More recently, natural wood was mainly used to finish the floor on the terrace, near the pool and in the gazebo, but now it is at the peak of popularity. deck board made of wood-polymer composite. This material is in no way inferior to natural wood in appearance, but in such characteristics as strength, reliability, durability and preservation of its linear parameters, it is far superior to it. In order for the decking board to serve for a long time and reliably, it must be laid correctly

Basic installation requirements

Although a WPC deck board is an analogue of natural wood, the process of laying it will differ from the installation of ordinary boards. A special feature of this material is the presence of a large amount of natural wood in its composition, so when temperature and humidity change, it will change its size.

During installation, it is imperative to leave compensation gaps , and fasten the boards only with the help of special assembly adhesives and self-tapping screws. Due to the fact that the material is used outdoors, fasteners must only be stainless .

There must be free space under the decking on which the decking board is laid to ensure ventilation . Since this coating is used outdoors, it is necessary to ensure good drainage; for this purpose, the base slope is about 1-2 degrees.

In order for water to drain better, logs are installed parallel to the drainage of water . If the descent cannot be done, then to create drainage, when installing the logs, plastic supports are placed under them.

The expansion gaps must not be covered with any materials. Contact of the flooring with the ground or lawn is not allowed; it is recommended that the distance from the boards to the ground be at least 8 cm.

Before installing the terrace board, it is necessary to properly prepare the base , this can be a concrete screed treated with a waterproofing agent, concrete slabs, a cushion of sand or crushed stone on which WPC logs are then laid.

If laying is carried out on logs, then the soil under the flooring must be treated with herbicides in order to completely remove the plants, or it can be covered with a special material that will not allow weeds to germinate.

The basis for the terrace board can be:

- concrete pillars or blocks that are laid on a compacted bed of sand or gravel;

- prepared base with sand cushion, concrete screed;

- monolithic concrete base;

- frame made of aluminum, metal logs or other materials that can withstand the corresponding loads

- operated roof.

Preparing the base for installation

The durability of the flooring directly depends on the quality of the drainage system. It is very important to create a concrete screed in such a way that water drains naturally. To do this, a slight slope is created in the direction of the logs towards the drainage pit or sewer.

You can check the quality of the drain immediately after pouring the screed and make adjustments if liquid accumulates on the surface. If the logs, according to the design, do not reach the drain, you can make a small gap between them (2-3 centimeters), into which the water will be drained.

If WPC deck boards are installed on the roof of a building, it is necessary to carefully treat the water-repellent layer. The fasteners must be in contact with it, and if there is no equipped drain, it can be cut directly into the covering. In this case, 2 cm channels will be used as a drain.

Technology and types of fastening

The simplest method is classic installation; in this case, the boards are mounted parallel to one another or at an angle of 30-45 degrees, which minimizes material waste. Even a beginner can cope with this task.

When laying using the deck method , the boards are mounted in a chaotic manner, but after 3-4 rows the end seam is repeated. The seam should overlap the next row by at least the width of the board. Material consumption will be minimal; pieces longer than 50 cm can be used.

When laying on deck, the consumption of lag increases, but the result is an unusual and durable coating; it is convenient to use over large areas if there are many obstacles.

Checkerboard laying is used in difficult areas and saves material. The symmetry of the seams is performed through one or several rows; the transverse seam can be repeated through a row in the middle or offset by 1/3 of the width of the board after two rows.

When performing multidirectional installation , the boards are laid perpendicular to each other. This method is recommended for use on sites that are long and small in width. artistic installation on your own, since this work requires special skills, but with its help you can create various ornaments and designs.

This coating can be attached in several ways:

- with the closed method, special clamps are used, they are inserted into the grooves of the boards and attached to the joists using self-tapping screws;

- with the open method , fastening is carried out with countersunk screws, which are screwed into the board from the front side and this is how it is attached to the joist.

Features of plastic decking boards

This material has a number of characteristics due to its production technology:

- the material is otherwise known as decking or wood-polymer composite (WPC). The name comes from the components used in production: wood flour (up to 80 percent) and monomers. All this is polymerized during production, but the pieces of wood cannot be processed, so they simply harden in the plastic mass. What is unique is that such an artificial material is not much inferior to natural wood and other materials produced on its basis (about

Tools and materials

To perform the work, you will need a standard set of tools:

- jigsaw or circular saw;

- drill;

- screwdriver;

- building level;

- roulette;

- pencil;

- mallet;

- extension.

