At the initial stage of construction, the necessary materials are selected, their features, cost and dimensions are analyzed.

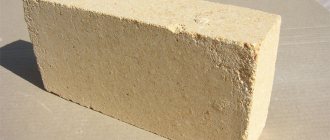

Single solid building brick m 150 is distinguished by its improved performance characteristics, texture, required dimensions and universal external features , and therefore it has found its application in various fields.

Many people use it to decorate the facade, while others use it as a basis for finishing with decorative elements. Regardless of the stage of construction, it is important to consider not only the size of a single brick, but also its other characteristics.

Features and Specifications

Single solid building brick m 150 is considered the most strong, reliable and durable material.

M-150

Its color can be completely different, from red to ivory, thanks to which the building material has found its use in various fields of construction. Here is the weight of the red brick. The shade depends on the components that are included in the clay mass.

Various colors

If we take into account the technical characteristics, then single brick is ideal for work on creating the base of the structure, as well as for the construction of load-bearing walls and partitions.

It is quite affordable and versatile, therefore, it has been actively used by builders for more than one year in a row. Before you agree on the supply of 150 grade briquettes, pay attention to its main technical characteristics.

Maximum strength

The briquette can withstand a variety of permissible loads, and at the same time it will not lose its original characteristics. Its strength is described by a peculiar number that comes after the letter “M”. This indicator must be indicated during production.

Maximum strength

A single briquette can be operated at a working pressure that should not exceed one hundred and fifty kilograms per sq/cm of working area.

The number also indicates the permissible and maximum pressure that an ordinary brick can withstand when compressed. Here is its size. You can pay attention to other briquettes; an increase in strength figures will be directly related to an increase in digital indicators.

Density

Many builders are primarily interested in this indicator. Single brick is marketed in two types: solid, and also with formed voids. This is the size of a solid brick. If they are present, the briquette is distinguished by its maximum heat retention and sound insulation properties, in other words, its density will be reduced.

So brick 150, as well as all analogues with number 75, are used by builders for the construction of low-rise buildings, and they have also found their application in individual construction.

If the density of the briquette is 150 or higher, it is rational to purchase it for the construction of walls in multi-storey real estate, as well as for the base.

Resistant to temperature changes

Resistance to temperatures below zero is characterized by a cycle of freezing and thawing, during which the material can retain its original characteristics.

Characteristics

Drying time

Single brick dries quickly and perfectly because it has a relatively low percentage of moisture absorption.

Red full-bodied

Solid building brick M150 is one of the highest quality, environmentally friendly materials that has the best performance. Single solid brick is in demand and popular among both builders and customers. Ordinary solid single brick M150 is very often used for the construction of underground garages, fences, wells, as well as for the construction of basement floors. One of the manufacturers of ceramic solid single bricks is the Lomintsevo brick plant. Brick is considered a truly classic option in construction, because its properties have been appreciated a very long time ago. And this is not surprising, because this is a durable and reliable material, a house from which will last for many years. And in recent years, along with the popularity of the “Loft” interior style, the demand for bricks among buyers has increased significantly. Such a brick is also called ordinary.

Ordinary solid brick M 150 is made from a mixture of quartz sand with water and lime. Solid construction brick M150 is produced under the most high-tech conditions, and its composition includes the best types of clay. The Lomintsevo plant has been manufacturing its products for more than 20 years, improving production technologies. Single solid brick M150, as well as other building materials of this plant, undergo quality testing in laboratories inside the plant. As a result, solid building brick complies with all GOST 5030-2012 standards. You can view the entire range of the plant’s products on their website - Lomintsevo brick factory official website. Our company SSK is a direct supplier of this plant, so you can also view ordinary solid single ceramic bricks on our website.

Bricks have common characteristics, these include strength grade (M and value), frost resistance (F and value) and size (there are single, one-and-a-half, euro and double). Building materials are selected for different construction needs.

In addition to the strength grade listed above, there are several alternative brick options for your construction:

| Brick from those. voids | Slotted brick | Double slotted brick | Solid brick M300 |

Production

Single red brick M 150 is made from clay mass , from which all unnecessary components are removed. Here is its size. The clay is diluted with water and mixed until smooth.

As a result of such simple manipulations, the brick becomes its usual shape when excess moisture is removed from it, which should completely evaporate.

