Laying asphalt

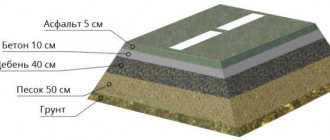

First of all, it is necessary to plan the area where the asphalt will be laid. The necessary work is planned taking into account the purpose of the coating. For a “light” highway, with low traffic flow, only 1 layer of crushed stone will be required, but to build a serious highway, a minimum of 3 layers is required.

Crushed stone fractions are arranged from maximum to smallest, after which they are carefully rolled with a roller. This is required to create a special cushion (base), on which asphalt is poured. All asphalt laying work is carried out taking into account the requirements of SNiP and GOST.

There are 2 main technologies for pouring asphalt:

- Cold way. They are most often used for repairing asphalt surfaces, since such material sets in a short time, and the repaired asphalt can be used without restrictions;

- Hot method. Used to create new asphalt pavement. For this method, the heated bitumen-based mixture must be poured and rolled until it cools down.

The cost of repairing bitumen should not be less than 0.5 liters, and when creating a new route, the material consumption must be calculated separately. In this case, it is necessary to take into account not only the dimensions of the asphalt surface, but also its structure and possible additional factors.

During work, it is imperative to use a special thermometer, which makes it possible to measure the temperature of the bitumen mixture. Constantly checking this indicator is of great importance, because after the material has cooled, it can no longer be used for asphalt pavement construction.

Application of impregnation

Currently, 3 types of impregnation are used for this purpose:

- Based on acrylic polymer. The most expensive coating, it is used only in small spaces, for example, on a tennis court. They create the highest quality protection, and they also come in several colors;

- Coal tar. Coating that is resistant to petroleum products. With the help of special components, in addition to a long service life, a visually attractive shade is achieved;

- Asphalt emulsion. An affordable and popular material, but it is not able to provide the necessary protection for the coating, which forces the asphalt surface to be repaired more often.

If cracks appear on the asphalt, a non-bitumen mixture can be used for repair. It’s better to use a sealant sprinkled with cement on top.

Is it possible to lay asphalt in rain and snow?

To understand whether it is possible to lay asphalt in rain and snow, you need to know about the methods of laying it. And there are only three of them:

- hot;

- cold;

- cast.

Hot way

relevant for the construction of new roads, repair work with the removal of old asphalt or small sections of roads in warm weather. The method involves the use of a bitumen mixture, which must be rolled until completely cooled. The peculiarity of installation is that certain conditions must be met: the air temperature outside must be above + 5 °C and there is no precipitation.

Cold way

chosen for so-called pothole repair. In this case, ready-made asphalt mixture is poured into the pit; no special equipment is required. Repair work can also be carried out in frosty temperatures of -20 °C. Cold asphalt can be laid in the rain, but the pit must be well dried. For this purpose, infrared heaters, aircraft engines and special reagents are used.

Cast method

Asphalt laying can be used in rain (not downpour), snow, frost down to -10 °C. The finished mixture is delivered to the repair site in thermos tanks, the temperature of which reaches about 200 °C. Because of this, asphalt has a structure similar to liquid glue. When such asphalt comes into contact with a wet surface, all moisture instantly evaporates. The method is quite expensive, so it is used only in emergency situations.

Important!

Asphalt can be laid in rain and snow, but certain conditions must be met.

Laying asphalt according to GOST

Mixing of components is carried out in accordance with GOST 9128, the mixture is divided into 2 types, according to installation conditions:

- for use at temperatures exceeding +5 degrees;

- for use at temperatures in the range -25 - + 5 degrees.

Crushed stone, which is part of the mixture for laying asphalt, must be selected in accordance with the requests specified in GOST 8267, screenings are standardized according to GOST 8736. Bitumen are used as the binder component of the mixture - BND 90130 and BND 6090, corresponding to GOST 22245.

The influence of material on the quality of asphalt pavement

In order not to buy low-quality asphalt concrete, the seller must be required to provide a certificate of conformity for the product. There are a number of laboratories that perform asphalt testing and sampling. Asphalt analysis is carried out by examining a selected core (asphalt core).

Improvement of asphalt pavements

Despite their practicality, asphalt sheets can be modernized. One effective method is to use mastics specifically designed to improve asphalt. They contain bitumen and special emulsions for it, which contain rubber and polymer additives.

In most cases, bitumen mastics are used heated, and emulsions are used without heating. Mastics close pores and cracks on the surface of the asphalt; this does not allow moisture to penetrate under the asphalt and destroy its structure - when freezing, moisture breaks the coating and creates water hammer when vehicles pass.

How is asphalt paving done?

