What is an armored belt

An armored belt is a closed (circular) monolithic concrete-metal structure under aerated concrete walls. In other words: this is a concrete strip of small height, which is placed on top of a gas-block wall when laying inter-level floors is planned. The number of armored belts in a house made of aerated concrete under floor slabs depends on the number of floors of the structure. The belts are placed between the foundation and the wall of the first floor (grillage), between floors, between the top floor and the roof (under the mauerlat).

According to the type of construction, the reinforcing belt for aerated concrete can be of two types:

- monolithic - made by concreting in formwork;

- prefabricated - assembled from factory-produced blocks.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

The main requirement for the design is solidity and the ability to evenly absorb and distribute loads acting from the higher levels of the house. Armored belts in a house made of aerated concrete, even under wooden floors, must be reinforced concrete. An exception is made only for light non-residential buildings. An armored belt made of bricks on aerated concrete walls under floor slabs is, as a rule, not used due to the excessive weight of the brickwork.

Is an armored belt needed for a monolithic floor in a house made of aerated concrete?

In accordance with the rules of SP 15.13330.2012, an armored belt is mandatory when using cellular concrete blocks for laying. Aerated concrete is a type of cellular concrete, which means that a reinforcing belt is needed in an aerated block house.

Functions of the armored belt:

- strengthening load-bearing walls made of aerated concrete;

- uniform load distribution;

- reducing the risk of cracks in masonry;

- elimination of point loads that are detrimental to aerated concrete;

- ensuring uniform shrinkage on unstable soils;

- ensuring seismic resistance.

In some cases, a monolithic belt on aerated concrete under the floors additionally helps to level the masonry in the horizontal plane. For example, if one wall sagged or for some reason turned out to be lower than the other walls, then the reinforcing belt will help level the structures in height.

Armored belt design

A monolithic belt under the floor slabs is created to smooth out the loads from the weight of the roof, interfloor panels on the main walls (their end plane). In this way, it is possible to distribute the load from the floor slabs in the most optimal way, achieving the strength of the entire structure.

Design planning includes:

- Definition of construction type

- Selection of the optimal reinforcement diameter, mesh pitch, number of layers - the power should be greater, the less durable materials are used in the masonry of walls (for example, for lightweight floor slabs, you can use a not very powerful belt)

- Calculation of dimensions in accordance with area, design features

- The thickness of the armored belt is determined - usually equal to the thickness of the walls

Depending on the place of use, the armored belt can be:

1. Grillage – is a support for the foundation, is made in a special trench at a depth selected in accordance with the weight, number of floors, dimensions and other characteristics of the building.

2. Basement - created under all load-bearing walls to distribute the load on the foundation, the height is 20-40 centimeters, the width is equal to the thickness of the walls, it is made with 12 millimeter reinforcement, and is laid with waterproofing.

3. Interfloor reinforced belt for floor slabs - installed after each floor, strengthening the walls and increasing rigidity, preventing movement and deformation, distributing the load evenly.

4. Unloading - under the roof, simplifies the creation of a rafter system, secures the mauerlat to the wall, levels them horizontally, distributes the weight of the roof over the entire perimeter, preventing point loads.

Characteristics of a monolithic belt

The main characteristics of an armored belt are its height, width and load-bearing capacity. In buildings made of aerated concrete blocks, the width of this structural element is taken equal to the width of the load-bearing wall or 20 cm wider if we are talking about a grillage. The greatest importance is the height, which depends on the location of the structure:

- Grillage is a belt between the foundation and the first level of a building. The height of the grillage is 30-50 cm.

- The basement belt is a monolithic strip separating the base and walls of the first floor. Height - 25-50 cm.

- Interfloor belt - reinforced concrete strip under the floor slabs between the floors of the house. Height - 20-30 cm.

- The belt under the roof mauerlat is an armored belt for aerated concrete under the beams of the rafter system. Height - 15-25 cm.

The bearing capacity is calculated according to the method described in SP 15.13330.2012. The result of the calculation is the dimensions and material (grade of concrete) that will be used for concreting. In the absence of these complex calculations, it is sufficient to use concrete grade M200 for the tape under the Mauerlat and M300 for other types of armored belts.

