What does it represent?

The blind area is an external basement waterproof concrete structure in the form of a continuous path along the perimeter of the building, sloping from the wall towards the surrounding topography of the local area. Its arrangement involves a tight but movable connection to the base of the house.

The structure is a layered “pie” consisting of materials that together keep the foundation dry. The basis of such protection is in proportion: a compacted, even underlying layer of sand (crushed stone, clay), waterproofing and a coating - concrete, which ensures the waterproofness of the structure.

Return to contents

Types of blind area, advantages and disadvantages

The following types of structures are distinguished:

- Concrete. Pros: practicality, affordable cost, long service life. The downside is regular sealing of cracks.

- Rubble (cobblestone). Lay out with stone, paving stones, tiles. Plus – affordability, aesthetics. The downside is low strength compared to concrete pouring.

- Sandy (soft). Pros: budget cost, speed of execution. Disadvantage: short service life.

On a note! The sand is poured with warm liquid glass and treated with a hardener. During the drying process, sandstone is formed. The material resists moisture and weather conditions. The service life is significantly increased.

- Clay. Practical and inexpensive design. The downside is that the clay is quickly washed away. To increase the service life, the mixture is sprinkled with crushed stone.

If desired, the owner chooses other options for the blind area, rolling the paths with asphalt or laying ready-made concrete slabs.

Soft blind areas

They are made from clay, sand or profiled membrane. The last option is considered new; the construction technique is similar to other options with one difference - a membrane is immediately laid at the bottom of the trench. There is geotextile on it, with a cushion of crushed stone and sand on top. The finishing layer is fertile soil. Plants are planted in it. The blind area is called hidden, it is not intended to be moved, it serves more as decoration.

Concrete blind areas

Rigid design option. It is a monolith made of concrete or asphalt concrete. Pros: good base protection, durability, maintainability. The downside is the possibility of cracking of the monolith.

Clay blind areas

In the classic version, the blind area is supplemented with a top layer of gravel or crushed stone. To increase waterproofing properties, a film is laid between the bottom layer of clay and the top coating.

Blind area made of paving slabs

The coating is classified as semi-rigid. Constructed from clinker bricks and paving stones. The laying technique is similar to sidewalks and includes a layer of waterproofing. The advantages are aesthetic appeal and good performance. The downside is that arranging paths takes a lot of time; finishing costs are also not considered budgetary.

On a note! A blind area made of tiles is the most repairable option. The technique is chosen in cases of significant seasonal soil movements, during which monolithic concrete will quickly become unusable.

Functions performed

A properly equipped blind area ensures the longevity of the structure, preventing the destruction of the foundation and structures of the house by moisture from precipitation and melt water. A blind area without concrete, created with your own hands, is a temporary measure that does not solve the entire complex of problems of such a design.

The main function of a proper blind area is to drain and transport water a sufficient distance from the foundation towards the lowest place on the site or into a storm drain.

In addition to the function of a horizontal hydrobarrier, the blind area (especially insulated) reduces the freezing of the soil around the house, which reduces the likelihood of it swelling (rising), and also reduces the thermal conductivity of the building. A blind area without concrete does not prevent periodic moisture of the soil close to the foundation and, as a result, the harmful effects that hard plant roots can cause to it. The protective device also gives the building an aesthetically complete appearance and can be used as a pedestrian path.

Return to contents

Instructions for making a blind area from crushed stone

Laying bulk material is most often temporary, but there are no restrictions on use depending on the type of soil. The choice of crushed stone depends on climatic conditions and the preferences of the owner. Dolomite crushed stone is resistant to temperature changes and tolerates frost; granite is more expensive, but the practical characteristics of crushed stone are higher.

Advice! For a blind area made of crushed stone around the house, it is recommended to take material of small and medium fractions. Gravel, expanded clay, and pebbles are chosen for areas with groundwater levels less than 1 m with a high probability of flooding of the area.

