MORTAR MIXTURE

The main properties of the mortar mixture are mobility, exfoliation, average density, and water-holding capacity. To assess the quality of the mortar mixture, an average sample is taken in the construction laboratory when preparing experimental batches, when unloading the batch from a mortar mixer or bunker (at the beginning, middle and end of unloading the mixture), from cars or mason's supply boxes in three places from a depth of 10-15 cm with shovels or scoops. In the last two cases, the volume of each sample should be at least 1 - 2 liters. By mixing individual samples, an average sample of the solution is obtained in an amount of at least 3–5 liters, which is sent to the laboratory, where the mixture is stirred for 30 s before testing. The mortar mixture is tested according to the GOST 5802 – 86 method.

The mobility of the mortar mixture is the ability to easily spread over the surface of the stone in a thin layer and fill all the unevenness of the base. The degree of mobility of the mortar mixture is determined using a device - the StroyTsNIL cone according to the depth of immersion of the steel cone into the mortar mixture.

The device for determining the mobility of a mortar mixture (Fig. 1) consists of a tripod, on the stand 1 of which holders 5 . At the end of the lower holder there is a clamping screw 8 that holds the sliding rod 4 of the cone 3 . A scale with divisions 2 , according to which the depth of immersion of the cone in the mortar mixture 7 and the volume of the immersed part of the cone are measured. The mass of the cone with the rod and ballast should be 300 g, the height of the cone should be 145 mm, and the base diameter should be 75 mm. Vessel 7 for the mortar mixture is made of sheet steel in the form of a truncated cone with a height of 180 and a base diameter of 150 mm.

To determine the mobility of the solution, the vessel is filled with the mixture approximately 1 cm below the edges. The laid solution is bayoneted 25 times with a rod with a diameter of 10–12 mm and shaken 5–6 times by lightly tapping the vessel on the table. The tip of the cone is brought into contact with the surface of the solution in the vessel and the rod is secured in this position with a clamping screw 8 , while noting the position of the arrow on the scale. Then turn the clamping screw, allowing the cone to freely plunge into the solution. After 1 minute, the depth of its immersion is counted on a scale with an accuracy of 1 mm.

Mobility (cm) is determined as the arithmetic mean of the two tests. The second test is carried out with a new portion of the solution. The difference in readings should not exceed 20 mm.

Based on the test results, the brand is determined by PC mobility

| Mobility brand | Immersion depth, cm |

| PC1 | From 1 to 4 inclusive |

| PC2 | Above 4 to 8 inclusive |

| PC3 | Above 8 to 12 inclusive |

| PC4 | Above 12 to 14 inclusive |

The working mobility of the solution (cm) in summer and winter conditions, depending on its purpose, is taken as follows:

- ordinary masonry made of solid brick, as well as masonry made of concrete stones and natural stones of light rocks - from 9 to 13;

- ordinary masonry made of perforated bricks or ceramic stones with slotted voids - from 7 to 8;

— rubble masonry – from 4 to 6;

— filling voids during rubble masonry – from 13 to 15;

– vibrating rubble masonry – from 1 to 3.

For masonry made of dry and porous stone materials, solutions with greater mobility are used, and for masonry made of wet and dense materials - with less mobility.

The stratification of the mortar mixture, which characterizes its cohesion under dynamic action, is determined by comparing the mass content of the filler in the lower and upper parts of a freshly molded sample with dimensions of 150 × 150 × 150 mm.

The mortar mixture is placed and compacted in a mold for control samples with dimensions of 150×150×150 mm. After this, the compacted mortar mixture in the mold is subjected to vibration on a laboratory vibration platform for 1 minute.

After vibration, the top layer of solution with a height of (7.5 ± 0.5) mm is taken from the mold onto a baking sheet, and the lower part of the sample is unloaded from the mold by tipping it onto a second baking sheet.

Selected samples of the mortar mixture are weighed with an error of up to 2 g and subjected to wet sieving on a sieve with 0.16 mm holes.

In wet sieving, individual parts of the sample placed on a sieve are washed with a stream of clean water until the binder is completely removed. Washing the mixture is considered complete when clean water flows out of the sieve.

