Wiring Requirements

Wooden building materials have a lot of positive qualities and are the most popular. But, in addition, they are very fire hazardous. Therefore, a number of requirements for laying cables in a wooden house must be met:

- Safety.

The choice of wiring is made in such a way as to prevent overheating of the wires, plus, the installation is done in metal pipes, so that even in the event of a cable fire, the open flame is not allowed to spread to adjacent wooden structures.

- Design.

The technical characteristics and performance characteristics of the cable for wiring in a wooden house must be strictly calculated for the peak load of each specific section of the electrical network. To prevent heating of the wiring section, a safety margin of up to 30% is required. Plus, it is strongly recommended to plan hidden wiring when drawing up a house project.

- Laying method.

Electrification can be carried out in an open or closed way. Both have positives and weak points. Hidden is considered safer, but much more labor-intensive during installation. For some, open electrical wiring in a wooden house is preferable because it makes it possible to easily and at any time have access to the electrical network for diagnostics or making minor changes.

Option for installing retro wiring in a wooden house using an open method Source ecomartver.ru

- Insulation.

In addition to wiring, electrical switchboards (decoupling units) must also be insulated from contact with wooden surfaces. The ideal solution would be to place the electrical panel in a room with a partition made of non-combustible material.

- Conductor.

Most often, it is recommended to use a three-core copper cable with flame retardant insulation.

- Automation.

Each power supply group requires the installation of a separate circuit breaker. In this case, it is necessary to strictly monitor the compliance of current ratings with the calculated load on the site. A strong overestimation of currents is unacceptable, because this may cause the conductor to overheat.

Independent laying of power cables and installation of electrical wiring in a wooden house is strictly not recommended without sufficient experience. It is better if a qualified specialist does this. However, knowledge of the basic rules of electrification is mandatory for owners of private houses, because this makes it possible to carry out partial diagnostics of the network and monitor the quality of work carried out by hired electricians.

A professional electrician will always do the job faster and better Source wixstatic.com

Providing power supply to a wooden house

The task of ensuring the safe functioning of the electrical network at home must first be solved on paper, that is, it all starts with the project.

At the stage of its development, decisions are made about:

- Connection to the central power grid.

- Organization of the input device.

- Method of laying electrical cables. It could be:

- Hidden wiring in a log house.

- Open, located on top of structures.

- Method of installation of electrical appliances:

- Switches.

- Dimmers.

- Rosettes.

- Svetilnikov, etc.

Attention! For those who are not qualified as an electrician, it is better not to undertake the development of a project and its implementation with their own hands. Invite specialists from a reputable company to both design and install the electrical network at home in order to close the issue of safety once and for all.

For those who intend to carry out electrical installation work on their own, this material will be useful as instructions for a step-by-step solution to the problem.

Electrical cable supply to the house

Connection to the power line is carried out in two ways:

- By air - less expensive and quickly feasible. To do this, use a self-supporting cable with a calculated number of cores and their cross-section.

For your information! The calculation of the power of an autonomous electrical network is carried out taking into account the planned load, which depends on the amount of electrical equipment in the house.

- Underground - more expensive and labor-intensive, but has a number of advantages:

- A cable laid underground will not disturb the exterior of the building or courtyard.

- In this case, the cable is reliably protected from damage, which prolongs its service life.

For underground installation of an input line into a wooden house, a power copper cable should be used.

For your information! The project for connecting private housing construction to the central power grid is subject to mandatory approval from the relevant local energy supply organization.

Input device

Reception and distribution of electricity to specific consumers inside the house is carried out through an input device-switchboard.

It is installed in a safe place with free access at any time and equipped with:

- Automatic switches.

- Residual current devices.

Attention! The power cable is introduced into the house through a built-in metal sleeve. When wiring the electrical network throughout the premises, rigid metal sleeves are also installed in places where the cable passes through walls and ceilings.

The input distribution board should be protected as much as possible from contact with wood; it is usually placed in a special metal box. The sizes of such boxes are selected for a specific number of “machines” and other devices.

Types and characteristics of wires

You should start by analyzing which cable to use for wiring in a wooden house - copper or aluminum. Both options can be used, but professionals prefer copper wires due to the following characteristics:

- less susceptibility to corrosion;

- better conductivity indicators;

- greater strength.

