Why use foundation waterproofing?

Foundation waterproofing

For those who are thinking for the first time about whether it is necessary to do waterproofing, we will answer right away - of course, it is necessary. After all, we are talking about protecting the surface of the supporting structure. This is almost always a basement wall or basement wall. One of the building materials that is used for protection is aerated concrete. Waterproofing of aerated concrete most often occurs on FSB blocks.

There are two types of waterproofing:

- vertical;

- horizontal.

The vertical type requires a lot of work, but the result is worth it. They start from laying the foundation, to those places where rain or other water waste may leak. The entire foundation row is cleaned of various types of protrusions and chips. All seams are cleaned and sealed.

In the horizontal type, everything is much simpler. Waterproofing of aerated concrete blocks occurs through the application of layers consisting of roofing felt sheets, which are made of bitumen. They are folded step by step into balls. Such balls of roofing material act as a shield to prevent any moisture from penetrating to the surface of the foundation block.

It is necessary to waterproof surfaces in the middle of the structure and on the surface. All work must be done at the same temperature balance, preferably at least 5 degrees.

And in this case, there is a need to clean all the protrusions, remove dirt, chips, and also seal the seams, treat everything with cement. Sometimes they use the method of applying liquid glass to the surface, which makes it possible to maintain the durability of the structure a little longer. And although this method is labor-intensive and expensive, its results are worth it.

Advantages and disadvantages of FBS

Many people want to build a basement from conventional FBS blocks, simply weighing their advantages and disadvantages compared to their competitors. It’s quite easy to do this in advance today - information about all building materials is widely available. So what are the advantages of such blocks?

Their list is quite wide and includes:

- Low price, which is affordable even for those with a limited budget.

- Availability of material that can be easily purchased in all regions and localities.

- There is no need to work independently with concrete, where the slightest mistakes can lead to dire consequences.

- A high level of cold resistance, which makes it possible to use the blocks even in the Far North.

- Wide range of sizes.

- Resistance to the destructive influence of the external environment.

In this video we will look at a base made of FBS:

All these positive qualities appeared thanks to the FBS manufacturing technology. Thus, for their high level of frost resistance, they should thank the presence of special additives added to the concrete solution at the production stage. The use of high-quality cement grades allows us to achieve good resistance to various external factors.

But, like any material, these blocks have their drawbacks. Their number is inferior to the number of advantages, but they are still worth taking into account when choosing a building material for the construction of a basement floor.

- Despite all its cheapness, a structure made from such slabs is one third more expensive than a monolithic one.

- Construction cannot be completed without the use of special equipment - the blocks are so heavy that people cannot simply lift them.

- This design requires extremely careful waterproofing of the base due to the presence of interblock seams.

But all these disadvantages for the majority are easily offset by the above advantages.

Variations with waterproofing work

Waterproofing work

One of the waterproofing layer options is applied to the foundation block:

- plaster layer;

- pasting layer;

- coating layer.

Type of plaster layer: this composition contains a part of cement mortar with several layers, to which certain additives are added - ceresite, any version of liquid glass, sodium aluminate. The foundation wall is protected from any wet penetration of aerated concrete blocks. Apply several times and only when hot.

Type of adhesive layer: budget option. It is also not labor-intensive. Waterproof material made of polymer-bitumen composition. Protects against moisture, both capillary and filtration. One of the simplest ways to waterproof aerated concrete blocks. The components are heated on the burner.

Having received the hot state of the composition, it is applied to the external foundation. Sometimes, when waterproofing adhesive type, materials with a dark-skinned surface are used. Then there is no need to heat the material.

Materials with a darkening surface:

- roofing felt;

- hydroisol;

- brizol;

- isol.

Ruberoid is used in the surface layers of the foundation roof. Waterproofing material is used around the perimeter. The waterproofing agent contains fiberglass material, which prevents the possibility of destruction due to the influence of fungi and rot.

Foundation waterproofing

One type of insulation is vertical insulation of foundation blocks. One of the most technologically difficult, but effective, injection waterproofing, increases the level of moisture resistance of the foundation material. Waterproofing by injection consists of filling microcracks, seams, and holes with a special compound under pressure.

This method of performing work requires quite a lot of resources and rare, expensive equipment. But the high cost is covered by durability.

