How to connect the halogen lamp protection unit?

An unpleasant feature of halogen lamps is that they burn out when turned on.

Simple incandescent lamps also have this feature, but to a lesser extent. A halogen lamp burns out, as a rule, when it is turned on, when the filament coil is still cold and its resistance is low. At the moment of switching on, a large current surge occurs, with a short-term release of high power on the spirals. To extend the service life of halogen lamps, there is a special device - a halogen lamp protection unit. The unit is connected in series with the lamp and limits the current at startup. The current passing through the lamp, and hence the intensity of the glow, gradually increases during the first seconds. Such a unit is also called a protection device, a protection device, or a soft start device for halogen lamps. The device can be used to protect both halogen and simple incandescent lamps.

Installation and connection of the halogen lamp protection unit.

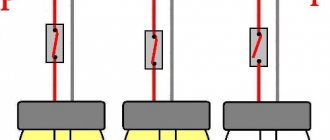

Connecting the block does not cause any difficulty since it has two terminals, and the polarity does not matter. It is better to make the connection in front of the first lamp in a phase break (Fig. 1). At the same time, the block itself is easily hidden behind a suspended ceiling. You can place the protection unit in the socket box behind the switch, although this can only be done if there is free space behind the switch. If 12 V halogen lamps are used for lighting paired with a conventional step-down transformer, the unit is connected to the gap in the primary winding (Fig. 2).

Connection diagram for the soft start unit for halogen lamps.

The selection of a halogen lamp protection unit is made based on the total power of all lamps, plus a margin of 25-30%. For example, if the power of all lamps is 350 Watts, it is worth buying a unit with a maximum power of 500 Watts.

Related materials:

Lamp protection unit: selection, principle of operation, installation and connection

Most often, the light bulb burns out when turned on, when the filament has not yet warmed up and has little resistance. To avoid such a development of events, a hardware device was invented - a lamp protection unit (it is also called a soft starter). The purpose of the unit is to prevent damage caused to the light bulb as a result of power surges in the network.

Incandescent lamps operate according to the principle of thermionic emission. When current enters the coil, it heats up, resulting in the production of light in the visible part of the spectrum. Moreover, the heat generation power is inversely proportional to the diameter of the conductor. As a result, the thinned sections of the spiral heat up very quickly, which leads to a loss of their strength. It is the thinned places that are the weak link, where burnout occurs.

Note! Lamp burnout is caused not only by voltage surges, but also by such phenomena as induced and parasitic pulsation.

Halogen light bulbs are also prone to burnout due to power surges. Such light sources have a feature that is unique to them - a tendency to overheat. An overheated light bulb can burn out at any time.

Not only incandescent and halogen lamps need protection, but also LED lamps.

At first glance, this looks strange, because LEDs do not have a spiral, and the glow of the crystal occurs as a result of the excitation of electrons, and not the heating of the spiral. However, the operating principle of LEDs also involves thermionic emission.

After several years, the semiconductor section burns out and, if you look closely at the LED lamp, you can see dull crystals with a pierced semiconductor layer.

Operating principle of the block

The protection unit runs in series with the lighting device and transmits electricity to a limited extent. The current is increased gradually - over 1-2 seconds. Without a block, current flows instantly, which often leads to lamp burnout.

The block structure is simple. For its operation, input-output, phase-ground, and polarity do not matter. The device should be connected in series mode with a switch installed in a phase break.

The soft start device allows you to:

- Avoid the negative impact of voltage surges when connecting the lamp.

- Stabilize the current in the light bulbs after exposure to starting electricity.

- Extend the life of the light source.

An important advantage of the protective device is that it prevents the lamp from flickering. Thanks to this, being in a lighted room is comfortable, since there is no excessive strain on the eyes.

Precautionary measures

When a light bulb burns out, the filament opens, which leads to a short circuit. As a result, there is a risk of failure of the protective unit. To prevent this, do the following:

- The protective device is installed in the most accessible area (socket box or panel). Getting to the ceiling block will be much more difficult.

- Install a dedicated circuit breaker on each line. The nominal value of the switch is selected with a small margin, since current drops are not taken into account with this connection option.

- Installation of the protective unit in rooms with high humidity levels is not allowed.