This happens not only from the surface of the M 150, but also from its internal parts. With uneven drying, many briquettes are deformed as a result, which leads to an increase in scrap.

At the final stage of production, the resulting brick is necessarily processed in a kiln under high temperatures, often exceeding eight hundred degrees.

Firing in a kiln

Increased temperature readings help all components of the brick set faster and remain united. If the M 150 is produced correctly, you will certainly hear a characteristic sound. It will be as loud, thin and audible as possible with minimal impact.

If a brick has been in a professional kiln for a long time, it is defective and can be quickly identified. As a rule, its edges are burnt and the core becomes black.

Defective

It would be irrational to use such a brick for the construction of load-bearing structures; it can only become the basis for the foundation. Here is the size of the red brick for the foundation.

How is a brand determined?

The brand is the main point according to which the strength of the briquette is determined.

The accompanying “M” number indicates the maximum pressure that the material you have chosen will withstand. At this stage, the boundaries are drawn at which it is rational to use this or that material.

Performance characteristics should be calculated using the formula pressure in kg. relative to one sq/cm. Accordingly, a logical explanation is given that the brand of brick in question should be operated at its optimal operating pressure.

Today, different companies offer their customers briquettes of different types and markings. So far, the maximum strength indicator is three hundred units. But despite this, 150 grade bricks are purchased most often. In second place is “M” 100, and in third place is “M” 125.

M-100

In addition, the number “M” can determine the areas of use of this briquette. For low-rise construction, bricks with an index of one hundred and one hundred twenty-five are purchased. To build load-bearing walls, purchase solid red brick of the hundredth grade. Here is its size.

But, if a builder plans to build a property with three floors, he will certainly purchase bricks of the density discussed in the article.

This is a prerequisite for quality, because for high-quality work it is necessary to use only those materials that will meet all specified technical characteristics and international standards.

Dimensions and specifications

The dimensions of the M 150 brick are nominal. A single block is 250 mm long, 120 mm wide, 65 mm high, a one-and-a-half block measures 250*120*88 mm, and a double block measures 250*120*138 mm. There are also non-standard sizes: quadruple, eighth, restoration, European. The weight of one single block is from 3.6 to 4.5 kg.

The main distinctive characteristics of the building material are strength and frost resistance. Strength is considered the ability of a material to resist internal stress and external changes in shape. Conventional letter designation M (brand) and a number indicating the load that the block can withstand per 1 cm2. Brick brand M 150 is durable, capable of withstanding significant loads - 150 kg in compression and bending. Products with grades lower or higher are also produced, for example, M75 or M200. Frost resistance is indicated by the letters Мрз, is calculated in cycles and means the ability of a product to withstand loads of freezing and thawing at time intervals.

Interesting Facts

Briquette 150 is actively used for the construction of many real estate elements. It becomes the basis of the main wall, which serves as the support of the building and extends completely from the base to the top, load-bearing partitions, in addition, it is the most purchased material for the construction of the base and ground floors.

Any construction certainly begins with the construction of a foundation, which differs from the types of future structures. However, low-rise buildings use a brick foundation.

For the base, only solid briquettes are purchased, because they, like no other object, are subject to attack by numerous aggressive factors - these are constant temperature changes and groundwater.

That is why, to create the base, solid briquettes are used, which will withstand all negative factors without any problems.

Types

As mentioned above, according to its structure, the briquette in question is produced for the market:

- full-bodied;

Full-bodied

- hollow.

Hollow

In the first option there are no voids. The briquette in question is not famous for its thermal properties , but it is optimally suited for foundation work, as well as for the construction of load-bearing structures.

Foundation

The M 150 also stands out for its low level of sound insulation. The hollow analogue, which has voids in its structure, is significantly lower in weight. It perfectly retains heat in a room, so it is used to build load-bearing structures and partitions between rooms.

Interior partition

Thanks to its improved soundproofing properties, briquettes are ideal for constructing partitions between rooms and apartments. If you purchased the M 150 cladding type, it can be used for wall decoration.

Brand 150 briquettes are:

- facing imported or domestic;

Facing

- ordinary construction worker.

Private construction worker

There are two types of 150 bricks available on the market: some are called ordinary, all others are called facing.

To ensure optimal adhesion, the manufacturer provided this material with special edges that have a relief structure.

Relief structure

If ordinary briquettes are used for the construction of load-bearing structures, they are additionally processed - either covered with a layer of plaster, or a special paint coating is applied.