Waterproofing foundations consisting of FSB blocks consists of the following steps:

- the seams of the blocks are embroidered to a depth of 50mm;

- a drill is used to divide holes in increments of 20 cm, reaching 75% of the wall thickness;

- parkers for injections are installed;

- a special modified polymer is poured;

- the procedure is performed with a pump for this type of work;

- parkers are removed;

- the holes are sealed flush;

- Coating water-repellent insulation of foundation walls is produced.

The second method is to carry out waterproofing work using the Penetron mixture.

Water-repellent treatment of the base is carried out as follows:

- clean the plaster layer from the walls using a chipper, a hammer drill, or a stiff wire brush;

- Concrete walls are cleaned of tile residues, dirt, paint layers, grease stains, oil - nothing should interfere with the adhesion of the mixture to the wall. If we have polished surfaces, we etch them with a weak acid solution for an hour and a half and then wash them with water.

- floors in basements and basements are being dismantled.

Might be interesting

Waterproofing

Foundation waterproofing: optimal choice of technology

Waterproofing

Clean water is the key to health, waterproofing concrete…

Waterproofing

Instructions for waterproofing a swimming pool

Waterproofing

Selection of materials, methods of waterproofing work...

Then the floor must be strengthened horizontally, for which a reinforcement network is used. The ends of the mesh are connected with reinforcement ties.

After strengthening the mesh on a horizontal surface, the structure is filled with a pre-prepared sand-cement mortar to which crushed stone is added.

Waterproofing methods

Waterproofing a foundation with your own hands can be done in several ways.

The first technology, injection, increases the margin of reliability and strength of the fundamental foundation. The injection process consists of filling cracks and seams using a special injection composition.

This technology requires significant material investments, and its implementation will require expensive equipment. But the high cost pays off with reliability and durability.

But how to waterproof a foundation from FBS blocks using this technology? Work stages include:

- The seams of the blocks are unstitched at a depth of thirty to fifty millimeters.

- Then it is necessary to drill holes at a distance of two hundred millimeters with a depth of two-thirds of the thickness of the foundation walls.

- After which it is necessary to install the parkers used for injection.

- A special modified polymer is poured between the FBS blocks.

- Injection is carried out using a pump designed to perform this work.

- Then the parkers are dismantled.

- Sealing of holes.

- Next, it is necessary to carry out coating waterproofing of the foundation walls.

The second technology is to carry out waterproofing using Penetron.

It is done as follows. Walls that have a plaster layer need to get rid of it. This work can be done using a hammer drill, a jackhammer, or a smooth, stiff brush. Concrete walls are cleaned of dust, greasy components, paint, dirt, tiles and other similar materials. If the walls are sanded, a weak acid solution must be applied to them and after an hour, they are washed with water.

If there are floors in basements or ground floors, they must be completely removed.

Then the floor is horizontally strengthened using reinforcing mesh, the ends of which are fastened using reinforcement ties. After which, all this must be filled with pre-prepared cement mortar with the addition of crushed stone and sand.

The beginning of preliminary waterproofing work includes the following actions:

- The cement mixture is removed from the seams of the masonry material. Places where leaks may occur are treated with a fast-hardening filling from Penelag, which sets in a short period of time.

In order to prepare Penelag you will need: dry Penelag mixture mixed with water in the proportion: one hundred and fifty grams of water per one kilogram of mixture. The water temperature should be twenty degrees. Be sure to mix thoroughly for three minutes until a thick consistency without lumps is formed. Do not dilute a large amount of material at once, since the solution should be used, at best, within thirty seconds.

- Next, all joints must be treated using an auxiliary penetrating material with waterproofing properties, Penetron. Application can be done using a wide brush or a synthetic brush.

Preparatory work for waterproofing

Preparatory work for waterproofing

Preparatory work for waterproofing consists of the following steps:

- removing the cement mixture from the joints of the brickwork material;

- areas of possible leaks are sealed with a quick-setting sealant from Penelag, which hardens very quickly. To prepare Penelag you need:

- dry mix Penelag;

- water.

The mixture is combined with water in a ratio of 0.15 liters of water per 1 kg of mixture. The temperature of the mixture should not be less than 20 degrees Celsius.

Step by step mixing:

- The mixture is thoroughly mixed to a paste-like mass, smooth, uniform consistency.

