Compared to conventional incandescent lamps, the design of an LED lamp is technically more complex. If for the former a transparent glass case is used, then in the case of the latter it will not be possible to see anything inside. In order to find out what such a light source consists of, it is necessary to disassemble it into parts.

The general design of LED light bulbs, regardless of the manufacturer, is almost identical (with minor differences). The range of standard products with E14 or E27 socket is divided into three categories - branded, low-grade Chinese and filament.

Low quality Chinese light bulbs

When disassembling a branded lamp, you can find all the structural elements necessary for reliability and durability. But if you look under the body of a cheap Chinese product, the first thing you won’t find is the heatsink and driver.

The driver is usually replaced by a power supply with a non-polar capacitor that is unable to stabilize the output current. Install such a block in the center of the board with diodes. If you look at it from above, you can see a diode bridge with resistors, and two capacitors from below. This allows you to significantly reduce the cost and quality of the product.

To cool the device, small holes are made in the housing. The efficiency is low, the crystals burn out very quickly. The board is installed on a plastic case and secured with latches. To connect to the base, two soldered wires are used.

Differences by food type

In accordance with this parameter, known samples of LED lamps are divided into the following modifications:

- with LEDs rated for 220 Volts.

- operating from reduced and rectified voltage 12 Volts.

The first light sources on this list operate in standard electrical networks and turn on like regular incandescent lamps.

LED lamps, designed for 12 Volts DC, due to their low voltage and wide selection of bases, are universal products.

To operate such lamps, you will need a special power supply that reduces the alternating mains voltage to a constant value of 12 Volts.

Filament lamps

The filament light source externally resembles an incandescent lamp, but structurally remains an LED product. In this case, there is no need for heat removal, but the use of devices in the domestic sphere is associated solely with aesthetic considerations.

The main element of a filament device is an LED filament. Depending on the number of such threads, products of different capacities are produced. A filament is a thin glass rod with SMD diodes on its surface. The upper part is coated with a phosphor that gives a yellow tint. To remove heat, a glass flask is used, the inside of which is filled with gas.

Due to the lack of space for the driver inside, manufacturers place a low-quality power module. This increases pulsation, which negatively affects the visual organs. To get rid of flicker, a plastic ring with a high-quality driver is added between the base and the bulb.

What are the benefits of such lamps

Now that you already know a lot about how an LED lamp works, it’s worth dwelling on its advantages. The main and indisputable thing is low energy consumption. A dozen LEDs produce radiation of the same intensity as a traditional incandescent lamp, but semiconductor devices consume several times less electricity. There is another advantage, but it is not so obvious. Lamps with this operating principle are more durable. True, provided that the supply voltage is as stable as possible.

It is impossible not to mention the disadvantages of such lamps. First of all, this concerns the spectrum of their radiation. It is significantly different from the sun - what the human eye has been accustomed to perceiving for thousands of years. Therefore, for your home, choose those lamps that shine yellow or reddish (warm) and have matte caps.

Operating principle of LED lamps

The operating principle of these devices is based on complex physical processes. When an electric current is applied, two substances made of different types of materials come into contact. This leads to the formation of a luminous flux.

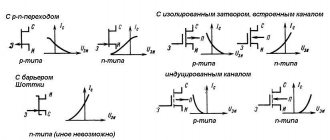

The paradox of the system is due to the fact that none of the materials used to make the two substances are conductors of electric current. These are semiconductors that can pass current in only one direction. Therefore, when connecting LEDs, it is important to observe polarity. One material is endowed with negative electrons, and the other with positive ions.

Other processes are also activated in semiconductors. At the moment of state change, thermal energy is released. Using an experimental method, the inventors found the desired combination of substances, in which, in addition to energy, light radiation also appears.

All devices that pass current in one direction are called diodes. LEDs are diodes capable of emitting light.

The first LED diodes emitted light in a narrow spectrum - red, yellow or green. At the same time, the glow intensity was minimal. For a long period of time, LEDs were used exclusively as indicators. Today, the radiation range has been significantly expanded and covers almost the entire spectrum. On the other hand, certain wavelengths are always longer, so these devices are divided into cold and warm light sources (depending on thermal temperature).

Assembly methods

Based on the assembly method, products are divided into several categories.

DIP

DIP stands for Dual In-line Package. The design of the instruments is interesting, but significantly outdated. The following LED sizes are available:

- 0,3;

- 0,5;

- 0,8;

- 1.0 cm.

Semiconductor products also differ in color, material of manufacture, and chip shape. Among the advantages of the DIP assembly, we highlight low heating and high brightness. There are single-color and multi-color (RGB technology). Can be recognized by its characteristic cylindrical shape and built-in convex type lens.