Manufacturing of the protection unit

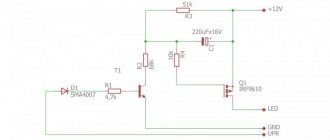

The scheme for smoothly connecting an incandescent lamp to the network is quite simple. However, when making a block with your own hands, you should take into account some technical nuances. You must also comply with regulations regarding electrical devices. As an example, below is a diagram according to which a self-made protection unit operates.

The diagram shown above shows the smooth switching on of an incandescent lamp. Moreover, polarity is not taken into account. The device is connected out of phase to create a series connection with the switch. The latter should be single-key.

When creating a block, it is also necessary to take into account the following circumstances:

- The field-effect transistor must be closed at the beginning of operation of the device. This element receives stabilization voltage, since it is included in the diagonal of the diode bridge.

- Capacitor C1 receives a charge when voltage passes through resistor R1 and diode VD1 until a level of 9.1 V is reached. This level is the limit due to the limiting effect of the zener diode.

- When the voltage reaches the desired level, the transistor opens little by little, which leads to an increase in current and a reduction in the voltage at the drain. Next, the light bulb filament begins to gradually heat up.

- For normal startup, a second resistor is required, since it makes it possible to discharge the capacitor after turning off the power supply to the lamp. At this moment, the voltage at the drain is small - about 0.85 V at a current of about 1 Ampere.

The unit will operate both in networks with a standard voltage of 220 V and at reduced voltage.

Soft starters make it possible to significantly increase the working life of light bulbs. However, their installation requires compliance with technical regulations and requires at least minimal knowledge of electrical engineering. If there are none, it is better to invite a professional to perform the installation.

Lamp protection unit: selection, principle of operation, installation and connection

Source: https://220.guru/osveshhenie/istochniki-sveta/blok-zashhity-lamp.html

Halogen lamp protection unit

2016-04-01

Tips No comments

As I promised in the article Installing and connecting spotlights, today I would like to talk a little about such a device as a halogen lamp protection unit.

As the name suggests, it is designed to protect halogen lamps from inrush currents; in other words, the protection unit is a soft starter. The fact is that when the lamp is turned off, the filament of the lamp is in a cold state and its resistance is low.

When switched on, a starting current will flow through the lamp for some time, significantly greater than the rated one, which will lead to a sharp increase in resistance, and consequently to overheating of the filament and its gradual burnout. This can occur from frequent switching on of lamps, as well as from power surges in the network.

In order to limit the current at the moment of switching on, and therefore ensure smooth heating of the filament and less wear, protection units are used. They are connected in series with the lamp and, in addition to protection against current surges, also provide a stable output voltage. In addition to halogen lamps, the protection unit can also be used with incandescent lamps.

Protection of halogen lamps 220 volts, smooth switching on

We have all been familiar with the problem of incandescent lamps burning out since childhood, when as children we had to unscrew the light bulbs willy-nilly and change them so that light would appear in the most cherished place in the house.

Times have changed, most of us already use LED or fluorescent lamps, but the problem remains relevant with halogen lamps. Personally, I encountered this problem when I installed 11 lamps on the ceiling in a room with halogen incandescent lamps. The price of one lamp is from 20 to 50 rubles; in a month, with rare use, at least 1 lamp burned out, which created problems, so I immediately purchased 10 spare lamps.

Being savvy in radio electronics, I knew about soft-start devices that significantly increase the life of incandescent lamps.

Due to the smooth switching on, more gentle modes act on the filament; there are no pulse-like bursts at the moment of switching on, due to which 90% of incandescent lamps burn out.

There was no desire or time to look for a diagram of such a device, go for radio components, solder, and out of good old habit, I decided to see what the Chinese were offering. To my surprise, I was unable to find soft-start units on Chinese websites and I started looking at regular online stores, one of the first was the website of a Belarusian company that produces Granite protection devices, the price for the 200 W units I needed was $5, I already I was about to order when I saw the banner “we collaborate with bloggers.” In general, I will tell you for a long time, the point is that the management sent me two halogen lamp protection units for free.

