The construction of a garage must be carried out according to the rules, but it also happens that a “house” for a car is bought and not built, and the roof is not in proper condition.

Foundation calculation

Try a new product

Try for free Find out more

In this case, complete waterproofing of the garage roof is required.

Why waterproof a garage roof: is there any significant point?

The roof not only hides the contents of the building underneath from various types of precipitation, but protects the contents inside - therefore its durability and integrity depend on its condition. If the roof is thermally insulated, it becomes even more important to waterproof it, because moisture can negatively affect the layer of material.

If the roof leaks, the car will soon develop corrosion, and there will be neither dryness nor warmth inside. A poorly equipped roof contributes to the appearance of condensation in the room, which leads to disruption of the microclimate.

Types of Materials for Moisture Insulation on a Garage Roof

There is a wide range of materials designed to insulate moisture, they are divided into types, and each has its own specific characteristics and properties. The application process also differs depending on the type of material.

Let's look at each type separately:

- Under-roof vapor barrier membrane. This material completely protects the garage from the penetration of dust, moisture and dirt. The membrane is not completely sealed, which allows steam to escape to the street. This reduces the moisture level in the room where your car is located. Excellent for pitched roofs.

- The next type is roofing felt. If you have a soft roof, then roofing felt is simply ideal as a waterproofing material. This material is also suitable for garages that have concrete roofs. If your garage has a concrete roof, then waterproofing is carried out from the outer surface of the room.

- Anti-condensation under-roof membrane. . This material does not condense moisture, but absorbs water. This type of waterproofing is based on viscose. The main area of use is garages that have a profile roof.

Types of waterproofing coatings for garage roofs

The garage roof will function as it should if it is protected by a layer of waterproofing material. The market offers quite a lot of similar products, our task is to figure out which of them have suitable characteristics for roofing.

Waterproofing coatings can be film, roll, coating and sprayed.

Roll

The garage can be waterproofed with bitumen coating. This is roofing cardboard that is impregnated with petroleum bitumen. Water does not pass through the layer, and it is quite strong and durable.

The roll type includes a membrane coating, which is expensive and high-quality in terms of its waterproofing characteristics.

Liquid

Liquid coating materials include bitumen mastic, polymer mastic, and penetrating primer.

Mastics are applied with rollers, brushes or a spatula.

Penetrating primer is used for concrete garage roofing. It enters its structure, producing crystallization there. In addition to the primer, there is liquid glass, synthetic resins (polyurea).

Liquid waterproofing is good because its materials are not afraid of oxidation processes, ultraviolet radiation and corrosion; it is used where winters are cruel and harsh.

Any mastic, except rubber, should not be applied to a wet surface.

Sprayable

Sprayed waterproofing of a garage roof is carried out with liquid types of materials using a sprayer. These can be polymer-bitumen plasticized compositions, polymer emulsions, liquid rubber.

Film

Along with rolled and sprayed waterproofing, you can also put film materials. It is sold in the form of rolls of special under-roofing film with micro-perforation.

Small pores are involved in the ventilation process, helping water vapor and condensation to circulate.

Let's call the second coating an under-roof anti-condensation film. This is a viscose material that perfectly absorbs moisture.

Types of liquid rubber for roof waterproofing

Several types of polymer materials are used to perform roofing work. They are usually distinguished by the method of application to the prepared surface. It could be:

- Using an industrial spray plant;

- Application of liquid waterproofing in bulk with distribution over the roof surface using hand trowels and trowels;

- Painting method using a roller, brush or any other painting tool.

As a rule, such a classification does not give a complete picture of the quality and properties of the resulting waterproofing. Therefore, it would be correct to distinguish liquid rubber by composition or method of preparation.

Garage roof waterproofing materials

A good choice and proper installation will provide the room with both warmth and dryness, and will also help it function for many years as a complete protection of the car from atmospheric agents. Let's take a closer look at the most popular materials for roof waterproofing.

Waterproofing for garage roof

Hydroisol is a fiberglass-based material rolled into convenient rolls. In addition to fiberglass, the composition contains polymers and bitumen.

Waterproofing is especially suitable for flat roofs or garage roofs with a slight slope. The quality of the coating is better than roofing felt.

