A year after the construction of the foundation of the house, it is imperative to prepare a blind area that will drain rain and melt water from the foundation. In the manufacture of such a structure, a variety of materials and technologies are used, but it is also necessary to take into account the fact that the base itself also requires protection from moisture. A blind area with waterproofing will ensure dryness in the basement and preserve the foundation for a long time.

In order to properly make a waterproofing layer, you first need to decide on the material for it.

Materials for the blind area

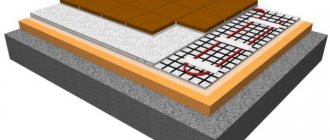

The waterproofing of the blind area consists of an underlying layer 20 cm high and a coating of bulk material that resists the penetration of water into the structure. Sometimes insulation material is additionally laid between these layers.

Important! If you use raw materials with a porous structure, then each layer must be treated with water-repellent preparations.

Today, the following materials are used for waterproofing blind areas:

- Hot tar or bitumen mastics. These compounds are used when coating the foundation.

- Ruberoid, hydroglass insulation, geotextiles.

- PVC films.

- PVP membranes (profiled).

- Geotextiles, rubemast.

If you plan to make a solid slab, it is best to use hydraulic cement or asphalt concrete. There are also specialized compounds that have waterproofing properties, for example, “Xypex”, “Masterseal” and other polymer preparations. They penetrate into concrete and reliably protect it from the harmful effects of moisture.

To waterproof soft blind areas, roll materials are used, but roofing felt and polyethylene cannot completely protect the foundation from moisture. Therefore, it is better to give preference to polyvinyl chloride films.

In addition, roll materials have the following disadvantages:

- The surface of the basement floor must be leveled, cleaned and thoroughly dried.

- Materials of this type have very low strength and fragility.

- The process of laying such materials requires a lot of effort and time.

- The waterproofing layer must be protected from mechanical damage.

Healthy! If you use rolled materials, it is recommended to carry out additional vertical waterproofing. To do this, the material must be wrapped on the wall of the house, 150-200 mm high.

Other nuances of waterproofing the blind area of a house

- To create a blind area, it is better to use solutions that are made using waterproofing cements. In this case, the protection of the blind area will be much higher.

- How to protect the blind area in case of excessive accumulation of groundwater and in case of poor drainage? It is imperative to make a groove along the perimeter of the blind area. This simple device for waterproofing the blind area, in turn, will ensure water drainage.

- Before filling the ditch for the blind area, you must first cover it with waterproofing. In this case, there must be an influx on the foundation walls. The best materials for this purpose are those based on polypropylene. Polyvinyl chloride films are also suitable. Ruberoid and polyethylene film are practically unsuitable for these purposes.

- Before covering a concrete blind area with materials with a pronounced porous structure, they must first be treated with a water-repellent agent. Without treatment, artificial stone is good for such purposes.

- Drainage profiled membranes will be very useful when installing a blind area. They thus represent an analogue of a concrete blind area. Thus, the membrane located on the ground will be covered with crushed stone and sand.

Following this, waterproofing the blind area around the house can be made from any coating. Here the owner’s hands are completely untied on this issue.

As you can see, waterproofing a blind area is a very simple matter. With a little skill, you will certainly be able to cope with such a problem.

How to waterproof a blind area

Depending on the availability of the basement, single-level and two-level blind areas are performed:

- If the house does not have a basement, then the waterproofing layer is laid at the basement level, that is, 200 mm above the ground. Since the base must be made at a slope of 2-5 degrees, the protective layer is laid along special protrusions. Thanks to this, each subsequent layer will protrude a certain distance.

- If the building has a basement, then it is necessary to perform two-level waterproofing. The first layer is located at the basement floor level, and the second layer is located at the basement level, above the blind area.

To make the base, follow these steps:

- Remove the top layer of earth, having previously calculated the width of the blind area (usually it ranges from 60 to 120 cm).

- Place a layer of clay 10 cm high at the bottom of the trench.

