Foundation formwork is a frame-panel form into which a mixture is poured to create a concrete strip or slab. The geometric parameters, proportions, and appearance of the above-ground part of the base of the house depend on the correct installation of the panel structure. If you set it using a level, making the edges strictly horizontal and vertical, this will allow you to avoid deformation during shrinkage in the future. The leveling procedure is carried out on terrain with any terrain - this is especially important in areas with a slope and slopes.

Leveling technology and methods

To get a strong frame for pouring concrete, you will need lumber of different sections: edged boards 100x25 and 150x30 mm for panels, timber 100x50 mm for supports and vertical posts. Before installing the panel structure, thoroughly clean and plan (level) the foundation pit dug with shovels. Then it is done step by step:

- placing vertical posts at intervals of 0.8-1.0 m;

- formation of the frame - lining the internal walls with boards using wood screws;

- supporting the panels with blocks in increments of 0.6-0.7 m.

If the walls are higher than 0.9 m, they are tightened with metal pins to avoid deformation of the structure due to the high pressure of the concrete mixture.

To level the formwork, select one of the two technological schemes proposed below.

1. Above the foundation. The shields are raised by several centimeters, then marks corresponding to the height of concrete pouring are applied directly on them with a marker (using a water or laser level).

2. Setting the frame to zero. In this case, first mark the height of the foundation and tighten the fishing line or cords. Focusing on them, they put up shields, which are cut down along the lines drawn along the fishing line. The poured concrete is compacted with a reinforcing bar and smoothed with a rule resting on the walls of the panels.

To set the formwork, use a water or laser level.

- Water. Marking begins by searching for the lowest point. A transparent level container is applied to it, and the height of the liquid is noted. Using the second flask, mark the remaining pegs. Lines are drawn along the marks along which the fishing line is pulled.

- Laser. The device finds the horizontal thanks to a self-leveling mechanism. The level is set on a tripod and all obstacles in front of the laser beam are removed. If necessary, the level is adjusted using a built-in bubble level. During operation, observe the distance from the device to objects specified in the instructions.

How to properly install porch formwork?

The foundation for the porch is built to prevent distortion of the shape of the steps due to seasonal temperature fluctuations. The position of the side panels is preliminarily marked, taking into account the placement and dimensions of the steps; using a level, they are aligned in the horizontal plane.

The frame should be 30 cm higher than the porch itself.

Transverse struts are installed between the panels to provide rigidity to the structure during pouring. The formwork is secured with pegs driven into the ground. Then longitudinal parts are added, repeating the location of the steps. The cracks are sealed and lubricated with mastic. Finally, the porch is reinforced and poured.

Formwork on sloped areas

For small differences in height (no more than 20 cm), the platform is considered horizontal. Sometimes the natural slope is partially cut off or, conversely, soil is added at the bottom of the site. The frame for the strip foundation is leveled in the usual way. On a slope with a large slope (height difference of 1 meter), a stepped tape or columnar type is laid.

- Installation of a stepped structure. The process is carried out in stages: installation of the lower tier, leveling, concreting. Next - placement of the second tier, leveling, pouring concrete. The main requirement is that the levels of each level correspond to each other.

- Installation of formwork for a columnar foundation. For each pillar on the slope, a frame in the form of a box (box) is placed. Each such element is manufactured and assembled separately. When assembling the box, the location of all its corners is checked by level. The finished boxes are installed on a flat surface of pre-dug, compacted and concreted holes (concrete height - 30 cm).

Errors and nuances

In order for the installation of formwork to ultimately ensure the creation of a strong and durable structure, it is necessary to observe all the details of the technological process, starting with excavation work. The uneven surface of the pit can disrupt the horizontal plane of the future foundation, so pay attention to the following details:

- If the house is being built on subsiding and heaving soils, the frame is placed on special foundation edges, which should be lowered below the soil freezing line.

- It is not allowed to place panels on freshly dug or bulk soil. An unstable base surface promotes cracks in the completed object. Before installing the formwork, be sure to remove debris and foreign objects from the ground, and eliminate unevenness. To maintain a horizontal level, the support posts are equipped with pads made from scraps of boards.

- It is important to correctly position the boards so that under the pressure of concrete there is no deviation from the vertical plane. If the foundation is no higher than 20 cm, stakes are sufficient to secure the panels; in other cases, supports, racks, braces or clamps will be needed.

Is a strip foundation suitable for installation on a slope?

Pouring the foundation

During installation, it is very important to follow existing building codes and regulations - this will help to pour a strong and reliable foundation made of monolithic reinforced concrete:

- It is not allowed to install the support posts of formwork panels on dug up or fill soil; it is necessary to ensure the reliability and stability of the structure, for which, on problematic soils, it is necessary to place cuttings of boards under the support posts.