Washed portions of the filler are transferred to a clean baking sheet, dried to a constant weight at a temperature of 105 - 110 ° C and weighed with an error of up to 2 g.

Aggregate content in the upper (lower) parts of the compacted mortar mixture V

the percentage is determined by the formula

, (7)

where m1

– mass of washed, dried aggregate from the upper (lower) part of the sample, g;

m2

is the mass of the mortar mixture taken from the upper (lower) part of the sample, g.

Indicator of stratification of mortar mixture n

the percentage is determined by the formula

, (8)

where DV

— absolute value of the difference between the filler content in the upper and lower parts of the sample, %;

åV

is the total content of filler in the upper and lower parts of the sample, %.

The separation index for each sample of the mortar mixture is determined twice and calculated, rounded to 1%, as the arithmetic mean of the results of two determinations that differ from each other by no more than 20% from the lower value. If there is a greater discrepancy between the results, the determination is repeated on a new sample of the solution mixture.

The average density of a mortar mixture is characterized by the ratio of the mass of the compacted mortar mixture to its volume and is expressed in kilograms per cubic meter.

To carry out the tests, a steel cylindrical vessel with a capacity of 1000±2 ml is used (Fig. 2).

Before testing, the vessel is pre-weighed with an error of up to 2 g. Then it is filled with excess mortar mixture.

The mortar mixture is compacted by pinching it with a steel rod 25 times and lightly tapping it on the table 5–6 times.

After compaction, excess mortar mixture is cut off with a steel ruler. The surface is carefully leveled with the edges of the vessel. The walls of the measuring vessel are cleaned with a damp rag from any solution that has fallen on them. Then the vessel with the mortar mixture is weighed to the nearest 2 g.

The density of the mortar mixture r, g/cm3, is calculated using the formula

, (9)

where m

– mass of the measuring vessel with the mortar mixture, g;

m1

– mass of the measuring vessel without mixture, g. Then converted to kilograms per cubic meter by multiplying by a factor of 1000.

The density of a mortar mixture is determined as the arithmetic mean of the results of two determinations of the density of a mixture from one sample, differing from each other by no more than 5% from the lower value.

If there is a greater discrepancy between the results, the determination is repeated on a new sample of the solution mixture.

Water-holding capacity is determined by testing a 12 mm thick layer of mortar mixture laid on blotting paper (Fig. 3).

| Rice. 3. Diagram of a device for determining the water-holding capacity of a mortar mixture |

Before testing, 10 sheets of blotting paper 2 are weighed with an error of up to 0.1 g, placed on a glass plate 3 , a gauze cloth pad 4 , a metal ring 1 and weighed again. The thoroughly mixed mortar mixture is placed flush with the edges of the metal ring, leveled, weighed and left for 10 minutes. The metal ring with the solution is carefully removed along with the gauze.

The blotting paper is weighed with an error of up to 0.1 g.

The water-holding capacity of a mortar mixture is determined by the percentage of water content in the sample before and after the experiment using the formula

(10)

where t

1

—

weight of blotting paper before testing, g;

t

2

-

mass of blotting paper after testing, g;

m

3 - mass of the installation without mortar mixture, g;

t

4

-

mass of the installation with the mortar mixture, g.

The water-holding capacity of the mortar mixture is determined twice for each sample of the mortar mixture and is calculated as the arithmetic mean of the results of two determinations that differ from each other by no more than 20% from the lower value.

Brand of mortar mixture by mobility

Page 1 of 4Next ⇒Mortars

Mortar is an artificial stone material obtained as a result of hardening of a selected mortar mixture of binder , water , fine aggregate and additives that improve the properties of the mixture and mortars.

Mortar mixture is a carefully selected, mixed and ready-to-use mixture of binder, fine aggregate, water and special additives, taken in certain quantities, until hardening.

Based on the type of binder , they distinguish between cement , lime , gypsum and mixed ( cement-lime , lime-gypsum , etc.).

