A simple staircase made from decking boards is a relatively inexpensive but interesting design that you can make with your own hands. Such structures are suitable for gazebos and verandas, serve as an excellent addition to the porch, and are used as elements of the interior interior.

In terms of external texture, the deck board imitates natural wood, although it is a composite material. Thanks to the properties and technical characteristics of WPC (wood-polymer composite), it is ideal for exterior decoration, does not require special care, and is resistant to humid environments and temperature changes.

What is a terrace board

In the assortment of construction stores, decking boards are found under the abbreviation DPK, which stands for wood-polymer composite. Professional finishers call such a board decking. The building material is made from wood chips, polymer resins, pigment components and fillers. Before becoming a finished product, raw materials undergo multi-stage processing, turning into a monolithic material with high strength values.

The advantages of steps made from decking boards are as follows:

- resistance to linear deformation - retains its original appearance and consumer properties even with intensive use;

- textured surface - this structure allows you to save on anti-slip rubber pads;

- neutrality to any external environment - the composite composition does not attract rodents and harmful insects, and is resistant to the appearance of fungus and mold;

- variety – there are no uniform standards in the manufacture of composite boards, so products of all sizes and colors are available for sale;

- safety – the composition does not contain chemically active substances and components, so WPC will not create problems for people suffering from allergic reactions or pathologies of the upper respiratory tract;

- simplicity - installation of the board is quite feasible on your own; during operation, the material does not require special care.

Of course, it was not without some drawbacks. The disadvantages of decking are low resistance to mechanical damage and high cost. The second drawback can be justified by the long service life - at least 15 years, according to manufacturers.

Installation of a porch made of WPC

If you decide to choose a wood-polymer composite for the construction of a porch, pay attention to a number of nuances that need to be taken into account.

- The right foundation is critical. To do this, you need to either pour it, weld a metal frame, or install steps on an existing concrete base.

- The next important point is the height of the porch. The platform should be made 50-70mm below the door level so that the door opens freely and does not spoil the surface.

- Pay attention to the calculations of the upper porch area so that the door can be opened outward. To take into account the correct depth of the porch, you should add 40-50cm to the depth of the door leaf.

- The height of the steps should be comfortable for each family member. One of the best height options is 15cm, with a tread width of about 30cm.

- To make the WPC porch safe, complete and beautiful, pay attention to the fencing of the steps and the installation of railings. Ecodeking products fully take this point into account. We have developed several types of components that can be assembled and created your own unique style, which will take into account not only the visual component, but also durable protection.

- The finishing of the side parts of the porch can be done from planken or WPC terrace boards.

Preparing the tool

It is impossible to make a porch from a terrace board with your own hands without a certain set of tools. It is impossible to predict all the nuances that may arise during the work process, but at the initial stage it is better to stock up on the following types of tools:

- screwdriver;

- hammer drill with a set of drills of various diameters;

- a circular saw and a fine-toothed disk or hacksaw to cut the board;

- hammer;

- building level;

- roulette;

- fasteners recommended by the decking manufacturer.

In addition, before starting construction, it is necessary to prepare a project for the future structure and draw up a detailed drawing. Don’t forget about personal protective equipment: gloves and goggles are mandatory attributes for any home handyman.

Decorating the porch with a terrace board

Making your own porch from decking boards

WPC is an excellent choice for designing large-area flooring. But, in this case, it is better to use a special type of product, which is equipped with special grooves at the ends. It is these gaps that help form a flat plane.

Installation of WPC with grooves is carried out simply according to a special scheme, which is much faster to do than making a porch out of brick or using clinker.

As you can see, installation is quite simple, but before you get started, familiarize yourself with the following subtleties of this process:

- Always leave a small gap of no more than 1.2 cm between the canvases. Don’t worry, because after a year such gaps will not be so visible, but they will protect your material from distortion.

- Do not use a blade less than 20 cm long for work. If the boards are too short, the risk of deformation of the coating will increase.

- The width of the WPC depends on the length of the flooring being covered. Most often, for lengths up to 12 m, a canvas 30 cm wide is used.

Well, are you now convinced that using decking boards helps in creating a high-quality staircase design, and also extends the life of the flight of stairs and makes them more attractive?

Building materials and additional elements

The staircase is part of the building structure, so such flights must comply with the requirements of SNiP. Without going into technical details, the following standards apply to the steps:

- width from 250 mm;

- height no more than 200 mm;

- the recommended angle of inclination of the stairs is 26–45 degrees;

- railing height no more than 110 cm;

- the distance between the vertical elements of the barrier is 100–150 mm.