Advantages of waterproofing:

- high strength;

- excellent elasticity indicators;

- muffles the sound of rain;

- excellent resistance to any weather conditions;

- service life is very long.

Hydroisol is laid in three ways: hot, mechanical, with bitumen mastic.

Liquid rubber

An emulsion of bitumen combined with synthetic resins turns into liquid rubber. The consistency, method of application, and characteristics allow it to be ranked alongside polymer mastic. The resulting membrane is elastic and durable, the material does not peel off.

Liquid rubber is very convenient for roof waterproofing; the material is modern and of decent quality.

Be sure to study the label, it is possible to confuse liquid waterproofing rubber and similar paint

The coating will last for decades, and roof repairs will most likely not be needed, even if the climatic conditions are harsh. The composition is suitable for covering roofs of any type and material, but it is chosen mainly by professionals.

Rubber is applied in two layers by spraying, using a spatula, brush, or pouring onto the surface.

Liquid rubber is also combined with water-based paints. This is done so that the coating is decorative.

If you apply two layers of different colors, it is easy to avoid gaps

Bitumen mastic

Bitumen resin made it possible to produce a very plastic adhesive composition. Some manufacturers include polymers in the material.

Bitumen mastic can be hot or cold, each with its own application features and characteristics.

Hot mastic is in a solid state, and after heating it becomes liquid and ready for application.

The cold version is sold in the form of a thick liquid, and before starting work, a solvent is added to it.

Bitumen mastic has a long service life, as manufacturers claim, at least 25 years. The material does not lag behind the base even after several years, and is not particularly expensive.

But there are some drawbacks: you can’t walk on such a roof because of melting on very hot days, and the product is not used as a stand-alone covering.

Polymer mastic

Polymer mastic is similar to bitumen, but the performance characteristics are better. This material is good when you need to treat a small roof, especially if work is carried out during construction. But you can cover the roof with waterproofing mastic at any time during the use of the garage.

It’s convenient that the product can be purchased immediately in a large metal container.

The price of the product is high, which can be considered a minus.

Membrane

For roof waterproofing, EPDM membranes and PVC are used.

EPDM membranes are composed of rubber and ethylene-propylene-diene monomer. The product is based on a polymer mesh, which serves as a reinforcing layer and gives strength to the material. Thanks to this approach to manufacturing, such sheet membranes can be used for different climatic conditions.

Installation is simple: with rolls up to 15 meters in width and up to 60 meters in length, you can cover a large surface area, and at a fast pace. The service life is very long.

The weight of the membranes is small, which also facilitates installation.

Unfortunately, if the roof surface is large, then one roll will not be enough; you will need to arrange a joining seam. What is needed is vulcanization of the seam, not gluing it, which will not last long and will collapse.

If we talk about the cost of such waterproofing, then this material will outstrip all other waterproofing materials in price.

PVC membranes are also sold in the form of rolls with polyester reinforcing mesh inside. Plasticizers are used as fillers for waterproofing materials. The membrane is applied overlapping, and the joints need to be reinforced with a torch, and the resulting seams are very strong.

The product's advantages compete with EPDM membranes, but the price is better.

Materials

There is a fairly wide selection of building materials for covering the roof of a garage. To ensure its protection, it is enough to lay just one of them:

It should be noted that the most common garages are metal or concrete. Liquid substances are most suitable for these types of roofing. They have the ability to penetrate into the smallest cracks, sealing them, leveling the surface and giving it a protective shell.

Liquid rubber for roofing

One of the most popular waterproofing materials these days is liquid rubber. It is perfect for processing both concrete surfaces and metal and wood surfaces.

The material can be in different consistencies, which are applied in different ways. The liquid substance must simply be poured onto the roof of the building and leveled using the rule.

There is also a sprayed type, which is applied with a special pump. Using a brush or roller, the paint look can be applied. To decide which application technique is right for you, you should determine the required thickness of the insulation layer, assess the presence and number of cracks on the surface.

There are two- and one-component rubber. The first type is intended for installing a mastic membrane, the second is used for waterproofing and sealing the coating.

In both cases, the surface is obtained without seams and joints through which moisture can enter, and has excellent protective qualities from exposure to sunlight and temperature changes. This coating is environmentally friendly and has a long service life.

Coating with waterproofing

Hydroisol is a rolled material, which is made on the basis of fiberglass and coated with a bitumen-polymer substance. These rolls are an excellent choice given that roof types vary.