The multilayer design is laid out similar to the previous tracks:

- the first layer at the bottom of the trench up to 50 cm deep is oily clay up to 15 cm thick;

- a layer of waterproofing made from sheets of roofing felt or thick film;

- sand cushion up to 15 cm thick, it is moistened and compacted;

- geotextiles are laid on sand, the edges are wrapped on the walls;

- crushed stone is poured to the top ground level.

Features: the areas where the film reaches the foundation are coated with bitumen, and a rolled lawn is laid on top of the crushed stone backfill. The material will protect the pillow from deformation and spreading. In this case, the curb stone is not installed; the blind area is made at the same level as the ground surface.

Requirements for the blind area and design rules

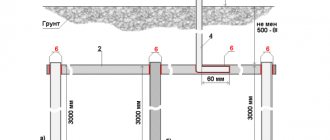

Diagram of a structure using reinforced concrete.

The encircling protective structure must have the same width, the value of which is 20–30 cm greater than the overhang of the roof eaves beyond the wall of the building. It is generally accepted that it is about 1 m (or more on subsiding soils). The blind area is buried to no more than half the depth of soil freezing in the area. The thickness of the concrete coating is selected within the range of 7 - 10 cm (up to 15 cm if used as a path).

The recommended slope of the coating is 92 - 94 degrees relative to the wall of the building (or 10 - 100 mm per 1 meter of blind area width). The height of the base above the blind area at the junction of the structure is set to 50 cm. Its outer lower edge should be raised approximately 50 mm above ground level, which prevents the accumulation of water at the edge. The technology for creating a structure assumes the possibility of its integral movement following soil deformations relative to the foundation, which provides a wall expansion joint.

Return to contents

How to choose the type of blind area?

The rules for selecting a design will determine the type of soil:

- Hard base. Used on soils of medium and high density. Service life more than 10-15 years.

- Soft design. A simplified version for any type of soil. The average service life is no more than 5-7 years.

- Semi-rigid base. Used on soils with a high water table and a buried freezing point of the soil.

Advice! On heaving soils, a semi-rigid blind area is used with restrictions on the type of materials for backfilling the layers.

Determining the thickness of the blind area around the house

Laying out a semi-rigid base requires calculating the thickness according to the type of material - clinker bricks, tiles or paving stones. The dimensions of the concrete coating are calculated using a complex formula:

- multiply the minimum elevation level above the site by the slope;

- multiply again by the width of the tape;

- divide by 100;

- The height difference is added to the result.

The standard minimum thickness of the blind area made of reinforced concrete will simplify the task. Taking into account the thickness of the edge of 7 cm, the slope of 5%, the width of the blind area of 100 cm, the height of the coating at the base is 12-12.5 cm.

How to make a blind area?

Markings are made on the area, the fertile layer of soil is removed. An underlying layer of sand (clay) is laid. Geotextiles (for example, roofing felt) are laid. The formwork is formed taking into account expansion joints. The area filled with concrete is reinforced. Concrete for the blind area is prepared in the correct proportion and poured into the formwork. The coating surface is drawn out with the selected slope along the edge of the formwork and leveled. The concrete is given time to dry.

Return to contents

Preparation of tools and materials

The quality of the markings is checked by the building level.

For excavation work you will need shovels, a pick, twine, tape measure, rammer, and pegs. The required volume of geotextile (waterproof film) for the water seal should be calculated. The required quantity and proportions of components for mixing concrete (washed sand, water, gravel, crushed stone of fractions 5 - 10 mm, cement) or a ready-mixed concrete (for example, grade M400 and higher) are required. Tools also include a mixer (container) for forming the solution, shovels, buckets, carts (stretchers), and a measuring bucket. The laying of the underlying layer must be provided with sufficient sand (clay).

The formwork is formed from boards, but a hacksaw, level, nails, and hammer are also useful. Reinforcement is performed with steel mesh (steel wire), which should be delivered. You will need a welding machine and a tool for cutting pieces of reinforcement. A long rule, trowel, and spatulas will help in laying and leveling concrete. The construction of seams will require polyurethane sealant.