- The panels must remain in an unchanged position for quite a long time, taking into account the impact on them of the mass of concrete poured into the structure, therefore wooden formwork can be strengthened by installing braces, racks and supports.

- In subsidence and heaving soils, the mold is mounted on special foundation edges buried below the freezing point of the soil.

Even if you follow all the recommendations, you may end up with an uneven horizontal base. The situation can be corrected by leveling the formwork for the foundation. The formwork rises along the side walls of the strip foundation. If the height of the leveled surface is more than five centimeters, a reinforcing mesh will be required.

There are several ways to determine the exact height along the entire perimeter of the formwork:

- Draw marks on the inner surface, then fill to their level;

- When installing the formwork, initially level the top of the boards. In this case, you will need to pour concrete to the border;

- Sew the slats at the required height. This mark will not be erased and will be clearly visible.

The strength of the building does not depend on the verticality of the foundation walls. This indicator only affects the appearance of the house. Simple plastering will help solve the problem of uneven walls. In those places where the depth of the depressions is more than five centimeters, a reinforcing mesh is installed. To ensure the verticality of the finished plaster, you can use a rule, slats or a building level.

Another case is a serious deviation from the vertical, skew. If such a problem arises, the formwork is re-erected along the finished foundation. If the distance between them is more than 0.5 meters, then a reinforcing frame will be required. This will help create a solid foundation for the house being built.

Optimal types of foundation for a slope:

- Strip foundation is the most common option, reliable and durable, simple and fast. Requires backfilling, at least minimal leveling of the terrain; it is more suitable for slopes with a slight slope or where another choice is not relevant (then choose a stepped belt type, which demonstrates greater load resistance and strength).

- Columnar foundation - when arranging a structure on a slope, be sure to back up each column with a supporting wall, which increases the resistance of the foundation to lateral deformations. Suitable for the construction of frame and wooden buildings.

- Slab foundation - involves the implementation of special reinforcement, which retains the soil during the movement. Rarely used for slopes, as it requires large-scale work, leveling the site, and is expensive.

- Pile foundation - suitable for all types of buildings, for the steepest slopes. A practical and effective option, but requiring the use of special heavy equipment. The design is reliable, durable, and economical. Piles are made of metal, wood, reinforced concrete, of any size and shape.

- Combined foundation - when several elements of a pile and strip foundation are built, for example.

When considering a columnar or strip foundation, the latter is usually chosen due to the simplicity and low cost of construction and the good quality of the foundation.

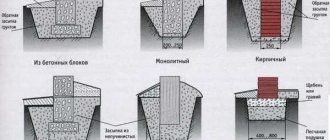

According to their design, strip foundations are divided into: prefabricated and monolithic strip. According to the depth of immersion, the structure can be of a recessed or shallow type.

Monolithic structures demonstrate better resistance to axial tensile loads and load-bearing capacity. Typically, a buried type is chosen that can withstand ground shifts and heaving when the soil around the house is affected by temperature changes. The greater the angle of inclination, the greater the depth of immersion.

A strip foundation is a simple and familiar design that you can make yourself. This type of base is also suitable for a slope, but requires taking into account the following nuance: at the lowest point, the height of the base should not be higher than four times its width. The steeper the slope, the higher and wider the base must be, which proportionally increases the cost of installing formwork, preparing mortar and pouring the base.

Thus, a meter height of the base will increase the cost of construction by almost 2 times due to the significant volume of earthworks. Such expenses are justified if it is planned to equip a useful room in the basement. Then the costs will be paid off by ease of use and the ability to make maximum use of the space.

Thus, a strip foundation is suitable for not very steep slopes; it is best to choose its stepped variety.

We suggest you familiarize yourself with How to properly install rafters on a pitched roof

Stepped strip foundations are installed during the construction of large-scale structures on sites where there is a large angle of inclination - most often when the difference between the horizontal level difference between the lower and upper points is more than 1 meter. The principle is simple: the stepped foundation is made in the form of horizontal platforms, which are located one above the other.

In terms of excavation work, this approach significantly facilitates construction, since ensuring horizontal alignment on a relatively small area is easier than on the entire large area: the volume of soil that is removed from the surface is reduced, and in the process of creating steps, their size is made optimal to obtain a suitable drop value heights for all areas.

Choosing material for construction

To install removable formwork, boards made of inexpensive wood are used. There are no special requirements for the material; the structure must be dismantled after the concrete has hardened.

Another option is possible - installing a frame made of expensive wood. After dismantling the structure, the boards are used for finishing work (for arranging the floor or ceiling, interior decoration, and so on).