Before carrying out work, you should clear the surface of debris and grains of sand and ensure the integrity of the coating. If cracks are found in it, they can be filled with liquid rubber.

The canvases are laid overlapping using the fusing method. The greatest durability and strength are found on flat garage roofs or on slightly inclined surfaces.

Waterproofing rolls can be laid using the following cold or hot methods. At the first time, the overlap of the canvases should not be less than 15 centimeters. The connection points between the two sheets should be secured with mastic. This method is easy to install, but its reliability does not guarantee long-term use.

Therefore, it is preferable to use the second method. It consists in the fact that the roll sheet unfolds gradually, simultaneously heating the inner side of the coating with a construction hairdryer or gas burner. The overlap should be 10 centimeters or more.

Membrane insulation

Another modern material is membrane materials, in particular polymer membrane. It is also produced in the form of rolls about 3mm thick, up to one and a half meters wide, and up to 60 meters long. The material consists of several homogeneous layers.

This is a fairly versatile option that can withstand both hot and frosty temperatures, and has a service life of up to half a century. This material is quite resistant to high humidity; it has also proven itself when tested with ultraviolet rays and mechanical stress.

The flooring technique is similar to the previous material. Clean the roof surface, completely level it (if the base is concrete), or treat it with anti-corrosion substances (if the base is metal). Next, you need to spread the roll and weld the seams.

Preparing the surface for waterproofing

First, the old insulator, if any, must be removed. Everything can be cleaned with a broom, or it is better to use a good construction vacuum cleaner.

The surface must be inspected: cracks and cracks must be completely sealed. Sand-cement mortar, fiberglass, and polyurethane foam will be useful for this.

DIY garage roof waterproofing

There is a difference what material the roof is made of: the process of waterproofing concrete, metal, slate and underground garage is different.

If the roof is made of concrete

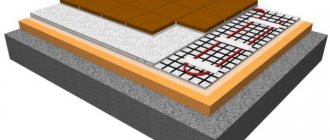

Concrete roofing is ideally not only waterproofed, but also insulated. Financially, this is much more profitable. Insulation is carried out with extruded foam plastic, which has suitable characteristics for this.

Sloping slope

If the concrete roof is sloping, then using welded products will be problematic and even useless.

Waterproofing work is carried out on the roof in the following order:

- prepare the surface;

- A primer or deep penetration primer is suitable for the initial coating;

- mastic is applied to the surface;

- Membranes are placed on the mastic, making the protrusions inward.

To ensure that the waterproofing sheets are securely fastened, they are fixed with dowels.

On the upper side, the film is fixed using a clamping bar. A layer of geotextile is laid on the waterproofing. This is done to create channels for water to flow to the drain.

Flat roof

A flat surface can be waterproofed by spraying or liquid materials. First, the base of the roof is also prepared, and then treated with a primer or bitumen-polymer mastic. After it has completely hardened, you can begin further work.

You can treat the surface with built-up roofing material, which is pre-rolled and left to rest.

The indicator coating looks like labeled polyethylene.

If you overheat roofing felt, it will become useless

The strips are laid with an overlap of 10 cm. Care must be taken where there are parapets, chimneys, and ventilation.

If the roof is iron

Metal requires a different approach: they don’t work on such a roof in the heat, but choose a warm day. The main thing is that it is above +5°C outside.

For processing you need a perfectly clean base. If there is damage to the roof, it needs to be restored and sanded. During treatment with liquid rubber, the material is first applied to these areas.

It is used cold: first it is applied to the roof surface with a brush in a layer of 4 mm. A thin layer is obtained, which is leveled with a wide spatula.

You can use both roofing material and waterproofing for coating. For them, you need to maintain an overlap of 10 cm, coat the seams with mastic and glue everything together with a torch.

After this, you can apply the second layer. If necessary, a third treatment is carried out.

Underground garage

Is it necessary to waterproof the roof of an underground garage? Of course you need it! First, the surface is prepared by cleaning it and covering it with bitumen. To make bitumen liquid, it is diluted with gasoline.

Coating with bitumen is carried out as follows: you need to apply it in a strip exceeding the width of the roll of the selected waterproofing material. After spreading, you should immediately roll out the canvas, pressing it to the roof using a heavy roller. The same applies to other bands.

