In the construction of a brick structure, the frost resistance of the brick is not the main, but significant factor influencing its choice, especially if it is used for laying external walls. Weather conditions are constantly changing, the temperature regime is not stable, which most exposes brick buildings to the risk of accelerated wear, cracks and a decrease in their service life.

Why is frost resistance important for brick?

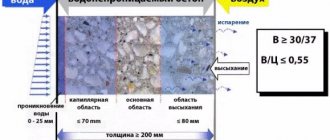

The concept of frost resistance refers to the ability of a substance or material to withstand defrosting/freezing cycles without loss of properties: structural damage, deterioration of strength and the appearance of visible external damage. The fact that frost does not destroy dry bricks is taken into account. The structure of the material contains porous formations into which water enters, freezing during frost and destroying the stone, since in the ice state it occupies a larger volume than in the form of a liquid.

The frost resistance grade is designated by the letter F and a number. According to GOST construction standards, the following grades are distinguished: F15, 25, 35, 50, 75, 100, 200, 300. Frost resistance can only be correctly determined by testing in laboratory conditions. The technique is step-by-step and consists in the fact that the sample is first kept for 8-9 hours in cold water, and then placed in a refrigerator at a temperature of -20 degrees. At the end of each stage, the material under study is checked for the appearance of external changes. Thus, a sample labeled F50 means that this species can withstand 50 freeze/thaw cycles without deformation.

Frost resistance of bricks

One of the main performance indicators of ceramic wall materials is frost resistance, which determines the durability of buildings and structures.

According to GOST 530–2012, ceramic bricks and stones must be frost-resistant and, depending on the frost resistance grade, in a water-saturated state must withstand at least 25 without any visible signs of damage or destruction (cracking, peeling, spalling, spalling); 35; 50; 75 and 100 cycles of alternating freezing and thawing. Thus, the following frost resistance grades have been established: F25, F35, F50, F75, F100 (grades F200 and F300 for clinker bricks). The frost resistance grade of facing products must be no lower than F50 (by agreement with the consumer, F35 is allowed), clinker bricks should be no lower than F75. That is, according to GOST 530–2012, there is a quantitative assessment of frost resistance - the number of cycles of alternating freezing and thawing, expressed by the frost resistance brand.

According to EN 771-1:2011, the manufacturer indicates only the frost resistance class of the brick, taking into account the use of masonry or its elements in non-aggressive, moderately aggressive and highly aggressive environments (Table 1). For LD bricks, frost resistance is not standardized. The concept of frost resistance grade is not used in EN 771-1:2011. A qualitative assessment of frost resistance is provided: the brick corresponds to class F2 if it can withstand 100 cycles of alternating freezing and thawing, otherwise the product is assigned class F1. The frost resistance class is indicated by the manufacturer in the product documentation.

Table 1

| Class | Wednesday |

| F0 | Non-aggressive environment. Masonry that is not exposed to moisture and alternating |

| F1 | Moderately aggressive environment. Masonry that is exposed to moisture and alternate freezing and thawing, but does not apply to structures in a highly aggressive environment. |

| F2 | Highly aggressive environment. Masonry that, due to strong exposure to rain and groundwater, is saturated with water and at the same time is subject to frequent alternate freezing and thawing and does not have effective protection. |

Domestic assessment of frost resistance is carried out in accordance with GOST 7025–91 “Ceramic and silicate bricks and stones. Methods for determining water absorption, density and frost resistance control” based on the degree of damage to the tested products after alternating cycles of freezing and thawing. This standard provides two methods for determining frost resistance - volumetric and one-sided. In this case, the main method is volumetric freezing: a quantitative assessment of frost resistance is made, i.e. The product brand is determined by frost resistance. The required number of samples is subjected to water saturation and then alternate freezing and thawing. The degree of damage to the samples is assessed every five cycles.

Standard EN 772-22:2006 “Methods of test for masonry units – Part 22: Determination of freeze-thaw resistance of clay masonry units” provides for the determination of frost resistance during one-sided freezing of a structural fragment assembled from the test brick, as closest to natural operating conditions tested materials.