- Due to the fact that the mixture hardens quickly, there is no need to prepare a large amount at once. The time for using the solution does not exceed 30 seconds before setting.

- Then all connecting surfaces are treated with an additional penetrating waterproofing material, Penetron. The material is applied with a wide brush or brush.

- Then the dry Penecrit mixture is diluted.

- To do this, prepare identical containers with measuring marks and a clean plastic container in advance.

- For mixing, use a drill or construction mixer.

- If small volumes are mixed, mixing is done by hand with obligatory hand protection with rubberized gloves.

Wild photo of foundation waterproofing fbs

Let's consider a unique case of unsuccessful waterproofing of the FBS foundation . The same 1 in 1000 mentioned above. Even seeing such photos is rare. Seeing this in real life is even more rare (to an enemy, i.e., a competitor, unless you wish

). By the way, the photo is clickable, click to enlarge and view.

Impressive? Do you understand how lucky you are that you only see something like this in a photo? And how unlucky was the director of XYZ LLC (the name, for obvious reasons, is not disclosed), who saw this with his own eyes, as the result of his work, the next day after applying liquid rubber to the FBS blocks.

I came in the morning to hand over the work to the customer and saw it. A very unpleasant situation. The first shock passed and two eternal questions in Russia arose: “Who is to blame and what to do?”

Over the course of three seasons, XYZ Company waterproofed nearly two dozen foundations with liquid rubber, half of which were made of FBS. And yet, I was unable to respond to the client’s criticism on my own. They needed “the help of the hall” or “a call to a friend”, in a word, they remembered that there is a site called b2bb2c.ru, which offers consulting services on waterproofing. As a result, they turned to us for advice.

Looking ahead, we note that based on many years of experience, fundamental and applied knowledge in this field, we explained the nature of this rare phenomenon with FBS blocks.

Readers of the site b2bb2c.ru have the opportunity to receive such a consultation for free so that they never see with their own eyes bubbles on liquid rubber at their facility. As they say, forewarned is forearmed.

Detailed explanations of what exactly happened here with FBS waterproofing can be seen and read here.

Making the mixture

The mixture is prepared at the rate of 200 grams of water per 1000 grams of Penecrit. It is necessary to thoroughly stir the composition until a thick, creamy mass without lumps is obtained. This composition is also prepared in small quantities. It is necessary to strictly maintain the proportions, since the difference between the material is that it achieves plasticity with constant stirring.

The longer the mixing process, the more plastic the composition will be. The period of use of the composition is no more than thirty minutes. The suture grooves between the FBS blocks are treated with special care with this composition.

After finishing the work, the foundation walls are moistened and then covered again with Penetton using a large brush or paint brush. The solution is used to insulate floor surfaces.

Foundation insulation from FBS blocks

Types of waterproofing

Some calculations based on the provided characteristics of the soil layers lying on the construction site, the groundwater level, freezing depth and average annual precipitation will help you avoid making a mistake in choosing a method for waterproofing FBS blocks. Relevant reference books and standards that regulate the use of certain materials and determine the waterproofing technology for a specific foundation will provide all possible assistance in resolving the issue.

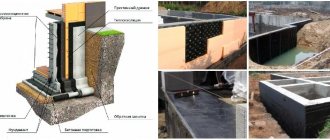

Waterproofing for foundations made of FBS blocks is carried out in two directions:

- horizontal;

- vertical.

Horizontal waterproofing is required at the level of the base of the foundation and at the junction of the blocks with the walls. It is installed to protect structures from capillary penetration of moisture from the ground below. Vertical waterproofing is necessary to protect the side surfaces of foundation walls.

Waterproofing work must be carried out at the stage of foundation construction, since subsequently its implementation will entail large financial costs.

The installation of waterproofing is especially important during the construction of recessed basements under the building. In this case, it is not recommended to neglect its application to the internal surfaces of foundation walls. Double protection prevents the accumulation of condensation and the development of fungal mold.

Other types of insulation

In addition to expensive injection insulation, you can use coating or cut-off horizontal insulation to protect foundation blocks.

For coating insulation, hot bitumen or mastics based on it are used. Bitumen, creating a film on the surface, seals pores, cracks, holes in FSB blocks, creating an impenetrable barrier for water.