Aluminum has only two advantages:

- less weight;

- low cost.

Otherwise, aluminum does not compete with copper due to its following properties:

- rapid oxidation, which means worse conductivity and faster heating;

- increased fragility, because several kinks in one place lead to wire breakage;

- the properties of the material weaken at the point of contact and slip out of the screw terminals over time (periodic checks of the contacts will be required).

There is also an inexpensive composite material called aluminum-copper that is used to make wire cores. Such a product takes the best properties from both metals, but at the same time the quality indicators of each of them are significantly reduced.

Wires also differ in the number of cores - they can be multi-core or single-core. In turn, the cores can be single-wire or multi-wire.

Types of electrical wires Source elkomp.ru

The wires also differ in cross-sectional size and rated operating voltage. They are usually insulated with vinyl plastic, PVC or rubber, depending on the AC rating of the wire.

For additional resistance to mechanical damage, the wires are sometimes covered with a cotton braid. And if the likelihood of mechanical damage is practically guaranteed, then a galvanized steel braid is applied.

Despite the cheapness of aluminum wires, copper wiring is more popular because... home owners often prefer to pay tribute to reliability.

For open wiring, so-called “retro wiring” is also used, which combines functional and decorative solutions in the house, i.e. Electrical wiring in a wooden house is laid along the walls, but as attractively as possible, with elements of decorating the room.

Additional materials used for electrical installation work

Electrical wiring in a wooden house with your own hands should ensure a continuous process; you need to stock up on tools and equipment. For this work, pliers, screwdrivers, a hammer, a chisel, a screwdriver, and a knife for electrical work are used.

There are two types of electrical panels: metal and plastic. For wooden buildings, experts recommend installing metal panels inside the house. Most often, the following types of cables are placed in the shield:

- to provide current to lighting devices;

- for sockets;

- for electric stoves;

- for meters that monitor electricity consumption;

- for RCD.

Electrical supply stores sell switchboards to accommodate 12 pieces of electrical equipment. For houses of standard dimensions with the usual arrangement of electrical wiring elements, panels with 9 places are used.

In addition, to install electrical wiring you must prepare:

- electrical wires of a certain cross-section. In wooden houses, a three-core VVG cable with a cross-section of 2.5 millimeters is used;

- sockets, switches, the number of these devices is calculated according to the diagram. Basically, when choosing, they pay attention to quality and combination with the colors of the interior. Sockets and switches equipped with brass and bronze contacts are used;

- cables and skirting boards with grooves;

- distribution boxes, insulating clamps and tape;

- electric meter, today there are two types of meters: one-tariff and two-tariff. At current electricity prices, it is more rational to use a two-tariff meter, since it records the tariff depending on the time of day;

- self-tapping screws, aluminum tape, fasteners - clips, clothespins, clamps.

The above list should be collected before the initial stage of the workflow.

Electrical wiring options in a wooden building

Wiring in a wooden house (cable routing) is carried out using the following methods:

- Outdoor (open).

Electrical wiring is installed using special insulators. This is a fairly safe and economical method that does not require capital investments. The cable is routed directly along the planes of the walls and ceiling.

External wiring near the panel Source sense-life.com

- Laying wiring in cable channels.

This method is also an open method. Special boxes are used, attached to the surfaces of the room, which visually hide the laid cable.

This also includes the fairly popular electric baseboard. Inside it there is a cavity in which the wires are fixed. This increases reliability and ease of installation.

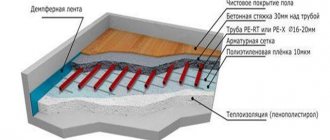

- Hidden (closed).

When metal (preferably copper) pipes in which the wiring will be laid are installed inside the walls. Of course, the pipes themselves must be installed during construction. This method is the most labor- and financially expensive. But it completely eliminates the possibility of mechanical impact and pressure on the cable, which is very important in wooden buildings, which often begin to “settle” over time. Accordingly, hidden electrical wiring in a wooden house is rightfully considered the most reliable and durable.