Fixed formwork is mounted from durable materials:

- Steel. Metal sheets are suitable for monolithic and strip foundations. The advantages include the ability to bend the sheets at the desired angle, excellent waterproofing of the foundation. The downside is the high cost of the material.

- Reinforced concrete. Reduces concrete consumption without losing structural strength. But the slabs are heavy, so working with them is quite difficult and requires the use of special equipment.

- Expanded polystyrene. The formwork is made up of separate blocks that are firmly fastened together. Among the advantages are ease of assembly and the ability to give a certain shape. The structure has thermal insulation and waterproofing properties. Disadvantages - difficulty in selecting individual parts (for example, round sides), high cost of material.

- You can build a structure for pouring the foundation from available materials: slate, corrugated sheets, unnecessary pipes and other items that can be shaped. If you make the calculation correctly, the benefits of using scrap materials are obvious.

Exhibiting the structure with your own hands

Construction work on placing formwork is carried out in several stages. The main condition for a good design is the creation of a perfectly flat surface. If errors are made when creating the formwork, the foundation will be built on an uneven site, which will lead to distortion of the building walls and destruction of the structure.

Preparatory work

Before installing the structure, it is necessary to carry out preparatory work:

- digging a trench for the future foundation;

- removal of construction waste;

- leveling the trench surface.

Slope specifics

Schematic representation of a strip foundation on an uneven area.

As a rule, in areas with a slope of up to 30 cm in one direction, the construction of strip block and monolithic foundations is more practiced. Such structures are durable, construction is relatively inexpensive, you just need to carry out earthworks.

Although such areas are considered level, in reality the situation will be deplorable, because there will be a sharp jump in heights on different sides of the base. Thus, a strip foundation with such a slope can be erected in the following ways:

- Simple option. When designing and marking the area for the future foundation, a pit is dug and the bottom is leveled. This is done in such a way as to obtain a perfectly flat bottom surface without even minimal slopes. It is clear that this method is financially expensive, because you have to do detailed geodetic surveys and correctly calculate the depth of the foundation. The method is easy to implement and is used for buildings that are small in size and weight.

- A more complex, but also reliable option is to carry out local deepening of the trench. In such cases, you need to first calculate the required immersion depth for each specific section of the base, and only then level the bottom.

We invite you to familiarize yourself with the Master flush for a chimney, installation, characteristics, dimensions, how to choose

ht = hpv hp, where:

- ht is, in fact, the required calculated depth of the trench;

- hpv is the difference in heights in different areas, and it is better to immediately select a larger value to obtain accurate data;

- hp is the thickness of the soil, which must be removed during the process of digging a trench.

If we take the maximum height difference to be 15 cm, and the thickness of the fertile layer is up to 40 cm, then the depth of the trench will be 55 cm. The depth of the trench is 30 cm, so the pillow must be made 25 cm thick.

A drainage ditch, tray or compacted earthen bank is also excellent for such purposes. After pouring the base, it is recommended to fill the ditch with sand and gravel, then compact it and install storm drainage systems on top.

Columnar base for uneven areas

Here it’s worth thinking about what type of foundation is best to use. For example, for a strip base you will have to use a lot of bedding, and you need to do this first at the lowest point and then evenly level the bottom horizontally. Such construction will be financially expensive, but it can be used in the construction of small buildings.

As an option, you can use a column-and-strip foundation here. It has a number of advantages over conventional tape, namely:

- there is no need to carry out detailed geodetic calculations and select the optimal installation depth of the tape;

- a minimum of sand cushion is used here, and the pillars can even be installed in several tiers;

- You can immediately install a concrete strip on the finished pillars.

It is clear that such a foundation on an average slope costs a little more, but in some cases it justifies itself. The construction of a strip structure has a number of nuances, namely:

- Incorrectly placed and compacted bedding will spread over time, followed by the tape.

- Before creating a sand cushion, you must first equip a foundation pit with smooth walls, and only then lay the cushion.

- There is no need to strictly adhere to the same thickness of the pillow; it can be different, but not less than 30 cm.

After erecting the structure, you need to make vertical soil dumping. For this, non-heaving soil, such as sand, is used. The blind area needs to be made away from the base at a slight angle, but always with a slope towards the larger side.

It is almost impossible to find horizontal and perfectly level areas for construction. A slope of up to 3% inclusive (a maximum difference of 3 centimeters for each meter of length) is not considered at all - such a section is called horizontal. When the percentage of slope is greater than the specified value, we can already talk about slope.

If the height at the lowest point of the foundation is 4 times greater than the width of the tape, then the slope is considered to be maximum.