"Piranha"

This group of lighting devices is characterized by a high luminous flux. They are made in a rectangular shape, have four PIN pins, and come in red, blue, white or green.

Compared to DIP technology, the products “sit” more rigidly and firmly on the board. The lead substrate increases thermal conductivity, but at the same time reduces overall safety during operation. Widespread use is due to the wide range of operating temperatures.

SMD technology

SMD stands for Surface Mounting Device (translated from English as “a device fixed to a surface”). These LEDs are characterized by power in the range of 0.01–0.2 W. The main feature is associated with the presence of several crystals (1–3) mounted on a ceramic substrate.

The body is coated with phosphor. Standard solder is used to connect the main board and pads.

Among the disadvantages, we highlight the low maintainability: if at least one diode fails, you will have to replace the entire board.

COB technology

The latest and most reliable LED technology is called Chip On Board (COB). Semiconductors are mounted on a board without a housing or any substrate, after which they are coated with a phosphor.

The main advantage is associated with a small luminous area at high power. The uniform glow of the product is guaranteed by the high density of LEDs and the presence of a phosphor. Such LEDs are more often used these days.

Device of LED light sources

The LED source consists of the following structural elements:

- LED diodes;

- drivers;

- frame;

- radiator;

- base

LEDs

Several years ago, the design of the LED lamp was slightly different due to the lack of a wide range of LED diodes. The most common were 3–5 mm chips. Later, 10 mm products appeared.

Today there are many more LEDs. The most commonly used are SMD 5050, SMD 3528, SMD 5730, SMD 2835, 1W, 3W and 5W.

The number of LEDs varies and is specified by the manufacturer. When installing several diodes, special calculations are made to determine the optimal current consumption. Solder is applied to textolite or aluminum boards. LEDs are assembled into groups connected in series. Again, the number of groups is unlimited.

The series connection provides a constant current, but there is a significant drawback - if at least one LED diode fails, the entire product stops working. On the other hand, the diode can be easily replaced with a new one.

The boards to which the light sources are soldered are classified by shape and can be round, rectangular, oval, polygonal, etc.

Drivers

Drivers are designed to convert the incoming voltage into a value suitable for powering the device. Moreover, the power supply for each group of LEDs may be different. The most common are transformer circuits with drivers.

Structural elements can be of two types - open and closed (in a housing). They are mounted in the housing of lamps and lighting fixtures.

Cheap drivers are used in ordinary flashlights, in which the LEDs are powered by batteries. In this case, there is no need for a current limiting resistor. Because of this, diodes can receive increased current, which leads to their rapid failure.

Chinese manufacturers often try to save money on devices by installing conventional current limiters with a capacitor-based circuit instead of drivers. Avoid purchasing such products, since in addition to being extremely uneconomical, they have a negative impact on human health (high pulsation).

Base

Since LED products are positioned as the best analogs to incandescent lamps, it is not surprising that they are manufactured with standard sockets - E27 and E14. The latter are often used in night and wall lamps.

The standards are different abroad, so you can often find E26 LED lamps there.

Frame

Unlike incandescent lamps, LED lamps do not need to be completely sealed, and there is no gas environment inside. One of the varieties of LED lamps is a filament source, which replicates the design of an incandescent lamp and requires a gas environment.

Consuming the same amount of electricity, the products shine much brighter than their analogues. A conventional LED lamp has a closed bulb made of glass or plastic. The matte coating reduces light transmittance, but this is a minor production cost.

Radiators

These electrical products are susceptible to high temperatures and overheating. For this reason, a heat dissipation device is necessary to increase service life. Aluminum boards partially reduce the impact of overheating, but this is not enough. Expensive and high-quality lamps necessarily use radiators, the size of which depends on the number of LEDs in the device.

The presence of a radiator increases the cost and dimensions of the product, but is a prerequisite for creating a high-quality and durable device.

Design and principle of operation

To understand the fundamental differences between an LED lamp as electrical equipment and in comparison with other devices, you should consider in detail its design features and the purpose of each element.

Rice. 1. LED lamp design

Structurally, the LED light bulb consists of:

- LEDs - in older models there was only one crystal that emitted light, but this technology had a number of difficulties, so modern models include several units or an entire matrix.

- Bulb or diffuser - can be made of glass or polymer. Designed for a smoother redistribution of light flux from point sources into the surrounding space.

- Current stabilizer or driver - designed to convert the electrical quantity supplied to the contacts of the diode light bulb, regardless of the voltage and power level, into a strictly established amount of electric current.

- Base – designed to connect LED lamps to the electrical network. Most often, standard bases E and G are used; other designs are less common.