The parcel arrived very quickly from Belarus, was packaged well, included advertising booklets and, most importantly, two devices for a 200-watt load. These are the lowest-power devices, and there are also ones for transformer chandeliers, LEDs, control systems and much more.

In this video I demonstrate the smooth switching on of halogen lamps and the operation of the Y-B22 remote control system, which suddenly broke down during the first power surge, or rather network interference (sparking at the input contacts).

The protection units are installed in the electrical installation box behind the switch, connected in series. The blocks emit a slight buzzing noise, which is audible in absolute silence; if the blocks are in a box in the wall, you will not hear any sound. Below is a short photo review and comments.

The parcel from Belarus arrived very quickly, I don’t remember, but no more than 2 weeks, packaged well, the manufacturer included a lot of promotional booklets as a bonus

A cardboard box from a higher power device in the background, 200 watt protection units are supplied in such nice packaging with instructions and connection diagrams

On the left we see the control unit and remote control from the Y-B22 device, which was very pleasing, but burned out due to network interference, maybe I’ll try to repair it later

I chose this model because it has the most attractive remote control design, but in reality the buttons stick and the quality is not at all what I would like, the chrome will quickly peel off with frequent use, typical Chinese low quality

This is what the Granite protection block board looks like, the only negative is the buzzing sound during operation, but if you install the blocks in a switch or box in the wall as indicated in the instructions, you will not hear any sound, I had to fill the boards so that it would not be heard from under the stretch ceiling epoxy resin

This is what the Y-B22 control unit looks like, on the right we see an attached circuit board, which is responsible for the remote control, so it failed due to interference in the network

What conclusions can be drawn: a protection device for halogen lamps is definitely worth buying (you can solder it yourself) if you have more than 10 lamps, since otherwise you will be tormented by changing light bulbs - this is unpleasant both from the point of view of convenience and from the point of view of finances (lamps you need to find and buy, which is not always easy). Since the installation of the Granit device, not a single lamp has burned out!

Lighting lamps have a short lifespan, which is a problem in today's world. When the lamps are turned on, they fail, which is a pressing problem. The filament produces little resistance when cold. It is too reduced than the resistance of a hot filament to electric current. We turn on the light, then the lamp filament is cold, and the current value is significantly higher than the nominal value, so it tends to burn out.

Lamps in lamps and chandeliers burn out for various reasons. If she is alone, then that is better. You can save on buying light bulbs if you know the main reason. In addition to saving money, your lamp will not break down, or worse, there will be no fire in the house.

There are many different lamp protection module options. We will look at some ways to protect lamps using real-life examples.

Connecting the halogen lamp protection unit

Let's consider the connection using the example of a Granit-600 halogen lamp protection unit from.

Here are its technical characteristics:

| Mains voltage | 220 V ± 20% |

| Load power | 600 W |

| Load voltage | No more than 230 V |

| Operating temperature range | −20…+40 °C |

As already mentioned, the protection unit is connected in series with the lamp into the phase wire break. Polarity does not matter at all.

In the case of connecting halogen lamps with a voltage of 12v through a step-down electromagnetic transformer, the protection unit is connected to the transformer in series with its primary winding.

This type of protection units is not suitable for use with electronic transformers. To connect via an electronic transformer, you can use protection units with the index “T” from the same “Nootekhnika”.

The power of the protection unit is selected depending on the total power of the connected lamps with a margin of 20-25% to increase its service life. It is advisable to install the unit in such a way that you can always have free access to it in the future.

In conclusion, I would like to note that the use of a protection unit can significantly (5-7 times) increase the service life of the lamp, so their use is very advisable.

Protection unit for incandescent and halogen lamps

It is a capacitor with a power of up to 200 W. There are protection schemes for halogen lamps with higher power. It protects the lamps by smoothly heating the filament, which will significantly slow down the wear process and increase the service life.

We will demonstrate its connection in practice, using incandescent and halogen lamps. It has no effect on energy-saving lamps.

To compare the results, let’s first connect without the protection unit. The lamp lights up instantly. Now let's connect the lamp protection unit. It is connected to the phase wire. To determine the phase, we use an indicator screwdriver. We connect the block using clamp terminals.