Materials and tools

Before starting work, the necessary tools are prepared and materials are delivered.

The set of tools is simple and can be found at every construction site. The formwork boards are secured with a screwdriver. A concrete mixer is useful for mixing concrete mixture. A shovel and a galvanized bucket are used to carry the solution. Compact the mixture by releasing air with a metal rod or vibrators.

To work on installing an armored belt you will need:

- concrete grade M200, ready-made or poured by hand;

- steel binding wire;

- reinforcing bars with a cross-section of 12 mm for longitudinal rods; reinforcement with a diameter of 8-10 mm is used for transverse rings;

- boards with a thickness of at least 20 mm for formwork panels;

- timber, cuttings of boards for connecting and fastening boards;

- screws, nails, fasteners for installing formwork on the wall.

We recommend: How to make a concrete monolithic (poured) house with your own hands

Instructions for installing the reinforcing belt

The technology for constructing a reinforcing belt is no different from the construction of a conventional foundation strip. An exception is the connection nodes of the armored belt with the ceiling or Mauerlat.

Blueprints

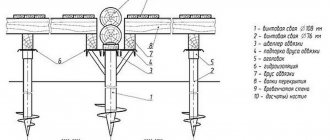

A monolithic aerated concrete belt for floors or beams is made according to the drawing, which is included in the project:

The armored belt under the Mauerlat will have a slightly different appearance:

Materials and tools

In order to make an armored belt in a house made of aerated concrete for slabs, a roof or a foundation, you will need the following materials:

- formwork or lumber for its construction;

- concrete mixture M200...M350;

- reinforcement with a cross section of 10-12 mm;

- metal anchors;

- film waterproofing.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

Tools you will need: a concrete mixer, a trench for pouring concrete, a hook for tying reinforcing rods, an angle grinder, a hammer, a tape measure, a building level, and welding.

How to connect an armored belt with aerated concrete masonry

The reinforcing belt and the wall on which it rests must create a single monolithic structure. This is the only way the belt will fully perform its functions. You need to think about connecting the belt and the wall at the stage of laying the gas block. At a height of 0.3...0.5 m before the future ceiling, reinforcement must be made inside the masonry by installing metal anchors inside the aerated concrete blocks, which protrude 10-20 cm above the surface of the masonry. These anchors are connected to the reinforced frame of the belt, forming a monolithic structure that can effectively absorb loads.

Armored belt device

The technology includes the following stages:

- Surface preparation - the top layer of aerated block masonry: removing dust, degreasing.

- Installation of formwork: removable - from lumber, non-removable - from heat-insulating materials.

- Knitting a reinforcing frame from reinforcement with 4 threads.

- Laying the reinforcing frame inside the formwork.

- Bundle of anchors and reinforced frame by welding.

- Preparation or ordering of concrete mixture.

- Layer-by-layer concreting of the reinforced belt to the required height.

- Concrete surface care.

- Laying waterproofing after reaching the design strength.

The armored belt for aerated concrete under beams is ready. After 28 days, construction can continue. In the case when it is impossible to wait for the concrete to gain strength by design, you can use ready-made reinforced concrete products to construct the belt.

Belt technology

The entire technological process consists of three stages:

Let's get acquainted with each point in more detail.

Formwork for monolithic belts

The design of the formwork must ensure its geometric immutability and rigidity throughout the entire process of use. It must be installed in accordance with the work plan.

Installation of formwork

When installing belts along the entire thickness of the walls, the formwork is first installed and secured from the outside as well as the inside. It can be made of wooden panels, metal inventory elements (reusable), moisture-resistant plywood, and other materials.

There are examples, if this is provided for by the project, when its role is played by thin walls made of brick or aerated concrete. The space between them is reinforced, filled with concrete mixture, and the walls themselves remain in the body of the structure.

The formwork is secured with nails using welding. Other fastening methods have not found widespread use. Since fasteners have to be constantly cleaned of any concrete mixture that gets on them.

