Warm water floor

In a wooden house you can make warm water floors.

They require a good foundation. Floorboards may not withstand the load on them from heating elements and concrete screed, on which a water floor is usually installed. To make the structure lighter, the heating cable (pipes) is placed in an “air cushion”. A warm water floor consists of hollow tubes through which hot water subsequently flows. It gives off heat to the floor and makes it pleasant to walk on.

In this case, seamless plastic, metal-plastic and metal pipes with a diameter of 16 mm are used. They are installed in increments that average 20-30 cm and are connected to a central heating system or an autonomously operating boiler with a pump.

The technology for installing a warm water floor consists of the following operations.

Thoroughly clean the boards of dust and debris, seal the cracks and cracks with wood mortar, knock together and strengthen the wooden floorboards. The floors are impregnated with an antiseptic, primed, and covered with a waterproofing compound. A heat-insulating fabric, for example, Penoferol, is laid on the subfloor, which is stapled onto wooden boards

It is important that the top layer is metallized. If this is not the case, then you should use foil. Then the pipes are laid and secured, connecting them together into a single system. Next, in the lower part of the room, a special damper tape is glued along the entire perimeter

During operation, the heated floor will heat up and expand. This may cause the concrete to crack. This tape will protect you from this. Next, pour the concrete screed, trying to hide the pipes, but not allow too much thickness (3-5 cm). This will make the wooden floor structure lighter.

In the house, such a floor can be made in any room. Concrete is an excellent conductor of heat. The water in the tubing system does not need to be heated to a high temperature. 40 degrees is enough. Even with such heating, it will be comfortable on a warm floor. Thanks to this device, the heat from the pipes will be reflected in the foil and transferred to the floor covering.

The length of one closed circuit recommended by experts should be no more than 80-100 meters. In rooms with an area of more than 30-40 m2, 2-3 circuits should be made. Otherwise, the liquid will cool quickly. For example, in a room measuring 6x6 m, pipes are laid in increments of 20 cm. The length of the circuit, taking into account the length to connect to the boiler, will be almost 100 m.

Laminate, linoleum, carpet and even tiles can be used as finishing material. If in the case of electric heating it is impossible to create a heavy load on the surface, then with an installed water system there is no need for this. Here you don’t have to specifically design the arrangement of furniture and furnishings.

A warm water floor can be made without a concrete screed, using a dry method. However, this method can lead to heat loss, since wood does not conduct it well. To avoid this, take the following steps:

- reduce the pitch between water pipes;

- create reflective surfaces (deflectors).

Warm floors in a wooden or stone house are an important part of the overall improvement. Thanks to it you can create a favorable atmosphere in your home

Water floor design for tiles

Warm water floors under tiles in a wooden house consist of a number of layers:

Waterproofing layer. The material depends on the method of installation of the system: if the installation is carried out on the ground floor and a screed is expected to be poured, you can use dense polyethylene or roofing felt. If the screed is dry, it is better to use a special waterproofing membrane.

- Insulation. It can be used as polystyrene foam or polystyrene foam.

- Metal heat distribution plates with pipe channels.

- Heated floor pipes.

- Solid base for tiles. Usually these are sheets of moisture-resistant plywood or plasterboard; a better option is gypsum fiber boards.

The thickness of a warm water floor under tiles in a wooden house can be different and depends on the insulation layer, the base, the diameter of the pipes and the type of screed. The height of a dry screed can start from 35 mm, which makes it a better choice for rooms with low ceilings, while the minimum height for a concrete screed is 80 mm.

Kinds

The design of a heated floor is a combination of heating components that are located under the floor covering and evenly heat its entire surface. Today there are two types of heated floors:

- electrical - heat is transferred from heating the conductors;

- water. Heat is supplied from heated water, which is filled with metal or plastic pipes. This flooring option cannot be installed in apartments, but it is perfect for country houses, as it has a number of advantages.

Electric heated floors include a heating element - there are cable, film and thermomats.

They differ from each other in the installation features and the level of energy consumption, which manufacturers are trying to reduce more and more each time, and they are achieving their goals.

Water floors also differ in installation technology:

- concrete technology - heating parts are hidden under a monolithic concrete screed;

- laying - several layers of different materials are laid.

What is better for a private home?