Based on density they are distinguished: heavy solutions with a density of more than 1500 kg/m3, usually made on quartz sand; light mortars with a density of less than 1500 kg/m3, produced on porous fine aggregate and with rock-forming additives.

by purpose : masonry - for masonry walls, foundations, pillars, vaults, etc.; plastering for plastering interior walls, ceilings, building facades; assembly - for filling seams between large elements (panels, blocks, etc.) during the installation of buildings and structures from ready-made prefabricated structures and parts; special solutions (decorative, waterproofing, grouting, etc.).

Binders. Portland cement and Portland slag cement with a grade 3...4 times higher than the grade of the solution are used Puffed lime in the form of lime paste is introduced into the mixer during the preparation of the mortar mixture; Ground quicklime is less commonly used. Construction gypsum is part of gypsum and lime-gypsum mortars.

Fine aggregate . Natural (quartz, feldspathic) and artificial (crushed from dense rocks and porous rocks; from artificial materials - pumice, expanded clay, perlite, etc.) are used Porous sands are used to prepare light solutions. If the sand contains large inclusions (clumps of clay, etc.), then it is sifted. For brickwork, sand mortars with grains of no more than 2 mm are used. For mortars grade M100 and above, sands must meet the same requirements regarding the content of harmful impurities as sands for concrete production. For solutions of grade M50 and below, the content of dust particles up to 20% by weight is allowed by agreement of the parties.

Plasticizing additives. Most often, mortar mixtures are laid in a thin layer on a porous base that can suck out water (brick, lightweight concrete, cellular concrete, etc.). To maintain the workability of mortar mixtures when laid on a porous base, inorganic and organic plasticizing additives are introduced into them, which increase the ability of the mortar mixture to retain water.

Inorganic dispersed additives consist of small particles that retain water well ( lime , thermal power plant ash , diatomaceous , ground blast furnace slag , etc.).

Organic surfactant plasticizing and

air-entraining additives : saponified wood pitch , rosin soap , soap naft , LST and others are introduced in an amount of 0.1...0.3% by weight of the binder.

They not only improve the workability of mortar mixtures, but also increase frost resistance, reduce water absorption and shrinkage of the mortar. Hardening accelerators are added to solutions used for winter masonry and plastering, which lower the freezing point of the mortar mixture: calcium chloride, potash, sodium chloride, bleach, etc.

The main properties of mortars are:

— strength (grade) for a given curing period;

— workability;

— adhesion to the base;

— frost resistance;

— deformation characteristics : shrinkage during hardening, affecting crack resistance, elastic modulus , Poisson’s ratio .

Workability is the property of a mortar mixture to be easily laid in a dense and thin layer on a porous base and not delaminate during storage, transportation and pumping with mortar pumps.

The workability of a mortar mixture is characterized by the mobility of the mixture or the depth of immersion (cm) of a standard cone into it and the water-holding capacity of the mixture.

The mobility of mortar mixtures is characterized by the depth of immersion of a metal cone (weighing 300 g) of a standard device. Mobility is prescribed depending on the type of solution and the suction ability of the base.

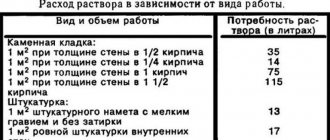

Depending on the purpose, a certain brand of mortar mixture is used according to mobility (Table 1).

Table 1

Compositions of construction mortar mixtures for masonry

| Cement brands | Composition in volumetric dosage for brand solutions | ||

| Cement-lime mortars | |||

| 1:0,5:5,5 | 1:0,8:7 | — | — |

| 1:0,4:4,5 | 1:0,5:5,5 | 1:0,9:5,5 | — |

| 1:0,2:3,5 | 1:0,3:4 | 1:0,6:6 | 1:1,4:10 |

| — | 1:0,1:2,5 | 1:0,3:4 | 1:0,8:7 |

| Cement mortars | |||

| 1:5,5 | 1:6 | — | — |

| 1:4,5 | 1:5,5 | — | — |

| 1:3 | 1:4 | 1:6 | — |

| — | 1:2,5 | 1:4 | — |

Notes. C

The elements have a bulk density of 1100 kg/m3. If the bulk density of cement differs from the above value by more than 10%, then the composition of the mortar mixture must be recalculated. The sand is taken in a loosely poured state with a natural humidity of 1...3%. Lime is grade II with a dough density of 1400 kg/m3; when using grade I lime, the amount of dough is reduced by 10%. The clay is taken in the form of a dough with a standard cone immersion depth of 13-14 cm.