Return to contents

Marking

A trench is marked around the house with pegs and string. The level at which the blind area adjoins the plinth is marked with beacons in 1.5 m increments. A layer of fertile soil is removed around the building, taking into account the layout of the surrounding surface. The bottom of the trench is compacted and leveled with the already formed slope (herbicides can be added). The depth of the passage can be 500 mm (on heaving soils).

Return to contents

Creation and compaction of a sand cushion

The bottom of the trench is lined with sand, the surface of which is also profiled with a slope. The material is abundantly moistened and compacted. The operation should be repeated at least twice. The thickness of the layer can be up to 20 cm. Its surface is carefully leveled.

Return to contents

Waterproofing

The use of rolled waterproofing materials for blind areas.

Its device involves laying two layers of waterproofing (for example, roofing felt) on a sand substrate, which are slightly folded onto the wall to create an expansion joint. At the joints the material is overlapped. Next, the geotextile is covered with a thinner layer of sand, and then gravel (about 10 cm thick) with a slope of the top layer and compacted. It is advisable to place a drainage system close to such a water seal.

Return to contents

Creating formwork

A removable wooden form encloses the concrete pouring area. It is reinforced with strong pegs from the outside. The form provides for transverse expansion joints (every 2 - 2.5 m), which are installed, including diagonally, at the corners of the formwork. Their tightness is formed by wooden blocks placed on edge (butyl rubber tapes), impregnated with waste oil and coated with bitumen.

The edges of the mold must be straight for the rule to apply. The difference in its height must correspond to the slope of the blind area. The height of the formwork corresponds to the thickness of the concrete. The expansion joint near the wall (10 - 20 mm wide) is filled with roofing material (hydro-swelling cord).

Return to contents

Reinforcement and filling

The process of pouring the blind area of a house with concrete.

A metal mesh of 50x50 (100x100) mm is used, which can be tied to pieces of reinforcement driven into the base in increments of 0.75 m. The mesh is raised above the level of crushed stone by 30 mm. Concrete is mixed and poured with your own hands in portions into the formwork sections to the level of its upper edge.

There should be no air pockets in the concrete. The correct proportions of the concrete mixture for the blind area must correspond in frost resistance to road concrete. The composition of concrete for the blind area is traditional (corresponding grade from M400 and above). Components that increase strength and durability can be added to the solution in proportion.

Return to contents

Leveling and drying

The upper surface is carefully leveled using the rule. Resistance to concrete erosion is increased by ironing, which is done 1 to 2 hours after pouring by covering the surface of the screed with a layer of dry cement (grade M400) with a thickness of 3 to 7 mm. Then the surface is rubbed and covered with an opaque film. The blind area is ready in 10 - 14 days.

Return to contents

Making a blind area with paving slabs

To construct the structure, tools and materials are required as for concrete paths, plus a certain amount of tiles.

Construction technique:

- Prepare the base. Dig a trench up to 1.5 m wide. Excavation depth is up to 0.3 m. Slope away from the base.

- Lay out a layer of clay up to 7 cm thick. Compact. Pour sand in a layer of up to 5 cm, compact again.

- Lay out the film. This is waterproofing the blind area around the house, which will ensure the integrity of the structure. Lay out the film in several layers, cut the rolls to length, and fold the edges onto the wall.

- Curbs are installed to limit the tile structure. The stone installation line is determined by the width of the tile. A trench under the curb is dug 20 cm wider than the stone.

- Mix the cement mortar with crushed stone and sand (1:3:4). Some of the concrete is poured into the trench, a curb is placed, the rest is poured into the voids between the stone and the ground.

- A layer of sand up to 5 cm thick is poured onto the layer of waterproofing material and compacted. A layer of crushed stone up to 10 cm is placed on top, compacted and sprinkled with sand again. The layer of the latter is no more than 5 cm.

Piece material is laid out on top of the finished base. The blind area around the house made of paving slabs should lie flat and tight, so the elements are adjusted during the laying process with a rubber hammer. After finishing the work, mix a solution of cement and sand (1:3) with a thick consistency.