Hidden electrical wiring in a wooden house can be installed under the subfloor Source tildacdn.com

See also: Catalog of companies that specialize in electrical work of any complexity

Electrical wiring in a log house

Housing should not only be comfortable, attractive and warm, the house should also be safe. Otherwise, there is a risk of not only losing all your property, but also losing your life, for example, if the wiring suddenly catches fire at night, when all family members are sleeping. Electrical wiring in a log house, according to the requirements of the PUE, can be carried out in an open or closed way. Electrical wiring work is highly complex, so it is best to entrust it to professionals. has extensive experience in constructing wooden houses using various turnkey technologies. Therefore, we will install the electrical network for your home. At the same time, we can offer several options for your consideration, from which you can choose the one that most satisfies you.

Subtleties of hidden electrical wiring in wooden buildings

So, installation of hidden wiring is carried out during construction or major repairs. At the same time, there are some subtleties: the wires are laid inside metal pipes, or corrugations, and the installation of absolutely all connection units must be carried out in special metal boxes, with mandatory free access to them. It is strictly forbidden to hide them with decoration. Therefore, they are placed in inconspicuous places or they try to select covers that will not stand out from the interior and attract attention.

In the case when the installation of hidden wiring in a wooden building is carried out not with a cable, but with the help of insulated wires, then it is necessary to correctly select the thickness of the walls of the metal pipes in accordance with the regulations:

- for copper wires with a cross-section of less than 2.5 mm, the thickness of the pipe does not matter;

- when the wire cross-section reaches 4 mm, the metal wall must be at least 2.8 mm;

- when the core cross-section is in the range of 4.5-10 mm, the wall is selected above 3.2 mm;

- wire cross-sections in the range of 10.2-16 mm will require a pipe with a wall more than 3.5 mm thick.

Hidden wiring in a wooden house is laid only in metal pipes Source remontnik.ru

In the case of laying electrical cables, there are no strict standards for the size of pipe walls, because Double or triple insulation available. It is even allowed to install using metal corrugation (metal hose), which increases the convenience and speed of installation.

But it should be borne in mind that with this installation method, there will be practically no access to the wires. And making changes to the laid network will be expensive and extremely troublesome. So, before carrying out wiring in a wooden house in a hidden way, it is recommended to carefully check the wiring diagram and carry out all the work thoughtfully, with all care and scrupulousness.

Features of electrical installation

The most common mistake that DIYers make when installing an electrical network is installing hidden wiring in the walls without protective devices. You can often see that the wire is hidden not in a metal pipe, but in a corrugated plastic pipe; this can ultimately lead to a fire. Hidden wiring in a log house made of rounded logs is dangerous for several reasons:

- When laying a cable, the insulation may be partially broken, and often the electrician does not even notice it. As a result, when the load is turned on, the damaged area will begin to heat up quickly, and this will lead to a short circuit. When heated, the corrugated wall of the pipe will quickly collapse, after which fire of the walls will become inevitable.

- The second reason why hidden installation of electrical wiring in a house made of rounded logs should be carried out only using a metal pipe is rodents that live in many wooden buildings. Rats and mice can chew through the plastic box and taste the insulation of the wire. This will again lead to a short circuit and a fire, and it is almost impossible to detect the damaged area immediately.

- Dust accumulates in the voids in wooden walls. This material ignites instantly when the temperature rises, and the fire will reach alarming proportions in a very short time. The house can be destroyed along with all its property in just a few hours.

The main reason for such problems is the desire to save money on calling qualified electricians and the desire to quickly complete the laying of cables. As a result, the structure is under threat, which could easily have been avoided if appropriate measures had been taken.

Electrical network installation: stages of work

Electrical wiring in a house made of rounded logs is laid in both hidden and open ways, but in both cases the work is carried out strictly in accordance with the standards. The first stage is drawing up a project for the building's electrical network: it must indicate all the sockets and switches that are supposed to be placed in the rooms, as well as all lighting fixtures. You need to have a rough idea of where the household appliances will be installed so that the sockets are conveniently located and there is no need for tees.

Current consumers are divided into groups, and each group is equipped with its own circuit breaker. If the wiring is supposed to be done in a small room, you can combine all the devices into one group. It is important to consider street lighting, as darkness in the area can cause injury.

For internal wiring, a VVGng-LS cable with copper conductors is used; it is equipped with non-flammable insulation to prevent fire and the spread of smoke.

