer of the required power for the voltage of one of the windings 220 V and the other 380 V. Most often, they already have windings connected in a star or triangle.

After that, the voltage from the network is connected directly to two phases of the winding on the lower side, and to the third terminal through a capacitor. The capacitance of the capacitor is calculated from the ratio of 7 μF for every 100 W of power.

The rated voltage of the capacitor must be at least 400 Volts. Such a device cannot be connected without a load. In this case, there will still be a decrease in both engine power and efficiency.

If the converter is made using an electric motor rather than a transformer, then the output will have a three-phase voltage, but its value will be the same as in the network, namely 220 V.

The conclusion suggests itself - the problem can only be solved using an inverter electronic method, by installing one high-quality and complete single-phase voltage converter.

Well, or by creating a generator-motor system, where the role of the generator, as in a power plant, will be performed by a synchronous generator, and the role of the drive mechanism can be performed by a single-phase motor (for example, from a vacuum cleaner), but at home this is absolutely not justified and impractical. We hope you now know how to get 380 Volts from 220 in an apartment and private house!

It will be useful to read:

Source: //samelectrik.ru/kak-iz-220-volt-sdelat-380.html

“An old-fashioned way” How to get three phases from a single-phase 220 V network

An old and proven method of obtaining three phases from a conventional single-phase 220 V network: diagram and description.

Good day! I want to show you one interesting way to get a three-phase network from a single-phase 220 V network, and without much expense.

But first, I’ll tell you about my problem that preceded the search for such a solution. I have a Soviet powerful table saw (2 kW), which was connected to a three-phase network. My attempts to power it from a single-phase network, as is usually customary, were not possible: there was a strong power drawdown, the starting capacitors got hot, and the engine itself got hot. Fortunately, at one time I spent due time searching for a solution on the Internet. Where I came across a video where one guy made a kind of splitter using a powerful electric motor. Next, he installed this three-phase network around the perimeter of his garage and connected to it all other devices requiring three-phase voltage. Before starting work, he came to the garage, started the dispensing engine and it worked until he left. In principle, I liked the solution.

I decided to repeat it and make my own phase splitter. The electric motor was an old Soviet one of 3.5 kW, with star-connected windings.

The whole circuit consists of just a few elements: a general power switch, a start button, a 100 uF capacitor and a powerful motor itself.

Diagram of a phase splitter from an asynchronous motor.

How does it all work? First, we supply single-phase power to the distributing motor, connect the capacitor with the start button, thereby starting it. Once the motor has spun up to the desired speed, the capacitor can be turned off. Now you can connect a load to the output of the phase splitter, in my case a tabletop circular and several more three-phase loads.

The frame is made of corners, all equipment is fixed to a piece of OSB sheet. Handles for carrying the entire structure have been redesigned on top, and a three-pin socket is connected to the output.

After connecting the saw through such a device, there was a significant improvement in operation, nothing gets hot, there is enough power, and not only for the saw.

Nothing growls or buzzes like it did before. It is only advisable to take the distributing motor at least 1 kW more powerful than the consumers, then there will not be a noticeable drop in power under sudden load. No matter who says anything about the sine not being pure or it will give nothing, I advise you not to listen to them. The voltage sine wave is clean and split exactly 120 degrees, as a result the connected equipment receives high-quality voltage, which is why it does not heat up.

The second half of the readers, who will speak in the 21st century and the large availability of three-phase voltage frequency converters, I can say that my solution is several times cheaper, since the old motor is quite easy to find. You can even take one that is unsuitable for the load, with weak and almost broken bearings.

My phase splitter in idle mode does not consume so much: 200 - 400 W somewhere, the power of the connected tools increases significantly compared to the usual connection scheme through starting capacitors. In conclusion, I would like to justify my choice of this solution: reliability, incredible simplicity, low costs, high power.

Watch the video:

Popular homemade products on our website

- Homemade converter of a single-phase 220V network into three phases

- The “old-fashioned” way of connecting a three-phase...

What is three-phase voltage 380 V and single-phase voltage 220 V - SamElectric.ru blog

Three phase = line voltage 380 Volts, Single phase = phase voltage 220 Volts

The article is addressed to novice electricians. I, too, was once a beginner, and I am always happy to share knowledge and raise the professional level of my readers.

So, why do some electrical panels receive a voltage of 380 V, and some - 220? Why do some consumers have three-phase voltage, while others have single-phase? There was a time when I asked myself these questions and looked for answers to them. Now I’ll tell you in a popular way, without the formulas and diagrams that textbooks abound.

Very briefly, for those who will not read further: the voltage of 380 V is called linear and operates in a three-phase network between any of the three phases. The 220 V voltage is called phase and operates between any of the three phases and neutral (zero).

In other words. If one phase approaches the consumer, then the consumer is called single-phase, and its supply voltage will be 220 V (phase). If they talk about three-phase voltage, then we are always talking about a voltage of 380 V (linear). Who cares? More details below.

How are three phases different from one?

In both types of power there is a working neutral conductor (ZERO). I talked in detail about protective grounding here; it is a broad topic. In relation to zero in all three phases - the voltage is 220 Volts. But in relation to these three phases to each other, they have 380 Volts.

Voltages in a three-phase system

This happens because the voltages (with active load, and current) on the three phase wires differ by a third of the cycle, i.e. at 120°.

You can read more in the electrical engineering textbook - about voltage and current in a three-phase network, and also see vector diagrams.

It turns out that if we have three-phase voltage, then we have three phase voltages of 220 V each. And single-phase consumers (and there are almost 100% of them in our homes) can be connected to any phase and zero. You just need to do this in such a way that the consumption in each phase is approximately the same, otherwise phase imbalance is possible.