And in such cases it is better not to build a continuous strip - a stepwise method is more relevant. A stepped foundation also has its limitations: the length of the horizontal step must be at least 60 centimeters, its height cannot be less than 30 centimeters. Each subsequent step must overlap the lower one in the structure by double the width of the entire tape or by at least 30 centimeters.

Advice from experts on setting up formwork

- The frame must be made in a separate area, on a flat surface. The entire structure is assembled at the site where the foundation is laid, in a trench.

- To strengthen the formwork, tie elements are installed along the entire perimeter of the structure every meter. The distance between spacers can be reduced to increase the strength of the formwork.

- It is important to properly level the top layer of formwork. If this is not done, the work will have to be redone.

- The boards need to be adjusted as close to each other as possible so that there are no gaps.

- Correctly selected formwork boards are the key to high-quality work and reliability of the finished structure. Choose a material without cracks and with a smooth surface.

- The bottom edge of the formwork should fit tightly to the soil. If the structure moves away from the surface of the earth, the foundation will be uneven.

- We must not forget about the reinforcement of the foundation. To prevent cracks from forming in the foundation, part of a section from the grid should become the beginning of another section.

Correctly constructing the formwork structure is not difficult if you have a standard set of tools (saw, axe, hammer) and fasteners (nails and screws). You can save money if you use ordinary boards left over from previous construction work. To create durable and reliable formwork, we recommend using metal or reinforced concrete - materials that retain their properties for 100 years or more.

There are several ways to level the formwork. The rules for carrying out work are reflected in specialized documentation: SNiP 3.01.03-84 “Geodetic work in construction” and SNiP 2.03.01-84 “Concrete and reinforced concrete structures”.

In most cases, individual developers do not have time to study the rules and regulations. Therefore, the most useful are the recommendations of builders, based on the requirements of SNiP and optimized for different conditions of concrete pouring work.

Installation work

It is convenient to mark the formwork on the building site using pegs and stretching a construction cord or fishing line over them. It is very important to remember that the foundation should be 10-15 cm wider than the walls. Each action should be checked with a level and a laser level - this way you can ensure the most even placement of the formwork panels.

It is possible to position the formwork correctly only by using a level, which should be used to periodically check for possible displacement of the panels during installation.

You can start installing the boards only on level ground, securing each board with scraps of reinforcement and wooden support pegs. The panels are secured from the inside with reinforcing rods - after concreting, the reinforcement will serve as an additional reinforcement element to impart vertical rigidity. Watch the video on how to install formwork without mistakes.

The lower edges of the formwork panels should rest completely on the upper surface of the ground, and adjacent elements should have the closest possible fit to each other.

The side panels are tightened using special ties made of timber, which are strengthened on top of the formwork panels from above. Screeds are installed every 0.5 - 1.0 meter.

We suggest you familiarize yourself with How to make formwork for piles from roofing felt

Selection of formwork material

Formwork is a frame whose cavity is filled with concrete. After it has set, the auxiliary structure is dismantled (removable formwork) or it remains in its original place and will be an integral part of the structure being erected (non-removable).

The first option uses new sheet materials intended for other purposes. But in this case, the inner walls of the frame are covered with overlapping sheets of thick polyethylene film, which is fixed to the boards with staples and a construction stapler. This precaution will protect the materials from contamination by cement-sand mortar.

For formwork you can use:

- Edged or unedged boards;

- Sheets of plywood or OSB;

- Flat slate;

- Cement particle boards (CSP);

- Foam plastic with a thickness of at least 5 cm;

- Chip-cement slabs (fibrolite);

- Metal sheets with a thickness of 2 mm;

- High strength plastic sheets.

Alignment

An important point in the construction of formwork is its leveling. Recommendation from builders: there is no need to try to level the upper planes of the frame “to zero.” On the contrary, it is better to make the walls of the formwork several centimeters higher than the planned height of the foundation. And on the inside of the boards, apply marks with a marker, drawing horizontal lines corresponding to the required plane of the foundation to be poured.

The main difficulty is to draw these lines correctly. It is not difficult to pour and level concrete over them. To complete the task, you can use a water level.

First, find the required height of the foundation at the lowest marking point. Apply a water level flask to it, remember or mark the water level. Then, using the second flask, the corresponding marks are placed on the remaining pegs. Draw lines and, if necessary, duplicate them with thin wire.

There is another point of view on alignment: the walls of the frame should be aligned “to zero”. For these purposes, at the marking stage, the height of the foundation is determined in the manner indicated above and ropes or fishing line are pulled at this level. Shields are mounted based on these devices.

The second way to level the formwork walls is to cut the panels along the lines drawn along the fishing line or rope. When pouring concrete, it is compacted with a reinforcement bar and leveled with a rule, which in this case should rest on the walls of the formwork.