Typical design of diesel fuel installations

Structurally, all diesel generators belong to the category of multi-purpose devices with internal combustion engines. The stations are produced in two types, providing for fixed and mobile use, depending on operating conditions.

Almost all diesel power plants are a fairly complex mechanism assembled from various parts and components.

The main components of the DES are:

- Four-stroke diesel engine. The number of cylinders ranges from 1 to 8 and corresponds to the declared performance of the unit.

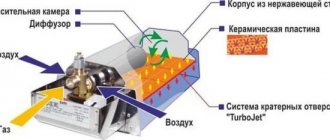

- Fuel system and air injection equipment. The mixture components enter the engine separately. Diesel fuel is sprayed into the cylinder through nozzles by a fuel pump, and air is pumped by a turbocharger. Under the influence of pressure, the air is strongly heated, igniting the atomized fuel.

- A cooling system that removes excess heat from heated parts and maintains the required temperature level. The coolant is water or antifreeze. Its movement inside the water jacket occurs through special channels, under pressure created by the water pump. At the end of the complete cycle, the coolant returns to the radiator tank and reduces the temperature under the action of the fan blades.

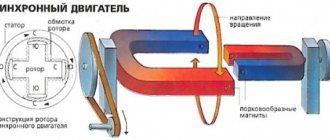

- Generator set. Produces electric current and, depending on the modification, can be single-phase (220 V) or 3-phase (380 V and above) type.

- Automatic control system. Better known as the automatic reserve entry system. This equipment automatically turns on the generator without operator intervention.

- Fuel tank. A fairly spacious tank with a volume of 200-300 liters.

- Frame. Metal frame on which all components and parts are placed. Damper pads are installed at the fastening points to provide protection against vibration vibrations.

- Container capacity, also known as casing. Installed on top of the entire structure, it protects the station from external negative influences. Reduces the noise level produced during operation.

Operating principle of a diesel generator

Briefly, the principle can be described as follows: The expansion energy of gases formed during the ignition of compressed fuel in the cylinders of a diesel engine is converted through a crank mechanism into mechanical energy of rotation of the crankshaft. The generator rotor, driven by the engine shaft, rotates and excites an electromagnetic field that creates an EMF (electromotive force) on the generator windings. The antiphase EMF generates an output voltage on the stator windings, which is stabilized by the control device and supplied to electricity consumers.

Principle of operation

The operating principle of a power plant is based on the interaction of all parts and components included in its design. It is included in the rules for the technical operation of diesel power plants. All such products are manufactured in a stationary or mobile design, and are used as autonomous, emergency or backup power sources.

The basis of any power plant is a diesel generator, which contains an engine and a generator set. Both components are connected to each other through a special coupling, which allows the torque to be converted into electrical energy.

The operation of diesel electrical installations occurs in a certain algorithm:

- Air mass is injected into each cylinder under high pressure. In a confined space, it is compressed and heated to a high temperature. After a certain period of time, fuel sprayed in the injectors is supplied to the cylinders. Under the influence of heated compressed air, diesel fuel vapors ignite, expand and create high pressure in the internal space of the cylinder.

- The hot gas mixture pushes the piston, causing the crankshaft to rotate. The motor starts up and transmits its torque to the generator rotor through a clutch.

- As a result of transformations, an electrical voltage with established characteristics is ultimately obtained.

How does a diesel power plant work?

Electric generators are devices that convert mechanical energy into electricity.

The fuel burning in the cylinder drives the moving part of the unit (shaft). He, in turn, rotates the rotor of the diesel generator set. During the rotation process, a magnetic field is created, which is converted into electric current. Stationary and mobile installations operate based on this principle.

Modern installations operate on the principle of electromagnetic induction (Michael Faraday is considered the discoverer). In the process of conducting research, the physicist discovered that moving an electric conductor in a magnetic field can cause a flow of electrical charges. The movement creates a potential difference between the two ends of the wire (conductor), causing electrical charge to “flow”.

Where are they used?

According to their functional purpose, the considered power plants are main or main, backup or spare and in case of accidents.

The first type of installations is used in the form of autonomous or independent voltage sources in construction sites and in agriculture, in the logging industry and in other remote points where, for a number of reasons, it is impossible to use and connect to stationary electrical networks.

Reserve diesel power plants. Replace the main power plants that failed as a result of the accident. They also provide backup power supply when external fixed networks are disconnected.

The operation of emergency devices is carried out in medical institutions, communication centers and other similar places where power outages are absolutely not allowed. They are in constant readiness to assume full or partial load during a power outage, which is also stipulated by the rules for the technical operation of diesel power plants.

The scope of use of this type of equipment is very large. Diesel stations are actively used in a variety of organizations and enterprises, by special and technical services and by owners of country houses. The main users are construction organizations, trading companies, shops and car washes.