Selection of the composition of the masonry mortar mixture

The selection of the composition of a construction masonry mortar mixture includes the calculation of the preliminary composition and its refinement during a trial batch .

Calculation of material consumption for a test batch

The consumption of materials is specified based on the results of the trial batch .

For a test batch of mortar mixtures with a mobility of up to 8 cm, the calculation is made for 2 dm3 of sand, and for a mobility of more than 8 cm - for 3 dm3 of sand.

The mobility of the solution for the test batch is determined based on its purpose according to the table. 3.

Table 3

Preparation of a test batch of mortar mixture

To prepare a test batch, weigh out the components of the mortar mixture according to the calculations performed. Sand is poured into a metal bowl, cement is added and thoroughly mixed by hand with a trowel for 5 minutes, then lime paste is added and mixed again. After this, add water and finally mix the mixture for 3...5 minutes.

Results of determining the mobility of the mortar mixture

| Brand and type of solution made from the mixture | Private test results, see | Arithmetic mean result, cm |

The solution mobility value (cm) is calculated as the arithmetic mean of the results of two tests.

Task for calculating the composition of a mortar

Exercise . Calculate the composition of the mixed masonry mortar. Determine the consumption of materials for a test batch to adjust the mobility of the mortar mixture. Calculate the consumption of materials for mixing the mortar mixer.

The initial data for calculating the composition of the mixed mortar are given in table. 6.

Table 6

Options for initial data for calculating the composition of mortar

| Option number | Brand (strength, MPa) of solution | Cement activity | Type of cement | Bulk density, kg/m3: | Purpose of the solution | Mixer volume, dm3 |

| cement | sand | lime dough | ||||

| M10 (1.0) | 41,5 | pc | For filling voids in rubble masonry | |||

| M25 (2.5) | pc | Mortar mixtures used when supplied by a mortar pump | ||||

| M50 (5.0) | pc | For masonry made of ordinary bricks | ||||

| M75 (7.5) | 40,5 | pc | For installation of concrete panels | |||

| M100 (10.0) | pc | For unstitching | ||||

| M75 (7.5) | 31,5 | Spz | For installation of walls made of large blocks | |||

| M50 (5.0) | Spz | For hollow brick masonry | ||||

| M25 (2.5) | Spz | Mortar mixtures used when supplied by a mortar pump. | ||||

| M10 (1.0) | 30,5 | Spz | For vibrating rubble masonry | |||

| M25 (2.5) | 43,5 | pc | For masonry of concrete stones | |||

| M50 (5.0) | 42,5 | pc | For installation of walls made of large blocks | |||

| M75 (7.5) | pc | For masonry made of ordinary bricks | ||||

| M100 (10.0) | pc | For installation of concrete panels | ||||

| M75 (7.5) | Spz | For masonry of concrete stones | ||||

| M50 (5.0) | Spz | For masonry made of ordinary bricks | ||||

| M25 (2.5) | Spz | Mortar mixtures used when supplied by a mortar pump | ||||

| M10 (1.0) | Spz | For filling voids in rubble masonry | ||||

| M25 (2.5) | Spz | For masonry of concrete stones | ||||

| M50 (5.0) | Spz | For installation of walls made of large blocks | ||||

| M75 (7.5) | Spz | For unstitching | ||||

| M100 (10.0) | Spz | For masonry of large blocks | ||||

| M75 (7.5) | pc | For unstitching | ||||

| M50 (5.0) | pc | For masonry of concrete stones | ||||

| M25 (2.5) | 33,5 | pc | Mortar mixtures used when supplied by a mortar pump | |||

| M10 (1.0) | 32,5 | pc | For vibrating rubble masonry | |||

| M50 (5.0) | 43,5 | Shpts | For installation of walls made of large blocks | |||

