What is an expansion joint in brickwork?

When constructing a house, it is necessary to provide for possible deformations in various elements of the structure. An expansion joint in brickwork can prevent damage to the integrity of the walls of the building being constructed.

Construction of an expansion joint.

- Types of seams that prevent deformation of structures

- Organization of thermal seams

- Sedimentary wall joints

Purpose of expansion joint

Why is an expansion joint needed in brickwork? Logically, it can be assumed that to increase the strength of the building, protection from deformation and destruction.

How does this happen? The structure of the building is divided into compartments, special attention is paid to the corners, the division occurs by gaps, which are expansion joints. They are filled with a special sealed material, which helps to increase strength, eliminating the possibility of cracks in walls and window openings, strong and uneven subsidence of the new room.

How do you know if they are needed? Often needed. This need is primarily determined by external conditions and geometric parameters. In Russia, the climate is conducive to a sharp change in temperature, with a large difference in these indicators depending on the time of year. Since the country is large, there are regions prone to unstable soil, dangerous weather conditions, and seismological instability. All this affects construction, because the building must comply with a number of rules and regulations so that it does not have to be rebuilt and equipped with a new room each time. A properly designed structure will last for many years and protect the life and health of its owners.

There are two types of seams. The design documentation for construction must necessarily contain information about their location and purpose.

Types of expansion joints for brickwork

Main classification of expansion joints:

- temperature;

- seismic;

- sedimentary

They differ only in the method of formation and the impact of the foundation (that is, whether the seam will touch and relate to the foundation). They can be divided into vertical and horizontal, depending on the type of installation.

The basis of the expansion joint is a synthetic elastic material with a high degree of resistance to deformation or tearing. It is capable of withstanding loads of tens of tons without any consequences for itself. You need to understand that brickwork, when the ambient temperature fluctuates from +40°C in summer to -30°C in winter, can expand and contract by up to 5-10 mm. Without an elastic seam, this leads to the appearance of those same cracks. Moreover, they do not always pass through the cement mortar line.

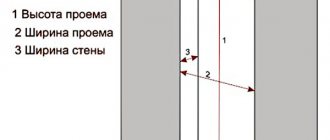

Scheme of arrangement of expansion joints.

Quite often the structure of the brick itself is destroyed. And if a masonry of 2 bricks is used, and there is insulation inside, then because of all this it will be damaged and lose its main function - protecting the room from the cold. This is especially true for polystyrene foam, which begins to rot when wet.

The thickness of expansion joints is on average 1-2 cm. Moreover, its structure can be quite different. Some people simply use synthetics, others also insulate the seam (and this is considered a more correct variation of the technology). The best mounting option is tongue and groove. Due to this, specialized stiffening ribs will be created, thanks to which the structure receives additional resistance to mechanical damage and loads.

Types of expansion joints: purpose and application

In the construction and design of structures for various purposes, an expansion joint is used, which provides strengthening of the entire structure and its protection from seismic, sedimentary and mechanical influences, from destruction, shrinkage and possible shifts and curvatures in the soil.

An expansion joint is a cut in a building that is filled with insulating material, dividing the structure into separate blocks. This reduces the load on parts of the structure, which increases the stability of the building and its level of resistance to loads. To prevent the occurrence of various types of deformations, the structure needs expansion joints.

Based on their purpose, expansion joints are divided into: temperature; shrinkage; sedimentary; seismic. In some buildings, due to the peculiarities of their location, combinations of methods are used to protect against several causes of deformation at once. This can be used when the construction site has soil prone to subsidence. It is also recommended to use several types of seams when constructing long, tall buildings with many different structures and elements.

Types of expansion joints

In any building, regardless of the type of material of the walls and foundation, the timing of construction and purpose, constant processes of deformation of structural elements occur. Ground movement, weighting of the structure, sudden temperature changes, combination of several structures from different materials - all this can cause deformation of a residential or industrial structure.

The use of expansion joints helps reduce stress in the structure of an object and allows the structure to be divided into several separate blocks for their free movement in a certain direction.

Classification of seams is carried out in accordance with factors that can cause deformation of the object under construction. They determine the types of expansion joints:

Expansion joints serve as protection against temperature changes and fluctuations. Even in cities located in temperate climate zones, cracks of varying sizes and depths often appear on houses during the transition from high summer temperatures to low winter temperatures. Subsequently, they lead to deformation of not only the frame of the structure, but also the base. To avoid these problems, the building is divided by seams at a distance, which is determined by the material used from which the structure is constructed.

