It’s easy to find out how much glue you need for aerated concrete. If you buy a mineral dry mixture intended specifically for laying aerated blocks, the answer to the question is easy to find - on the label. Manufacturers must indicate the calculated consumption rates of the adhesive mass. Typically, the estimated consumption is 1.5 kg per square meter of masonry.

However, in reality situations often arise that are similar to “it was smooth on paper...”. Although the blocks are distinguished by their geometric accuracy, the aerated concrete surface sometimes has to be tapped. When installing jumpers and strapping belts, you have to spend more glue. For these reasons and others, actual consumption may differ greatly from expected consumption.

In this article we will try to figure out what factors determine the actual consumption of glue during the construction of an aerated concrete house. And let’s finish the review with the development of mini-software that will help make accurate calculations of adhesive for aerated concrete: the calculator will work online.

Properties of aerated concrete adhesive

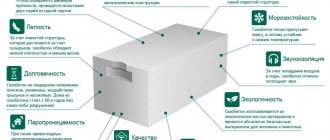

Ten properties of glue that strengthen walls:

- High adhesion - about 10 atm. Thanks to redispersible polymer additives, the bonding ability of the adhesive increases so much that the walls turn into a monolith.

- The strength of mortar joints after 28 days is more than 200 atm. The connections are stronger than the blocks themselves.

- Moisture absorption capacity. The glue not only does not release, but also absorbs all moisture from the surrounding material. Thanks to this property, the composite polymerizes and forms high-molecular compounds - endless chains of complex particles held together by interatomic bonds.

- Water resistance: the glue is not afraid of exposure to any moisture - neither sorption nor pressure.

- Frost resistance and heat resistance. The walls can be used at temperatures of -50 – +80°C. Ready-made adhesive joints can withstand more than 75 freezing cycles.

- Winter resistance of the adhesive mixture: masonry using winter grade adhesives can be carried out at temperatures from –5 to –10°C.

- Plastic. The presence of fine aggregates, the particle size of which is less than 0.6 mm (even smaller than in an hourglass), allows you to apply the adhesive suspension in a layer of 1 mm.

- Fast setting. Due to the highly enriched binders - Portland cement and gypsum, the glue sets within 10 minutes.

- Thermal conductivity. Thin seams do not impair the ability of the blocks to prevent heat loss. The thermal conductivity coefficient of the masonry remains equal to 0.14 W/m*°C.

- Durability: The adhesive is made up of 95% natural minerals. Their durability is time-tested - from 100 years and above.

It should be added to the above that the speed of construction from aerated concrete, thanks to the use of glue, increases 3 times:

- block walls can be laid in 1–3 weeks;

- It will take 2-3 months to build the same brick walls.

Consumption of “Real” masonry mixture

Another well-known composition in construction circles for laying aerated concrete blocks is presented on the market under the Real brand. This is a cement-based granular mixture that is waterproof and frost-resistant. anti-frost additives to the adhesive solution . A special feature of this solution is the possibility of applying a thin layer due to its high adhesion and plasticity.

In particular, the thickness can not exceed 3 mm, while ensuring a modest mixture consumption. In this case, it is possible to create a millimeter layer, but, of course, in special cases. As a result, a 1 mm layer consumes no more than 2 kg/m2. The average consumption of aerated concrete adhesive per 1 m3 is 21–25 kg , which makes it one of the most economical materials for installation in its category. We can say that thin seams will not provide the proper level of fixation of the block, but in practice, with such a scheme, not only material is saved, but also cold bridges are reduced . In addition, plastering costs are also reduced. Thus, conventional solutions require further application of mixtures in layers of at least 8 mm, and the Real adhesive joint is quite suitable for coatings no more than 5 mm thick.

Return to content

Glue composition

- Adhesive for aerated concrete consists of 95% natural rocks:

- Portland cement is used as a binder.

- An additional binder is gypsum. The material improves plasticity and enhances moisture absorption of the glue.

- The main filler is purified, sifted fine-grained quartz sand.

- The share of plasticizing additives is 5%. The functions of additives are to improve adhesive parameters, bind excess moisture, and increase the elasticity of the solution. Thanks to this last quality, the glue fills any – even the most microscopic – irregularities in the walls.