Remove a row of tiles from the sand, lay the mortar on the sand in a layer of 3 cm, return the tiles, and press them in. The installation of all piece cladding is carried out in the same way. During the work, check the evenness of the layout, not forgetting about the slope away from the base.

Important! The technological break for drying is at least 3 days. At this time, they do not walk on the path; they cover it with film when it rains. On average, the composition dries up to 14 days.

After drying, the path is cleaned of dust, the seams and voids are treated with cement mortar. Rub the seams and leave to dry. The installation of the tile blind area is complete.

Step-by-step instructions for making paving slabs with your own hands

How to protect the blind area from destruction?

The width and density of wall expansion joints and expansion joints filled with waterproofing should be controlled, and they should be repaired in a timely manner. For the latter, it is better to use vinyl tapes up to 15 mm thick rather than wood. On heaving soils, the blind area is not connected to the base of the house, and a storm drain and drainage system are created around the building, the structure of which effectively drains water into the external system.

The tightness of the concrete surface is increased by treating it with a deep penetration primer, a water repellent, a solution of liquid glass and cement. Additionally, the blind area around the building is decorated with stone, tiles (paving, clinker, etc.), and pebbles. Concrete acts as a solution.

Return to contents

Making a soft blind area

The main difference in the design is that there is no hard top covering. A soft blind area around the house up to 0.8 m wide and up to 0.4 m deep includes a layer of waterproofing. The general technique is similar to constructing a concrete structure, but with some nuances.

How to properly make a blind area around the house:

- the area is marked;

- dig a trench;

- Clay is poured onto the bottom in a layer of up to 12 cm;

- lay out the waterproofing material, placing the edges on the walls of the trench;

- pour sand in a layer of up to 6 cm;

- cover the sand with geotextiles;

- pour crushed stone on top of the material in a layer of up to 6 cm;

- the pillow is covered with geotextiles;

- pour a layer of clean sand up to 10 cm thick.

The final stage is decorating the top level with any chosen material. The soft structure is ready.

Construction of a soft blind area

Schematically the pie looks like this:

Sheets of penoplex or extruded polystyrene foam, polystyrene foam or sprayed thermal insulation are used as a thermal insulation layer. The layers are laid out as follows - insulation, waterproofing, drainage, geotextile sheets, sand and finishing.

Repair of concrete blind area

Crack in the concrete blind area.

Most often, the installation of an expansion joint fails, which over time loses its tightness due to expansion. A common reason is a broken technology for forming the correct concrete solution and temperature and humidity conditions for strength development. A slight increase is “treated” with sealants and foam fillers. The wide gap is widened and filled with sand-cement mortar with fine crushed stone, maintaining the isolation of the blind area from the base.

Then the dry surface is primed. The same is done with cracks in the surface of sections of the blind area: small ones are spilled with liquid sand-cement mortar, large ones are opened deeper in the form of a cone and filled with bitumen mastic, covered with sand. Significant damage (splits) are concreted with a new mixture in the mode of long-term post-wetting and covering with film.

Return to contents

What is an insulated blind area and when is it needed?

A warm blind area is a structure with a layer of special insulating material laid out. The scheme is used if the house has a used basement, ground floor or soil with a high level of humidity.

A layer of insulating material allows you to maintain a certain temperature inside the building, protects the foundation from freezing and deformation. The insulated blind area around the house is a path up to 1.5 m wide, and in addition to protecting the foundation, it reduces the amount of heat escaping through the base.

Design and diagram of the correct slab base for a house

The classic “pie” of a slab base consists of the following layers:

- A cushion made of non-metallic materials - sand, crushed stone, sand-gravel mixture.

- Concrete screed to strengthen the structure and provide a perfectly flat surface.

- Several layers of rolled waterproofing material.

- One or two layers of insulation (most often extruded polystyrene foam).

- A reinforcing frame made of one mesh or two spatially connected belts made of corrugated steel reinforcement.

- Directly a layer of concrete slab 0.1–0.4 m thick.

- A layer of waterproofing applied to a hardened slab.