The rules for laying asphalt mostly depend on the type and purpose of the coating, but some standards cannot be changed. Such rules are clearly stated in GOST and SNIP, and they ensure the durability and quality of future roads and sidewalks.

According to GOST requirements, asphalting of roads and sidewalks must be carried out under suitable weather conditions. The production of the mixture is also determined by the standards of these documents. Laying asphalt SNIP (building codes and regulations) also determines the quality of the finished work, from the stage of preparatory work to the final cycle.

Basic requirements of the standards:

- Immediately before laying asphalt, heated bitumen or bitumen emulsion is applied to the prepared surface.

- Laying hot asphalt should be carried out exclusively at positive air temperatures (not lower than 5 degrees).

- The mixture must be at a certain temperature, so before application it is kept hot (not lower than 100 degrees).

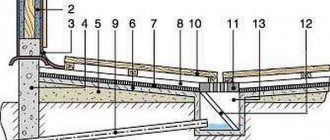

- The thickness of the asphalt mixture layer is determined by the purpose of the coating. Asphalt is applied in sections of a certain length, after which it is leveled and compacted.

- Compaction of the layer must begin immediately after backfilling. For this purpose, special equipment is used - a roller, brick press or asphalt paver.

- The applied layer should harden for at least a day, but for cold asphalt this time can be only a couple of hours.

Modern additives - plasticizers allow installation even at subzero temperatures. This mixture is called asphalt concrete. It is quite expensive and is most often used for emergency road repairs in winter.

If it's minus outside the window

At sub-zero temperatures, asphalt is laid using cold mixtures. This is a polymer asphalt obtained thanks to additives, due to which it is plastic and frost-resistant. Adhering to technology, the use of the composition requires the addition of bitumen thickeners. There are two types of cold mixtures used: fine-grained and sandy, fractions - 5 mm and 10-15 mm.

In extreme weather conditions it is very important to obtain a durable coating and this technology allows you to achieve this. The cost of the work is high, but cold modified mixtures are increasingly being used due to the ability to carry out work in snow and rain, as well as temperatures of + 60 °C.

Scope of technology application:

- coatings located next to the rails;

- spot repairs of highways and routes;

- access roads, parking lot coverage;

- preventive measures during road repair work;

- formation of a blind area in other cases.

Before work, the surface should be cleaned of excess moisture, snow and debris. Additionally, temperature control mechanisms are required.

Do-it-yourself asphalt laying

In your home or country house, asphalt pavements are suitable for constructing sidewalks and creating paths; they are used to make blind areas. In addition, this material can be used to create roofing coverings.

The paths are laid in stages:

- Preliminarily remove debris and remove soil to a depth of 30 cm;

- After this, curbs are installed , serving not only as decoration, but also as walls for bitumen;

- Next, arrange a pillow. A layer of crushed stone is poured to a depth of 15 cm, then it is compacted, a layer of fine crushed stone is filled in and rolled again. The sand is poured last, in a layer of 5 cm. The prepared pillow must be thoroughly shed with water and then rolled with a hand roller;

- Hot asphalt must be spread evenly over the area of the path. After that, the unevenness is leveled with a motor mop, while simultaneously filling the resulting depressions with new portions of asphalt. Since the material cools quickly, it is better to do the work with 1-2 assistants;

- After the asphalt has been laid and leveled , you need to compact it with a hand roller. Before work, the roller needs to be lubricated with diesel fuel; this will help create an even and smooth coating (the asphalt will stick to a dry roller). It is advisable to coat all tools used during work with diesel fuel.

When laying asphalt, it is important to monitor its temperature. It must be maintained at a level of at least 120 degrees; a coating laid from cold material will completely deteriorate in a short time.

In addition, when laying, it is important to perform only straight movements with the tools; in no case should they be returned to you along the surface of the coating.

After completing all the work, you can impregnate the coating by replacing the impregnation with a special paint intended for asphalt. With its help you can get the shade you need.

Technologies for laying asphalt, which have GOST recommendations.

Let's take a closer look at what asphalt laying technologies exist. So, before laying asphalt, it is necessary to carry out preparatory work. We prepare the place for asphalt in advance.

GOST identifies several main stages of asphalt laying.

The first, as already mentioned, is preparatory.

The second is the design and laying of the supporting layer. It may consist of crushed stone.

Next, the third stage is laying the asphalt itself. Quality depends on it; it must comply with all norms and standards.

Before laying asphalt, it is necessary to prepare all the necessary technical devices. Let's look at them.

Firstly, you will definitely need a device that is used for mixing mixtures. You will also need a container to mix the bitumen, and prepare a device that will control the temperature. And, of course, you need a device that can mix and prepare everything. These devices are simply necessary and they fully comply with asphalt paving standards. Depending on what kind of asphalt you lay, how long it will last.