- Lay the waterproofing material by folding its edge onto the wall of the house.

- Pour sand 10 cm high and compact it.

- Lay the geotextile and sprinkle it with a thin layer of sand (about 5 cm).

- Place crushed stone, pebbles or gravel 15 cm thick.

- Lay another layer of geotextile and sprinkle it with sand again (if the blind area is soft, you can skip this step).

- Fill the base with cement and lay paving stones on it. If you are preparing a soft base, you can immediately lay out the paving slabs by tapping them with a rubber hammer.

You can also perform horizontal waterproofing using:

- Cement screed made of PC and sealants 20-25 mm thick.

- Ruberoid or roofing felt, which is laid in two layers and glued with mastic.

- Asphalt screed 25-30 mm thick, which is laid at the level of the base of the building.

When working, you should pay attention to some features of waterproofing.

Membrane waterproofing installation technology

This type of material is relatively new, and the technology for its installation differs significantly from the use of adhesive or weld-on materials, but it is quite simple. Membrane insulation is characterized by high quality protection and resistance to foundation shrinkage.

Depending on the direction of waterproofing, different materials will be used. So, to arrange the vertical walls of the foundation surface, it is necessary to use a profiled membrane, which has protrusions in the form of spikes on one side. It allows you to evenly distribute pressure over the surface of the foundation, and also condenses moisture on its outer studded side, which easily flows into the drainage due to the loose fit of the soil. For a horizontal surface, it is necessary to use a smooth membrane that will not allow moisture to rise through the pores of the concrete.

The technology for laying these types of membranes is as follows:

- The profiled membrane is secured using special PVC-coated metal elements. They are fixed to the foundation walls, after which the membrane is fixed to them using a special construction heat gun.

- The smooth membrane is laid on the foundation with an overlap, and the joints are welded using the same construction hair dryer.

Features of blind area waterproofing

When waterproofing a blind area, you must consider the following recommendations:

- When making a protective “tape” around a building, it is best to use solutions that include waterproofing substances.

- Rolled materials can only be used if the differences in base height do not exceed 2 mm.

- If it often rains heavily in your region, then after constructing the foundation, dig a gutter around its perimeter that will drain the water.

- It is not recommended to use scrap as a filler for the base, since this material will contract and expand with temperature changes.

- The depth of the blind area may vary depending on the groundwater level, the amount of precipitation and climatic conditions, and the presence of sewage systems.

There is also a painting waterproofing of the blind area, which is performed by applying bitumen mastic.

Membrane waterproofing installation technology

This type of material is relatively new, and the technology for its installation differs significantly from the use of adhesive or weld-on materials, but it is quite simple. Membrane insulation is characterized by high quality protection and resistance to foundation shrinkage.

Depending on the direction of waterproofing, different materials will be used. So, to arrange the vertical walls of the foundation surface, it is necessary to use a profiled membrane, which has protrusions in the form of spikes on one side. It allows you to evenly distribute pressure over the surface of the foundation, and also condenses moisture on its outer studded side, which easily flows into the drainage due to the loose fit of the soil. For a horizontal surface, it is necessary to use a smooth membrane that will not allow moisture to rise through the pores of the concrete.

The technology for laying these types of membranes is as follows:

- The profiled membrane is secured using special PVC-coated metal elements. They are fixed to the foundation walls, after which the membrane is fixed to them using a special construction heat gun.

- The smooth membrane is laid on the foundation with an overlap, and the joints are welded using the same construction hair dryer.

We suggest you familiarize yourself with what depth to pour the foundation for a house

Painting waterproofing

Protecting the base of a blind area from moisture with paint-based waterproofing is inexpensive and easy to install. Before treating the surface of the base, it must be primed with bitumen mastic. After this, a bitumen-polymer, cement-polymer, bitumen or polymer paint composition is applied to the primer layer with a brush.

Healthy! If the composition is applied to rubble walls, they must first be leveled.

