Fastening the Mauerlat to a wall made of expanded clay concrete blocks

When planning to fill an armored belt under the Mauerlat, it is important to consider the dimensions and characteristics of the fastening system.

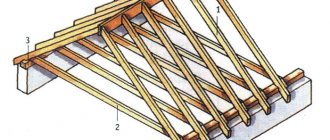

Mauerlat is an intermediate beam through which the rafter system is connected to the walls with anchors, studs or wire. After laying the Mauerlat, it is important to securely fasten the roof of the house.

When making walls from cellular blocks, you should consider attaching the Mauerlat to expanded clay blocks without an armored belt, as well as together with it.

Let's consider how to install the Mauerlat so as not to destroy porous concrete. After all, if fastened incorrectly, the blocks can crack.

How to attach the Mauerlat - fixation options

Builders use the term “mauerlat” in their vocabulary, meaning a special frame fixed to the end surface of the main walls.

Regardless of whether brickwork is used for the construction of load-bearing walls or porous blocks are used, a mandatory element of the building is the Mauerlat.

It is made from channel or wooden beams. Mauerlat combines the roof structure and the frame of the house into a general scheme.

The damper frame ensures uniform distribution of loads on the walls and reliably connects the roof truss to the frame.

One of the elements that no roof can do without is the Mauerlat

Depending on what materials are used for the construction of walls, various methods of fastening the Mauerlat are used:

- installation of the Mauerlat on the end plane of the walls without filling the reinforced belt. This fastening option allows you to firmly fasten the support beam to the surface of an aerated concrete, brick or expanded clay concrete wall. During the process of laying the top level of blocks, a wire is installed between them, which is threaded through holes in the frame. Then the ends of the wire are twisted;

- installation of the Mauerlat on a reinforced belt constructed around the perimeter of the supporting surface of the house frame. This method is used to fix the Mauerlat to walls built of brick or composite blocks. The installation technology involves pouring a reinforced concrete belt in which pieces of reinforcement with a diameter of 8-10 mm are concreted. Steel rods are used to fix the Mauerlat.

The method of fastening the load frame is indicated in the building design.

Attaching the Mauerlat to expanded clay blocks without an armored belt

When deciding to use expanded clay concrete blocks for the construction of the walls of a building, their load capacity should be taken into account.

Porous expanded clay concrete is not able to withstand significant loads.

However, if the weight of the roofing structure is small, it is permissible to install a Mauerlat on the end surface of expanded clay concrete walls.

To do this, follow these steps:

- Cut pieces of steel wire.

- Lay the wire between the blocks of the upper rows of masonry.

- Complete the laying, ensuring that the free ends of the wire come out.

- Lay the wooden beam on the surface of the expanded clay concrete walls.

- Tighten the Mauerlat with wire through the pre-made holes.

The strength of the armored belt under the Mauerlat directly depends on what its design will be

The number of connections made must correspond to the number of rafter supports.

All types of porous concrete are characterized by insufficiently high strength. This must be taken into account when choosing a fastening method. Let us next consider how to secure the Mauerlat to aerated concrete without an armored belt.

Installation of a Mauerlat on aerated concrete without an armored belt

The technology for installing the Mauerlat on the surface of aerated concrete walls that are not equipped with an armored belt is similar to the method of attaching to expanded clay concrete blocks.

When performing work, you should pay attention to a number of points:

- laying rolled wire between aerated concrete blocks a couple of rows before the top of the wall;

- selection of the length of the wire sections to ensure reliable tying of the Mauerlat;

- ensuring the horizontality of the upper plane of aerated concrete for laying timber;

- correspondence of wire laying areas and fixation points to the total number of rafter beams.

Wire fasteners securely attach the support beam to the aerated concrete walls.

Ensuring structural strength when fixing the Mauerlat with an armored belt

To increase the reliability of fastening the Mauerlat and prevent deformation of the building frame, a reinforced belt is constructed.

