Recommendations for choosing LED devices

LED lamps for proper emergency lighting must be selected according to the tasks that need to be solved. Non-permanent devices must be purchased to provide emergency lighting in rooms where people are not present all the time - in basements and technical facilities.

Non-permanent devices are purchased for those premises where there are always people inside. Using LED equipment saves space and energy costs.

Combined LED lamps are equipped with a switch with which you can select the operating mode based on the installation location and the need for use at the moment.

Emergency lighting devices intended for use in office buildings and public organizations are usually installed on the surface of the ceiling or at the top of the walls. They are used to provide light for office and retail premises, healthcare and educational institutions. They are also necessary for the correct evacuation - an emergency lamp indicating an exit is placed in places where people need to escape in case of emergency situations in the building. The output designation device is shown below.

Industrial LED lighting is used in warehouses, production workshops, garages, hangars, and workshops. In industrial conditions, it is rational to install an additional explosion-proof emergency lamp. An explosion-proof device for work in underground mines and chemical industry facilities, for example, the Raketa 01-28 lamp, is especially relevant.

Lamps for emergency lighting Raketa are a good representative of this equipment, which has earned credibility in the modern market. Among these devices, two types of devices can be distinguished, namely 01-30 LED (combined type device) and 01-28 (intermittent device). “Raketa” equipment is used in retail premises, office complexes, at home, and on vacation (flashlights for fishing, hunting, lamps for camping). The Raketa 01-30 LED device is shown below.

LED emergency lamps are presented on the modern market in a wide range. If it is necessary to select such equipment for lighting, you should take into account the type of object, whether the device belongs to a particular group of devices, as well as the level of possible financial costs.

Emergency light sources are needed both to ensure correct evacuation measures and for the proper work process in production workshops. It is possible to purchase this equipment for solving everyday problems: lighting corridors and stairs in private households, as well as recreational areas - fishing, camping and hunting. High-quality LED lamps are able to solve all the tasks with minimal energy costs.

Optimal parameter value for the workplace

Workplace lighting requirements are determined by a number of parameters. Key lighting requirements:

The brightness should be adjusted in such a way as not to create problems with the human visual organs. It should not be weak so that the employee does not have to strain his eyes, but it should not be blinding, which will make it impossible to work. The illumination should be uniform. An employee should not suffer from an excess of unfortunate shadows. If the base light is not enough to eliminate them, then you need to connect auxiliary light sources

For example, a table lamp. The perception of light can be individual, so it is important to leave the employee the opportunity to independently debug some parameters that will provide him with a comfortable perception of light and productive performance.

Insufficient lighting and failure to comply with these requirements when organizing the workplace will lead to deterioration in the vision of employees in the office or other premises, a decrease in work efficiency and poor achievement of company goals. If some employees have pre-existing vision problems, they may need to provide additional accommodations to enable them to work effectively.

Two types of light are used in everyday life: natural and artificial. A combination of these types is considered optimal. This combination is called a combined (mixed) option.

Organizing a comfortable workplace

Depending on the working conditions, the following standards are determined:

- a small office requires average light of at least 500 lux;

- open space is standardized to at least 750 lux;

- conference room - 300 lux;

- reception room, secretariat - 300-500 lux;

- rooms with computer equipment - 400 lux;

- technical premises and corridors - 100-200 lux;

- archive room - 75 lux.

If employees work at a computer, then it is imperative to regulate breaks in their activities. Failure to comply with the rule will negatively affect their health and productivity. During the day, employees can work without breaks for no more than 2 hours, at night - no more than an hour. Every employee must take a break from work for up to fifteen minutes. This will create the necessary conditions for your eyes to rest. In addition, it is useful to do exercises to relax your eyes. But the latter measure is not mandatory; it is only recommended.

Visual comfort factors

Workplace lighting requires taking into account several factors. These factors include the following:

- color interior of the room. It is best to use light, green or yellowish shades, as they have a positive effect on vision. Such shades are more gentle and do not require excessive strain on the visual organs;

- adjusted brightness and contrast;

- light uniformity;

- eliminating glare and flickering from surfaces (for example, a monitor screen).

All these factors affect light, along with it comfort, the degree of fatigue and relaxation of the eyes. It is necessary to select the right lamp and organize the most comfortable conditions for employees both in terms of outdoor and indoor use (organize emergency lighting, general lighting, etc.).

Selecting lamps for workplace lighting

LED lamps will give the workplace a suitable parameter value. In addition to fulfilling the central task, they have the following advantages:

- low cost;

- long period of operation;

- low power consumption.

Second place can be given to halogen lamps. But when purchasing them, it is worth considering that they have a high degree of heating and it will not be possible to integrate them into any devices.