In addition, you will need to purchase the following materials:

- terrace board;

- composite joists;

- special fasteners;

- finishing corner;

- end strips.

A few installation nuances

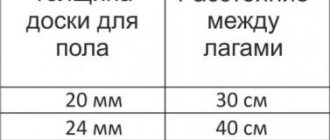

Regarding the distance between the lags, it must correspond to the load:

- With an acceptable (optimal) load, you should adhere to the range between the bars of 400 mm:

- With a passage of 300−350 mm:

- At high - 150−200 mm:

- The bars can be wooden, plastic or aluminum. The base from which they will be produced varies depending on the choice of foundation load. For medium loads, logs can be wooden or plastic;

- under high loads, it is more rational to use stronger materials. The size of the installed bars must be at least 40 mm.

Next, the material is attached to the bars. The first board is secured with a curly nail or special clips.

Curly nails

The repairman makes the place for attaching the first board himself. Here's how to attach a larch deck board. The second and all other boards must be secured with clips to the previous analogue. When installing the boards, all ends of the bars are closed.

Thanks to this, the flooring becomes as interesting as possible, which allows you to implement even the most daring design solutions.

Installation process of polymer boards, instructions

First, a flat surface is prepared; it can be concrete slabs, screed or sand cushion. The base must be sloped or for drainage; supports will need to be placed under the logs. When laying on the ground, use a material that will not allow weeds to germinate.

To lay WPC decking boards, you must use special composite logs. If the length of the surface to be covered is large, then the logs are laid end-to-end, not connected to each other, and a gap of 6-7 mm is left.

A gap is also left between all fixed stops. The distance between the lags should be about 300-350 mm, if the load on the floor is high, then it is reduced to 250 mm, and when laying diagonally, the distance is 200 mm.

The logs are laid on a clean, dry and level base parallel to the drainage of water.

The boards are fastened perpendicular to the joists; starting clips are used to fix the first board. The screws cannot be screwed in very tightly; the first board is attached to the starting clamp. Further installation is carried out using clips that are fixed on the joists.

It is necessary to leave a gap between the longitudinal joints; if the terrace is long, then the boards are laid end to end and a gap of about 6 mm is also left. The last board is cut to size, after which it is fixed to the joist using self-tapping screws, screwing them in at an angle of 45-50 degrees. This fastening will then be closed with a corner or end strip.

The gap between the profile and the fixed stop must be at least 2 cm.

The board can protrude no more than 50 mm beyond the edge of the joist, the end part is covered with a bar or corner, and side plugs can be used.

Finishing the installation process

Once the installation of WPC decking is completed, it is necessary to carry out final steps that will eliminate any imperfections created during the installation process.

This is the only way to obtain a beautiful coating that you won’t be ashamed to publish in a photo on a social network or present to guests. No one will doubt the quality of the work performed.

It is worth noting the following elements that will help improve the appearance of the flooring:

- plugs that allow you to close the cracks at the end of the flooring;

- it is more practical and cheaper to use decorative strips that cover the entire edged part of the boards;

- a more expensive option is composite corners, which are almost identical in appearance to flooring boards. However, the design of this element is such that it requires a certain space. It can be compensated by increasing the gap between the flooring and the nearest obstacle;

Naturally, it is necessary to select plugs depending on the thickness of the WPC decking board, but most often these are standard sizes. Upon completion of work, it is necessary to clean the coating from construction waste, dust, debris, etc.

It is important to remember that any mistake during the installation process can result in negative consequences during operation. The biggest mistakes result in a reduction in the service life of the flooring, which according to the standard should last more than 25 years.

Flooring on an exploited roof

After installing a usable flat roof, you can proceed to the stage of laying the finishing coating. Recently, most often for these purposes, WPC decking boards are used, which feel great outdoors, are strong, reliable, durable and beautiful.

Regardless of what type of covering you choose, a parapet is installed on the roof in use along its entire perimeter , which will simultaneously perform a protective and decorative function.

To lay the decking board, it is necessary to prepare a flat base, which should have a slope towards the edge of the roof. The base can be covered with a screed and leveled with crushed stone, after which support posts are installed and logs are attached to them. Using adjustable posts allows the joists to be aligned with the sloping base, resulting in a smooth finish.