Insulation of foundation wall blocks is carried out as follows:

- the surface is thoroughly cleaned of dirt, soil, concrete humps;

- carefully isolate the cracks with a solution of cement and sand;

- prime the surface of the walls;

- the first ball of heated bitumen is applied to the dried layer;

- after the first ball of bitumen has completely dried, a second layer is applied with strokes perpendicular to the strokes of the first layer to create a durable coating;

- For proper effect, such a coating should not have a thickness of less than three millimeters in one ball.

Working with hot bitumen is quite dangerous due to its heating to a temperature of at least 120 degrees for work. Hardening takes place very quickly, so it only takes 4-5 minutes to apply to the wall. If it's cold enough outside, working with a hot compound is very inconvenient.

Cold bitumen mastics are much more effective in this case. This mastic contains polymers, which makes it plastic.

The most modern material for coating waterproofing of foundation blocks is penetrating waterproofing with penetrating compounds. The composition is based on cement, quartz dust, and polymer additives. When the mixture is applied to concrete, it gets inside due to capillary suction and crystallizes in the pores of the concrete. As a result, after the mixture dries, we obtain a monolith that is one third stronger than a concrete base. As water tries to penetrate deeper, the concrete becomes even stronger.

Dry penetrating mixtures are sold dry in bags and diluted with water to the consistency of thick sour cream. The composition should be easily applied with a brush or brush. When working, you need to observe a time lag of 30 minutes, since the solution sets quickly. It is strictly prohibited to dilute the solution.

The stages of foundation waterproofing with penetrating insulation look like this

- the foundation is cleared of dirt:

- wall blocks are cleaned of remnants of paint, plaster, and old coatings;

- if the surface of the old foundation coating is glossy, it is treated with acid for several minutes;

- The surface must be damp when applying the waterproofing solution.

The solution is applied manually with a brush or roller in several layers. The full effect of waterproofing with a penetrating mixture is visible after a few days.

Basic methods of vertical waterproofing

Before applying a waterproofing layer to the constructed structure, the surface of the FBS blocks must be prepared in a certain way - cleaned of dirt, gotten rid of protrusions, leveled with a cement-sand mixture. It is necessary to carefully repair chips and cracks, and the seams of the block masonry should be treated with a cement-polymer composition.

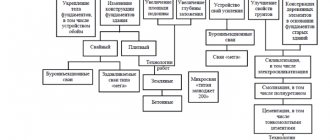

Depending on the materials used for vertical waterproofing, there are several main methods of its construction:

- plastering – based on cement compositions;

- coating or spraying - using mixtures based on bitumen or polymer;

- adhesive – using rolled materials.

Each method has its own advantages and disadvantages, and they are used depending on the ground conditions of the construction site. In particular, one of the determining factors is the groundwater level.

Plaster waterproofing

Plaster applied to foundation walls simultaneously performs two functions. In addition to sealing cracks and seams between blocks, it waterproofs the underground structure to some extent, which is a definite advantage. But plaster protection is used only if the groundwater level is below the foundation level.

In addition to cement, the mixture contains liquid glass, sodium aluminate and other additives. The finished solution is applied with a spatula onto a plaster mesh pre-installed with dowels, which improves the retention of the applied layer on the foundation walls.

The main disadvantage of plastering is the low hydraulic stability of the cement layer, which contributes to the appearance of cracks in it.

Coating and sprayed waterproofing

It is the most common method used to protect underground structures from groundwater, the level of which rises above the base of the foundation. A wide range of ready-made bitumen mastics are used here as insulating materials. The availability and low cost of the ingredients that make up the mixture allows you to independently make a simple coating mastic from:

- construction bitumen;

- used machine oil.

Cheap technical oil acts as a plasticizer, preventing molten bitumen from quickly hardening. When processing FBS blocks, the mastic penetrates into all cracks and gaps, preventing further moisture from penetrating inside the foundation walls. The surfaces are coated with the heated mixture in several layers. The disadvantages of using traditional bitumen mastic are its mediocre water resistance, weak adhesion and the fragility of the layer.

Cooling and reheating of bitumen is not allowed, as this leads to a partial loss of its waterproofing properties.