In third place is a fluorescent lamp; it can also be used, but its light is much worse (it is unnatural).

It is best to combine options and purchase auxiliary light (special electrical installation, etc.).

Lighting workplaces requires choosing the appropriate type of lamp; also pay attention to the location of the lamp, thanks to which the work area is illuminated. This determines how successful the chosen option will be.

An incorrectly positioned lamp will lead to eye fatigue and poor vision, while a correctly positioned lamp will help you perform your job successfully.

Emergency light supply standards

Lighting standards in emergency situations are somewhat lower than those used under normal conditions. Since it operates from autonomous power sources, it must be calculated in accordance with their power. The light supplied from the backup source must be at least 30% of normal working lighting. If an increased supply of light is required due to, for example, a continuous production cycle or the characteristic features of a given facility, then the achieved indicators should be laid down at the design stage with justification for the emergency lighting system used.

The electrical installation used, regardless of the established parameters of the light standard, must supply the object with 50% of the standardized illumination 15 s (no more than this time) after the failure of the main power sources. Within 60 s from the start-up, the power source must supply 100% of the set norm. If a different norm for light supply is established, then these changes made during the design and noted as a special norm in the technical documents for the equipment during its operation must be notified to the persons responsible for the operation of the emergency special lighting system during a special period, who notify about this personnel (if such a case occurs) in order to avoid panic fears. If sequential or localized activation when power sources are depleted is provided, then such actions should also be automatic. For example, when one of the batteries (another power source) is depleted, the next one is automatically turned on, etc.

The uniformity of evacuation lighting should be 1:40, or 0.5 lux, over the entire free floor surface area. The exception is a half-meter edge around the perimeter of the room. The color rendering index for large rooms should be 40 or higher.

If there is traumatic equipment at the enterprise and narrow passages between it, the illumination should be at least 15 lux, and the unevenness of illumination should be 1 in 10. Movement areas in the premises should be illuminated from 0.5 lux, and open spaces should be illuminated with an illumination intensity of 0.2 lux.

Evacuation safety signs

Evacuation safety signs are installed in rooms without natural light with simultaneous occupancy of more than 30 people and in rooms with natural light with an area of more than 100 m² with simultaneous occupancy of more than 50 people. And if we are talking about preschool educational organizations, educational and medical institutions and buildings with permanent residence of people with limited mobility, then evacuation safety signs are installed regardless of the number of people in the premises. In addition, in such institutions the use of light railings is allowed. Safety signs must comply with the requirements of GOST R 12.4.026 “System of occupational safety standards. Signal colors, safety signs and signal markings"

.

Permanent evacuation safety signs are installed:

- Above each emergency exit;

- On evacuation routes, clearly indicating evacuation directions;

- To designate a medical aid station;

- To designate the locations of primary fire extinguishing equipment;

- To designate the locations of emergency communications equipment and other means intended to notify of an emergency.

The brightness of evacuation safety signs within any part of the colored surface of safety signs in all directions must be at least 2 cd/m² in the absence of smoke, 10 cd/m² in smoke conditions. The maximum uniformity of brightness distribution within the colored surface of safety signs must be at least 1:5. The ratio of the brightness of the safety color to the brightness of the contrast color must be no less than 1:15 and no more than 1:5.

In rooms where smoke is possible, evacuation safety signs should be placed at a height of no more than 0.5 m from the floor, and their external lighting is not allowed.

The size of an evacuation sign, in particular its height, is determined by a special formula: h = l / Z, where l is the distance to distinguish the evacuation sign, Z is the distance factor, which is taken equal to 100 for signs illuminated from the outside, and 200 for illuminated ones from the inside. For example, if it is necessary to install a sign that is illuminated from the inside and must be visible from a distance of 10 meters, then its minimum height should be 10 / 200 = 0.05 meters or 50 millimeters. Moreover, this is the height of the colored part of the sign - the plastic frame is not included in this value.

In normal mode, evacuation safety signs must be powered from a source independent of the working lighting power source, and in emergency mode, switch to power from a third independent source, for example, a battery built into the lamp. The duration of operation of evacuation safety signs must be at least 1 hour.

Emergency lighting

6.1.21. Emergency lighting is divided into safety and evacuation lighting.

Safety lighting is designed to continue operation in the event of an emergency shutdown of the work lighting.

Work lighting fixtures and safety lighting fixtures in industrial and public buildings and open spaces must be powered from independent sources.

6.1.22. Lamps and light indicators for evacuation lighting in industrial buildings with natural light and in public and residential buildings must be connected to a network not connected to the working lighting network, starting from the substation panel (lighting distribution point) or, if there is only one input, starting from input distribution device.