Expansion joints divide the structure into blocks along the entire height of the building, without involving the foundation below ground level, since the underground parts of the structure do not experience temperature fluctuations to the same extent as the above-ground parts of the building. The size of the compartments depends on the materials of the walls and the estimated temperature of the area during the cold season.

Shrinkage joints are used less frequently than others, mainly when creating a monolithic concrete frame. They are formed along the entire height of the building, capturing the underground parts of the foundation. Since concrete often becomes covered with cracks when hardening, which subsequently grow and create cavities, the building structure may fail and suffer. The seam is applied only until the foundation has completely hardened.

Thus, the concrete foundation shrinks completely without becoming cracked. To ensure that the seam is completely sealed and does not allow moisture to pass through, special sealants and waterstops are used. Shrinkage joints are used for different number of storeys in different parts of the building and protect against the formation of cracks in various elements of the structure.

Temperature-shrinkage joints are used when it is necessary to combine different types of expansion joints.

Sedimentary expansion joints are structures used in the construction and design of structures of different heights. They are associated with the unevenness of the soil under the structure and different loads on different areas of the building, when a part of a building with a large number of floors exerts much more pressure on the soil than a part of a building with fewer floors.

Uneven pressure can cause the soil to sag, causing intense pressure on the foundation and walls. Various surfaces of the structure are covered with a network of cracks and are subsequently subject to destruction. To prevent deformation of structural elements, a sedimentary expansion joint is used, separating not only the walls, but also the foundation, thereby protecting the house from destruction.

Such a sedimentary expansion joint has a vertical shape and is located from the roof to the base of the structure, ensuring the fixation of all parts of the structure and protecting the house from destruction and deformation of varying degrees of severity. Upon completion of the work, it is necessary to seal the recess itself and its edges to completely protect the structure from moisture and dust. For this, conventional sealants are used.

Work with materials is carried out according to general rules and recommendations. An important condition for arranging a seam is that it is completely filled with material so that there are no voids left inside. On the surface of the walls they are made of tongue and groove, with a thickness of about half a brick; in the lower part the seam is made without a sheet pile. To prevent moisture from getting inside the building, a clay castle is installed on the outside of the basement. Thus, the seam not only protects against the destruction of the structure, but also turns out to be an additional sealant that protects against groundwater.

This type of seams must be installed in places where different sections of the building come into contact, in cases where part of the building is placed on soil of different flowability, or when others are attached to an existing structure, even if they are made of identical materials. The sedimentary joint is also used when there is a significant difference in the height of individual parts of the structure, exceeding 10 meters, and in any other cases where there is reason to expect uneven subsidence of the foundation.

Seismic (anti-seismic) joints are structures that are created to strengthen buildings in areas with a high seismic nature: the presence of earthquakes, tsunamis, landslides, volcanic eruptions. Seismic joints are designed according to a specific pattern, creating separate ones inside the building. non-communicating vessels, which will be separated along the perimeter by expansion joints.

Construction seams are designed only for horizontal movements of the structure and act similarly to shrinkage seams. As a rule, they are equipped in parallel with shrinkage joints and of the same type.

Insulation joints are equipped to protect the floor screed from the transfer of deformation stress along walls, columns, and foundations under heavy equipment.

Application of expansion joints

When temperatures fluctuate, structures made of reinforced concrete are subject to deformation. They can change their shape, size and density. As concrete shrinks, the structure shortens and sags over time. Since subsidence occurs unevenly, when the height of one part of the structure decreases, others begin to shift, thereby destroying each other or forming cracks and depressions.

Each reinforced concrete structure is an integral indivisible system, subject to changes due to soil settlement, sudden temperature fluctuations, and sedimentary deformations between parts of the structure. Constant changes in pressure lead to the formation of various defects on the surface of the structure - chips, cracks and dents. To avoid the formation of building defects, several types of cuts are used to increase the strength of the structure and protect it from various destructive factors.

In order to reduce the pressure between elements in multi-story or extended buildings, it is necessary to use sedimentary and temperature-shrinkable types of seams. To determine the required distance between joints on the surface of a structure, the level of flexibility of the material of the columns and connections is taken into account. The only case where there is no need to install expansion joints is the presence of rolling supports.

The distance between seams often depends on the difference between the highest and lowest ambient temperatures. The lower the temperature, the farther apart the recesses should be located. Temperature-shrinkage joints penetrate the structure from the roof to the base of the foundation, while sedimentary joints insulate different parts of the building. A shrinkage joint is sometimes formed by installing several pairs of columns.