Additionally, the lamp contains a polymer or metal housing. However, LED lamps may have a built-in matrix, and it is mounted directly into the LED spotlight.

The principle of operation of an LED lamp is the following sequence of electrical energy transfer:

- When an electric lamp is placed in a socket and an alternating mains voltage is applied to it, the LED source receives power.

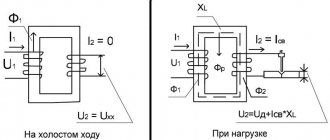

Figure 2. Operating principle of an LED lamp

- As you can see in Figure 2, the alternating voltage in the LED lamp is initially supplied to the rectifier bridge, where it is converted into rectified voltage. A capacitor installed after the bridge additionally smoothes out ripples.

- The rectified voltage then passes from the rectifier device to a microcontroller that controls the amount of generated electric current.

- Then the power is supplied to a pulse transformer, which supplies electrical voltage directly to the lighting source.

- When the required level of electric current is reached, the LEDs glow.

This example shows the principle of operation and design of a galvanically isolated LED lamp. This is a more expensive, but also more reliable way to protect a person from electric shock. In practice, there are also cheaper LED lamps; their products use cheaper driver boards or conversion methods that do not provide the required level of safety and service life.

Layout of components

Depending on the manufacturer, the device and design of the lamp are different. On the other hand, the general layout principle remains the same. The assembly begins with the base, where the driver, radiator, board with LED diodes and bulb are installed in sequence.

For comparison, let's look at the device of a product from two manufacturers.

LED lamp BBK

The base is made of plastic. A high-quality driver is installed inside. The body is made of aluminum, which acts as a radiator. A board with diodes and a lens are attached there. The presence of this lens reduces the light output of the device.

Gauss lamp

Again, the base is made of plastic, there is a driver and an aluminum case with an installed diode board. The design guarantees the durability of the product.

How to check an LED lamp when purchasing

Pick up the LED lamp and inspect it externally to make sure there are no flaws. This can only be done if a transparent flask is used. First, check the radiator (it is available in a cast or stacked type). The higher the power of the product, the larger the radiator should be. An excellent option would be to use aluminum or ceramic coolers.

Ideally, the electrical element should be coated with thermoplastic. Make sure that there are no gaps or mechanical defects in the base. Also, in any store it is possible to connect the lamp to an electrical network to check its functionality. Once you have done this, take a look at the light emitted. Use the camera on your smartphone to make sure there is no flickering or ripple. Never buy a lamp that flickers when in use.

The information obtained on the design and operating principle of an LED lamp may not be enough to select a high-quality lighting device characterized by safety, reliability and durability. There are also other criteria to consider, including features and manufacturer, as detailed in this article.

Advantages and disadvantages of LED lamps.

pros

- energy efficiency - power consumption is 8-10 times less than incandescent lamps;

- long service life - they shine about 25 times longer than incandescent lamps;

- practically do not heat up;

- a wide selection of color temperatures allows you to “play” with interior lighting;

- stable brightness during voltage fluctuations;

- instant on;

- the number of starts does not affect performance;

- resistance to mechanical damage and vibration;

- Possibility of use in a “smart home”;

- excellent decorative qualities - available in many interesting shapes and sizes;

- do not attract midges and other insects due to the lack of ultraviolet light;

- safe disposal and operation due to the absence of hazardous substances.

Minuses

- relatively high cost, although it is constantly decreasing;

- flickering (pulsation), which is invisible to the naked eye, but very dangerous for vision (more common in cheap models, which are often produced without a driver);

- design complexity leads to increased cost and decreased reliability compared to incandescent lamps;

- unsuitable for use at very low and very high temperatures;

- in many models, the brightness cannot be adjusted using a dimmer;

- if a backlit switch is used, the LED lamp may flicker or glow when turned off (how to avoid this, read the article “Why does the LED lamp blink”);

- decrease in brightness during operation;

- a high percentage of defects among products, especially among inexpensive ones.

In conclusion, it is worth noting that LED light sources are truly economical lighting devices. Just before choosing, you need to carefully study the technical specifications.

Firstly, they are economically feasible to replace incandescent lamps with a power of over 60 W. Otherwise, the cost of the LED lamp itself will not pay off.

Secondly, it is worth replacing only light sources in lamps that operate the maximum number of hours per day.

And thirdly, experts advise first trying out several brands of LED lamps to determine whose color temperature (and other parameters) will suit your eyes 100%.

- Related Posts

- LED warehouse lighting: selection, calculation and installation

- Wood's lamp: principle of operation, types, scope of application

- Aquarium lamps and fixtures: types, requirements and characteristics