The scheme is complemented by a drainage ring around the perimeter and a blind area with a backing made of insulation. As a rule, in order to prevent mixing of non-metallic cushion materials with the ground, the bottom of the soil is covered with geosynthetic fabric.

Do you need crushed stone?

The cushion under a slab foundation can consist only of a compacted sand layer and a footing, but most practicing builders add a layer of medium-fraction crushed stone to the “pie.”

This material is characterized by frost resistance (F15 to F400) and increased resistance to frost heaving forces, therefore significantly reducing the risk of possible deformations in the foundation due to temperature changes. The crushed stone is laid in a layer of up to 20 cm on compacted sand. The non-metallic material is irrigated with water and thoroughly compacted with a vibrating plate.

Warm blind area around the house materials and technology

Normal temperature inside the house, especially in the cold winter, is the main condition for comfortable living in it.

It depends on many characteristics of the house, one of which is the presence of a blind area around its outer perimeter.

Experienced craftsmen, who know about all the negative aspects of the absence of a blind area, recommend that this part of the work be completed when building a house.

A warm blind area can be not only practical, but also beautiful

Selection of materials

The choice of external coatings is made depending on the performance properties of the material and the design preferences of the owner. The most popular coating options are:

- asphalt;

- concrete;

- special tiles for sidewalks;

- natural stone.

On our website you can find contacts of construction companies that offer house insulation services. You can communicate directly with representatives by visiting the “Low-Rise Country” exhibition of houses. Using tiles as a material for external finishing of a blind area

An insulated blind area around the house, unlike the usual, lightweight version, involves the use of additional insulation. The quality and performance characteristics of a blind area of this kind depend on the choice of materials, which must have:

- Necessary thermal insulation properties with a long service life.

- Increased strength characteristics, resistance to moisture, various living organisms.

Not all insulation materials meet such requirements. The most commonly used types are:

- expanded clay;

- Styrofoam;

- polyurethane foam;

- expanded polystyrene.

The listed materials are suitable to varying degrees for performing such work.

Styrofoam

The material is used, as a rule, for independent insulation work. This is a very easy, inexpensive, widely available option. Its disadvantages:

- at low temperatures it becomes very brittle and quickly collapses;

- suitable for rodents;

- absorbs water.

Features of the construction of the blind area

If you wish, you can build a warm blind area around the house with your own hands.

The main thing is to figure out how to insulate the blind area around the house and perform all the steps in a certain sequence.

However, for an excellent result that you can be satisfied with for many years, it is worth turning to specialists. Please note that the work will require significant physical effort.

There are several types of blind area. A rigid structure involves making the top, outer layer using concreting or asphalting methods. The concrete mixture is poured onto a reinforced lattice, superimposed on successive layers of waterproofing materials, sand, crushed stone and insulation.

At subzero temperatures, water freezes, concrete cracks and collapses.

Rigid blind area around the house

Soft construction is a more reliable option for insulating the base and foundation of a building built on moving soil. Such construction is resistant to vibrations of soil layers.

Any of the materials described above is chosen as insulation. It should be noted that working with polyurethane foam requires special, expensive equipment.

When a warm blind area is constructed around a house, all stages are performed sequentially, according to the proven methodology

When constructing a blind area, you need to pay attention to significant nuances:

- If the soil is clayey, it is enough to make a trench 45 cm deep. In loose soil - at least 60 cm.

- A clay castle is erected in loose soil; its thickness depends on the quality of the soil. It is correct if the castle is made with a slight slope from the house.

- The main purpose of sand is to make the area for laying insulation more even, so its amount can be minimized. High-quality surface leveling is achieved using a vibrating plate.

- Instead of pure sand, it is better to use a mixture of sand and loam. The degree of water resistance of this composition is much higher.

- The thickness of the insulation on the blind area and foundation must be sufficient to retain the heat of the earth. In central Russia, the thickness of the insulation is at least 10 cm, on the foundation - 5 cm.

- The height of the blind area at the base of the house relative to the ground surface is 30 cm. This will ensure that water drains away from the house during rain.

When choosing a soft blind area, lay paving slabs or stone.