6.1.23. The power supply of lamps and evacuation lighting indicators in industrial buildings without natural lighting should be carried out in the same way as the power supply of safety lighting lamps (clause 6.1.21).

In industrial buildings without natural light in rooms where 20 people or more can be present at the same time, regardless of the presence of safety lighting, evacuation lighting along the main passages and light “exit” signs must be provided, automatically switched when their power is interrupted to a third independent external or local source (battery, diesel generator set, etc.) not used in normal mode to power work lighting, safety lighting and evacuation lighting, or emergency lighting lamps and exit signs must have an independent power source.

6.1.24. When classifying all or part of safety lighting and evacuation lighting fixtures into a special group of the first category for power supply reliability, it is necessary to provide additional power to these fixtures from a third independent source.

6.1.25. Evacuation lighting fixtures, light indicators for evacuation and (or) emergency exits in buildings of any purpose, equipped with autonomous power sources, in normal mode can be powered from networks of any type of lighting that are not switched off during the operation of buildings.

6.1.26. For rooms in which people are constantly present or which are intended for the constant passage of personnel or unauthorized persons and in which safety lighting or evacuation lighting is required, it must be possible to turn on the specified types of lighting during the entire time when the work lighting or safety lighting is on. evacuation lighting should turn on automatically when the working lighting goes out in an emergency.

6.1.27. The use of common group panels for working lighting, safety lighting and (or) evacuation lighting, as well as the installation of control devices for working lighting, safety lighting and (or) evacuation lighting, with the exception of devices for auxiliary circuits (for example, signal lamps, control keys), in Shared closets are not allowed.

Power supply of safety and evacuation lighting from common panels is permitted.

6.1.28. The use of networks supplying power electrical receivers to power security lighting and evacuation lighting in industrial buildings without natural light is not permitted.

6.1.29. It is allowed to use hand-held lighting devices with batteries or dry elements for safety lighting and evacuation lighting instead of stationary lamps (buildings and premises without permanent occupancy, buildings with a built-up area of no more than 250 m2).

How to make emergency lighting options

It is necessary to think about installing emergency equipment at the design stage. On the diagrams, this type of equipment is marked with the letter “A”.

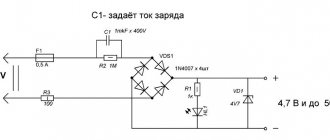

As an option, you can initially select the type of luminaires equipped with BAPs. Thus, in the event of an accident, only one module will turn on, providing not 100, but 10-15% of the lighting. In this case, the location of the lamps and their equidistance from each other are of great importance.

Both LEDs and high-pressure lamps can be used as a module.

The BAPs themselves are available in the form of built-in and external equipment. The first type is mounted between the driver and connected to a single module. The second is used when upgrading already installed work lighting. It connects directly to the power source and projects a voltage of 220 V, thus providing 100% light output.

Technicians most often choose the second method, as it has a number of advantages:

- low time costs for modernization (does not require equipment disassembly);

- a smaller number of light points due to the higher power of their operation (all indicators comply with the standards);

- saving financial costs on equipment and installation (the difference can be 35-40%);

- connecting several devices to one UPS at once.

In the latter case, when using a powerful battery, you can connect emergency lights located at a distance of up to 200 meters, for example, those used on the external walls of a building.

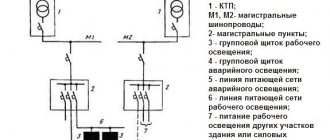

Centralized emergency lighting

The centralized system is one of the most technologically advanced and modern solutions. It is often used in large areas: shopping centers, airport halls, office buildings.

To operate such a system, it is inappropriate to use built-in power supplies, so most often power supplies are mounted separately and connected to several light points at once. Testing is carried out using a special controller device with the direct participation of two people.

This solution has its advantages:

- Automated testing mode with recording of the result in the controller memory.

- High reliability.

- Cost-effective compared to equipping each lamp with a separate battery.

- Longer service life of centralized BAP (up to 12 years).

- Possibility of connection to emergency lighting of fire automatics.

- Control from one remote control.

- Possibility of upgrading an already installed system.

The centralized emergency lighting device can be divided into simple and addressable systems. In the first case, lighting fixtures are grouped by floors or zones. In the second, each lamp is equipped with its own separate “address”. All of them are visible to the system that manages them.

The choice of lighting option depends on the area, the number of lighting fixtures and illuminated signs.

According to SP 52.13330.2011:

Types of emergency lighting are given in clause 7.104 of SP 52.13330.2011 “Natural and artificial lighting (SNiP 23-05-95)”:

Emergency lighting is divided into evacuation and backup.