A temperature-shrinkage joint is usually formed by installing paired columns on a common foundation. Settlement joints are also designed by installing several pairs of supports that are located opposite each other. In this case, each of the supporting columns must be equipped with its own foundation and fasteners. The design of each seam is designed to be clearly structured, reliably fix the structural elements, and be reliably sealed from wastewater.

The seam must be resistant to temperature changes, the presence of precipitation, and resist deformation from wear, shock, and mechanical stress. Seams must be made in case of uneven soil or unequal wall heights. Expansion joints are insulated using mineral wool or polyethylene foam, which protects the room from low temperatures and provides additional sound insulation.

Inside the room, each seam is sealed with elastic materials, and on the outside - with sealants that can protect against precipitation. Such seams make it possible to reduce the load on building elements in areas of possible occurrence of various deformations that can arise as a result of various reasons:

Sudden changes in external temperature; Seismic activity; Uneven soil settlement; Impacts that pose a danger to the stability of load-bearing structures of buildings.

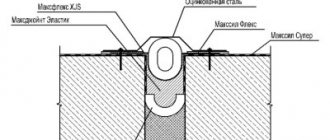

There are various ways to seal expansion joints: sealants, putties, waterstops, and other types. For example, waterstops are used as waterproofing of expansion joints in monolithic buildings, foundations of various structures, etc.

The waterstop is a polyvinyl chloride tape that is mounted into the formwork when installing the structure in parts. The waterstop has a cavity structure, which makes installation easier and determines the reliability of joints in expansion joints.

Types of expansion joints in a brick multi-storey building

In addition to temperature ones, there are other types of expansion joints in masonry, such as:

- shrinkage;

- sedimentary;

- seismic.

All types of special gaps protect each structural unit of the house from destruction and prevent the formation of cracks in load-bearing and other walls. Temperature and shrinkage voids are made in all brick houses without exception. Sedimentary ones perform a protective function against destruction under high loads and are needed in multi-storey buildings and houses with an extension. They are made starting from the foundation, but the device is made on the principle of vertical temperature gaps, so it is possible to combine them into heat-shrinkable ones and create them in one firmware. It is advisable to create seismic voids only in areas with increased seismic activity.

Kinds

Settlement joints are the most popular because very often the subsidence of the structure occurs unevenly along the entire length and there is a risk of destruction of the building for this reason. These seams are made starting from the base of the foundation to the beginning of the roof. During construction, you need to take into account that all seams must be dried, and the shear thickness should not exceed 1/4 of the brick.

The thickness of the expansion joint in brickwork: the joint is 10-20 millimeters, it replaces some of the vertical ones.

An urgent need arises when an old wall adjoins a new one, when connecting two parts of a building, building on ground with uneven settlement and erecting structures in dangerous areas, that is, those where earthquakes, hurricanes and the like regularly occur.

Temperature-shrinkage seams deserve special attention. Why? Because they protect buildings from cracks and destruction associated not only with temperature changes and changes, but also with shrinkage. To summarize, we can say that they are relatively universal.

They are usually used when there is a strong temperature difference between winter and summer, for example, as happens in Russia. Their thickness depends on the time of year and temperature during the laying process and is indicated in the set of building codes and regulations (SNiP).

How to make it yourself

The ideal solution is to install a vertical or horizontal expansion joint during the construction work associated with the construction of the building. In such a situation, it becomes possible to use it to make connections between concrete and ceiling, ensuring uniform deformation of the seam section along its entire height or length. This measure further reduces the likelihood of cracks forming in monolithic elements of the object.

The seam formed at the construction stage is easy to install. To do this, it is enough to step back from one brickwork, paved the resulting gap with waterproofing material and sealant.

All this is covered from above with a solution of decorative plaster mixture used for exterior finishing, or with siding panels, if their installation is planned by the design task. Similar actions are carried out indoors if masonry work is carried out in a thickness equal to one brick stone. The seam area can be additionally insulated from moisture on top by covering it with a mesh of mineral wool. By the way, this precaution will enhance waterproofing.

If the building has been in operation for some time, the correct solution would be to install expansion joints along the threads and cracks, if any have already formed. The principle of performing installation work is similar, as are the building materials used for these purposes. There is only one difference - ties in the form of steel pins are installed in the cracks.

The necessary materials are inexpensive, but to form the recesses you will need to work with a hammer drill.