As a more reliable and high-quality alternative, it is recommended to use liquid polymer mastics on a bitumen or cement-sand base, purchased in construction stores. They have increased moisture resistance due to the additional introduction of hydrophobic synthetic additives into the composition. Such mastics do not require heating, and the number of applied layers can be reduced to two. Their only disadvantage is their high cost.

Liquid rubber is considered one of the polymer materials that makes it possible to create a highly reliable waterproofing layer. It is applied using a sprayer, deeply filling pores and cracks. Also, one- and two-component compositions are used in the work, spread on the surface to be treated with a brush or brush.

Adhesive waterproofing

This method is considered quite effective, as it is used as an additional method when waterproofing FBS blocks with liquid bitumen. The block foundation is covered with roll or film materials on a surface pre-treated with mastic. It should be noted that the once widely used roofing felt and roofing felt are gradually being replaced by more progressive waterproofing materials made on the basis of fiberglass. It has a double-sided coating of modified bitumen with additional protection in the form of a polymer film.

The rolled material, heated with a burner, is overlapped onto the bitumen layer, with an overlap of 10-15 cm. To avoid the formation of air inclusions, the surface of the waterproofing material is rolled with a roller.

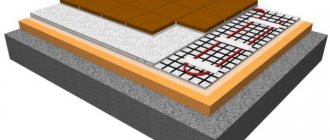

Horizontal waterproofing of foundation cushion

Materials for work

Bitumen mastic, roofing felt

Waterproofing the foundation from FBS, if there is no basement or cellar

Block foundations can be laid on different foundations. This depends on the structure of the soil and the height of the groundwater. Here are two types of grounds:

Monolithic concrete screed

Cushion made of crushed stone and sand

If a concrete screed is used, the procedure is as follows:

The screed must be completely ready. The concrete should set and harden.

The surface of the screed is treated with bitumen mastic.

Then rolls of roofing material are rolled out onto the mastic. The mastic acts as an adhesive and connects the roofing material to the base. Rolls should be laid with an overlap of 15-20 cm. The joints of the rolls can be slightly melted with a gas burner. This way, after hardening, you will get a solid coating.

The waterproofing of the pillow is ready, you can begin laying the foundation blocks.

If compacted crushed stone and sand are used as the base, then the waterproofing technology is slightly different. Then the finished pillow is covered with a layer of heated bitumen.

Waterproofing of FBS foundation with basement

If the house is planned to have a basement, the waterproofing layer should be installed below the floor level - where the floor meets the foundation wall. Here is the order of work:

The foundation pit is being prepared. The bottom is leveling out.

A layer of clay is poured onto the bottom and compacted thoroughly.

Then concrete of the required thickness is poured. The concrete pad should set completely. You need to allow at least 10 days for this.

When the concrete has set, the entire surface should be coated with bitumen mastic. Then the rolls of roofing felt are laid (here you also need to lay the rolls overlapping).

Horizontal insulation FBS

Strip and monolithic foundations require insulation at or below 10 cm of the basement floor level both in the basement and in the place where the foundation joins the wall. Clay should be poured into the bottom of the pit and compacted. Fill the top with concrete. After 10 days, treat it with bitumen mastic and lay roofing material on it. Then lubricate the surface of the foundation blocks with mastic again and lay the roofing material. Fill the top with concrete, which must be leveled and reinforced. The second thing to do is this: after 2 hours, pour sifted cement on top of the concrete and level it. After it gets wet, they act in the same way as with a concrete screed. When the strip foundation is completed, it is waterproofed again. To do this, the blocks are covered with bitumen mastic and roofing material is laid on top. The procedure is performed 2 times. The edges of the rolled material, which hang from the FBS, are brought down and pressed down with vertical waterproofing.

Foundation insulation diagram.

Waterproofing may require the presence of a drainage system if the ground water is high and the soil permeability is insufficient.

To arrange it, dig a trench around the perimeter of the house at a distance of 0.7 m from it. The depth is determined by the water level. The width is approximately 40 cm. The trenches should be located with a barely noticeable slope towards the storage pit. Geotextiles need to be laid on the bottom, the edges are wrapped around the sides of the trench by about 90 cm. A layer of gravel is poured over the entire trench. Then special perforated drainage pipes are laid. A layer of washed gravel (20-30 cm) is poured again. They wrap everything in the remaining edges of geotextile and take the pipes into a collection pit. Next they are covered with soil.