This unit is designed to work with transformers and step-down coils. It is not designed to work with fluorescent lamps, electric motors and similar mechanisms, devices similar to it. We connect the network, the lamp lights up in about two seconds, a very smooth start. The lamp will not burst if turned on abruptly and will last longer.

For comparison, let's connect a halogen lamp. We insert the lamp into the socket and connect it to the network. Connecting the protection of halogen lamps is similar. This ignition can be used where there is an incandescent filament.

You can also install a thermistor. The part is cheap, but it works reliably and does not create any interference. You need to take a large thermistor for slower heating, with a resistance above 0.5 kOhm. It can be easily built into any housing or switch. Insulation is put on the terminals; it does not melt, since the temperature is low.

It is better to connect ordinary incandescent light bulbs with a spiral to a lower voltage (180-200 V). If the voltage is 240 volts, then two lamps can be connected in series.

Halogen lamps love a constant, precise voltage, so they must be connected to a stable voltage, and a soft start must be made (lamp protection unit).

Halogen lamp protection unit. Selection, installation, connection.

Halogen lamp protection block Granite

Halogen lamps have an unpleasant feature - they burn out when turned on. Conventional lamps, of course, also have this disadvantage, but not to such an extent.

Halogen and incandescent lamps, as a rule, burn out when turned on, when the filament is still relatively cold and its resistance is low. In this case, a large current jump occurs, and a short-term high power is released on the spiral. This effect is described in detail on SamElectric in the article Resistance of an Incandescent Lamp Filament.

To extend the life of halogen lamps, such a device was invented - a halogen lamp protection unit . The principle of operation of the protection unit is extremely simple - since the lamp burns out at the moment of a sharp jump in current through it, this device is connected in series with the lamp and limits the current at the initial moment.

The current, and therefore the brightness, gradually increases over 1 - 2 seconds. Connecting the protection unit is not difficult. It has two terminals, polarity, input-output and phase-ground do not matter. It is better to connect it in series with the switch in a phase break.

Such a unit is sometimes called a soft starter, a protection device, or a protection device. The device is used not only for halogen, but also for conventional incandescent lamps.

Installation and connection of the halogen lamp protection unit

Physically, the protection unit can be installed in the ceiling, directly at the location where the lamp is installed. If there are several lamps, then the block is placed in front of the first lamp, as shown in the photo below.

Installing a protection unit in the ceiling

It is easier to place the protection unit in the mounting box under the switch, if free space allows and if the power of the unit does not exceed 300 W.

If a backlit switch is used, it is recommended to connect a resistor with a resistance of 33 kOhm - 100 kOhm and a power of 1-2 W in parallel to the block. This is not done for the reason described on SamElectric in the article Fluorescent lamp blinks. There's another reason. For the backlight to glow, current must flow through the lamp circuit, but the protection unit in the inactive state represents a break. As a result, without a resistor, the backlight will not work or will be very dim.

Selection and installation of a halogen lamp protection unit | Generators for everyone

Most often, halogen lamps burn out at the moment they are turned on, when the filament has not yet had time to warm up and has low resistance. To prevent the failure of lighting devices, hardware has been developed - protection units. The main task performed by the halogen lamp protection unit (BZGL) is to nullify the harm that sudden surges in current in the network can cause to lighting devices. Another name for the block is a soft starter.

The principle of operation of the system is not complicated: since the lamp is vulnerable to a sharp increase in current, the protection unit is connected in series with the lighting device and passes the current with limitation. Thanks to BZGL, the current rises smoothly - in approximately 1-2 seconds instead of instantaneous supply. The structure of the unit is quite simple, and for its operation, input-output, phase-ground and polarity are unimportant. It is recommended to connect the device in series with the switch in a phase gap.

Note! Protective devices can be used to protect not only halogen lamps, but also standard incandescent lamps.

Installation and connection

The protection device is often installed in the ceiling - where lighting fixtures are installed. If there is more than one lamp, the BZGL is placed before the first lamp.

If there is free space in the wiring box below the switch, it is easier to place the unit in this location. There is one more restriction on placing the unit in the mounting box: its power should not be higher than 300 watts.