Sedimentary joints are arranged perpendicular to the walls or foundation. In this place, the bricks are not tied to each other, but a waterproofing layer is laid in two or three layers. The foundation seam is made straight, for walls - with a tongue and groove, the thickness of which reaches a quarter or half of the brick stone. A gap of one or two bricks is placed above the foundation cut to prevent pressure from the tongue and groove on the masonry if uneven settlement occurs. All connecting areas are reliably sealed from the negative effects of a humid environment.

The size of the sedimentary joint is one to two centimeters, so when installing it you will not change the overall length of the building. The outer side of the sedimentary seam is sealed with tow impregnated with resin, silicone-based sealant, and special sealing materials.

Sedimentary separations are arranged in the following cases:

- connection of newly built walls to existing ones;

- connection of individual parts of structures - verandas to the load-bearing wall;

- in cases of work in areas with weak soil composition.

Types of expansion joints and their waterproofing

Deformation is a change in the shape or size of a material body (or part of it) under the influence of any physical factors (external forces, heating and cooling, changes in humidity from other influences). Some types of deformations are named in accordance with the names of the factors affecting the body: temperature, shrinkage (shrinkage is a reduction in the size of a material body when its material loses moisture); sedimentary (settlement is the subsidence of the foundation when the soil underneath is compacted), etc. If by a material body we mean individual structures or even a structural system as a whole, then such deformations under certain conditions can cause violations of their bearing capacity or loss of their performance qualities.

Long buildings are subject to deformation under the influence of many reasons, for example: with a large difference in the load on the foundation under the central part of the building and its side parts, with heterogeneous soil at the base and uneven settlement of the building, with significant temperature fluctuations in the outside air and other reasons.

In these cases, cracks may appear in the walls and other elements of buildings, which reduce the strength and stability of the building. To prevent the appearance of cracks in buildings, expansion joints are installed, which cut the buildings into separate compartments.

Depending on the purpose, the following expansion joints are used: temperature, sedimentary, anti-seismic and shrinkage.

Structurally, an expansion joint is a cut that divides the entire building into sections. The size of the sections and the direction of division - vertical or horizontal - are determined by the design solution and power calculation of static and dynamic loads.

To seal the cuts and reduce the level of heat loss through expansion joints, they are filled with an elastic heat insulator, most often these are special rubberized materials. Thanks to this division, the structural elasticity of the entire building increases and the thermal expansion of its individual elements does not have a destructive effect on other materials.

As a rule, a temperature expansion joint runs from the roof to the very foundation of the house, dividing it into sections. There is no point in dividing the foundation itself, since it is located below the freezing depth of the soil and does not experience the same negative impact as the rest of the building. The spacing of expansion joints will be influenced by the type of building materials used and the geographic location of the object, which determines the average winter temperature.

Waterproofing expansion joints

To avoid heat loss through the seams, as well as moisture and water particles getting inside, each seam is waterproofed.

The simplest option is to use construction tow soaked in bitumen. Professional builders consider this method outdated and prefer more modern materials.

Seams are often filled with construction foam. However, it does not have sufficient elasticity and can tear when the seams expand and, therefore, allow moisture to enter.

The method of using a particular material is always described in detail by the manufacturer in the instructions.

In general, embedding usually consists of the following steps:

- Cleaning the seam.

- Degreasing surfaces.

- Profile settings.

- Filling with sealing mastic.

Building protection technology

Typically, the protection of structures is organized through several technologies and measures. There is a set of recommended rules on this topic, which was discussed above.

This article talks about protection technology by creating expansion joints - this is a fairly effective and time-tested method. There are modern technologies being implemented that are at the stage of experimental testing, so it is better to use either temperature, shrinkage, or a combined technique. The choice depends on the type of building, soil and climate.

Strength, stability and reliability are the three pillars of building protection and proper organization of construction. It all starts with the design stage, where you need to study the terrain, the climate and weather depending on the time of year, the purpose of the room, the activity of its use and load. An expansion joint in brickwork ensures that all available and recommended levels of structural safety are met.

All this, one way or another, affects the safety and integrity of the building.

conclusions

To summarize, it is worth noting that building structures are subject to the destructive effects of the external environment, such as temperature changes and drying by the rays of the sun. Rain, salt, snow and wind, exposure to moisture coming from inside the building, earthquakes, dangerous weather events - all this can lead to cracks and destruction. This is dangerous financially, socially, and in life terms - people may suffer. Therefore, at the design stage, pay attention to such an important stage as creating an expansion joint in the brickwork.