Bitumen mastic is applied in 2-3 thin layers no more than 2 mm thick. After treatment, the surface is checked for cracks, swelling and other defects. If any are found, the surface is cleaned and re-coated with a waterproofing compound.

It is worth considering that when working with hot materials, you must adhere to the following precautions:

- The boiler for boiling bitumen must be installed at a slight angle so that the molten liquid does not fall into the fire. You also need to prepare sand and a fire extinguisher nearby.

- When using several grades of bitumen, the lower grade melts first, and then the high one. If you add low-grade bitumen to hot concrete, this will lead to rapid foaming, which can cause the composition to spill out.

- The amount of bitumen in the boiler should not exceed 2/3 of the tank volume.

- To avoid hot splashes, slowly lower pieces of bitumen along the side of the boiler.

- You can work with molten mastic only in protective clothing.

Blind area in house construction

The basis of any capital structure is the foundation. For the construction of houses in individual housing construction, the bearing capacity of the underlying soils and their water content on an annual basis are studied in accordance with the normative procedure. After erecting any type of foundation, floors and walls, it is necessary to pay attention to the contact area between the vertical plane of the foundation and the soil outside the house.

Even a short rain will cause water to flow down the walls of the house and enter this contact zone. There is a constant wetting of both the foundation itself and the underlying soil. Its load-bearing capacity changes. Drawdowns occur. In more severe cases, the basement floods.

Heaving soils are especially dangerous. Their constant shifts caused by the influx of water lead to the destruction of the building.

Protective role of the blind area

Preventing the negative consequences of wetting the foundation and soils in its vicinity is carried out by constructing a blind area around the entire building. This is a hard, durable waterproof strip, 0.9–1.3 meters wide, which slopes away from the house. Many people think that the blind area is the sidewalk around the house. Like a roof that protects the entire house from precipitation, the blind area protects the most important thing on which this house stands - the foundation. When constructing residential buildings, regulatory documents unambiguously and clearly indicate the need to construct this part, immediately after the construction of the building.

It happens that in individual housing construction, when constructing a house independently and slowly, the construction of the blind area around it is postponed indefinitely. This should not be done.

Types and types of blind areas, materials for their waterproofing

The choice of blind area design determines the amount of precipitation falling on it. If the drainage from the roof is not organized and is not diverted down by special pipes, then the blind area will be subject to strong influence of jets of water flowing evenly from the entire roof. Such a blind area should be stronger and thicker.

There are several types of blind areas, they are either made on site or assembled from ready-made elements:

- a simple, bulk blind area made of clay covered with crushed stone;

- blind area made of clay, crushed stone and additional waterproofing material;

- a blind area made of concrete (with or without reinforcement), which is poured on site;

- blind area made of ready-made reinforced concrete slabs.

For waterproofing blind areas, materials of varying cost and manufacturability are used:

- bitumen mastic or hot tar is used for coating the foundation and sizing;

- rolled waterproofing materials - roofing felt, hydrostekloizol, hydrostekloizol, etc.;

- modern inexpensive rolled materials - geotextiles, polypropylene, rubemast and other numerous rolled materials used primarily for roofing;

- for solid blind areas, hydraulic cements and asphalt concrete are used;

- from effective modern materials for waterproofing the blind area around the house, special compounds penetrating into concrete are used that make it protected, Xypex and its analogues,

- Mastersil and his clones;

- other polymer waterproofing compounds.

Adviсe

- The combination of liquid material and rolled material is used only if there is high humidity in the area or there is a risk of breakthrough of nearby sources.

- To fill the channel, crushed stone of only the middle fraction is used.

- When waterproofing the blind area, the foundation is simultaneously sealed.

- If your building does not contain gutters, then it is better to pour concrete.

- Mixing concrete with clay is not recommended. It is better to use only high-quality mixtures, then the blind area will serve you for a long time.

- When using joint sealing products, the surface is first cleaned of dirt and dust.