Sockets are selected depending on the type of wiring, hidden or open; they can be combined into blocks for ease of placement.

You should also choose the right input cable; it must match the power of the network.

Layout diagram

Any work on laying or changing cables is preceded by preparatory actions, which include drawing up a wiring diagram. The competence and technical accuracy of the created project guarantees high-quality installation and safety of the electrical circuit, in accordance with all rules and regulations.

An example of an electrification scheme for a private house Source freelancehunt.com

When creating an electrical wiring diagram, it is recommended to take into account a number of nuances:

- Important electrical components (panels, meters, sockets) are placed in easily accessible places so that it is possible to approach them at any time for prompt repair or replacement in order to prevent fire or short circuit.

- The location of the switches is selected so that they remain in open areas, not cluttered with furniture. Failure to comply with this rule is inherent in Soviet buildings - and to this day, “hidden” switches can be found in the house of a mother or grandmother. The ideal height for any switch is considered to be a distance of over 50 cm from the floor level.

- The location of sockets should be thoughtful, taking into account the location of all household appliances. The number of sockets should preferably correspond to the number of equipment, so that extension cords do not have to be used. According to the standard, one socket is enough for every 6 m². But if necessary, it is advisable to make more of them. Sockets are usually located at a height of 25-50 cm.

Option for the electrical wiring plan for the room, with a clear visualization of the location of sockets and lighting controls Source tehznatok.com

- It is necessary to exclude possible twists or numerous kinks in the electrical cable . The lines must be laid parallel and perpendicular to the floor, ceiling or walls, i.e. only straight lines with right angles. As a rule, bottom or top electrical wiring is used, i.e. the laying is carried out 15 cm from the floor or ceiling.

- Wire switching must be arranged in metal junction boxes. The use of plastic or wood products is prohibited.

Having thought through the location of household appliances in the house and outlining the wiring diagram, you can move on to the next stage.

Cable wiring, installation of sockets and switches

The cable is laid in accordance with the diagram. To do this, routes are determined in kind, that is, on the surface of the wall of the house, after which distribution boxes are installed and installation points for sockets, lamps and switches are marked. The cables used must have the appropriate cross-section to ensure full use of the system.

When laying cable wires in metal boxes or pipes, the interior of the walls must be finished. For hidden wiring, the use of corrugated pipes is prohibited, as this can lead to fire.

Laying cable wires in a pipe includes the following steps:

- preparation of channels (grooves). External distribution boxes are installed at the junction points of the wires to ensure open access;

- When laying cables between rooms, holes are made in the walls using metal sleeves with plugs. Metal sleeves suppress the fire, ensuring the circuit is closed.

When laying cable wires externally in pipes, the wires should not fit tightly to the surface of the pipes. They should be filled halfway. Electricians recommend using copper pipes because such products have greater flexibility, which is important during installation. Cut wires must be processed and stripped. The pipes are installed on the wall surface using clamps.

We are preparing a home electrification project

When designing electrical wiring for a wooden building, you should contact your electricity supplier to obtain specifications. Further work is carried out based on these indicators. They start by calculating the total power consumed by all electrical appliances at home, taking into account lighting sources.

Example of technical conditions for connection to electrical networks Source chebo.pro

We select devices and cables

You can decide on the right cable without abstruse calculations, simply using the data from reference materials on electrical engineering. The selection of the core cross-section is carried out based on the expected load indicators.

The power consumption level of any equipment or devices is displayed in the technical specifications. passports or operating instructions. Based on these numbers, a wire with the required cross-section is selected for wiring in a wooden house. The input cable is also selected by summing up the power of available electrical devices.

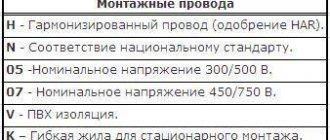

Recommendation! A little specifics on the question of which wire is best to use for wiring in a wooden house. You need to choose a cable marked with the letters “NG”, i.e. “does not burn” or “LS” indicating reduced smoke emission. The internal wiring of a private house is usually laid with wires having a cross-section of 1.5 to 2.5 mm.

Selecting an electrical cable

To ensure that the electrical wiring in a log house is truly safe, choose a specific type of cable for the power supply with the letters in the marking:

- NG, which means non-flammable.

- LS, that is, it has reduced smoke emission.

