Skinny concrete - what is it?

All concretes are divided into three categories - skinny, standard, fat. Lean ones differ from the rest in their low concentration of binder components (cement) and high content of fillers. This ratio makes it possible to obtain solutions of increased rigidity, which combine complete homogeneity and easy installation using vibrating plates or rollers.

The production of the material is due to the fact that not all construction industries consider it advisable to use fatty solutions. For many jobs, it is sufficient to use concrete mixtures that meet the requirements of strength and frost resistance, but do not increase the cost of the final product.

Preparation of concrete

For large volumes of work, it is better to order concrete from the factory. Making large quantities of mortar by hand or even using concrete mixers is a difficult task, and laying it in batches requires additional effort to ensure that the layers adhere well. However, you can prepare concrete manually. In this case, there are two sequences of actions:

- First, concrete and sand are mixed dry. It is mixed until the color becomes uniform. Then crushed stone is poured in, everything is mixed again, and water is added last.

- First, water is poured into it and cement is poured into it. When everything is mixed, add sand and then coarse aggregate.

The order of adding components for concrete during mixing may be different.

In the first option, there is a possibility that during manual mixing, unmixed composition will remain at the bottom, near the walls of the container, which will lead to a decrease in the strength of the concrete. The solution is to mix everything well and thoroughly. But you can’t spend too much time on this: the solution will begin to set.

The second option has its disadvantages: obtaining a homogeneous cement laitance (a mixture of water and cement) sometimes takes a lot of time. As a result, there is simply not enough of it to form bonds with the backfill: the cement “seizes” and the strength of the concrete also decreases.

All this is not so critical when using concrete mixers, but it is also not ideal. There is another difficulty here. Concrete is usually delivered to the construction site in carts. The entire volume does not fit into one, and the remainder is left to spin in a concrete mixer. This is better than leaving it just standing, but if you mix it too long, the solution may begin to delaminate, resulting in lower concrete strength. The solution is two carts and two people to carry them. The filling method - first or second - choose for yourself.

For small volumes, concrete can be mixed by hand

So after all, how to prepare concrete. The choice is yours. If the volumes are small, you can knead by hand. Just do it carefully. To pour the foundation, it is better to order a mixer, but you can also use a concrete mixer (or two, depending on the volume). And to solve problems with the heterogeneity of the mixture (although it is better that it is good), treat the concrete being laid with a vibrator. Most of the problems will go away.

We recommend: Painting on wet plaster or how to make a fresco yourself

Next, we’ll talk about the requirements for concrete components, their sizes and qualities.

Brands of lean concrete

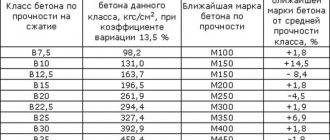

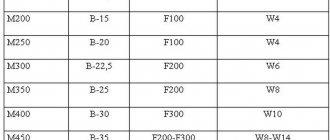

In construction, there are 5 grades of lean concrete, which differ in class, technical parameters, and area of application.

| Brand | Class | Characteristics |

| M200 | B15 | It has parameters close to those of heavy concrete and can be used for foundations and floors. |

| M150 | AT 10 | It has sufficient strength and a long service life, suitable for screeding or increasing soil stability. |

| M100 | B7.5 | A mortar with low strength parameters is used for work that does not require increased resistance of concrete to loads. |

| M75 | They have an extremely limited scope of application. | |

| M50 | B3.5 | — |

Characteristics of lean concrete grades

Skinny concrete is characterized by different grades. This is an important indicator of a material's ability to withstand compressive loads. In accordance with GOST standards, Portland cement or slag block cement is added to the thin concrete mixture as a binding element. The level of strength of the material depends on the constituent components and their quality: the lower the grade, the harder the solution is.

In construction, depleted material of grades from M100 to M200 is used (M75 is used extremely rarely). To stabilize the soil on which the building will be erected, a mixture of M100 or M150 is suitable. The M200 brand mortar is more plastic, therefore it is suitable for interfloor ceilings, slabs, blocks, and staircase openings.