The logs should be laid with the groove up and the corrugated side towards the base; this will help install the self-tapping screw when attaching the clip to the center of the log.

It is impossible to rigidly attach the logs to the base ; it is recommended to use steel or aluminum brackets, which are installed at intervals of 1 m. Using a decking board on an existing roof is very convenient; you practically do not need to take care of it, since all the dirt will be washed off during rain. Experts recommend planning the creation and arrangement of a serviceable roof at the design stage of building a house.

Recommendations for preparation for installation

Before laying the decking board with your own hands, you need to decide on the place where the decking will be installed. Depending on the nuances of the base, a material of appropriate density is selected. Often, the manufacturer offers instructions for laying decking boards, which indicate the optimal conditions for using a specific type of coating.

For example, balconies and loggias can be covered with medium-density boards, since the rooms are not heavily trafficked. The same flooring is suitable for treating the area around the pool, since no one walks there in heavy shoes, and bare feet or flip-flops will not be able to deform the covering.

It is worth remembering that the moisture resistance of a board is directly proportional to its density, since dense material does not absorb moisture well and has low evaporation.

Therefore, it is necessary to carefully consider whether the board is suitable for a specific location and how appropriate its installation will be. Particular attention should be paid to areas near gazebos, residential buildings or on terraces, which are characterized by intense traffic from residents and their guests.

Operation and care

It is very simple to care for such a coating; for this, a brush is used, the movements of which are carried out in the direction of laying the boards. Domestic sinks can be used, but the water pressure should not exceed 80 bar. Do not use solvents, aggressive detergents or stain removers.

It is necessary to ensure that the gaps are clean, otherwise moss may appear in them. To prevent the development of moss, the surface must be cleaned regularly. To ensure that the flooring wears evenly, it is recommended to periodically rearrange the objects on it.

If greasy stains appear, they must be removed immediately; household degreasers are used for this. When a stain appears, it can be sanded, and after a while, the discolored area will become equal to the color of the main coating. To remove scratches, you can use a metal brush, but before doing this, the boards must be well wetted; over time, the color of the treated area will even out.

Laying

Installation of the material in question is carried out exclusively on a solid base. This can be a simple concrete or cement screed. Here is about cement GOST 31108 2003.

Concrete base

The technology for laying the above-mentioned plastic terrace boards is quite simple and does not require a certain level of training from the master to achieve the intended goals.

Shchebnevaya

Gravel

Any of the materials described above should be poured into the prepared ditch prematurely. Its depth is determined by the owner himself during installation.

During construction, you also need to take into account the minimum depth of the ditch, which should be at least 15 mm. If you take measurements at random, then this is approximately half of the device for digging the earth. Of this volume, approximately 1/2 should be allocated for the embankment.

The rest is occupied by the screed, which will be located below ground level. The screed is not poured in a perfectly even layer; it does not need to be made the same as for residential premises.

Building the internal supporting structure

This is necessary so that any precipitation, technical water or other liquids do not remain on the coating, but quickly leave it. To create a slope, use beacon profiles. You will also be pleasantly surprised by the prices.

When installing flooring for terraces and special paths, the screed must be dried. Preferably at least 7 days, subject to acceptable weather conditions. It should be dry and sunny outside, at most cloudy.

Here's how long it takes for the screed to dry. This can last at least a month. After the solution has completely dried, you need to immediately install the logs; they are essentially aluminum or wooden bars.

The second option allows you to do it yourself and it will be much cheaper. The bars are necessary to create a high-quality base.

Installation of logs

It is necessary to maintain the level of the bars on which the plastic decking board can be installed without problems, and the slope will be adjusted in the corners. This must be taken into account when creating a screed. In this case, the main thing is that the water drains not only from the foundation, but also from the coating.

Plastic decking boards, the manufacturer of which indicated the need to maintain the optimal distance between adjacent bars, are installed today in many houses or cottages.

Advantages

Today on the modern construction market there are many manufacturers who can let customers purchase goods from them. Therefore, the price of a plastic decking board from the manufacturer will differ significantly from what you will be offered in the store.

In specialized shops and on virtual networks you can see a variety of prices for one linear meter of material. As already written above, plastic boards have a significant advantage: resistance to moisture. Even if it is completely immersed in water, the material will not rot or deform in any way.