- It should be remembered that the blind area runs along the entire perimeter of the building, so when choosing a material, remember that it must match the style of the building and all work must be done carefully.

- Plants have no less destructive power than moisture, so if you find roots in the soil, they must be treated with herbicides to prevent their germination.

- An expansion joint should be left at the junction of the blind area and the foundation. This is necessary in cases where materials change their size due to the ambient temperature.

- Drying concrete too quickly can cause cracks to appear. To avoid this, the concrete layer is covered with PVC film or a wet piece of fabric. On hot days, periodically water the blind area with water, this will give it even greater strength.

We suggest you familiarize yourself with the blind area around the house - how to do it correctly. The best blind areas for modern types of houses (145 photos)

Technologies for waterproofing the blind area around the house on your own

When making a blind area, it is necessary to remove the soil and plant layer along the entire perimeter of the house at a distance of up to 1.3 m. If you make a budget version of the blind area from clay, you need to ensure that it is compacted and tightly adjacent to the foundation. It is advisable to spray the junction with hot bitumen. You can glue a strip of rolled material to the vertical surface of the foundation concrete. When pouring clay and compacting, it is necessary to create a slope of the blind area away from the house. It is enough to make a 10% slope.

If funds allow, all clay after compaction is covered with a layer of rolled waterproofing material. To enhance the waterproofing ability of the blind area, several layers can be laid with hot bitumen. Then backfilling with crushed stone and compaction occurs.

As an option, the waterproofing layers are backfilled with sand, followed by laying artificial stone or paving slabs.

One of the most common ways to construct a waterproofing blind area around a house is to make formwork and simply pour concrete into the prepared bed (with a layer of crushed stone) for the blind area. You can use reinforcement mesh. Next comes the formation of the slope. This horizontal layer of concrete acts as a waterproofing barrier. Decorative tiles can be laid on top of the concrete layer.

Instead of pouring monolithic concrete on site, you can prepare a base of sand and crushed stone, pour bitumen and lay ready-made concrete slabs.

We should not forget that the blind area plays not only a protective role. It must carry an additional aesthetic load and correspond to the architectural design as a whole.

The article discusses the need to construct a blind area in individual housing construction. The main role of the blind area is shown - waterproofing the foundation and soil. Options for various designs of blind areas are given. An overview of materials for waterproofing blind areas around the house is given.

Waterproofing the blind area of a house using the painting method

This method of waterproofing a blind area is now quite popular, despite the fact that it appeared relatively recently. It is based on ensuring a significant increase in the durability and strength of the structure due to the influence of hydraulic pressure.

This effect is possible due to the penetration of insulating materials deep into the pores of the blind area (about 40 centimeters). In this way a crystalline structure is formed. Water is not able to filter through the concrete body.

The painting method is quite popular. How to treat the concrete blind area in this case? Good protection of a concrete blind area is achieved by using bitumen mastic. It is applied with a brush to a clean and dry surface on top of the primer.

If necessary, the walls can be easily leveled with mortar. This method is also applicable to rubble walls.

This whole process should be divided into several steps, carefully treating the entire surface.

In the end, you should get a continuous waterproofing of the blind area around the house. Under no circumstances should there be any cracks or swelling on it. When applying mastic to an uncleaned or damp wall, these defects may well appear. To get rid of defects, these areas need to be cleaned again, then dried and also covered with a new layer of mastic.

Bitumen mastic is also used as an adhesive solution for horizontal adhesive waterproofing. This method is typical for using roofing felt or roofing felt.

Materials for waterproofing the blind area must be cut into small pieces before installation. It is necessary to make allowance for overlap during the installation procedure itself. Before processing the concrete blind area, careful grinding should be done.

Mastic is also used in areas of overlap seams. After the final layer, mastic is applied to the material itself. It should be applied in a continuous layer. Then everything is covered with dry sand. The blind area with insulation and waterproofing is ready!

We invite you to familiarize yourself with Crochet washcloth with elongated loops: pattern for beginners