Owners of private houses have the right to independently choose the type of heating and water supply. Unlike apartments, where the use of water-heated floors is impossible, everything is permissible in your own home. You can heat the room with radiators, underfloor heating, or use a combined system.

A traditional heating system includes the operation of a boiler and a battery - radiators. It is also sometimes necessary to use a convector, thermal panels and other additional elements. This technology provides a good effect both during normal rotation of water and during operation of pumps.

The main advantage of this device is the simple installation and maintenance of the main pipeline. If you decide to use radiators as the main source of heat, then the only problem you will encounter is creating openings in the walls for the pipe to pass through.

A heated water floor in a country house is connected to the heating system according to a similar scheme, but has more advantages compared to radiator heating. A warm floor allows heated air to heat a room of any size, even a large area. And the convector heats the room unevenly, raising warm air upward. Moreover, the water system is much more economical in terms of energy consumption.

Another main advantage of a heated floor is that it does not take up space in the room; all its elements will be carefully hidden under the floor covering. Purchasing materials for its installation will cost less than materials for radiator heating. In addition, the convector dries out the air, but the warm floor maintains optimal humidity in the room.

Water heated floor under tiles on the first floor

A water heated floor in a wooden house under tiles on the first floor can be done with a concrete screed. When poured correctly, it does not connect to the base and does not have a negative effect during seasonal changes in the wood. Many experts do not support this idea and are inclined to believe that it is better to use dry screed, but, nevertheless, this technology continues to exist and is used quite often.

Even in a wooden house, a concrete floor has a number of advantages. It is more durable, does not deform or creak over time, and can withstand greater loads. You can easily lay any decorative covering on it, in particular tiles. Concrete screed transmits heat much better than dry screed, so it is not necessary to heat the water to a high temperature: already at a temperature of 40 degrees you can feel a pleasant warmth.

Water heated floor under tiles with screed for the first floor

A water-heated floor in a wooden house under tiles with a concrete screed is installed according to the following scheme:

- Preparatory stage. The old floors are removed and the base is prepared (cleaned and made smooth).

- Waterproofing is laid on the surface. The outer edges are placed on the walls, and the inner edges are overlapped and secured with mounting tape.

- A damper tape is installed along the perimeter at a height of two centimeters from the surface of the screed, compensating for expansion when heated.

- Foam or polystyrene mats are laid over the waterproofing. On the upper floors of buildings, where there is a heated room below, a layer of insulation 4 mm thick will be sufficient; on the first floor it should be made thicker - 8-10 cm.

- Heat-distributing plates are laid over the entire surface of the insulation, attached to the channels of the mats. Heated floor pipes are laid in their grooves.

- The ends of the pipes are connected to the heating system and checked for functionality and tightness.

- If the heated floor is ready for use, pour a concrete screed, the thickness of which should be 3-7 cm.

- At the end of the work, you must wait for complete drying, which occurs by 25-28 days.

- When the screed has dried, the tiles are laid.

Advice: for high-quality screed, it is better to use mixtures of grade M-300 and higher, which are characterized by high strength and allow you to create durable structures from concrete.

Features of heated floors in a wooden house

Accordingly, all layers of the “pie” will be laid on the support beams: subfloor, vapor and waterproofing layers, finishing treatment for laying the floor covering and the cladding itself. Naturally, among all these layers there will be a heating system. The underfloor heating system is laid on top of the rough base with an emphasis on preparing various protective and insulating layers for the system elements.

To install a warm floor in a wooden house with your own hands, you can use one of the following methods:

- A combination of dry and concrete screed. This is a universal technology that involves laying two types of screed at once, which allows it to withstand heavy loads on the floor. It can be used for a wide variety of heating systems. The dry bulk part of the screed allows for increased hardness and strength to protect the heating elements of the heating system.

- Liquid screed over existing floors. This is perhaps the most difficult method, as it requires careful preparation of the wooden beams. Concrete screed is highly valued due to its thermal insulation properties and increased heating efficiency of the entire system as a whole. It is most advantageous to use such a base in rooms with high humidity, cold and heavy flooring.

- Free installation with ventilation gap. It is used exclusively for heating equipment as an auxiliary system in relation to the main heating of the house. In combination with ventilation gaps, a powerful heating system cannot be used; additional holes as air outlets will reduce the efficiency of the system.

- Application of reflective plates. This option is a compromise if you cannot do without pouring a concrete screed. The plates are used to reflect the flow of thermal energy, increasing heating efficiency.