In accordance with the modes and conditions of future operation, the appropriate power of the equipment is selected. It should be taken into account that prolonged operation at full load or too small loads lead to a reduction in the service life and the period of normal operation of the station. For constant operating mode, the load should be no higher than 60-80% of the rated capacity, and when using the backup option, this figure is 70-90%.

Design features

As already noted, all electrical installations with diesel engines are of the mobile (AM) or fixed positional (ASD) type. Stations equipped with automation are marked with another letter A.

Mobile diesel power plants are mounted on trailers of cars and trucks or other most suitable means of transportation, and are equipped with a hood. They are often installed directly into the body. This provides protection from precipitation and other negative influences that may occur outdoors. Each station is a complete electrical installation containing separate blocks and components installed on a single frame structure.

Classification of diesel engines

There are many modifications of these units, which, according to their characteristics, are conventionally divided into several categories.

Housing type and design

- Open version. They are installed indoors, not exposed to external influences, equipped with ventilation, heating systems, fire extinguishing means, and alarm systems. Used only in a stationary version.

- Covered with a casing. A separate metal structure covers the diesel generator set from the outside. Provides sound insulation and protection from rain, snow, dust and low temperatures. Can be used outdoors. As a rule, they have small dimensions and low power.

- Containerized. In this case, all technological devices and equipment are placed in a special container-type container or block box. The metal structure is lined with insulation on the inside and coated with anti-corrosion compounds on the outside. In addition to the main components, there are ventilation, heating systems and other equipment for the life support of the station inside. This allows the launch to be carried out immediately after its arrival at the site.

Mobility

- Stationary installations, also known as autonomous diesel power plants. Their main positive qualities are high energy productivity and a wide range of potential capabilities. Installed indoors in open form.

- Mobile power stations. They are closed with a special protective casing or placed in a container and installed on a separate chassis. Can be transported to any distance.

- Portable models of diesel generators. They have low productivity and small dimensions. They have found their application in dachas, country houses and cottages.

Power

- Household electrical installations. They are used in the form of various power sources - main or backup. Their performance is in the range of 8-50 kW.

- Diesel generators for industry. The power range is wider, ranging from 50-1600 kW. They are used in production, construction, boiler rooms and other areas with large amounts of energy consumption.

Control type

- Manual. The station is started and turned off using a button pressed manually. However, basic control equipment is available. The only drawback of such installations is the need for constant operator duty.

- Automatic reserve entry. Provides independent switching on of the station when the voltage in the stationary network is turned off. Once the power supply is restored, the unit switches off automatically. Functionality may vary between models, so in some cases an operator may be required.

- Remote control. Performed via a connected computer. This system allows you to control the power supply of several objects at once.

Engines used in diesel generators

The main differences between diesel engines related to their power are determined by their dimensions, cooling and air supply systems. According to the cooling method, engines are distinguished: - Air-cooled - used in low-power diesel generators. — Liquid cooling. The liquids used are water or antifreeze. By air supply method: - Without turbocharging. — With turbocharging, when a turbocharger forces air into the engine combustion chamber using a drive from diesel exhaust gases. — With turbocharging and intermediate cooling of incoming air.

Compared to gasoline engines, diesel engines have a number of advantages: lower cost and fuel consumption, longer service life, higher fire safety. These factors are especially important in the case of long-term use of the power plant as the main source of power supply or when it is connected for a long time as a backup. Among domestic manufacturers, we can note the products of the Yaroslavl (YaMZ) and Minsk (MMZ) plants.

Maintenance and operating recommendations

With constant and long-term use of installations, it is necessary to comply with the rules of technical operation of diesel power plants. Maintenance is carried out by specially trained personnel. Persons authorized to use stations must be well aware of the principles of their operation, design differences and features, and the potential capabilities of control systems.

From time to time, all employees performing maintenance of diesel power plants are required to pass exams on job descriptions, labor protection and safe use of installations. Based on the results of the exams, a certificate is issued allowing work as a power plant operator.

When performing maintenance on diesel stations, the following actions are performed:

- Before starting the engine, an external inspection of the installation is carried out in accordance with the technical specifications. Protective screens are installed on all moving parts. The device must be free of visible damage and leaks of fuel and lubricants. The engine oil is preheated to 35 degrees. This makes starting easier and increases service life.

- After switching to operating mode, you need to regularly monitor the oil level in the lubrication system. The permissible natural loss is 100 g for every 100 hours worked by the unit.

- The components are regularly cleaned of dust and dirt accumulated over the past period, oil traces and drips are removed. Thus, the power plant does not overheat and its service life is extended.

- The load should be controlled so that the number of consumers does not exceed the rated power of the generator. For this reason, the generator set most often becomes overloaded and stops working normally, even to a complete stop. Working without load for more than 30 minutes also negatively affects the life of parts, causing their premature wear.

- In case of forced downtime of the generator for a long time, it is recommended to start it at least once a month for 1 hour.