When the material is securely fixed, it is treated against fungus, dried, and then coated with a primer. A layer of insulation should be attached to the waterproofing, then a geotextile, drainage profiled membrane and again geotextile. Only after this you can fill everything with soil.

If the roof is covered with slate

Slate is considered a natural material, but it should also be waterproofed. The best way would be to lay roofing felt or membrane film, which is quite simple to do.

A waterproofing agent is laid on the roof sheathing, gradually moving further. Each time the roll is thrown over the ridge if the roof has two slopes: this eliminates the appearance of unnecessary cold bridges. The overlap is maintained at 10 cm.

Fastening is carried out using metal brackets to the sheathing. You definitely need to check how securely everything is fastened. The joints are then treated with coating materials in the form of cold mastic or liquid rubber.

Types of garage waterproofing

Many car enthusiasts are wondering how to waterproof a garage roof with their own hands, and what materials are best to use for this. The construction market has a wide range of options for waterproofing coatings, which differ in service life, reliability and installation method. The most commonly used types are:

- Waterproofing film. A thin waterproofing film made of polyethylene serves as an excellent barrier to the penetration of atmospheric moisture. It is used as underlayment waterproofing for garage roofs, as it is not strong enough to be used as a topcoat.

Important! Roof waterproofing can be lining and finishing, depending on the strength and water resistance of the material. Some coatings (roofing membranes, rolled bitumen materials) can be used as an independent coating, while others, for example, film or mastic, are used only as auxiliary ones.

If you need to replace and repair the garage roof waterproofing yourself

No matter how the product manufacturer promises that its products will last for decades, it happens that it is necessary to replace or patch up a layer of waterproofing material.

If the material is soft or its damage is not extensive, you need to do the following:

- the canvas is cleaned of debris and dirt, especially a lot of attention needs to be paid to leaky areas;

- the surface is inspected to see if there are still places somewhere that require replacement. They need to be peeled and cut with a knife;

- if swollen areas or cracks are found, then you need to make a crosswise cut there;

- the cut areas need to be bent and pressed with something heavy. The debris in the hole is cleared, now you can dry it with a hair dryer;

- a new roll of material is taken and pieces are cut to replicate the problematic exposed areas. The pocket needs to be coated with resin or mastic, a patch should be inserted there, liquid bitumen should be poured in, the edges should be bent back, and pressed firmly in the original position.

But that’s not all: for strength it is necessary to apply additional patches to the already sealed “envelopes”. But the size of the piece should already exceed the glued part by 20 cm around. The applied elements are also treated with mastic.

Thorough repair of the waterproofing layer

If you need a major roof repair, the steps will be different. First you need to remove the eaves and front strips, and the gutter. To cut strips in an old 3 mm thick waterproofing material, you can use a wall cutter. Dismantling will be significantly faster. If the thickness is significant, then you will have to take a roofing ax.

The canvas must thus be divided into square elements and removed from the roof.

When the base is deprived of the hydraulic barrier, it should be cleared of any debris and fasteners. If there are cracks there, you need to treat them with a cement mixture.

When the base is properly prepared, a new water-repellent layer needs to be laid. Laying is done from the underside of the slope. All work is carried out as if the coating is being laid for the first time.

Waterproofing technologies

Do-it-yourself waterproofing of a garage roof is a routine operation familiar to every craftsman; it is carried out regularly in order to protect the building from leaks. It is first performed during the construction of the roof, and then periodically repeated as minor defects and wear appear. The installation technology of waterproofing material consists of the following stages:

- First, the rafter frame of the garage roof is constructed, the rafter legs are installed so that their ribs are in the same plane.

- The waterproofing material is cut into strips corresponding to the length of the slope.

- The cut strips are laid on the surface of the roof slope so that they overlap each other by 15-20 cm.

- The waterproofing is fixed to the rafter legs so that it sag slightly so that the pressure arising from the influence of water does not lead to rupture of the material.

- Counter-lattice slats are fixed on top of the waterproofing film along the rafters, forming a ventilation gap.

Please note that there are different ways to fix waterproofing material. The mechanical method involves attaching the strips using a construction stapler or nails. Adhesive involves gluing waterproofing to the rafters, for which bitumen mastic is used.