Under the pressure of the concrete mass, in case of improper fastening, the panels can bend or move. This is fraught with the formation of uneven surfaces of the structure, which, after disassembling the panels, have to be cut down, hewn, and sometimes plastered.

Reinforcement of monolithic belts

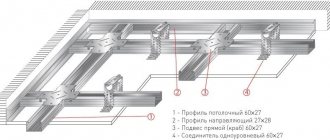

Let's consider what kind of reinforcement is used for the armored belt. Reinforcement should be carried out with welded frames and meshes manufactured in factories. The use and installation of products in construction conditions is permissible for additional elements or sections of connection between frames and meshes.

The construction of monolithic belts involves placing reinforcement cages inside the formwork. They are spatial blanks of 4 or 6 bars of longitudinal reinforcement of a periodic profile (class A - III).

Reinforced belt for aerated concrete under floor beams made of U-blocks

To construct a reinforcing belt, you can use specialized reinforced concrete products: U- or U-shaped blocks made of reinforced aerated concrete, ordinary concrete or fiber-reinforced concrete. When using ready-made blocks, no formwork is needed, and there is no need to calculate the height of the reinforced belt for aerated concrete under the floor beams. The technology will be as follows:

- P- or U-blocks are mounted around the perimeter of aerated concrete walls using aerated concrete adhesive.

- The prepared reinforcement frame is placed in the recess of the block.

- The space is concreted with M200 concrete mixture.

The main load here is taken by the U-block, and the layer of monolithic concrete is small, so the strength gain lasts 3-5 days.

The installation of a reinforcing belt is a prerequisite for the construction of a durable house made of aerated concrete. The construction of the structure must be approached responsibly and high-quality materials must be used.

How to make an armored belt with your own hands

Now that we’ve figured out what an armored belt is, let’s find out how to make it with your own hands. With a brick armored belt, everything is simple. Typically, masonry is made of solid red brick of minimum grade M100 in several rows with reinforcement with masonry mesh. You can also reinforce the masonry with reinforcement with a diameter of 6-8 mm. With a concrete, monolithic armored belt, the situation is more complicated.

First you need to set up the formwork. This can be either wooden formwork or “tray” or permanent formwork, if we are talking about an armored belt on aerated concrete or foam concrete blocks. You can use factory U-blocks or make your own trays. To do this, it is not necessary to cut a U-block from a regular gas block. It is enough to make masonry from a thin gas block on the outside and inside. The space between these blocks can be insulated with extruded polystyrene.

After you have made the formwork, a reinforcement frame is placed inside the tray.

Sufficient reinforcement for an armored belt measuring 200 by 200 mm is a frame of 4 threads of reinforcement with a diameter of 12 mm (two on top and bottom), fastened with transverse clamps with a diameter of 6-8 mm every 30-50 cm.

The standard overlap of reinforcement should be 30-40 diameters. That is, if you are laying 12 mm reinforcement, then when building it up, you need to make an overlap of about 40 cm.

In corners, the reinforcement must be bent so that the corner is connected by solid reinforcement.

It is advisable to place the frame made of reinforcement on plastic clamps of the thickness of the protective layer of concrete. And put the clamps on the vertical clamps. If there are no factory fixings for the protective layer, you can use pieces of stone, brick, etc.

Pins under the Mauerlat or pieces of reinforcement are attached to the reinforcement frame for subsequent fixation of the floor slabs.

Now you can proceed directly to pouring the reinforced belt with concrete.

If you will be pouring purchased concrete, choose the M200-M250 brand. This grade of strength is absolutely enough for private construction.

If you plan to prepare concrete for pouring the armored belt yourself, then use the universal recipe for the proportions of concrete for the armored belt: 1 part 500 grade cement, 2 parts sand, 4 parts crushed stone.

You can also use one of our construction calculators to calculate the composition of concrete. Don't forget to add concrete plasticizer to the mix. This will make the filling more convenient for you, and the resulting armored belt more durable.

After pouring, cover the armored belt with film to prevent sudden drying. For the same purpose, wet the concrete for the first 2-3 days.

The armored belt will be ready for loading in a week. Full maturation of concrete will be completed 28 days after pouring.