Evacuation lighting is divided into: lighting of escape routes, evacuation lighting of high-risk areas and evacuation lighting of large areas (anti-panic lighting).

Emergency lighting is provided in case of power failure of the main (working) lighting and is connected to a power source that is independent of the power source of the working lighting.

Evacuation lighting (clause 7.107 SP 52.13330.2011) of high-risk areas should be provided for the safe completion of a potentially dangerous process or situation.

Evacuation lighting of large areas (anti-panic lighting) (clause 7.108 SP 52.13330.2011) is provided in large rooms with an area of more than 60 m2 and is aimed at preventing panic and providing conditions for a safe approach to evacuation routes.

Backup lighting (clause 7.109 SP 52.13330.2011) should be provided if, according to the conditions of the technological process or situation, normal continuation of work is required in the event of a power failure of the working lighting, and also if the associated disruption of maintenance of equipment and mechanisms may cause:

- death, injury or poisoning of people;

- explosion, fire, long-term disruption of the technological process;

- leakage of toxic and radioactive substances into the environment;

- disruption of the operation of such facilities as power plants, radio and television transmission and communication centers, control centers, pumping installations for water supply, sewerage and heating, ventilation and air conditioning installations for industrial premises in which the cessation of work is unacceptable, etc.

Backup lighting should generally not be used for emergency lighting purposes. If emergency lighting is designed to be used for emergency lighting purposes, it must satisfy the relevant requirements specified above for emergency lighting.

According to clause 7.110 of SP 52.13330.2011, the illumination from backup lighting must be at least 30% of the standardized illumination for general working lighting. The need to create higher illuminance levels for backup lighting is determined by technologists depending on the operating conditions of a given facility.

Backup lighting should provide 50% of the rated illumination no more than 15 s after a power failure of the working lighting and 100% of the rated illumination - no more than 60 s, unless otherwise established by special standards or appropriate justification.

Illuminated signs (safety signs) are installed (clause 7.111 SP 52.13330.2011):

- above each emergency exit;

- on evacuation routes, clearly indicating evacuation directions;

- to designate a medical aid station;

- to designate the locations of primary fire extinguishing equipment;

- to designate the locations of emergency communications equipment and other means intended to notify of an emergency.

In normal mode, the power supply of light indicators must be supplied from a source independent of the power source of the working lighting; in emergency mode, switch to power from a third independent source, for example, a battery built into the lamp. The duration of operation of light indicators must be at least 1 hour.

For emergency lighting the following should be used (clause 7.112 SP 52.13330.2011):

a) LED light sources;

b) fluorescent lamps - in rooms with a minimum air temperature of at least 5 ° C and provided that the lamps are powered in all modes with a voltage of at least 90% of the nominal voltage;

c) high-pressure discharge lamps, provided they are instantly or quickly re-ignited both in a hot state after a short-term shutdown, and in a cold state;

d) incandescent lamps - if it is impossible to use other light sources.

clause 7.113 Emergency lighting fixtures may be provided with continuous operation, switched on simultaneously with working lighting fixtures, and intermittent operation, automatically switched on when the power supply to the working lighting in a given area is interrupted. If luminaires with the same type of housing are used for working and emergency lighting, emergency lighting luminaires must be marked with a specially printed letter “A” in red.

What is the difference between an emergency lamp and an emergency sign?

The emergency lamp and emergency indicator perform different tasks, which is reflected in their technical characteristics.

1. Emergency indicator. The purpose is to inform people about evacuation routes, the location of fire hydrants, emergency and emergency exits, etc. They are informative in nature; various pictogram inscriptions are placed on the body. They have low power and can operate continuously or only turn on in emergency mode. The power supply is completely autonomous from batteries (switched on in case of an emergency) or from the main or backup power supply.

2. Emergency lamp. It is installed in such a way that when the main working lighting is turned off, people can freely leave the work area and get to the nearest emergency sign. They can be separate or mounted in one housing with the main work lamps.

Emergency lighting works constantly or turns on only after emergency situations occur. The power of the lighting fixtures is much less than that of the main lamp. An exception is rooms that constantly require high lighting: operating rooms, chemical production, server rooms, etc. In these rooms, emergency lighting should ensure the completion of started processes, including surgical operations.

Some types of emergency lighting can have both automatic and manual activation. Due to this, the reliability of device operation during emergency situations increases.

Emergency lighting diagram with automatic transfer switch

The independent type in this large group is formed by systems that are additionally equipped with a device for self-starting the reserve.

The emergency lighting modules of the circuit, which uses a self-starting reserve device, are represented here by the following components:

If electricity is supplied to the first input, it passes through one contact, one circuit breaker and through the bus for normal operation. If there is a failure in the supply of electricity to the first input, the previously used contact opens, at the same time the contact for emergency operation closes, after which electricity is supplied to consumers from the second input.