- Fillers that increase the thermal conductivity of the adhesive mixture.

Consumption of Kreps masonry mixture

The composition of the Kreps brand can be ranked among the most economical installation products for aerated concrete blocks . The glue mass includes cement, as well as fractionated fine-grained sand and modified additives. The average thickness of the Kreps mortar when forming interblock joints is 2 – 3 mm. The minimum thickness of the mixture minimizes the risk of the formation of cold bridges without affecting the quality of the masonry. Provided that the material is laid with the correct geometry, the consumption of aerated concrete adhesive per 1 m3 will be no more than 25 kg, that is, one bag of the mixture. If you calculate by area, then 1.6 kg will be enough per 1 m2 . Even with a small thickness, the hardened composition will be able to ensure the reliability of the masonry in conditions of frost and mechanical stress.

Return to content

What is the glue consumption rate?

Typically, manufacturers indicate the norm - 1.4 + 0.2 kg of glue per 1 m² of aerated concrete surface, if the thickness of the seam does not exceed 1 mm. It is believed that to lay 1 cubic meter of blocks you will need 1 bag of dry adhesive mixture - 20–25 kg.

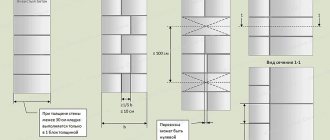

Let's check these statements. First, let's calculate how much glue is needed to lay 1 row of the wall.

At first glance, you might think that for laying a 10-meter wall made of blocks 0.1 m wide, one and a half kilograms of dry powder will be enough for us.

SExp. horizon = 0.1 m x 10 m = 1 m² (1).

However, we must take into account one more point that we had previously forgotten - the area of the vertical seams.

If we assume that we purchased blocks 500 mm long and 400 mm high, then it turns out that we will need to coat another 19, 20 or 21 edges with glue. The total gluing area will increase by 0.8 m².

SExp. vert. = 0.1 m x 0.4 m x 20 units. = 0.8 m² (2).

Since the gluing area has increased by 1.8 times, the glue consumption will be approximately 2.7 kg.

But if the length of our blocks is not 50 cm, but 40 cm, then the vertical edges will increase from 20 to 25 pieces. This means that the area of vertical joints will also increase - from 0.8 m² to 1 m². Consequently, the calculated rate of glue consumption for laying the 1st row of gas blocks will be not 2.7 kg, but 3.0 kg.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

So: the volume of masonry has not changed, but glue consumption has increased. In both cases, we determined the glue consumption for a 10 m long wall. The volume of gas blocks in both cases was 0.02 m³.

0.1 m x 0.4 m x 0.5 m = 0.02 m³ (3).

It is not difficult to guess that consumption will also increase as the height of the blocks decreases.

The first conclusion suggests itself: with the same thickness of the seam, the glue consumption per 1 cubic meter of aerated concrete may be different. We found out the reason - the required amount of the mixture changes as the geometric dimensions of aerated concrete blocks increase or decrease.

In general, experts know: the actual consumption of glue per 1 m³ of masonry under seemingly identical conditions can vary significantly by 2–3 times. The specific norm can be either 15 kg per cubic meter or 38 kg.

Consumption of masonry mixture "Insi-Block"

The plant for the production of autoclaved aerated concrete blocks "Insi-Block" also produces masonry mixtures. The adhesive solution is made from quartz sand, cement, polymer additions and mineral additives, which increase strength, processability and moisture retention . In order to ensure all the described adhesion qualities, it is necessary to adhere to the optimal thickness of the laying layer, which is 2-4 mm. If this condition is met, the glue consumption for aerated concrete blocks will be about 28 kg per 1 m3. But it is important to take into account that this volume is relevant for the minimum permissible thickness of 2 mm. If laying is done on a layer of 4 mm, then, accordingly, the consumption of the dry mixture will be increased.

Adhesive for aerated concrete blocks “Insi-Block” is available in 25 kg bags, so it is advisable to purchase it at the rate of 2 bags per 1 m3 . Regarding water consumption, the manufacturer provides the following data: 0.21 liters per 1 kg of styling composition. In this consistency, the solution can retain its adhesive properties for 3 hours.

Return to content

What determines glue consumption?