If we are talking about a backlit switch, a resistor is connected in parallel to the BZGL, the resistance level of which can vary from 33 to 100 kOhm, and the power can be within 1-2 watts. In order for the backlight to glow, current must pass through the circuit of the lighting device, but the BZGL, when turned off, forms a break in the flow. The consequence of a broken circuit is a non-working or dim backlight.

For 12-volt halogen lamps you also need a BZGL. If an electromagnetic transformer is used, the BZGL is installed in the gap of the primary winding. However, if an electronic transformer is used, a standard block with a pair of leads will not work. Here you need a specialized block with four outputs, designed specifically for electronic devices. The BZGL power level is selected taking into account the total power of all lighting devices, but with a power reserve of 40-50%.

When a halogen lamp burns out, the filament opens, resulting in a short circuit. As a result, the protective block may burn out. To avoid such consequences, it is recommended to take the following actions:

- The BZGL is installed in an easily accessible area (socket box or electrical panel). If the unit is mounted in the ceiling, it will not be easy to quickly reach it.

- It is advisable to have a separate circuit breaker for each line. The rating must be selected with the minimum possible margin, since current surges during connection are excluded in this case.

Selecting a protective block

You should choose a BZGL based on two parameters: power and manufacturer. The power factor is discussed above, but we’ll look at the manufacturers below.

Among the manufacturers of protection units, the following brands are the most famous:

- "Feron" (China);

- "Camelion" (China);

- "Shepro" (Russia);

- "Granit" (Belarus);

- "Composite" (Russia);

- “Zzhik” (Russian-Chinese production).

As examples, we will characterize products under the brands “Feron” and “Granit”. Their models are the most common on the market.

The main advantage of Feron is its low cost. It should be noted that this is practically the only advantage of this company’s products. The list of shortcomings of equipment from a Chinese company is quite extensive:

- Significant voltage drops are possible, which leads to insufficiently efficient operation of the lamps;

- flickering, both during connection and during operation;

- frequent interference into the electrical network;

- low quality of soldering and components used.

Forum on electrical and electrical equipment “Electric House”

Club of electricians, power engineers, electricians, electricians, electricians, electricians, designers and just amateurs.

- Links

- Unanswered messages

- Active topics

- Search

- our team

- Toplist of messages

- Acknowledgments

- Contest

- Links

FERON halogen lamp protection unit

Remember, you can thank the author for an interesting message by clicking

or increase his reputation by clicking in the message. Before asking a question, use the search - it is possible that such a topic already exists on the forum. For violating the rules, your question may be deleted without explanation! How to join the Electricians Club and become a VIP user?

- Send topic by email

- print version

FERON halogen lamp protection unit

- Quote

- Quote

FERON halogen lamp protection unit

Connect wires from the 220V network to the 220V terminals on both transaxles.

Connect 6 lamps to the 12V output terminals of the first trans (105).

Re: FERON halogen lamp protection unit

- Quote

- Quote

Re: FERON halogen lamp protection unit

Re: FERON halogen lamp protection unit

- Quote

- Quote

- Main news

Re: FERON halogen lamp protection unit

- Quote

- Quote

Re: FERON halogen lamp protection unit

- Quote

- Quote

Re: FERON halogen lamp protection unit

- Quote

- Quote

Re: FERON halogen lamp protection unit

- Quote

- Quote

Re: FERON halogen lamp protection unit

- Quote

- Quote

Re: FERON halogen lamp protection unit

- Quote

- Quote

To sum up the topic: I removed the block and turned it on directly. As they said, when the electrician replaced the unit, the transformer began to crackle and hum and suddenly the chandelier stopped working. I still don’t understand how such a block (with a minimum number of parts) can withstand a load of 1 kW? I believe that something is not right here! although the block was connected in a gap! The triac costs bt 139 but it’s not the one that failed! What can you say about this, fellow experts?

Posted 1 hour 25 minutes 32 seconds later:

Smooth switching on of incandescent lamps.

The use of tungsten filament bulbs is justified by their low cost. They are still in demand. Burnout of filament coils usually occurs at the moment of switching on. This is due to a tenfold increase in amperage due to the high resistance of the cold spiral. Devices for smooth switching on incandescent lamps allow you to avoid such jumps.