The test is carried out automatically in a climate chamber. The test mode is established by EN 772-22:2006. The test samples are pre-saturated with water, then a wall fragment is assembled from them using a cement-sand mortar or using foam rubber as a material for seams. Then a test is performed that involves alternating phases of freezing and thawing with simultaneous irrigation of the test fragment with water. In this case, there is a qualitative assessment of frost resistance, i.e. the material corresponds to class F2 if it can withstand 100 cycles of alternating freezing and thawing. Only a visual assessment of damage is carried out, which should not exceed permissible values. Damage assessment after less than 100 cycles can be carried out for products that are declared suitable for use in moderately aggressive environmental conditions (F1).

Signs of damage given in the technical requirements section of GOST 530–2012 “Ceramic brick and stone. General technical conditions”, clause 5.2.7, are cracking, peeling, spalling, spalling, while in the mandatory Appendix B of the standard there is an additional sign of “crack”. It should be noted that the damage drawings given in the Appendix are taken from the draft European standard EN 772–22 “Test methods for building blocks. Part 22. Determination of frost resistance of ceramic bricks”, where the method of one-sided freezing is given. All this leads to ambiguity in assessing the frost resistance of the tested materials and unpredictability of the results.

There are also differences in the number of samples taken for testing. So, for example, according to GOST 530–2012, 35 bricks (25 stones) are selected to evaluate the appearance, dimensions of products and deviations; to determine the compressive strength - 10 bricks (5 stones). According to EN 771–1:2011 this quantity is 10 samples for dimensional determination and 10 samples for strength testing, etc.

The review shows that testing methods, as well as quality indicators of ceramic wall materials in accordance with Russian (GOST) and European (EN) standards differ significantly. GOST 530–2012 notes the presence of provisions borrowed from EN standards. It is obvious that work on harmonization of GOST and EN standards for ceramic wall materials will continue. In addition, the EN standard does not standardize any indicator of the quality of a ceramic product - all of them are declared by the manufacturer, which does not improve the quality of the product.

The choice of test method should be determined depending on the climatic zone and operating conditions of the materials being tested. It should be noted that the humid climate zone is the most aggressive compared to the normal and dry climate, and therefore products used in this zone should be tested only by the one-sided freezing method.

What does it depend on?

The frost resistance of a material is influenced by 2 factors:

- chemical composition;

- shape and size.

Material composition

Manufacturing technology is the first thing that affects the quality of the material. Companies producing building materials use equipment that changes production technology. In creating bricks, special dispersed additives are used that prevent the liquid from hardening. The second factor is the quality of raw materials. The better the clay and sand, the higher the resistance index: a sample made of kaolin clay is considered non-frost-resistant, and material containing a high content of quartz and calcium silicates has a frost resistance level 40% higher than ordinary.

Sizes and shape of bricks

The standard material size is 25x12x6.5 - this is single. To speed up construction, one-and-a-half and double versions are made, which are 30-40% higher than the ordinary one. The concept of the shape or size of a brick refers to its fullness or porosity. The more holes and pores the finished material has, the less frost-resistant it is.

Laboratory tests have proven that the frost resistance of sand-lime brick is 2-3 times higher than that of ceramic brick.

Material grades

The main property of each type of brick is strength. This concept assumes that there is no destruction of the material structure and deformation under load and internal/external influences of various natures. According to construction standards, this parameter is designated by the letter M and the corresponding number, which measures the load withstood by the sample per 1 cm². GOST established 8 strength grades: M-75,100, 125, 150, 175, 200, 250, 300.

Brand of brick. Strength and frost resistance

Home » Tips » Brick brand. Strength and frost resistance

print version

The brand of brick allows you to determine its strength and is indicated by the letter “M” and a number (from M75 to M300, the higher the number, the stronger the brick) and frost resistance - that is, the ability to withstand a certain number of freezing/thawing cycles. The frost resistance of bricks is indicated by the letter “F” and a number (from F15 to F100); facing bricks do not have the F15 grade.

The strength of a brick is the main property of a brick to maintain its shape without deformation and destruction under certain internal loads, such as compression and bending due to the presence of layers of mortar, and other influences.