Consumption is affected by:

- Varietal category of aerated blocks: the seam between blocks of the 1st category can be 1-2 mm; blocks of the 2nd category are laid on a layer 3–5 mm thick.

- Type of tool used. The solution can be applied using a spatula-comb. In this case, it all depends on the size of the teeth. To obtain a masonry layer of 1 mm, you should use a spatula with 3 mm teeth. The best result will be obtained if you use a carriage for the adhesive solution.

- Weather conditions – temperature and humidity of the surrounding air.

- Conditions for preparing the solution - water temperature, cleanliness of the dishes, serviceability of spatulas and carriages.

When calculating the need for glue, you should also take into account the fact that every third seam will be enlarged - it will contain reinforcement, and, according to technology, it must be tightly closed with mortar.

To be completely sure that materials will be purchased in abundance, the consumption rate should be increased. We recommend taking the joint thickness not 1 mm, but 3 mm as the optimal base value for calculating the requirement.

What you need to know about aerated concrete adhesive

Glue for aerated concrete blocks is a regular cement-sand mixture, which has its own characteristics. First of all, it is fine grinding and special proportions of an adhesive mixture that improves adhesion, cement and sand. Ideally, the layer between bricks should be 1-2 mm. This can be done if you follow the technology and skills in applying the solution. In practice, not every builder can lay blocks this way, so the recommended consumption increases. Which one depends on the specific case, but overspending can be averaged.

Keep in mind that the recommended layer of 1-2 mm ensures minimal heat loss, so you should adhere to the rules of masonry and achieve the thinnest seam. If this causes difficulties in advance, special microspheres filled with gas can be added to the glue. They also have a small fraction, and at the same time they allow you to insulate the mixture used, eliminating cold bridges.

This way out of the situation is suitable for builders without experience who are engaged in the construction of a building for personal purposes. Additives in the form of microspheres help to avoid possible heat leaks through the joints between bricks. If you do not have this material - how to get out of the situation, purchase bulk vermiculite. With its help, you can also insulate the masonry mortar and make larger seams without compromising the thermal conductivity of the structure.

Please note that the consumption of aerated concrete adhesive per m2 in the online calculator is given taking into account the standard consumption. When building independently without skills, it is better to estimate how much actual volume will be spent on your event; for this, use a factor of 1.3-1.5.

How to correctly calculate the glue for aerated concrete blocks per 1 m³

To make the calculation more accurate, you should lay out a test row and measure the actual glue consumption. Based on the data obtained, the most probable glue consumption per unit area can be determined. After this, all that remains is to carry out the necessary calculations using the algorithm given below.

The calculation is performed in 5 stages:

- Calculation of the volume of walls, taking into account openings for windows and doors.

- Calculation of the volume of one aerated concrete block.

- Calculation of the adhesive surface area of one block. This is the sum of the base area and the end area (short sidewall).

- Calculation of the required number of blocks - in pieces.

- Calculation of the mass of adhesive powder, provided that the consumption is 1.5 kg per 1 m² of area with a mortar joint thickness of 1 mm.

You can determine the adhesive consumption for aerated concrete blocks per 1m³ of masonry using our calculator.

Preparation of masonry mortar

Sequencing:

- To prepare the solution, you will need an electric drill with a stirrer attachment, a mixing container (preferably plastic) and a GRAS brand adhesive mixture.

- You need to pour the required amount of water into the container, taking into account the calculated volume of the solution. Carefully pour the dry mixture into the water and stir using a drill with an attachment until smooth. The consistency should resemble thick sour cream.

- Let stand for 10 minutes, then repeat kneading.

- Important: the shelf life of the finished product is limited; therefore, dilute as much glue as you can produce. Remaining composition should be disposed of immediately.

- After use, rinse working tools and containers with warm water.

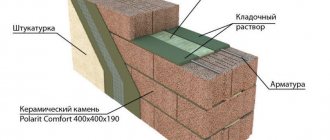

The adhesive solution for thin joint masonry is applied to the horizontal and vertical surfaces of the block using a notched trowel. The block is installed in place and adjusted with a straightening hammer. We remind you: the thickness of the seams should be 1-3 mm.

produces adhesive for aerated concrete blocks that meets standards using modern technologies and affordable prices.