Requirements for installing heated floors in a wooden house

Wood as a building material has its own characteristics that must be taken into account when arranging a heating system:

- Wood is a highly flammable material and requires increased protection against open flames and overheating, which can occur in electrical wiring during a short circuit.

- If heated floors are laid under linoleum or carpet, you need to carefully study their composition before purchasing. Some varieties of these materials release harmful volatile compounds when exposed to high temperatures.

- It is not recommended to use materials with low thermal conductivity (for example, natural wood) as a top decorative coating. Heat will not penetrate well into the room, and the wood itself may overheat.

- The best option is to install a heating floor system under the tiles. There is also a specialized laminate on sale with higher thermal conductivity, which would also be a good option.

- Electric floors, with the exception of rod floors, cannot be installed in a room with a lot of furniture, since in this case the system may overheat.

There are four main types of electric underfloor heating:

- Cable systems that use wire in coils.

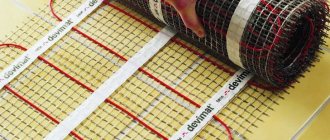

- Cable mats.

- Infrared film.

- Rod mats.

All floors powered by electricity can be laid in a wooden house, subject to compliance with the rules of electrical installation regulations and fire safety. Installation of film systems, as well as cable and rod mats, is usually carried out using the dry method on a flat wooden base; cable in coils is most often laid along logs. If it is necessary to lay the heating system on a concrete base, installation is carried out using a wet method with screed pouring.

When installing a heated floor with your own hands, you must comply with the following requirements:

- all contacts of heating elements must be well insulated; direct contact of the cable with wood is not allowed;

- the temperature inside the system should not exceed 30 degrees;

- It is necessary to exclude sudden changes in temperature; changes within 5 degrees are possible within a day.

When installing a heated floor in a bathhouse and sauna, increased safety requirements are imposed. There is high humidity in the steam room, and if installed incorrectly, the wires may short out, leading to a fire. Therefore, you need to pay special attention to waterproofing, and in general it is advisable not to make a heated floor in a bathhouse with your own hands, but to turn to competent specialists.

Features of laying electric heated floors on a wooden base

The popularity of installing electrical cable mats on wooden floors is explained by the fact that in this case there is no need to tear off previously nailed boards.

To do this, use one of the following methods to install heated floors on a wooden floor:

- Heating cables are laid on the wooden floor inside pre-sawed cutouts. The standard depth of these niches is 20 mm. Laying a cable heating system on a wooden floor requires relatively little material and time costs.

- On top of a wooden surface. To smooth out the unevenness of the base, plywood is laid on top of the floorboards. After laying the heating mats, you can use any of the listed finishing materials - laminate, parquet, linoleum.

What is important to know?

You can install heated floors in one of the following ways:

- on an existing wooden floor;

- on a wooden floor with an air gap (on joists);

- on a concrete base;

The choice of heating system will determine whether cement filling, leveling compound, tile adhesive or mastic will be required - that is, “wet” installation. The following types of heating elements are suitable for heating a wooden floor: infrared film, cable on a mounting plate, cut cable, heating mats.

Looking ahead, we note that the installation of heating mats requires a concrete base or cement-sand screed. This cannot be provided for in every wooden house, and perhaps only on the ground floor. Infrared film and cables on plates can be installed on wooden flooring. Cut-off heating cable can be laid either in a screed or dry (on joists). In the latter case, it is extremely important to correctly calculate the power. But here you can look at specific heated floors for a wooden house, which are suitable for the situations discussed in the review.

Installation of wooden floors with electric heating

Electric underfloor heating in a house can be installed in two ways:

- install heating mats;

- Place a heating cable on the floor.

In the first case, you can do the work yourself; installing a heated floor is easier and faster. The floor rises no more than 3 mm. This means it is ideal for rooms with low ceilings. However, such a heated floor system is characterized by low power, so it is used only as an additional source of heat.

When laying the heating cable, the floors are raised by more than 30 mm. It is not recommended to install them yourself under a wooden floor. It is advisable to consult a specialist.

Both types of heating can be done under any floor covering.

To install infrared mats, take the following steps:

- prepare a wooden base: eliminate floor unevenness, significant defects, prime;

- lay a layer of heat-insulating material;

- spread strips with heating elements evenly;

- install a heated floor temperature sensor;

- fix the cable;

- spread a thin layer of leveling mortar over the mats;

- then lay the flooring or lay tiles;

- Be sure to install a floor heating thermostat.