| M75 (7.5) | pc | For masonry made of ordinary bricks | ||||

| M100 (10.0) | 38,5 | Shpts | For installation of concrete panels | |||

| M75 (7.5) | 34,5 | pc | For masonry of concrete stones | |||

| M50 (5.0) | 32,5 | pc | For masonry made of ordinary bricks | |||

| M50 (5.0) | pc | For masonry made of ordinary bricks | ||||

| M25 (2.5) | pc | Mortar mixtures used when supplied by a mortar pump | ||||

| M10 (1.0) | Spz | For filling voids in rubble masonry | ||||

| M25 (2.5) | pc | For masonry of concrete stones | ||||

| M50 (5.0) | Spz | For installation of walls made of large blocks |

Control questions

1. What are the purposes of mortars?

2. What types of solutions are there and what technological features do they have?

3. Name the compositions of mortars.

4. List the main properties of mortars.

5. List the main properties of mortars.

6. What are mixed solutions?

7. How does the brand of mortar mixture in terms of mobility depend on the purpose of the mixture?

8. What brands of masonry mortar are there in terms of strength and frost resistance?

9. How is the composition of the masonry mortar determined?

10. How is the mobility of a mortar mixture determined?

11. How is the brand of mortar determined by strength?

Literature

1. Mikulsky V.G. Construction materials (materials science and technology): Textbook. – M.: IASV, 2002. – 536 p.

2. Belov V.V., Petropavlovskaya V.B., Shlapakov Yu.A. Laboratory determination of the properties of building materials: a textbook. – M.: Publishing House of the Association of Construction Universities, 2004. – 176 p.

The author of the guidelines is Professor of the Department of Construction Production of the Cheboksary Polytechnic Institute of the Moscow State Open University, Doctor of Technical Sciences Savelyev V.V.

Mortars

Mortar is an artificial stone material obtained as a result of hardening of a selected mortar mixture of binder , water , fine aggregate and additives that improve the properties of the mixture and mortars.

Mortar mixture is a carefully selected, mixed and ready-to-use mixture of binder, fine aggregate, water and special additives, taken in certain quantities, until hardening.

Based on the type of binder , they distinguish between cement , lime , gypsum and mixed ( cement-lime , lime-gypsum , etc.).

Based on density they are distinguished: heavy solutions with a density of more than 1500 kg/m3, usually made on quartz sand; light mortars with a density of less than 1500 kg/m3, produced on porous fine aggregate and with rock-forming additives.

by purpose : masonry - for masonry walls, foundations, pillars, vaults, etc.; plastering for plastering interior walls, ceilings, building facades; assembly - for filling seams between large elements (panels, blocks, etc.) during the installation of buildings and structures from ready-made prefabricated structures and parts; special solutions (decorative, waterproofing, grouting, etc.).

Binders. Portland cement and Portland slag cement with a grade 3...4 times higher than the grade of the solution are used Puffed lime in the form of lime paste is introduced into the mixer during the preparation of the mortar mixture; Ground quicklime is less commonly used. Construction gypsum is part of gypsum and lime-gypsum mortars.

Fine aggregate . Natural (quartz, feldspathic) and artificial (crushed from dense rocks and porous rocks; from artificial materials - pumice, expanded clay, perlite, etc.) are used Porous sands are used to prepare light solutions. If the sand contains large inclusions (clumps of clay, etc.), then it is sifted. For brickwork, sand mortars with grains of no more than 2 mm are used. For mortars grade M100 and above, sands must meet the same requirements regarding the content of harmful impurities as sands for concrete production. For solutions of grade M50 and below, the content of dust particles up to 20% by weight is allowed by agreement of the parties.

Plasticizing additives. Most often, mortar mixtures are laid in a thin layer on a porous base that can suck out water (brick, lightweight concrete, cellular concrete, etc.). To maintain the workability of mortar mixtures when laid on a porous base, inorganic and organic plasticizing additives are introduced into them, which increase the ability of the mortar mixture to retain water.

Inorganic dispersed additives consist of small particles that retain water well ( lime , thermal power plant ash , diatomaceous , ground blast furnace slag , etc.).

Organic surfactant plasticizing and

air-entraining additives : saponified wood pitch , rosin soap , soap naft , LST and others are introduced in an amount of 0.1...0.3% by weight of the binder.