It should be clarified that these are not mandatory, but recommended requirements, so each master can design a staircase from a decking board according to individual dimensions. However, the characteristics listed above are considered optimal for convenient and safe operation.

In addition to the tools and basic materials listed above, the work process may require hardware, clamps (metal or plastic clips), end caps, profiles and corners.

Stages of installation work

Installation of decking begins with preparing the base. To prevent the porch steps from sagging after a certain time, a small foundation is poured under the stairs. While the base dries and gains strength (on average 1–2 days), you can start preparing building materials and sawing the WPC according to the required dimensions.

Installation work is carried out according to the following scheme.

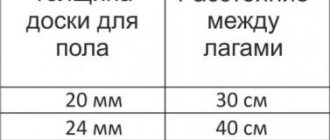

First, the logs are laid. These elements are mounted directly to the base, fixed to the foundation with self-tapping screws or dowel nails. The location of the joists should always be parallel to the staircase descent. Recommended distance between individual elements: 40–50 cm. Logs are necessary for laying the porch and steps.

When the installation of the frame is completed, steps are laid from the prepared decking board.

Note! Work is always carried out from the porch to the base, the starting step is attached to the surface of the porch with clamps.

After the first, the second and subsequent stages are installed. The second decking is also attached to the joists with connecting clips, maintaining a small gap between the steps of 15–20 mm. This distance is maintained throughout the entire flight of stairs. The gap is designed to compensate for the expansion of the board caused by temperature.

Install risers. A metal corner is placed between the steps, which will serve as the basis for attaching risers: vertically located boards that give the stairs a more interesting and complete look.

At the last stage of construction, the end parts are covered with decorative overlays, which are screwed to the terrace board with self-tapping screws.

Design options

The attractiveness of WPC for the construction of stairs is due to the fact that this material allows the implementation of any design solutions. From the decking you can make a standard rectangular staircase for the porch to the house or make a twisted composition that will gracefully go to the second floor.

It is noteworthy, but risers for decking stairs are not a prerequisite. The free space between the steps gives the structure an original appearance.

As a fence, you can use traditional vertical balusters made of solid wood with figured cutting and wooden or plastic railings. If funds allow, you can order a metal fence, for example, artistic forging.

Porch design

The porch can be made either very small - just a flight of stairs, or a complex system - several flights, railings, terrace, veranda.

Outdoor steps for porch made of WPC

WPC elements will find their application in any of the designs. That is, from a wood-polymer composite you can make a wide variety of porch options for your home.

In general, the design of a WPC porch consists of:

- Frame structure;

- Main steps;

- End parts of steps (risers);

- Fencing system.

Based on the chosen project, the entire porch or only part of it can be made from WPC.

WPC porch fencing

Moreover, if you have an old staircase, you can update it by using elements made of wood-polymer composite.

Flights of stairs

Full flights of stairs or individual steps can be made from elements of a wood-polymer composite.

Closed version of the WPC staircase

The march design can be free or have side walls.

Open version of the WPC staircase

Unlike the closed version of the flight of stairs, the open type does not have risers.

Porch frame

The frame for a porch made of WPC can be made from:

- Metal;

- Monolithic concrete;

- Blocks;

- Brick;

- Tree.

The metal frame for the stairs is made of profiled metal pipes or galvanized profiles.

Metal frame for stairs

Wooden frames are made of logs, timber, boards.

Wooden porch frame

As a rule, the main porch structure is made of monolithic concrete, blocks or bricks, which is then sheathed with WPC elements.

WPC fencing

Products made from wood-polymer composites used for fencing structures are distinguished by a smooth surface without defects or irregularities. In appearance they are identical to natural wood.

WPC porch fencing

In addition to the fact that fencing elements made of WPC have all the advantages of this material, they can be mounted in structures of various shapes.

WPC fencing options for porch

The modular system of products allows installation quickly and simply, according to the instructions that are usually included with the sets of elements.

Modular porch fencing design

The parts can be used to create structures for complex and non-standard shaped systems of porches, terraces, and verandas. And also combine different types of fencing.

Combination of different types of WPC fencing for porch and terrace

In addition to the main elements of the porch, related components are made from wood-polymer composite:

- Decorative corners and strips - necessary for finishing the end and side surfaces of boards. You can match them to the tone of the main board or choose a contrasting option. These parts are fastened using self-tapping screws, sealants or glue.

- Support logs - used as support when constructing steps or flooring. Since they are also made of WPC, they have all the properties of this material.

- Shock-absorbing pads - required to prevent boards from squeaking.

Before installation, it is also recommended to purchase special fastenings for WPC products.