If electricity is not supplied to both first inputs, the system signals this and the fuel generator is automatically started, after which the third emergency contact closes. After which the electricity is supplied to the third input. If necessary, two relays stabilize the voltage at the input and continue to monitor it.

These devices not only evaluate the voltage value, but also its dynamics. That is, the system controls surges and dips in the supply of electricity. Thanks to this, you don’t have to worry about the light going out or the lamps flickering.

Emergency lighting, emergency lighting diagram with automatic transfer switch

The lighting element is connected to the bus for normal operation through automatic protective devices, and to the bus for emergency situations through protective devices, while the bus itself is connected to the first through the fourth relay contact.

The second power input can be represented by a separate phase of the network or simply an independent power system. Very often, inverters are used for such purposes, which transform the battery charge into alternating current. These systems are very often installed in stadiums and other crowded places.

The main advantage of these systems is the long service life of the lighting elements, since they are not subject to the destructive effects of power surges, and reliable energy reserve is also important.

Regulatory documents and categories

For the design and installation of emergency lighting equipment and elements, one of the fundamental documents is used. This is SP (set of rules) 52.13330.2016. According to established rules, emergency lighting is divided into two types:

- for the purpose of evacuating people;

- to create backup lighting.

Evacuation lighting can also be divided into the following subtypes:

- ensuring the safe exit of personnel during man-made disasters;

- illumination of escape routes in high-risk areas;

- spreading light over large planes (areas) to prevent panic (anti-panic lighting).

What does the term "security lighting" mean?

Security lighting can be called a set of measures taken for lighting in emergency unpredictable cases, aimed at the functioning of the uninterrupted retreat of people to a safe place. It is necessary for the safety of people, no matter where they are.

It doesn’t matter whether it is a large manufacturing enterprise, an institution, an office, a school or a kindergarten. Taking care of every person is important, be it a team of ten or more than several thousand people

This also applies to life support facilities, such as water supply, communications, sewage treatment plants, various control points, etc., which are needed to prevent the aggravation of already difficult situations that have arisen.

Why do you need backup lighting?

Backup lighting is aimed at maintaining the production technological cycle at enterprises or its safe completion in emergency conditions and involves a gradual transition of personnel to evacuation from production premises.

Categories of emergency lighting consumers

There are three lists of consumer categories. They are used to guide and in accordance with them, emergency lighting systems are installed at the following facilities:

The first category is strategic facilities of particular importance, whose personnel are unsafe to be in the current conditions, and their work is aimed at ensuring the security of the state. Backup lighting here is similar to working lighting.

The second category refers to those enterprises where minor downtime is allowed, but it leads to mass defects and disruption of the work of other significant facilities associated with this enterprise.

Third category

At such facilities, a lack of electricity is acceptable for no more than a day. It is permissible to run emergency and evacuation lighting here automatically from batteries or diesel generators.

Emergency lighting is designed on the basis and in accordance with the set of rules.

How are emergency lighting fixtures designated?

Requirements for technical parameters and marking methods are specified in the provisions of GOST 21.210-2014. For marking, the recommendations of section 3 of the IEC 598-1-86 standard apply. The housing of the emergency lighting luminaire must be clearly marked indicating the rated voltage and operating mode of the device (continuous or non-continuous). If lighting devices require periodic replacement of batteries and lighting devices, then the technical parameters must be marked on the visible part of the housing.

Autonomous luminaires must have information about the frequency of checking and recharging the battery and the battery life. If necessary, temperature conditions for the operation of lighting devices can be indicated; all inscriptions are in the same language.

Emergency lighting fixtures and associated equipment must have a red marking of Ø 30 cm or more. If emergency lamps are placed in the same housing as permanent ones for working lighting, they are marked with a large letter “A” in red.

How should emergency lighting luminaires differ from task lighting luminaires?

| Color | Incorrect answer |

| Marks or coloring | Correct answer |

| There are no fundamental differences | Incorrect answer |

If the transformation ratio is greater than one, then this transformer is considered to be:

| Promoting | Incorrect answer |

| Downward | Correct answer |

| Increasing | Incorrect answer |

| Descending | Incorrect answer |

Who is covered by the Rules for the Technical Operation of Consumer Electrical Installations?

| For organizations, regardless of ownership and legal forms, individual entrepreneurs operating existing electrical installations with voltages up to 220 kV inclusive, and citizens - owners of electrical installations with voltages above 1000 V | Correct answer |

| For organizations, regardless of ownership and legal forms, operating existing electrical installations with voltage up to 220 kV inclusive | Incorrect answer |

| For organizations, regardless of ownership and legal forms, individual entrepreneurs operating existing electrical installations with voltage up to 220 kV inclusive, as well as for electrical installations of power stations, block stations | Incorrect answer |

| For organizations, regardless of ownership and legal forms, individual entrepreneurs operating existing electrical installations with voltages up to 380 kV inclusive, and citizens - owners of electrical installations with voltages above 380 V | Incorrect answer |