They not only improve the workability of mortar mixtures, but also increase frost resistance, reduce water absorption and shrinkage of the mortar. Hardening accelerators are added to solutions used for winter masonry and plastering, which lower the freezing point of the mortar mixture: calcium chloride, potash, sodium chloride, bleach, etc.

The main properties of mortars are:

— strength (grade) for a given curing period;

— workability;

— adhesion to the base;

— frost resistance;

— deformation characteristics : shrinkage during hardening, affecting crack resistance, elastic modulus , Poisson’s ratio .

Workability is the property of a mortar mixture to be easily laid in a dense and thin layer on a porous base and not delaminate during storage, transportation and pumping with mortar pumps.

The workability of a mortar mixture is characterized by the mobility of the mixture or the depth of immersion (cm) of a standard cone into it and the water-holding capacity of the mixture.

The mobility of mortar mixtures is characterized by the depth of immersion of a metal cone (weighing 300 g) of a standard device. Mobility is prescribed depending on the type of solution and the suction ability of the base.

Depending on the purpose, a certain brand of mortar mixture is used according to mobility (Table 1).

Table 1

Brand of mortar mixture by mobility

| Brand of mixture | Mobility norm, cm | Purpose of the mortar mixture |

| PC4 | From 1 to 4 inclusive | Vibrated rubble masonry |

| PC8 | Over 4 to 8 inclusive | Rubble masonry is ordinary, made of hollow bricks and stones. Installation of walls made of large blocks and panels, jointing of horizontal and vertical joints in walls made of panels and blocks, cladding work |

| Pk12 | Over 8 to 12 inclusive | Masonry of ordinary bricks and various types of stones, plastering and facing works |

| Pk14 | Over 12 to 14 inclusive | Filling voids in rubble masonry |

Water holding capacity —

this is the property of a mortar mixture to retain water when laid on a porous base, which is necessary to maintain the mobility of the mixture, prevent delamination and good adhesion of the mortar to the porous base (brick, etc.). Water-holding capacity is increased by introducing inorganic dispersed additives and organic plasticizers into the mortar mixture. The mixture with these additives releases water to the porous base gradually, while it becomes denser, adheres well to the brick, making the masonry stronger.

A workable mortar mixture is obtained if the grain composition of its solid components is correctly assigned, determined by the ratio of sand, binder and dispersed additive. The binder dough fills the voids between the sand grains and evenly covers the sand grains with a thin layer, reducing internal friction.

The quality of masonry depends on the workability of the mortar mixture . A properly selected mortar mixture fills unevenness, cracks, and depressions in a brick or stone, so a large contact area is obtained between the mortar and the brick (stone), as a result, the strength and solidity of the masonry increases. The durability of external walls also increases.

The strength of the solution is characterized by its brand . Based on their compressive strength at 28 days of age, mortars are divided into grades: M4, M10, M25, M50, M75, M100, M150, M200 and M300. Mortars of grades M4 and M10 are made using air and hydraulic lime, etc. The grade of the solution is determined according to the compressive strength of the sample in the form of cubes measuring 7.07 × 7.07 × 7.07 mm, made from a mortar mixture and hardened for 28 days at 15 …25°С.

Mortars for masonry of external walls and external plaster have frost resistance grades : F10, F15, F25, F35, F50, F100, F150, F200 and F300, and the grade increases for wet operating conditions. The frost resistance of solutions depends on the type of binder, water-cement ratio, added additives and hardening conditions. The frost resistance of a solution is characterized by the number of cycles of alternating freezing and thawing that standard cube samples saturated with water with a size of 7.07 × 7.07 × 7.07 cm can withstand (a decrease in the strength of the samples is allowed no more than 25% and a weight loss of no more than 5%).

Approximate compositions of masonry mortars [2] are given in table. 2.

table 2

1Next ⇒

What to do if there is no reciprocity? And now let's come down from heaven to earth. Have you landed? Let's continue the conversation...

System of Protected Areas in the USA The study of specially protected natural areas (SPNA) in the USA is of particular interest for many reasons...

What makes your dreams come true? One hundred percent, unshakable confidence in your...

WHAT HAPPENS WHEN WE FIGHT Without understanding the differences that exist between men and women, it is very easy to lead to a quarrel...

Didn't find what you were looking for? Use Google search on the site: