AABl cable is a wire in which an aluminum core acts as a current-carrying element. The insulator is impregnated special paper, the coating is an aluminum shell. The main purpose of the wire is to install power lines in the ground. The conductor may consist of one or more wires. To ensure its protection, armor made of steel strips is used, as well as additional external coating. In addition to the protective function, these elements increase the operating life of the conductor.

The cable can be installed in accordance with the UHL category according to State Standard 25870.

During operation, the wire should not experience excessive stretching. When installing the cable, it is necessary to establish in advance the corrosive activity of the soil. It is permissible to lay the main line with medium and low activity levels, as well as the absence of stray currents.

Application

The cable transmits and distributes electrical energy in non-mobile installations. In this case, the line characteristics must comply with the voltage limits - 10 kV and frequency - 50 Hz.

If the conductor contains two current-carrying copper cores with an area of 1.5 mm2, it is most rational to use the AABL cable in the electrical wiring of vehicles.

According to the climate class, the cable can be installed and operated in moderate and cold climates. The wire operates in soil with a low or medium tendency to metal corrosion and in the absence of stray currents. Also, a prerequisite for this conductor is the absence of large tensile forces.

The TsAABL modification (with a fixed insulating composition for impregnation) is used for the installation of vertical and inclined power lines. Such a cable is not sensitive to changes in the height of the line.

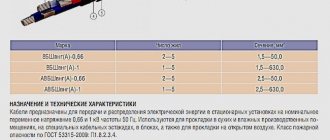

Cables VBBShv, VVGng, VVGb

VVG cable is an abbreviation for standard copper power cable. The insulation in it is made of PVC. There are both multi-wire (mp) and single-wire (os) wires; sector-shaped ones are less common. Each individual core is made of PVC.

VVGng cable is identical in its characteristics and parameters to those of cable products marked VBBShV. Its only difference is that this type of cable uses special polyvinyl chloride insulation of reduced flammability.

The VBBShnv cable is a reinforced power cable, made of copper with armor consisting of two steel strips. PVC plastic is used for the outer layer of protection.

Unlike VVG, it uses special polyvinyl chloride insulation of reduced flammability. This type of cable is used to transmit electrical energy in difficult conditions.

Wire composition

The AABL power cable consists of several layers:

- The current-conducting element can be single- or multi-wire. In the first case, class I wire with an area of 25 to 240 mm2 is used. In the second case, class I and II wire is used with an area of 70 to 800 mm2.

- An insulating layer made of special paper impregnated with a viscous non-drip mixture. In this case, a numerical identification is applied to the insulator, and they also differ in color. Depending on the number of cores, the following colors are used: white (yellow), brown (black), red (crimson), blue (green).

- Filler – strands of special paper used for the insulating layer.

- Belt insulator made of paper impregnated with a similar mixture.

- A paper screen with high current conductivity, installed on wires rated for 6000 volts or more.

- Aluminum shell.

- Bitumen pad, polyvinyl chloride film and crepe paper.

- Armor – a pair of steel strips.

- The outer layer is a yarn of glass or cable, as well as a coating that prevents cable turns from sticking during transportation and storage.

How to choose AABL wire

An insulated conductor is exactly the same as a non-insulated conductor with the only difference being that the core is covered with a layer of insulation so that the metal does not come into contact with any other elements such as other conductors, people or metal objects. Insulated wire is used much more often than bare copper in both homes and offices. The advantages and disadvantages of using aluminum or copper conductors have been debated for many years. Most of the concerns on the part of users are related to the fact that reliable information about them does not exist, or it is long out of date.

Note! Aluminum has a higher thermal expansion than copper and steel, but it is important to know which aluminum alloy is used.

To understand the differences in use of these two materials, it is necessary to know their mechanical and electrical characteristics. Three materials are used as conductors in electrical distribution boards: copper, aluminum and silver.

Due to the fact that copper is becoming increasingly scarce, and the demand for it is only growing, the cost of this metal has increased proportionally in recent years, so the use of aluminum is becoming increasingly popular. In the case of silver, due to its high cost, it is only used to coat joints and contact surfaces. Copper is also sometimes used in its pure form, as its commercial conductivity is 98%. On the other hand, pure aluminum cannot be used as an electrical conductor because it is too soft for mechanical components, so it is always used in alloy with other materials.

You may be interested in Description of PRKA wire

Important! Regardless of the material used, the appropriate conductor size must be considered to meet the above requirements. In the case of aluminum, its cross-section must be larger to achieve conductivity levels similar to those of copper.

When choosing a cable, you need to pay attention to the following aspects:

- Number of cores

- Core cross-section.

- Presence of copper cores.

- The presence of protective covers.

Specifications

Main technical characteristics of the AABL cable:

| height difference when constructing a highway | with a wire of 1000 V - 25 m, 6000 V - 20 m, 10000 V - 15 m; |

| installation temperature | 0 degrees, when it is lowered, the conductor must be preheated; |

| duration of warranty service | 4.5 years after starting work; |

| network test | 4/17/25 kV, 50 Hz, 5 minutes; |

| normal operating conditions | temperature +35 degrees, humidity – maximum 98%; |

| operating temperature limit for the core | +80 degrees; |

| normal voltage | 1/6/10 kV at alternating current (frequency 50 Hz), 2.5 kV at direct current; |

| bend radius | 25 outer diameters; |

| duration of work | 30 years; |

| long-term heating temperature | +80 degrees; |

| insulating layer resistance | 100 MOhm/km; |

| working temperature | from -50 to +50 degrees; |

| operating temperature at overload for core | +105 degrees. |

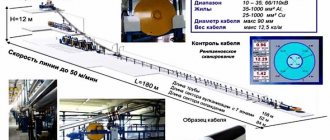

Description of cable AABL (10 kV)

The AABl-10 cable is intended for power transmission in fixed installations in networks with an alternating current voltage of 10 kV with a frequency of 50 Hz and 24 kV with a direct current voltage (2.4 times higher than alternating current). A cable of this type with 2 aluminum sections of 1.5 sq. mm is used for subway networks, railways, trams, trolleybuses, i.e. for electrified transport.

Decoding of the power cable AABL (10 kV)

- A - Aluminum conductor

- A - Aluminum shell

- B - Armor made of two steel strips

- l — The pillow contains an additional lavsan ribbon

Cable design elements ААБл (10 kV)

- Aluminum conductor:

- Phase paper insulation impregnated with a viscous or non-drip insulating impregnation composition;

- Filling from paper bundles;

- Belt paper insulation impregnated with a viscous or non-drip insulating impregnation compound;

- Screen made of electrically conductive paper for cables for voltages of 6 kV and more;

- Aluminum shell;

- Cushion made of bitumen, PVC film and crepe paper;

- Armor made of steel strips;

- An outer cover made of glass or cable yarn and a coating that prevents the cable from sticking together.

- single-wire (class 1) with a cross-section of 25-240 sq. mm., - multi-wire (class 1 or 2) with a cross-section of 70-800 sq. mm.;

core markings: - digital: 1, 2, 3, 4, - color: white or yellow, blue or green, red or crimson, brown or black;

Scope of application of cable AABL (10 kV)

Most often, the AABL-10 cable is used in temperate and cold climates (from -50 to +50). The cable can be laid in earthen trenches with low corrosion activity. The cable must be installed in areas of the ground where there are no stray currents. Do not subject the cable to tensile loads to avoid damaging the steel armor and screen. Cable brand AABL-10 can be laid without preheating at a temperature not lower than 0°C (in accordance with GOST 18690). Cables with a viscous impregnating composition without the use of special devices (for example, locking couplings) are intended for laying on routes with a level difference between the highest and lowest points of the cable location of no more than 15 meters.

Service life is at least 30 years. The period may be extended depending on the technical condition of the cable.

Cost of cable AABL (10 kV)

The Cable Systems company can offer you the most interesting and favorable prices for the AAB-10 series cable thanks to long-term and well-coordinated work with manufacturers. We are official partners of factories producing cable products, so we guarantee low prices and excellent quality.

Price

Our company has favorable conditions for purchasing goods. The price of AABL cable is calculated depending on several factors, including the cost of copper used to produce the cores. The customer can fill out an application in a convenient way - leave it on the website or send it by email. Our employees will make a profitable offer in the shortest possible time, taking into account the availability of goods in stock and current discounts. The final cost is determined depending on delivery conditions and order volume. The goods can be delivered to any city in Russia; if the goods are not in stock, they can be ordered from the manufacturer at the request of the customer.

All products have a certificate of conformity and a quality passport, and complete information about them is provided upon request.

Wire installation

Before buying an AABL cable, you need to familiarize yourself with all the nuances, including installation rules. The conductor is installed directly in the ground under conditions of low or medium corrosive activity. An important aspect is to eliminate the possibility of stray currents and tensile stresses. There are also certain conditions for installing cables when there is a difference in height. If it is necessary to install a main line with a level difference from 15 to 35 m, it is necessary to select a wire with a non-draining impregnation composition of the insulating coating. Such conductors are designed for use in temperate zones and cold climates.

What are the problems when using wire?

Copper is an excellent conductor of electricity and is in strong demand due to its high electrical conductivity, corrosion and temperature resistance. These characteristics of this metal put it in first place when carrying out electrical installation work.

You may be interested in this Features of the screw terminal block

On the other hand, aluminum has very noticeable disadvantages when it comes to conducting electricity and especially in the production of electrical and electronic circuits. Due to its greater ductility, aluminum is less preferred than copper.

Problems during operation

The most notable disadvantage of aluminum cables is that they tend to deform more as temperatures change than their copper counterparts, so they are not recommended for use in applications that operate at high temperatures.

Another disadvantage to add is that aluminum is only 60% conductive compared to copper, which means using a larger diameter to conduct the same amount of electricity as copper. In addition, aluminum quickly oxidizes and breaks down upon contact with wet surfaces.

Important! Most problems can be avoided before the facility starts operating. To do this, you just need to choose the most suitable cable and carry out installation according to all the rules.

The best manufacturers

The modern market for cable and wire products offers a wide range of products. However, not all manufacturers ensure that their products comply with established quality standards. Manufacturers of AABL with a good reputation:

- Sarankable;

- Kamkabel;

- Kavkazcable.

The products of these manufacturers are always of high quality; they comply with GOST standards and declared characteristics. Professionals advise turning to these factories to get high-quality products and ensure the network has a long trouble-free service life.