When is an extraordinary personnel knowledge test carried out?

| When new or revised rules and regulations come into effect for the Consumer | Incorrect answer |

| At the request of government supervisory and control authorities | Incorrect answer |

| When testing knowledge after receiving an unsatisfactory grade | Incorrect answer |

| If there is a break in work in this position for more than 6 months | Incorrect answer |

| In any of the above cases | Correct answer |

Which of the listed works can be classified as work performed as part of routine operation in electrical installations with voltages up to 1000 V?

| Removal and installation of electricity meters, other instruments and measuring instruments | Correct answer |

| Repair of starting and switching equipment installed on panels | Incorrect answer |

| Replacing lamps and cleaning luminaires at a height of more than 2.5 m | Incorrect answer |

| Any of the listed works | Incorrect answer |

In what sequence is it necessary to carry out technical measures to ensure the safety of stress relief work?

| Carry out the necessary shutdowns, check the absence of voltage on live parts, install grounding, hang prohibition and instructional posters | Incorrect answer |

| Hang up prohibition and instructional posters, make the necessary shutdowns, check the absence of voltage on live parts, install grounding | Incorrect answer |

| Carry out the necessary shutdowns, hang prohibiting posters, check that there is no voltage on live parts, install grounding, and post warning signs | Correct answer |

| Carry out the necessary shutdowns, hang prohibition and instructional posters, install grounding, check the absence of voltage on live parts | Incorrect answer |

What is meant by step tension?

| Voltage between two conductive parts or between a conductive part and ground when simultaneously touched by a person or animal | Incorrect answer |

| Voltage between two points on the ground due to the spreading of a fault current to the ground when they are simultaneously touched by a person’s feet | Incorrect answer |

| The voltage produced when current flows through a conductor between two points | Incorrect answer |

| Voltage between two points on the surface of the earth at a distance of 1 m from one another, which is taken to be equal to the length of a person’s step | Correct answer |

| Voltage between two points in an electrical circuit with different potentials | Incorrect answer |

Organization of emergency lighting

When organizing emergency lighting, the route of personnel to emergency exits is taken into account. In this case, the supply of light is given greater importance in the following areas:

- staircases;

- locations of fire extinguishing equipment;

- zones of track changes (turn, intersection, bend);

- places characterized by unequal heights of planes (sharp changes in the form of steps where they are not expected);

- locations of medical centers;

- narrow passages;

- porches of buildings (entrance-exit).

To check each lamp, a button or connector must be placed near its installation site, designed to test its operation at least once every two weeks with an entry in the lamp inspection log. This is the responsibility of the chief power engineer of the enterprise. It happens that a group of lamps is tested where it is impossible to check them one by one. Test buttons must be self-release

When checking, you should pay attention to whether there is a bare, uninsulated wire, in order to avoid a short circuit.

Arrow pointer

Arrow signs are installed along evacuation routes. If the standard requirement is 1 sign per 25-40 m, their number can fluctuate greatly due to turns, bends, and corridors. The decision on the quantity is made according to the method of visibility of one indicator after another.

These signs do not have the same level of illumination as lamps, but they play the role of road signs (how and where people should move), and the illuminating effect is quite sufficient. Sometimes signs are not illuminated themselves, but are positioned so that they are illuminated by emergency lamps. The main thing here is the clarity and visibility of the leading arrows.

Some features of emergency lighting organization

Particular attention should be paid to timely replacement of failed batteries. It does not matter whether it was used to generate electricity, but it must be replaced once every four years

This is its service life.

Some lamps that play the role of fire alarms must be purchased with the appropriate certificate. This type of device is required to have it.

Remote controls are widely used. For fire safety purposes, some production facilities are deliberately de-energized at night (for example, various types of warehouses). Therefore, its use to turn on emergency lighting is most useful when the warehouse is already de-energized or this will happen after some delay when the warehouse equipment is turned off and the emergency lighting is turned on instead.

Requirements for emergency lighting

Now let's figure it out, what exactly should this lighting provide? It is clear that the proper level of illumination is sufficient to perform functional duties and evacuate. But what level is considered sufficient?

So:

- For safety lighting, it must be at least 5% of task lighting. Moreover, in all cases it should not be lower than 10 lux for incandescent lamps and 30 lux for gas-discharge lamps. In general, the issue of lamps for the emergency network is separate, and we will consider it below.