Now about the cross-section and number of wires in the wires, which directly depends on the power consumed by the electrical equipment.

- For lighting, it is laid from three-core cables with a cross-section of 1.5 mm square (3x1.5).

- For wiring to sockets you need a 3x2.5 cable.

- Cable for electric stove no less than 6 mm2.

- Nothing additional is connected to the wire supplying a block of sockets from 4 points or more.

- Completely separate from the rest of the equipment, the following are connected: a heating circulation pump and a water supply pump.

- Also, a heating boiler and water heater are subject to mandatory autonomous connection (if there is a need for them or in the absence of gas supply).

Calculating the power supply for heating equipment is quite complicated.

First, the power of the equipment (boiler) is calculated for:

- A certain volume of premises.

- Required temperature.

- Heat loss through house structures (floors, windows, doors, walls and ceilings).

Interesting! It is worth noting that the thermal conductivity coefficient of rounded logs is very low compared to stone and concrete. Therefore, heat loss through the walls of the log house will be minimal, of course, this is the case if the caulking was carried out in compliance with all the features of the process.

You can count on complete fire safety of a wooden home and efficient, uninterrupted operation of the electrical network only when the instructions are followed:

- Selecting cables and cable channels for a wooden house.

- The installation was carried out according to all rules and in accordance with the project.

Advice! Upon completion of electrical installation work, it is necessary to check whether the insulating sheath of the cables is damaged. To do this, measure the insulation resistance of the cores.

Electrical wiring in a house made of rounded logs should be subjected to a preventive check for insulation damage every three years to eliminate possible short circuits in the network.

Grounding

The presence in a wooden house capable of rapid ignition of a lightning rod and a grounding circuit is another important part of fire protection. And not only electrical equipment is subject to grounding here, but also metal channels and pipes through which wires pass.

Video description

Answers to the questions of which wire to use and what are the differences between single-core and stranded wires can be obtained by watching this video: The

input circuit breaker is selected so that the peak power load in the building does not cause a shutdown, plus 20-30% of the power reserve. Plus, the short circuit current is calculated, upon reaching which the circuit is guaranteed to break.

The selection of a machine for single-phase power supply occurs as follows:

- The sum of the powers of all household electrical appliances is calculated and the maximum current indicator is determined using the formula IHOM=P/U*cosф, where cosф corresponds to 0.8. The result increases by 10% and the resulting current strength will become the indicator at which the machine will operate. Usually it does not exceed 25A.

- Then the current level due to which the short circuit effect will occur is determined by applying the formula Isk=3260*S/L. Here S means the cross-sectional area of the wiring, and L means its length. This calculation is made on the longest section of the network with a minimum cross-section of cores.

- Circuit breakers are characterized by the current strength at the moment of a short circuit, divided by the rated current strength. The electrical network of almost any private home belongs to networks with a mixed load. The ideal circuit breakers for them are type “C” devices.

Types of circuit breakers Source vse-e.com

Installation of machines and power supply

In accordance with the drawn up diagram, distribution boxes are installed, fixing points for switches, sockets and electrical devices are marked. The base of the electrical panel is mounted in the designated location with the following steps:

- The counter is installed.

- The automatic input device is mounted on the metal profile. Phase and zero are connected to it.

- The terminals from the meter to the input machine are switched.

- The wiring is laid in a wooden house in a cable channel and connected to the meter.

- Automatic devices for all power consumption groups, RCDs and voltage relays are mounted on a metal profile or DIN rail.

Outside, cables for a wooden house are supplied by air or underground. The latter method will be cheaper, but its reliability will be lower. Input by air is made using self-supporting insulated wires. The main point that must be remembered is the arrangement of a fireproof sleeve at the point of entry into the building.

An example of connecting an electrical cable over the air Source fisenich.com

The underground connection is made through a metal pipe in order to protect the cable from the influence of environmental factors. The underground installation of electrical wiring to a wooden house must be coordinated with the energy company responsible for the site.

Connecting the power cable to the house underground Source emra.by

Electrical panel design

External wiring in a wooden house is connected to the distribution board. Next, the current flows to the equipment, which is responsible for the safety and accurate operation of the electrical system. For a wooden house, a metal box with 15 modules and a grounding bus is preferable.