If you plan to lay tiles on boards with warm electric heating, it is recommended to apply leveler in 2 layers.

The heating cable is usually laid on a concrete screed made on a reinforcing mesh. It can be done over wooden floors. It should be taken into account that the floors will become higher by about 30 mm or more.

- a thermal insulation sheet or a heat-reflecting substrate is placed on tightly lying boards without obvious defects;

- then they throw the reinforcing mesh;

- a heating cable is attached to it with plastic stitches;

- concrete solution is poured on top and distributed in an even layer;

- after it hardens, waterproofing is spread;

- Next, they place a layer under a certain floor covering: under the tiles - glue, under the laminate - underlay.

In addition, you should install a temperature sensor in the corrugated tube and a thermostat.

There is another option for laying a warm electric floor on a wooden base: in a concrete screed created on top of the boards, on a mounting tape.

During installation and subsequent operation, it is important to follow safety rules, since electricity can harm people’s health and property.

Follow the instructions. Do not change the length of the cables on your own. Observe the temperature in the room: it should not be lower than -5 degrees. Before turning on the system, it is important to ensure that the screed is completely dry. The underfloor heating cable should not be located under heavy furniture.

Among the many advantages of an electrically heated floor, there are disadvantages of such a device. The main thing is high energy consumption during operation. If there is a need to create warm floors in the house, it is worth calculating everything several times and determining the possible benefits

It is important to find out the total cost of the system and electricity costs

Basic requirements for installing electric heated floors

Wood is a natural material that is highly flammable. Considering that an electric heated floor works on the principle of thermal radiation, which means that the cable heats up during operation, it is necessary to strictly follow the rules of electrical installations.

Scheme of floor installation on a wooden base

- Strict adherence to electrical installation rules will eliminate the possibility of wooden floors catching fire. In the absence of special skills, installation of electric floor heating options should be entrusted to specialists.

- The electrical cable should be laid on wooden floors, previously protected with metallized plates. In this way, it will be possible to avoid its contact with the tree.

Disadvantages and advantages of heated floors

Warm floors “work” throughout the entire area of the house, which allows not only to obtain a surface that is pleasant to the touch, but also to contribute to the overall heating of the home. When learning how to make a heated floor in a wooden house with your own hands, the owner will first assess the complexity of installation and compare the efficiency of water and electrical systems. The efficiency of full-fledged heating boilers significantly exceeds that of electric underfloor heating, which tips the scales not in favor of the latter.

Despite the huge number of positive reviews and recommendations, warm water floors also have disadvantages. They are related to the features of operation. Once you cover the floor with carpet or linoleum, the floor will immediately stop warming up properly. When laying tiles on a screed with pipes, it is worth considering that due to temperature changes, the glue may not withstand it and may crack. Another drawback is the high cost of flooring, amounting to about 1,500 rubles only for materials per 1 sq.m. The price, together with the work, can reach 3,000 rubles per 1 sq.m.

Some tips for safe operation

When planning the installation of heated floors, do not forget that neither electrical cables nor water pipes should be laid under heavy pieces of furniture. Also, you should not install heated floors in close proximity to a wood-burning, gas fireplace, stove or other heating devices.

For rooms for various purposes, you can program different temperature conditions, for example, in the bathroom and living rooms it will be comfortable at 22-24°C, and in the kitchen and corridor 20°C is enough

Practical nuances:

After completing the repair, you should leave the heating system on and maintain the same temperature for 3-5 days

This precaution will allow the entire floor “pie” to be heated evenly and thoroughly and ensure reliable operation of the system. At the beginning of the heating season, you need to properly prepare the floor heating system for operation. To do this, you should increase the heating degree by 5-7 units every day until the temperature reaches the required value.

This approach will avoid sudden temperature changes that can damage laminate and other materials. Similarly, the heating is turned off during the warm period. Do not forget that film infrared floors do not tolerate moisture well. Therefore, it is not recommended to install it in rooms with a humidity level above 70%, and after wet cleaning, wipe the laminate dry. The optimal temperature for heated floors is considered to be within 20-30 degrees.

And lastly, do not cover the heated laminate flooring with carpets or other furnishings that interfere with the effective distribution of heat.