Characteristics of lean concrete grades - table

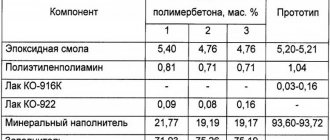

To prepare different grades of material you will need the following components:

| Brand of ready solution | Volume of materials used (l) | |||||

| Cement M400 | Sand | Crushed stone | Cement M500 | Sand | Crushed stone | |

| M100 | 10 | 41 | 61 | 10 | 53 | 71 |

| M150 | 10 | 32 | 50 | 10 | 40 | 58 |

| M200 | 10 | 25 | 42 | 10 | 32 | 49 |

Composition and main components

If we look at lean concrete in detail - what kind of substance it is, it is worth paying attention to the main components of the material. The structure of the mixture includes several components:

- binders (Portland or slag cement grade M300 and higher);

- medium or fine sand;

- fillers (most often crushed stone);

- purified water.

Based on the aggregates used, the material can be fine-grained or coarse-grained. In the first case, the dimensions of the crushed stone do not exceed 5 mm, in the second - they can reach 35–40 mm. Experts do not recommend using a larger fraction of filler, since during installation there is a high probability of deterioration in the stability of the solution.

The ratio of components in the mixture depends on the type of cement used, the degree of porosity of the crushed stone and the requirements for the strength of the finished concrete surface. The table below shows the approximate proportions of the components.

| Brand of lean concrete | Cement M400, kg | Crushed stone, kg | Sand, kg |

| M100 | 10 | 61 | 41 |

| M150 | 10 | 50 | 32 |

| M200 | 10 | 42 | 25 |

Application

Lean concrete has found its use as a layer when laying sidewalks or platforms.

Basically, “thin” concrete mortar is used to create three-dimensional structures that do not require high quality stone and increased strength. These include:

- arrangement of underlying layers when creating sidewalks, platforms, road surfaces and other asphalt areas;

- construction of the base for the foundation and the lower part of the walls of buildings;

- creation of coatings for prefabricated reinforced concrete foundations;

- pouring floor screed in industrial and residential buildings;

- preparing the base for the pool.

Also, the use of such concrete is present in the installation of soil slabs, the construction of preparation of pile, strip and slab foundations. The main task of the concrete solution is to level and strengthen the soil where construction is planned. For such purposes, a composition of grade M100 or M150 is used, and in the manufacture of blocks, slabs, stairs, balustrade columns and floors between floors, M200 is used.

Specifications

When figuring out what lean concrete means, you can determine the characteristic differences of the material by the technical characteristics of the manufactured coating. Its properties are regulated by GOST 25192-2012. According to the accepted standard, the mixture has the following parameters:

- compressive strength – from 75 to 250 MPa;

- density – from 2450 to 2500 kg/m3;

- mobility – from 10 to 15 cm;

- frost resistance – in the range of 50–100 freezing/defrosting cycles;

- hardness – from 90 to 120 s.

Due to the reduced strength, the mixtures are compacted using a roller or vibrating plate. This allows you to increase the density of the material, increase the adhesion of components, and remove excess air. The compaction coefficient during such work should average from 0.98 to 1.

Composition and types

The composition of lean concrete is dense and is determined by the scope of application. Mortar is widely used in construction. If it contains limestone, granite or crushed gravel, laying is carried out using a roller or vibrating plate.

You can determine what lean concrete is by the concentration of its constituent components, regardless of the filler fraction. The following types of mortar are used in construction:

- Fine-grained - with a crushed stone content of 5–10 mm;

- Large-fraction - with filler 20–40 mm.

Skinny concrete

Scope of application

The low strength of lean concrete partially limits their scope of application. Most often, the material is used in road construction for the construction of multilayer coatings. It serves as the base for the road surface and allows you to strengthen the upper layers of the road being built. In addition, mixtures can be used in the construction of buildings for the following purposes:

- forming a cushion for a monolithic or prefabricated foundation;

- subfloor installation;

- increasing soil stability during landscaping;

- foundation construction for swimming pools and similar structures;

- filling the cavities of blocks intended for the construction of a foundation.

Proper laying of lean concrete involves careful preparation of the base with the formation of a sand cushion. The surface is pre-cleaned of debris. If work is carried out in winter, snow or ice is removed from the base. The mixture is evenly distributed over the surface to a thickness of up to 100 mm. As mentioned above, after application it is compacted, which increases the strength of the finished coating.