Manufacturers offer several models that work on the same principle: they briefly change the phase angle of the current. Knowing the basics of electrical engineering, it is not difficult to assemble a soft start circuit for an incandescent lamp with your own hands. Connecting such a device significantly reduces energy costs and increases the level of comfort: the UPVL with a regulator sets the required degree of luminescence. Automatic headlight switching on automatically saves motorists from frequent replacement of halogen and traditional light bulbs.

Causes of premature burnout

When filament lamps are turned on, according to Ohm's law, with a high resistance of the cold filament, the current increases proportionally. In a standard light bulb with a low power of 55 W, the current reaches 60 A in a fraction of a second. When the tungsten heats up, the current instantly returns to normal. The moment of switching on is a real test for an incandescent coil.

The trouble is that there are no perfect spirals. During operation, the metal burns unevenly. As a result, in thin sections of the tungsten spiral, at the moment of heating, the current power is maximum, they flare up and break.

The service life of the filament coil depends on several factors:

- the quality of contact between the cartridge and the base, when there is burning, the risk of a short circuit increases;

- frequent on/off, this mode of operation is not provided;

- unstable voltage, it has been established that a change in voltage by 1% reduces the service life of the filament coil by 7–8 times;

- old wires, the insulation begins to crumble over time, the connection density of the conductors decreases;

- vibration, high ambient humidity.

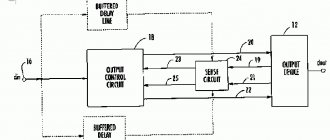

Principle of operation

The phase regulator is the basis of any device for smoothly switching on incandescent lamps. It saves you from surges in unstable voltage; it is used when connecting household appliances powered from a 220 V mains voltage. The principle of the UPVL device is to gradually increase the power load. It is connected in series to the electrical circuit between the supply wire (phase) and zero. During switching on, the increase in current strength is limited, the voltage gradually increases to 180–210 V. The consumption of the device itself is within 1.5 volts.

The device circuit must contain semiconductor devices. A half-wave (minus) passes through one, while the other goes to the capacitor (plus) at this time. When its charge reaches the opening value of the pn junction, the power supply restrictions are removed. Current and voltage are stabilized.

Purpose of the protection unit for halogen lamps and incandescent lamps:

- stabilization of starting current;

- increasing the service life of halogen light elements by 6 times;

- reducing the risk of deformation of the tungsten helix;

- eliminating the blinking effect.

The disadvantage of the device is considered to be a slight decrease in the power of the luminous flux.

Ready solutions

Installation of a factory-made protection unit does not take much time. They are produced with different periods of voltage adjustment - from a fraction of a second to three. The maximum voltage also varies. When choosing a device for soft switching on incandescent lamps, you must carefully look at the markings. The dimensions of the block depend on the load. Models with power up to 1100 Watt have been developed. Typical ones used in everyday life are usually limited to 150 W. If a device is purchased for the purpose of protection against power surges, it is necessary to provide a 30% safety margin. It is calculated up to the total power of connected devices.

For light-emitting diode (LED), fluorescent lamps, incandescent lamp protection units are not provided.

Modified devices - dimmers or dimmers - have additional functions:

- provide adjustment of light radiation;

- equipped with software systems that operate by clap, voice command or remote control;

- smoothly turn off the light.

Smooth switching on of incandescent lamps will extend their service life. Scheme for smooth switching on of lamps.

The situation when an incandescent lamp fails and at the same time many dangerous fragments fly around the room is by no means new. Moreover, this can happen both with a long-running instance, and with one installed quite recently. They burn out the moment they are turned on, because for a very short period of time (literally tenths of a second) the amount of current that comes to the filament is significantly higher than its rated value, but this is enough for it to burn out.

The situation can be corrected by smoothly switching on incandescent lamps , the basis of which is a device - a protection unit, which allows for fairly slow (2-3 s) ignition of the tungsten filament. You can make it yourself or purchase it ready-made.

Features of choosing a protection unit

When choosing such a device, you should take into account the total load, which is easy to calculate, taking into account the number of incandescent lamps and their power. This value requires a power reserve; it is better if this value is approximately a quarter of the obtained value. This will extend the life of the device, ensuring smooth switching on of incandescent lamps. Overloading the unit is unacceptable, as this will lead to significant overheating of all elements, and it will quickly break.