Installation requires the following requirements:

- Location 120-140 cm above the floor.

- The back wall is tightly attached to the wall surface with self-tapping screws.

- If more than 15 modules are used, then two DIN rails must be installed inside.

Often RCDs are not installed, since in the presence of automatic machines it is not required. But electricians advise installing it. You will need it when you have to manually disconnect the house from the power supply.

Subtleties when installing hidden wiring

First of all, you need to clearly understand which cable to choose for a wooden house. Regardless of choice, it must have a non-flammable insulating coating. In addition, it must be placed inside a corrugated metal sleeve or solid pipe.

The most important thing during installation is to carefully and in accordance with the diagram make holes and cuts for corrugations, cables, junction boxes, sockets, switches, etc.

Most often, hidden wiring is carried out 15-20 cm below the ceiling level, but electrical points are placed at the discretion of the master or owner in order to make them as convenient and accessible as possible. The wire is fastened in the corrugation using special clips and self-tapping screws. There is another advantage of hidden wiring - it does not interfere with subsequent finishing work in the room.

At all points that require the presence of distribution boxes, switches or sockets, “tails” of up to 15 cm are drawn out in order to then make wiring and connections.

Important! When installing hidden wiring in a wooden house, it is better to use cables with a larger cross-section than required by the external installation method, because There will be no natural cooling inside.

Additional work

Electrical installation work is completed by arranging grounding and installing residual current devices (RCDs) to prevent network overload. The RCD reacts to the slightest change in current in the network, which may be a sign of a short circuit, and turns off the system. All work on the installation of electrical equipment must be carried out by specialists who will correctly calculate the power of the equipment and select everything necessary for installation.

It is important to remember that any electrical wiring requires timely repair and periodic replacement. It is recommended to change the wires every 10 years. In addition, you will have to respond in a timely manner to all alarm signals, such as sudden tripping of an RCD, heating sockets, the appearance of a spark, etc.

If such symptoms occur, it is necessary to take immediate action without waiting for a short circuit, which can be very expensive. And here one of the disadvantages of hidden wiring is fully manifested: detecting damage in this case will be much more difficult, and after any repair work you will have to rebuild the wall again.

Electrical installation in a private home is a responsible and dangerous task, so compliance with all precautions is necessary. It is extremely undesirable to save on calling a specialist: any mistake can lead to malfunctions in the electrical network, which will lead to equipment failure and other troubles. Faulty wiring is one of the most common causes of fires, so every owner should take care of safety.

Andrey Ponamarev

Author of publications on 1Drevo.ru with the topics: Polishing the house | Log house made of rounded logs | Insulation of a log house | Houses made of profiled timber | Houses made of laminated veneer lumber | Outbuilding made of laminated veneer lumber | Pine windows | Construction of a house from cylinders | Wooden floors | Cladding walls with clapboard | Porch | Material for home, etc.

Collections of publications on topics:

Wiring in a wooden house Electricity in a wooden house Electricity in a wooden house Electricity in a house Electrical wiring in a house

Was this publication useful to you?

Bookmark it on social networks!

Total score: 5Votes: 10

Calculator for building a house from rounded logs

How to build a combined house from rounded logs and timber

We recommend! — Encyclopedia Wooden Houses — NEW

You can find out detailed and expanded information on the topic of the article from the book “Wooden Houses,” which reflects all stages of building a house, from laying the foundation to installing the roof. Book price = 77 rubles.

You may also be interested in other BOOKS on building houses from wood with your own hands.

We recommend other posts on this topic:

Features of installing electrical wiring in a house made of timber

Requirements for placing an electrical panel in a residential wooden house

Which method of wiring installation should you choose: hidden or open?

Features of electrical wiring in a wooden house

What rules govern the entry of electrical cables?

Laying electrical wiring in a log house - hidden and open installation

Installation of grounding with a residual current device (RCD)

In addition to grounding the junction box, in order to ensure reliable protection of electrical appliances and household appliances, it is necessary to arrange a full-fledged grounding circuit.