Read more about phase imbalance and what causes it - here.

And it is best to protect yourself from phase imbalance using a voltage relay, for example Barrier or FiF EuroAutomatika.

In addition, it will be difficult for the overly loaded phase and it will be offensive that others are “resting”)

Both power systems have their pros and cons, which change places or become insignificant when the power passes the 10 kW threshold. I'll try to list.

Single-phase network 220 V, advantages

- Simplicity

- Cheapness

- Below dangerous voltage

Single-phase network 220 V, cons

- Limited consumer power

Three-phase network 380 V, advantages

- Power is limited only by wire cross-section

- Savings with three-phase consumption

- Power supply for industrial equipment

- Possibility of switching a single-phase load to a “good” phase in case of deterioration in quality or power failure

Three-phase network 380 V, cons

- More expensive equipment

- More dangerous voltage

- Limits the maximum power of single-phase loads

When is it 380 and when is it 220?

So why do we have a voltage of 220 V in our apartments and not 380? The fact is that, as a rule, consumers with a power of less than 10 kW are connected to one phase. This means that one phase and a neutral (zero) conductor are introduced into the house. This is exactly what happens in 99% of apartments and houses.

Single-phase electrical panel in the house. The right machine is introductory, then through the rooms. Who can find mistakes in the photo? Although, this shield is one big mistake...

However, if you plan to consume power more than 10 kW, then a three-phase input is better. And if you have equipment with three-phase power supply (containing three-phase motors), then I strongly recommend introducing a three-phase input into the house with a linear voltage of 380 V. This will save on wire cross-section, on safety, and on electricity.

Three-phase input. Input machine for 100 A, then - to a three-phase direct connection meter Mercury 230.

Despite the fact that there are ways to connect a three-phase load to a single-phase network, such modifications sharply reduce the efficiency of motors, and sometimes, all other things being equal, you can pay 2 times more for 220 V than for 380.

Single-phase voltage is used in the private sector, where power consumption, as a rule, does not exceed 10 kW. In this case, a cable with wires with a cross section of 4-6 mm² is used at the input. The current consumption is limited by the input circuit breaker, the rated protection current of which is no more than 40 A.

I already wrote about choosing a circuit breaker here. And about the choice of wire cross-section - here. There are also heated discussions of issues.

And if you are at all interested in what I write about, subscribe to receive new articles and join the group on VK!

But if the consumer’s power is 15 kW or higher, then three-phase power must be used. Even if there are no three-phase consumers in this building, for example, electric motors. In this case, the power is divided into phases, and the electrical equipment (input cable, switching) does not bear the same load as if the same power was taken from one phase.

An example of a three-phase electrical panel. Consumers are both three-phase and single-phase.

For example, 15 kW is about 70A for one phase; you need a copper wire with a cross-section of at least 10 mm². The cost of a cable with such cores will be significant. But I have never seen single-phase (single-pole) circuit breakers with a current greater than 63 A on a DIN rail.

Therefore, in offices, stores, and especially in enterprises, only three-phase power is used. And, accordingly, three-phase meters, which come in direct connection and transformer connection (with current transformers).

What's new in the VK group Samelektrik.ru?

And at the input (in front of the counter) there are approximately the following “boxes”:

Three-phase input. Introductory machine in front of the counter.

A significant disadvantage of a three-phase input (noted above) is the limitation on the power of single-phase loads. For example, the allocated power of three-phase voltage is 15 kW. This means that for each phase - a maximum of 5 kW. This means that the maximum current in each phase is no more than 22 A (practically 25). And you have to spin, distributing the load.

I hope it is now clear what three-phase voltage 380 V and single-phase voltage 220 V are?

Star and Delta circuits in a three-phase network

There are various variations for connecting a load with an operating voltage of 220 and 380 Volts to a three-phase network. These patterns are called “Star” and “Triangle”.

When the load is designed for a voltage of 220V, it is connected to a three-phase network according to the “Star” circuit , that is, to phase voltage. In this case, all load groups are distributed so that the powers in the phases are approximately equal. The zeros of all groups are connected together and connected to the neutral wire of the three-phase input.

All our apartments and houses with single-phase input are connected to Zvezda; another example is the connection of heating elements in powerful heaters and convection ovens.

When the load has a voltage of 380V, it is switched on according to the “Triangle” circuit, that is, to linear voltage. This phase distribution is most typical for electric motors and other loads where all three parts of the load belong to a single device.

What is important to know

In a three-phase network, all three phases have a shift of 120 degrees. If it were necessary to convert three-phase 220 Volts to 380V, or single-phase 220V to the same, but with a voltage of 380V, then this can be done very simply using a conventional step-up transformer. In this problem, it is necessary not just to increase the voltage, but to obtain a full-fledged three-phase network from a single-phase one.

There are three main ways in which this manipulation can be done:

- using an electronic converter (inverter);

- by connecting two additional phases;

- due to the use of a three-phase transformer, but the power is still reduced.

Before converting the mains voltage, you need to consider whether it is possible to connect the motor to a standard single-phase network without loss of power. First you need to look at the plate on the engine itself, some of them are designed for both of these voltages, as shown in the first photo. You just need a capacitor for starting.

The second plate shows that the machine is designed exclusively for star connection of windings and a voltage of 380 Volts:

You can, of course, disassemble the engine and find the ends of the windings, but this is already problematic. Let us dwell in more detail on the creation of a high-quality three-phase network of 380 V from 220.