One of the acceptable options is the Uniel Upb-200W-BL . You can connect fluorescent lamps with a total power of no more than 160W to it. Just keep in mind that the use of a protective block leads to a voltage drop, so the load is noticeably reduced and is only 171V.

What is the soft start device for halogen and incandescent lamps used for?

The device for smoothly switching on incandescent lamps for 12 and 220 Volts is a small block, approximately the size of a matchbox with two wires. Let's figure out what the protective switching unit for halogen and incandescent lamps is used for. Frequent and

The main reason for the burnout of tungsten spiral lamps is the sudden heating of the lamp coil at the moment voltage is applied to it. It is the sharp transition from a cold state to a hot state that leads to the malfunction of the lamps by burning out the coil. To slowly warm up the latter, a soft-start device for halogen and incandescent lamps was invented. The circuit of the protective switching unit allows you to smoothly and slowly increase the voltage to the lamps. The most popular devices come in 150, 300, 500, 750 and 1000 watts.

When choosing a device, you need to take it with a power reserve of 20-30%. This is due to unstable voltage in the network. That is, for example, your total lamp power is 300 watts, then it’s better to take 500. In addition, the difference in cost usually does not exceed 10-15 UAH. The most common manufacturing companies of this type of device are Svetkomplekt and Feron.

The first manufacturer’s device allows the lamps to turn on more smoothly, unlike the second one. Although both fulfill their intended purpose - preserving the durability of the lamps. I installed both of them myself, so far they work without problems, although the reviews of others are worse about “Feron”.

As for the types of lamps, these include: conventional incandescent lamps on a threaded socket of type E14 and E27 (except for energy-saving ones), pin and linear halogen lamps, on a connector of type GU5.3 and G10. You can also connect the lamp protective switching unit through a transformer with a 12 Volt output. Below are the wiring diagrams for the lamp soft start device. Not used for fluorescent lamps and housekeepers.

After purchasing this device, the question immediately arises of how to connect the halogen lamp protection unit. You can do it yourself without resorting to the services of an electrician. When connecting to 220 Volts, the number of lamps should not exceed the power of the unit itself. There can be either one or a certain number of lamps connected in parallel, but again, I repeat, no more than the power of the unit itself. To be more precise, the unit is selected after determining the total power of the lamps.

If you use a circuit with a transformer, then you need to take into account both the power of the latter and the power of the unit and lamps. Transformers can be used both electronic (not always) and conventional ones with primary and secondary windings. The lamps are also connected in parallel. If there are a lot of lamps, but the power of the block is not enough, then you need to take several blocks and evenly distribute them by the number of lamps. It should be noted that there are already electronic transformers with a built-in soft start unit, plus they already have built-in overload protection.

It seems that everything has already been sorted out, but the question remains where the protective switching unit for halogen and incandescent lamps is installed. Due to its small size, it can be installed directly in the top chandelier cap or in the box where the switch is located. If the lamps are installed in a plasterboard ceiling, then this is as easy as shelling pears - it simply lies on the plasterboard from the inside and is connected into a gap, preferably a phase wire, to all the lamps.

Protecting halogen lamps using an electronic unit

Modern people have been familiar with incandescent lamps for a long time, and their failure, even the first time they are turned on, will not surprise anyone. With the development of innovative lighting systems, many have switched to light sources based on LEDs and halogen lamps. LED lamps are not afraid of frequent switching on or off, unlike halogen and incandescent light bulbs. A special gas based on bromine or iodine vapor (halogen vapor) is added to the halogen light source, which significantly increases the service life and temperature of the coil, which, in turn, increases light output. However, like incandescent lamps, halogen light devices burn out from a sudden supply of supply voltage, that is, when turned on. To extend the service life of this type of lamp, a protection device was created that ensures smooth voltage supply. The use of such an electronic unit increases the service life of halogen lamps from 2–4 thousand to 8–10 thousand hours.

Halogen lamps have a number of advantages and the main thing is the reduction in the dimensions of the bulb, which makes this type of lighting very compact. Due to the small volume of the flask in which the filament and gas vapor are located, the working pressure in it increases, which leads to a decrease in the rate of evaporation of the filament.