The width of the armored belt must correspond to the width of the wall

It allows you to solve a number of serious problems:

- form a solid horizontal base along the contour of aerated concrete or brick walls;

- prevent local pushing of porous concrete in places where rafter beams are attached;

- give an additional reserve of rigidity to the aerated concrete or expanded clay block frame of the building.

Carry out work on the construction of the armored belt in the following order:

- Mount the formwork structure along the contour of the box.

- Assemble and install the reinforcement cage inside the formwork.

- Place and attach threaded rods to the reinforcement to secure the Mauerlat.

- Keep the threaded part of the studs clean after concreting using polyethylene or a rag.

- Fill the formwork with concrete mixture.

- Dismantle the formwork elements after the concrete has hardened.

Fastening the Mauerlat to cinder blocks

Mauerlat is a wooden structure through which the roof is attached to the walls of the house and onto which the roof rafter system is attached. Usually this is a wooden beam made of coniferous species. The timber of the timber must be at least second grade. Pine or larch is used for production.

The dimensions of the timber can be: 150x150mm; 150x100mm; 80x180mm; 100x100 mm; 200x200 mm.

Before fixing the wooden beam of the Mauerlat, it must be impregnated with an antiseptic. This will help prevent possible wood rot on the cinder block.

If you choose wood yourself, you need to take into account the knowledge passed down from generation to generation - a tree cut down in winter does not rot longer, and one cut down at the end of the month is better preserved than one cut down at the beginning of the month.

https://www.youtube.com/watch?v=9k3rj-x2YuM

Wall mounting methods:

- fastening with anchor bolts;

- wire fastening;

- fastening with studs.

Fastening with anchor bolts

When building a house from brick or cinder blocks, it is better to use the most reliable fastening of the Mauerlat - using anchor bolts secured in an armored belt. The armored belt is a homemade reinforced concrete structure. It consists of a frame made of metal reinforcement and wire. This frame is immersed in a mixture of cement, sand and crushed stone. In other words, an armored belt is a reinforced concrete structure.

Here doubt may arise about the need to create an armored belt if the house is built from cinder blocks, which, in themselves, create a fairly strong structure. The thing is that the Mauerlat is attached to the walls of the building with anchor bolts, and attaching anchor bolts to blocks is strictly prohibited. This can cause even cinder blocks to crack and break.

The armored belt will increase the resistance of the building structure to current deforming loads: wind, house shrinkage, seasonal fluctuations of the foundation, point loads from slabs or beams. When pouring an armored belt, you need to know that it is poured as a single whole. It should not have any breaks.

Whether the Mauerlat will be able to fulfill its load-bearing function depends on how correctly the armored belt to which it is attached is made. The strength of the armored belt depends on how the formwork was installed during its creation.

Fastening the Mauerlat can begin after removing the formwork, when the concrete has completely hardened - this means 4 or 5 days after pouring the concrete.

You need to decide in advance how many anchors you will install to attach the Mauerlat to the cinder block walls. The number of anchors must be no less than the number of rafters that will be attached to the mauerlat.

We must not forget that the location of the anchor bolts should not coincide with the location of the rafter legs. This will reduce the rigidity of the structure. It is advisable that the anchors be located in the middle between the rafters.

Attaching the Mauerlat to expanded clay blocks

Mauerlat is a wooden beam that distributes the load of the total weight of the roof onto the walls, which is relevant in areas with strong gusts of wind and a lot of falling snow. The principle of installation, and even the fastening of the Mauerlat to expanded clay blocks, concrete or brick, differs due to the characteristics of each material.

In modern low-rise construction, the question often arises: “How to attach the Mauerlat to expanded clay concrete blocks?” First, it’s worth finding out what this material is.

Expanded clay concrete is one of the new concretes that quickly gained recognition in the building materials market due to its excellent thermal insulation qualities and versatility, as well as the possibility of use in load-bearing and enclosing structures.

Expanded clay concrete belongs to the class of lightweight concrete and consists of cement, water, foamed and baked clay. A similar composition of expanded clay concrete blocks suggests several options for attaching the Mauerlat.