- As for evacuation lighting, the standards here are not so strict. Lighting on the floor of the premises should be 0.5 lux. If this is an open area, then the norm is 0.2 lux.

- A separate issue is the difference in illumination for different areas. After all, if there is a big difference, the lighting will blind people. Therefore, the calculation of emergency lighting should be carried out in such a way that there is no difference of more than 1/40 between the maximum illuminated and dark areas.

Emergency lighting requirements

- Clause 7.65 of SNiP 23 – 05 – 95 requires that evacuation route signs be installed in all premises with an area of more than 150 m2, or in places where more than 100 people can be present at the same time, or in places without natural light and where more than 50 people are present at the same time.

- But arrows on the walls, which should be located every 25 meters and at every turn, are not very beautiful. Therefore, it is permissible to use lamps with an escape route indicator. A prerequisite is to connect these luminaires to the emergency power supply network.

Evacuation type of lighting

Evacuation lighting of routes along which people are evacuated is provided in places:

- passages, corridors and at their intersections;

- differences in floor and ceiling heights;

- on stairs and landings;

- at stands with fire extinguishing equipment and evacuation plans;

- exits from buildings;

- at warning and communication means;

- paths leading to first aid medical stations.

It should be noted that in rooms with an area of 60 m2 or more, anti-panic lighting lamps are additionally installed. This ensures safe access to escape routes and prevents people from panicking.

Emergency lighting design

Emergency lighting design

Does your building need to be equipped with emergency lighting? and if so – why? What standards are the design of emergency lighting based on, and how difficult (and expensive) is it to install additional lines in an existing room? We have to deal with these and many other similar questions regularly, since the development of electrical projects is one of the main areas of our activity. This article is an explanation regarding emergency lighting standards, conditions for its design and installation. We will not abuse terminology and will talk about what guides us when developing electrical emergency lighting projects.

Justification of requirements, illumination of design standards

There are dozens of regulatory documents that justify the requirements for the use of emergency lighting. There is simply no point in listing all these regulations, departmental orders, rules, etc. - each regulatory authority relies on its own (departmental) standards.

For example, the Ministry of Emergency Situations justifies the mandatory design and installation of emergency lighting by the technical regulations “On Fire Safety”; Representatives of energy supervision refer to the PUE, and when it comes to children's institutions, emissary inspectors appeal to sanitary requirements.

Kindergarten power supply project

To determine the feasibility (and validity) of using emergency lighting, let us refer to SP 52.13330.2011.

So, emergency lighting should be provided where interruptions in standard lighting can lead to an industrial or man-made incident, to a long-term disruption of the technological cycle, or to disruption of the operating mode of significant facilities (for example, public heating and water supply facilities) and children's institutions (in this case the number of children does not matter).

Of course, the wording is somewhat vague, but this is enough to create an overall picture. Details can be found in Federal Law No. 123 “On Fire Safety”.

In any case, if your facility arouses increased interest from the Ministry of Emergency Situations or Rostechnadzor, we can say with absolute certainty that you cannot do without the design and implementation of emergency lighting.

There are two types of emergency lighting - evacuation and backup. The name of the first one speaks for itself; the second is designed to ensure a normal technological cycle or its completion during power outages, prevent injury to personnel, damage to property and many other negative consequences.

Main technical aspects of emergency lighting design

Emergency lighting is mentioned (and specified) in several chapters of the Electrical Installation Rules (PUE, section 6). Let us briefly describe the main parameters taken into account when designing emergency lighting lines:

- 1) emergency lines are connected to networks independent of the permanent power supply circuit;

- 2) the activation interval of the backup lighting should not exceed 15 seconds. after turning off the working lighting, and no more than 60 seconds. – if the backup lighting provides illumination similar to the standard one;

- 3) evacuation lighting is activated half a second after an accident on the main line. In a maximum of 10 seconds. illumination parameters must be identical to the standardized indicators;

- 4) duration of operation of evacuation lighting – at least 1 hour;

- 5) it is recommended to use LED and fluorescent lamps in emergency lighting networks. Gas-discharge lamps and incandescent lamps are allowed with a number of reservations;

- 6) there are two emergency lighting schemes. The first option provides for constant power supply to emergency lamps, the second – automatic switching on in case of power outages.