After installation, it is necessary to control the hardening process and prevent the solution from drying out. To do this, the concrete is sprayed with water and covered with polyethylene. Further work can be carried out only after the material has hardened until the strength indicators of 1.5 MPa are reached.

Areas of use

The use of this concrete for auxiliary purposes.

It is the low strength of lean concrete that narrows the range of suitable areas for its use. Most often this material is used in the following construction areas:

- laying the base under the main road surface during the construction of highways. To improve the properties of concrete and to extend its service life, waterproof modifiers are added to the composition;

- during the construction of different types of buildings as a basis for the foundation;

- processing of block foundation seams;

- use as a base for laying an asphalt platform or sidewalk;

- arrangement of cement screeds in waterproof conditions;

- pouring the preparatory foundation for the construction of a pool bowl;

- installation of heterogeneous floors in the ground.

Return to contents

Advantages and disadvantages

Despite the low strength, lean concrete is recognized by builders. There are many reasons for this:

- ease of mixing and subsequent installation;

- reduction in production costs due to low cement content;

- short hardening times, reducing the time for construction work;

- uniformity due to increased filler content;

- possibility of producing solutions directly on the construction site.

Mixtures have not only advantages, but also some disadvantages. In particular, due to its low strength parameters, the solution cannot be used on objects that have high requirements in terms of reliability. During installation, there is a high probability of cracks appearing, which can reduce the performance characteristics of the finished coatings.

If you know the parameters of lean concrete, what it is and why it is used, you can successfully use it in civil and road construction. The material will allow you to create durable coatings with a sufficient level of strength and low costs of work.

Author of the article

Material properties

Despite the high sand composition and low cement content in the mixture, lean concrete contains relatively good qualities. Among them are:

- Reliability. It has a high strength and uniformity of composition.

- Persistence. Endowed with high physical and mechanical parameters. The load of products made from “thin” concrete can withstand from 5 to 15 MPa.

- Economical. The cost is significantly low due to the low cement content, which reduces the cost of its purchase. Also, the use of active mineral additives makes it possible to save the consumption of the solution itself.

- Convenience. The ability to mix concrete directly at the pouring site and use additional stone, recycled and industrial materials.

- Increased hardening speed. Allows you to speed up subsequent work.

- Reduced density. Gives little weight.

- Good frost resistance.

- Water resistance at surface pressure of 0.2-0.4 MPa.

Lean concrete GOST 26633 91

This is a fine-grained material, that is, it does not contain crushed stone of large fractions. It is made from sand, a small amount of water, cement and filler. This durable but thin material is widely used in individual construction for finishing work.

Compliance with state standards ensures that the characteristics of the mixture are preserved. This means that the parameters of frost resistance, water resistance, mobility, rigidity, and compressive strength will be exactly the same as to ensure the durability and workability of concrete.

Lean concrete has average performance, but nevertheless it has a number of advantages. The main feature of the mixture is its low price and rapid hardening, which saves time during construction work.

Lean concrete GOST 26633 2012

Lean concrete is made not only from large fractions of crushed stone, but also from small ones. It is called fine-grained. What's good about it?

- Fine aggregate provides a more uniform concrete structure.

- Better adhesion between small fractions of sand and crushed stone.

- Improved frost resistance, can almost double.

- Possibility of producing a high-quality mixture in the absence of coarse filler.

- Used for the manufacture of thin-walled structures.

- Due to its tensile strength and good frost resistance, it is often used in road construction.

When choosing concrete, you need to pay attention to the parameters and characteristics. And be sure to understand for what purpose you are choosing the mixture. Compliance with GOST is the main indicator of quality.

Compaction coefficient of lean concrete

Concrete is subject to deformation, like any material. With high-quality installation, it acquires strength and durability. Skinny concrete is always compacted with a roller or vibrating plate at the end. This is called compaction. This procedure distributes the mixture over the mold, helps better adhesion of the components to each other and displaces excess air.

The compaction coefficient of concrete in a well-placed mixture is usually 0.98-1. In laboratory conditions, experts calculate the correct coefficient. For a good mixture, the amount of water must be balanced correctly, since its content greatly affects the density index.

produces high-quality concrete mixtures in accordance with GOST. We sell products wholesale and retail. It's easy to place an order with us. There are three options: call, visit the factory in person, or write by email.