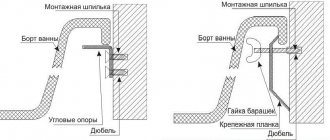

Fastening to the armored belt using metal pins

This method is used to create a single structure of wooden beams around the perimeter of the house with the installation of U-blocks that create a single reinforced concrete belt. In U-blocks, studs located at the same level are fixed with concrete, onto which a wooden beam with pre-prepared holes is placed, hammered with a sledgehammer for a better fit. Additional safety of the structure is increased by securing the timber to the studs using nuts and washers. To reduce the cost of construction, the studs can be replaced with conventional fittings.

Fastening the Mauerlat using anchors

In this option, fastening is done through the use of wedge anchors. Dowels in the form of a harpoon-type wedge are inserted into pre-made holes. This design ensures that the dowels are tightly pressed into the expanded clay concrete due to the expansion of the wedge, which ensures high reliability of the entire structure. Unfortunately, this method of attaching timber to expanded clay concrete blocks can seriously hit the construction budget, since one anchor costs about three to four thousand rubles.

: Expanded clay concrete blocks with cladding

Fastening the Mauerlat using chemicals

Chemical fastening is a new development in the field of installation, characterized by both low cost and the ability to fasten the Mauerlat to expanded clay blocks without an armored belt. The fastening capsule, whose cost does not exceed 200 rubles, contains highly active chemical elements that practically fuse the Mauerlat into aerated concrete. This fastening option improves the quality of the surface of the material, increasing protection from humidity and temperature changes.

Types of Mauerlat fastenings

For many years, tying wire fastening was preferred. However, technology does not stand still. Although quite a few options have been created, each of which facilitates and speeds up the process, not all of them are equally effective.

Steel wire

It is also a knitting wire, at least 5 mm thick. An old, but quite reliable method. The length is chosen so that it covers several rows of bricks or beams along with the mother log. The wire is pulled together, its ends are secured and the excess is cut off. There are some disadvantages to consider.

Firstly, it's appearance. Gradually, rust appears that cannot be removed. Secondly, the material is uncontrolled: the tightening force is applied randomly, as a result of which it is easy to damage the wooden beams. The wire itself stretches and the tension weakens, which can have a negative impact later. The advantage is its versatility in use: suitable for attaching the Mauerlat to foam blocks, wood, and bricks.

Metal studs (rods)

Modern reliable way. The studs protect the structure from moving to the sides, which occurs due to the wind. They are a rod with a diameter of up to 52 mm with an external thread. Secure with a nut. Metal rods are even sold in meter lengths, so it is convenient to cut them to the desired length.

The studs are walled into the wall through brick, blocks or timber several rows before the end of the masonry. This complicated method is justified by its high reliability. There is a guarantee for the strength of even the most complex roof structures.

Anchors

An almost universal method, reliable and easy to use when attaching a Mauerlat to an armored belt. Long anchors with large diameters are produced especially for this type of work. The mat is installed on the finished wall. Vertical holes are drilled in it and in the wall with a hammer drill into which anchors are inserted. They are hammered in with a hammer and then tightened with nuts.

But there is a limitation: fastening the Mauerlat to the reinforced belt with anchors cannot be done on hollow wall material. For example, a brick with voids inside - the anchor will not be able to anchor in it.

Suitable for fragile surfaces where reliable fastening is required. It consists of metal fasteners (threaded fittings, studs) and different types of adhesive composition:

How to attach a Mauerlat to expanded clay concrete blocks without an armored belt

To evenly distribute loads from wind, snow and the weight of the roof itself onto the walls, a wooden beam (mauerlat) is used.

Its installation is the first step in the construction of any roof. It is important that this design be taken into account during the design, since otherwise the resulting forces will not be properly transferred to the enclosing and load-bearing elements of the building.

Existing fastening methods

Refusal to use an armored belt in most cases is an unreasonable risk. It is the installation of a reinforced concrete strip along the perimeter of the external walls of the house that allows you to achieve reliable fastening and be confident in the stability of the roofs in all weather conditions.