The list of technical aspects for emergency lighting networks could take a very long time - there are really a lot of requirements and they are quite specific

It is worth mentioning separately that the parameters of emergency lighting always attract close attention from supervisory authorities: this applies to both actual characteristics and design solutions. If you are striving to obtain an electrical lighting design that fully complies with regulatory requirements, Energy Systems, whose specialty is the development of electrical design, will be able to help you

Below you can use the online calculator to calculate the cost of designing power supply networks:

24.06.2014

Selecting light sources for emergency lighting

According to SP 52.13330.2016, certain light sources can be used for emergency lamps. When choosing, proceed from the characteristics of the building, type of food and other aspects. Main options:

- LED lights. The best solution for today, providing good quality light without flickering. This option is also characterized by low power consumption, which is especially important when using battery power; you can install a battery with a smaller capacity and thereby reduce the cost.

- LED strips are another option that have the same characteristics as lamps, but take up less space. Using tape, you can create continuous lighting along the length of the corridor, which will further increase safety during evacuation.

- Fluorescent lamps can be used if the room temperature does not fall below 5 degrees. This option only works normally in warm conditions, so it should not be installed in unheated industrial premises or in cold corridors.

- Gas discharge lamps are also allowed to be installed. But only on condition that they turn off quickly and flare up again without problems after a short shutdown.

- Incandescent lamps are not recommended for use in emergency lighting. But if there is no other way out, you can use them too.

LED equipment is best suited for emergency and backup lighting systems.

The illumination standard for all types of lamps is 15 lux, with the exception of incandescent lamps, their indicator is 10 lux.

There are requirements for lamps that must be met. Therefore, you need to understand them in order to avoid mistakes when designing and installing the system:

- All components of the system, which include, in addition to the lamp, the unit, the control unit and the battery, must be located in the housing or at a distance of no more than half a meter from it.

- Also, emergency lamps must have an indicator showing in which mode the equipment is operating.

- The lamp must provide a color rendering index of at least 40 Ra.

- You should know the difference between evacuation and emergency lamps. The first type indicates directions and exits; most often, pictograms or arrows are pasted on the surface. Emergency ones are used everywhere and provide normal visibility so that a person can see where he is going.

The battery is most often located inside the lamp housing.

Emergency lighting lines, if powered from a separate circuit, should not run near the main wiring to prevent damage to both circuits at the same time.

Main conclusions

Safety lighting of escape routes is a mandatory requirement for office and public buildings, shopping and entertainment centers, school and medical institutions and industrial workshops. The installation of emergency equipment and its requirements are regulated by legislation, regulations and government standards.

- There are evacuation and backup types of lighting. Each has its own installation location.

- Technical requirements for emergency lamps are set out in PUE-7.

- All devices undergo preliminary testing for flammability and noise immunity.

- Testing of devices should be carried out every 2 weeks.

- Emergency lighting is closely related to the concept of fire safety. For the most efficient operation, the lighting system is connected to the fire alarm system.

- A centralized system is more reliable, more convenient and cheaper than an autonomous one.

Properly organized emergency lighting is a guarantee of preserving health and saving lives in the event of a fire or any other mortal danger.

Next LightingHow to make lighting in a bathhouse or sauna with your own hands

Related Posts

- Main types and parameters of outdoor lighting control cabinets

- Illuminance unit

- How to calculate how many lumens are needed per square meter in an apartment or other room

- Lighting for a private home

- Which ceiling lighting is better?

- DIY garage lighting

- DIY LED phytolamp for seedlings

- Staircase lighting in a private house: 35 photos

- How to install light in a steam room?

- How to calculate the power supply for an LED strip

- How to choose the right light sensor, description and classification

- Instructions for installing LED strip on the ceiling

- Selecting and installing lighting for kitchen cabinets

- Organizing proper lighting in a greenhouse: lamp placement diagrams and practical tips on how to install optimal lighting for greenhouses (95 photos)

- Advantages of using LED strip for plant growth and development

- What is illumination, color temperature, light brightness: calculation and illumination standards

- Spotlights in kitchen design: advantages and disadvantages, options for spotlights, how to choose the right one

- LED lamps: warm light or cold, what’s the difference?

- Why is the LED lamp blinking?

- Options for connecting two light bulbs to one switch

- Dimmer for 220 volt LED lamps: do-it-yourself operation and connection features

- Fluorescent lamps: parameters, device, circuit, pros and cons compared to others

- What are track lamps, what are their advantages and features: how to choose and connect hanging lamps with or without a busbar?

- How to place spotlights on a suspended ceiling: optimal distance and examples of diagrams

- Diagram for connecting a 220V LED strip to the network: correct installation of the backlight

Read with this

- Main types and parameters of outdoor lighting control cabinets

- Illuminance unit

- How to calculate how many lumens are needed per square meter in an apartment or other room

- Lighting for a private home

- Which ceiling lighting is better?

- DIY garage lighting

- DIY LED phytolamp for seedlings

- Staircase lighting in a private house: 35 photos

- How to install light in a steam room?

- How to calculate the power supply for an LED strip