Strength grade is the main indicator of a brick. The strength of a brick is determined by the digital value next to the M marking. It can be M75,100,125,150,175,200,250,300. The numbers show the pressure in kilograms per 1 cm2 of surface that a given brand of brick can withstand.

Accordingly, a fence can be built from brick of grade M-75, and a multi-storey building - from brick of grade no lower than M-150, while stronger bricks are placed at the base of the building and foundation, since the lower floors can withstand the load of the upper ones, and the upper one part can be made of M-100 grade brick. Also for interior work - load-bearing walls are made of M125-M150, and internal partitions are made of M-100. M-200 brand bricks are used for the construction of elevator shafts and chimneys and meet the highest quality requirements.

Different bricks (solid or hollow) that have the same strength rating will have the same strength properties. You can independently check the strength of a brick by throwing it onto a wooden surface from a height of human height. A durable brick should not break.

The frost resistance of a brick determines the number of freeze/thaw cycles that a brick undergoes without signs of deformation, loss of strength or weight loss, which is essential in our climate. In this case, the brick is placed in cold water for 8 hours and, after it is saturated with water, it is frozen in a freezer at a temperature of -18°C for 8 hours, then thawed in water for 8 hours at a temperature of up to +2°C and frozen again.

The brick is saturated with water because the frost resistance of any material depends on its water absorption, because everyone knows that water, freezing and thawing, destroys it. Brand F15 means that a brick with these characteristics can withstand at least 15 freeze/thaw cycles. For our latitudes, it is recommended to use bricks with frost resistance of at least F35, while the facing brick, as well as bricks for basements and plinths, should be grade F 50.

It is important that hollow bricks cannot be used for external structures, such as a plinth or foundation, since water entering its voids will accelerate destruction. You can check frost resistance by hitting the brick with a hard object. The sound of the impact should be clear and clear, which indicates the good quality of the clay and firing, and, accordingly, frost resistance.

Types of bricks and their frost resistance

Factories produce 15 varieties of material, each with certain characteristics, but the following are most often used:

- Full-bodied. This is an ordinary building brick, which is characterized by low porosity, in contrast to hollow brick. Samples marked M200-300 are used to create heavy structures and poles. Solid brick is characterized by frost resistance F50-75, which allows its use in various branches of construction. For external walls, it is necessary to lay brick in 2 layers and insulate it.

- Hollow. Its distinctive feature is the increased number of holes in the structure. The shape of the voids varies from cylindrical to oval and rectangular. It has a high ability to conduct and retain heat, but is used for lightweight structures, cladding and interior partitions. The frost resistance of hollow bricks varies from F15 to F50.

- Silicate. Made from lime and impurities, it costs less than ceramic. It is not resistant to moisture, but this can be removed with waterproofing. Its frost resistance is from 15 to 50 cycles.

- Facade. Facing bricks are used to lay out the front parts of buildings: it conducts heat poorly, but it is resistant to sub-zero temperatures. The frost resistance of this sample is from 25 to 75 cycles and the cost is much higher than that of ceramic bricks.

For cladding the facades of large buildings, laying roads and streets, clinker stone is used, the strength of which reaches the value of M-1000. This material is characterized by the best frost resistance among all types and can withstand up to 100 cycles. To create furnaces, fireproof and fireclay bricks are used, which do not collapse under the influence of high temperatures. Their frost resistance is F15 - F50. When choosing a material, it is advisable to focus on weather conditions: if there are no severe frosts in the area, reaching 40 degrees, it is not advisable to choose too stable options and overpay extra money.

How is the frost resistance of bricks determined?

The frost resistance of bricks is determined in several main ways:

- standard method. From the batch of material to be tested, 5 bricks are selected and placed in a special freezer. After several cycles of freezing and thawing, the degree of change in the strength of the stone is determined, which makes it possible to evaluate frost resistance;

- accelerated method. Samples of the material are kept for 4 hours in a previously prepared solution of sodium sulfate. After this, they are placed in a drying cabinet and cooled. The number of such cycles directly depends on the brand of brick.