All existing alternative methods cannot adequately guarantee the durability and stability of the roof frame.

Let's consider the methods used for attaching the Mauerlat to expanded clay concrete walls:

- using wire;

- using dowels and anchors;

- using chemical anchors;

- installing metal pins on the plates in the previous rows.

Fastening with wire

For work, bundles of steel wire with a diameter of at least 3 mm are used (the bundle consists of 4 or 3 wires). For the last 2 rows, bundles are laid on the solution so that they hang on both sides to a sufficient length for tying the Mauerlat.

The spacing of the wire should correspond to the pitch of the rafters. The fastening points are located between the rafters.

The installation sequence is as follows:

- A waterproofing layer is laid on the tiled wall.

- The timber is laid on top of this layer, leveling horizontally.

- Using a crowbar, tighten the wire to press the beam tightly against the wall.

There is an opinion that wire under high wind loads can damage the integrity of the masonry and weaken the fastening of the Mauerlat.

Dowels and anchors

The use of these fasteners can cause splitting of expanded clay concrete blocks. If the developer still dares to use dowels and anchors to fix the Mauerlat, then you should choose products with a length of 300 to 500 mm.

The high cost of dowels and anchors of this size is another disadvantage of this method.

The installation procedure for this method is as follows:

- Laying waterproofing (the best option is roofing felt).

- Installation of the Mauerlat and its alignment.

- Marking the timber to determine the places of support for the rafter legs and the location of the anchors between them.

- Holes are drilled in the Mauerlat and the wall, into which an anchor is installed and hammered to its entire length with a hammer.

- Using a wrench, the anchors are tightened until the beam is tightly pressed against the wall.

There is no reliable data on the reliability of installation of the Mauerlat using dowels and anchors. Therefore, when choosing this method, the developer acts at his own peril and risk.

Chemical anchors

The essence of the method is the use of special chemicals that harden quickly, have excellent adhesive properties and a long service life.

Industrially produced mixtures have a high price and a long service life (up to 50 years). However, there is a cheaper way to replace it - use epoxy resin and hardener.

After a day, such a homemade mixture acquires its final strength characteristics. The following brands are known that produce chemical anchors: “Technox”, “Tecscal”, “Fischer”, “Hilti”, “Sormat”.

There are the following types of industrially produced chemical anchors:

- Ampoule. A special capsule is inserted into the drilled hole for the anchor and then the anchor is drilled. The capsule collapses and upon contact with air its contents harden within 45 minutes.

- Polymer compositions in tubes. Their use is carried out using a dispensing gun.

- Chemical anchors. They provide for drilling a cavity in the wall material. The cavity resembles a cone, narrowed at the top. It is filled 75% with a special compound and then the anchor is screwed in.

The high cost of this method is more than compensated by its performance characteristics.

Avoiding cracking of wall material due to the absence of thrust loads is one of the main advantages of using chemical compounds.

Chemical anchors

The essence of the method is the use of special chemicals that harden quickly, have excellent adhesive properties and a long service life.

Industrially produced mixtures have a high price and a long service life (up to 50 years). However, there is a cheaper way to replace it - use epoxy resin and hardener.

After a day, such a homemade mixture acquires its final strength characteristics. The following brands are known that produce chemical anchors: “Technox”, “Tecscal”, “Fischer”, “Hilti”, “Sormat”.

There are the following types of industrially produced chemical anchors:

- Ampoule. A special capsule is inserted into the drilled hole for the anchor and then the anchor is drilled. The capsule collapses and upon contact with air its contents harden within 45 minutes.

- Polymer compositions in tubes. Their use is carried out using a dispensing gun.

- Chemical anchors. They provide for drilling a cavity in the wall material. The cavity resembles a cone, narrowed at the top. It is filled 75% with a special compound and then the anchor is screwed in.

The high cost of this method is more than compensated by its performance characteristics.

Avoiding cracking of wall material due to the absence of thrust loads is one of the main advantages of using chemical compounds.