Therefore, such a briquette, in terms of its external characteristics, is as simple as possible; its front part is never processed. In addition, the briquette can be produced in a non-uniform shade and GOST allows its distorted shape.

Facing

Facade facing bricks with appropriate markings have found their wide application for the construction of various objects. This has become available due to the fact that different companies supply the market with a variety of shade variations, as well as briquettes of numerous textures.

Facade

The cladding analogue is used for real estate decoration - thanks to it, the object acquires ideal external characteristics. The front side of the building, fences, openings on staircases, underground passages and even arches are finished with facing bricks. Here is its size.

Private

Solid single building brick, marked m 150, the price of which depends on the density, can be sold from 10-20 rubles.

In addition to density indicators, the cost of a product is also affected by its quality and the manufacturer. Therefore, when purchasing the basis for the construction of objects, you should not look for cheap options.

In the future, this may lead to a series of unpleasant events, which will be reflected in the premature deformation of real estate. The material discussed in the article is universal and can be used for all types of structures.

The external characteristics of an ordinary solid briquette suggest that it will be additionally processed with some other components to give it a finished and aesthetic appearance.

The surface of a solid briquette is often smooth, but textured analogues can also be found on the market. The latter are designed to improve the adhesion of the product to each other. This characteristic is very important, especially if, in addition to its mass, the building will be subject to additional load.

Characteristics of briquette 150 grade.

- dimensions: 25x12x6.5cm;

Single

- weight: from three kilograms;

- strength index: 150;

- resistance to sub-zero temperatures: from 50;

- moisture absorption: from eight percent and above;

- shade: can be anything from ivory to red. Here is the size of a red solid brick;

- surface: can be either as smooth as possible or with corrugations.

If you want to build a brick building, choose only high-quality material and never give preference to cheap ones.

Before you start laying, do something like an analysis: why are you building the building, what functions will it perform, what role is assigned to this or that element, whether the building will come into contact with aggressive environmental factors.

Brick manufacturers advise that those buildings that will be in contact with negative factors be built from high quality materials, which are distinguished by improved technical features.

Other components of the property can be created from cheaper brands of briquettes, thereby reducing construction costs and the structure will not be overloaded.

For more information about ordinary solid building bricks, watch the video:

conclusions

Today, the modern construction industry has entered a new stage of its development. Production has reached a new level, thanks to which companies are releasing various variations and shades of construction briquettes onto the market.

Many products allow customers to choose bricks that are acceptable in cost and quality for a variety of work areas. Therefore, when choosing a 150 grade brick, you will definitely not go wrong regarding the quality and durability of this material.

But, just don’t forget to pay attention to the rating of the manufacturer and supplier. Brick 150 has taken its special place at any stage of construction. Knowing its technical characteristics, the builder will easily create a strong supporting structure that will meet all international standards.

Features of the use of various types of bricks of the M150 brand

Comparative heights of different types of ceramic blocks

Forms of release of ceramic building materials produced by firing are also divided by size:

- Single hollow and solid material - dimensions 250 x 120 x 65 mm;

- The thickness of one and a half bricks is 88 millimeters;

- The double ceramic block has a height of 140 millimeters.

For reference. One meter of masonry includes thirteen rows of single, ten one and a half and six and a half double bricks.

When carrying out construction work with your own hands, you should pay attention to some technological features of the use of ceramic building materials:

- The use of materials with void widths from 16 to 20 millimeters requires greater consumption of masonry mortar . In addition, the solution fills voids during work, which reduces thermal performance;

- The size of through voids in the block should not exceed 16 millimeters, according to GOST 530-71 . In this case, the masonry mortar is evenly distributed over the surface and does not penetrate into the voids of the block;

A varied surface texture guarantees the beauty and originality of the masonry

- The certificate for the material must contain not only technical characteristics, but also guarantee the environmental safety of the material;

- To reduce the humidity of load-bearing walls, it is necessary to minimize the consumption of cement-sand mortar during laying . Excess mortar significantly reduces the thermal performance of the load-bearing walls of the building;

- For the construction of load-bearing walls of buildings with several floors, it is better to use double bricks of the M150 brand, and for internal partitions a single block is sufficient, the price of which is an order of magnitude lower.

Advice. A professional calculation of the loads on the walls and foundation of the building will help you choose the right brand of ceramic brick.