Therefore you will need:

- three-meter reinforcing rods with a cross-section of at least 30 cm in the amount of 3 pcs.;

- a dug ditch in the shape of a triangle, about 50 cm deep and up to one and a half meters on a side;

- reinforcement is driven into the ground at the vertices of the triangle;

- the rods are connected to each other with a steel angle and fixed by welding;

- the resulting triangle of one of the vertices is connected to the house by a trench (of the same depth), into which the same corner is placed and welded to the contour.

Directly next to the building, the corner is welded to a meter-long reinforcing rod. Ideally, after burial, a 30 cm piece of rod should remain on the surface. A copper cable from the distribution panel passing through the RCD is attached to the end of this rod. The normal cross-section of such a cable will be 2.5-4 mm.

Example of ground loop equipment Source remontnik.ru

Common mistakes during installation work

Statistics prove that fires in wooden buildings are most often caused by errors and violations that occur during the installation and use of electrical wiring. These are mainly the following shortcomings:

- When installing in a hidden way, cables are laid under the ceiling without additional insulating measures. If the wire cross-section is chosen incorrectly, overheating and contact with the wooden surfaces of the interfloor ceilings occurs.

- When laying cables under regular skirting boards. Space is limited, the cable is in contact with the body of a wooden or plastic baseboard. To lay wiring in this way, it is recommended to use special skirting boards of appropriate design and with the necessary clearances.

- Rules for installing wiring in a wooden house prohibit the use of corrugated PVC pipes. Instead, it is necessary to use free cable channels or metal corrugations. Unfortunately, some home owners try to save money at this point.

Types of wiring in a wooden house

As in houses made of other materials, wiring can be installed in an open or closed way.

If all the rules of the PUE and the requirements of the safety regulations are observed, the latter option will require more time and money, which is what pushes “home-grown” specialists to commit violations. In fact, it is quite possible to make fireproof wiring. We will assume that the wiring plan is already available, the cross-section of the wires has been selected according to the expected load (how to make the necessary calculations is indicated on our website) and the only question left open is compliance with the necessary requirements and standards.

Test events

When testing electrical wiring, they use very precise electrical measuring instruments that have the appropriate certificates. Test activities consist of the following:

- visual inspection;

- measurements of resistance indicators on the surface of insulating coatings of wiring;

- measurements of ground loop resistance indicators;

- checking the correct operation in the phase-zero circuit;

- testing of automation and RCD;

- reading indicators in the “device-grounding” circuit.

Testing activities and commissioning of the electrical network are carried out by the governing body to which documents were submitted for permission to electrify the structure. After checking, the relevant specialist confirms the correct operation of the electrical wiring of the entire area. In fact, this is a guarantee that the work was performed with high quality, and allows the consumer to use the electrical network in full without any fear.

Carrying out electrical measurements and testing of the electrical network Source remstroy-blog.ru

Let's remember the main thing

Although the material presented gives a general understanding of how to properly install electrical wiring in a wooden house, it is important to understand that all the work described is quite complex and dangerous. Most of what is described will require utmost attention and constant concentration, because... Working with electricity can be dangerous to health and life at any stage. Therefore, it is recommended to leave the installation of electrical wiring in a wooden house in the safe hands of a qualified specialist. After all, incorrect work at any stage can lead to irreparable consequences.

Ratings 0

Development of project documentation

First, a power supply project is prepared. The data for it is obtained from the RES. Based on them, the electrical wiring project in a wooden house is calculated. The power of all equipment in the building must be taken into account.

Electrical wiring diagram.

Sequence of development of a power supply project:

- First, the plan indicates the location of all sockets, switches, lamps, and equipment with individual connections.

- A cable is selected individually for each point. A wire with three cores is used for a two-key switch and sockets with grounding.

- The location of installation of distribution boxes is marked on the plan with the calculation: one element for two adjacent rooms.

- The power of each installation is separately marked. If there is an electric motor, indicate its starting power.

- Devices are grouped by power. All lamps fall into one category, and equipment with increased power requirements falls into another. Separate machines are used for different groups.

- The plan marks the distance from all coverings (walls, ceiling floors), as well as windows and doors to the electrical wiring in a wooden house. In the future, focusing on the diagrams, it will be possible to prevent breakdowns of the electrical network during repair work.

Electrical wiring diagram in a wooden house.

Rotating the wires is only allowed at an angle of 90 degrees. Be sure to calculate the minimum load on the network when all equipment is operating simultaneously.