The main reasons for poor road quality

Important!

Failure to comply with the regulatory requirements of SNiP and GOST when carrying out repair work leads to poor condition of roads.

There are a number of main reasons for the deteriorated state of roads:

- when carrying out paving work during rain, water gets into the asphalt layers, which leads to the appearance of holes;

- savings on the emulsion mixture;

- the layer is laid of inadequate quality, which is why the crushed stone does not adhere properly to the old asphalt;

- replacing crushed stone with crushed brick, which leads to subsidence and collapse of the road surface;

- the use of asphalt of inappropriate quality and laying of insufficient thickness provoke the appearance of cracks and destruction.

We cannot exclude the fact of human negligence during the work, non-compliance with laying technologies in rain and snow.

Asphalt repair

The structure of asphalt is destroyed not only from physical stress, but also under the influence of the sun's rays, which over time destroys the bitumen and makes the surface fragile.

There are 3 main asphalt restoration technologies:

- The first method: sealing cracks in the coating using tar. The surface intended for repair is cleaned in advance. Taking into account the size of the crack, 2-3 cm is covered with sand and then filled with tar, or if the width of the defect is small, tar is used immediately. After 10-15 minutes have passed, the sealed asphalt must be leveled with a spatula. Do the same with other cracks on the surface.

- Second method: you can buy rolls of ready-made asphalt. This is an inexpensive and practical product and what is important is that it is convenient to use for minor repairs. The rolls are rolled out, and after removing the protective layer, they are placed on the surface with an adhesive surface. Press the roll tightly for a few seconds and the repair is complete.

- The third method: will make it possible to eliminate small holes and damage on the asphalt surface. The defect must be cleaned in advance, all debris removed and dust removed. Densely fills all voids with bitumen composition. After 2-3 minutes, the sealed area must be leveled and compacted.

To prevent the destruction of asphalt, it must be renewed every 4-5 years, and any cracks found must be sealed with water and chemically resistant sealant.

If the asphalt begins to crumble, then this coating must be completely changed. It is very easy to apply the sealant, pour it out of the container and brush the surface to be treated well with a stiff brush.

Asphalt repair in winter

To repair asphalt in winter, you will need to first prepare the work site: clear the snow, chip off the ice and treat the defect area with a special compound.

Snow and moisture cool the asphalt; for this reason, it is not worth laying and repairing thick layers of asphalt in wet weather.

In light rainfall, work can only be done on the entire asphalt surface, but work can be done in parts at intervals; during snowstorms and heavy rain, asphalt cannot be poured. Otherwise, after a short time, the bitumen coating will require repairs.

If you eliminate defects in a timely manner, repairing the most worn areas, then it will last much longer. The most important thing during repairs is to carry out milling correctly, this means removing a layer of old coating at the site of the defect using cutters.

A seam cutter is also necessary for removing the used coating layer and for creating seams. Heated asphalt is transported in a kocher; it is designed for transporting hot bitumen mass. To reduce the cost of manual labor, specialized enterprises use real automated complexes.

For example, for the repair of highways, units are used to remove a layer of worn-out pavement, which simultaneously perform cutting of defective material and milling.

When should cold and hot paving be used?

There is a cold and hot method of laying asphalt.

Cold laying is most often used when repairing roads. The main thing in this process is to compact the coating well. The advantage of using cold asphalt is its all-season use.

Article on the topic

“Let's rid the city of potholes!” Where to report broken roads

Road repair work can continue even in winter.

There are several types of cold asphalt:

– Cold summer asphalt. Ambient temperature during installation is from +15 to +30 °C.

– Off-season cold asphalt. Ambient temperature during installation is from -5 to +15 °C.

But this method is not suitable for the construction of a new road or major repairs of an old one. In this case, resort to hot styling. Asphalt must be laid while hot. However, in the fall and early spring it is difficult to achieve high-quality road repairs using hot laying.

Instead, cast asphalt technology is used. Mold asphalt is a mixture of sand, gravel and ground limestone with bitumen. Cast asphalt does not need to be rolled with rollers; its consistency is such that it lays down in a dense cast layer without the need for additional compaction. Cast asphalt is water-resistant, so it can be laid even when it rains. The temperature of poured asphalt during installation can vary between 200–250 degrees. The technology allows laying asphalt at -10 °C. The maximum thickness of cast asphalt should not exceed 25–30 mm. Cast asphalt, like other types of asphalt, can be used not only in road construction, but also in such types of work as roofing, bridge coverings, and interior decoration.